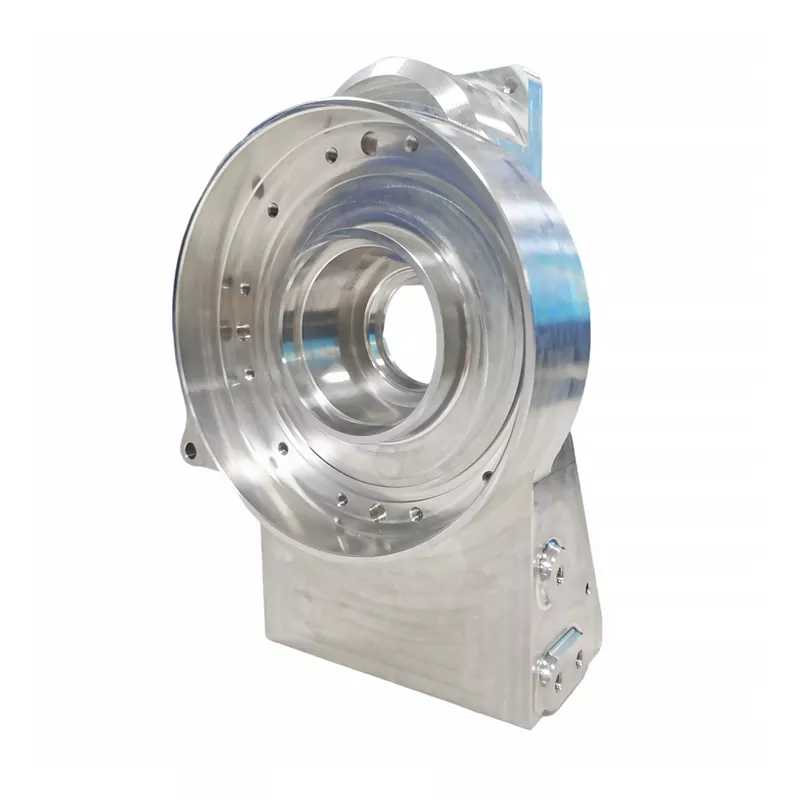

5 Axis CNC Milling Service

Elimold offers 5-axis milling services to manufacture your custom parts and is a one-stop shop for all your machining needs for custom part production. 5-axis milling provides greater precision than traditional machines. 5-axis milling has faster cycle times and less material waste than 2- and 3-axis milling. Contact us now for a free instant quote.

Your Partner for Precision 5-Axis Milling

At Elimold, our commitment to high-quality, precision-engineered solutions is reflected in our ability to deliver any milled component or project with exceptional accuracy, efficiency and adaptability. By leveraging advanced 5-axis milling techniques, optimized tooling and cutting-edge CAD/CAM software, we can easily handle complex geometries and tight tolerances, reduce setup times and achieve high-quality surface finishes. Our valuable expertise enables us to tailor solutions for challenging projects while increasing efficiency through automation and streamlined workflows. Strict quality controls, including statistical process control (SPC) and in-line metrology, combined with 5-axis CMM in ISO Class 8 cleanrooms, ensure consistent, reliable results on every project, allowing us to meet and exceed customer expectations with unmatched speed and cost-effectiveness.

5-Axis CNC Milling Capabilities

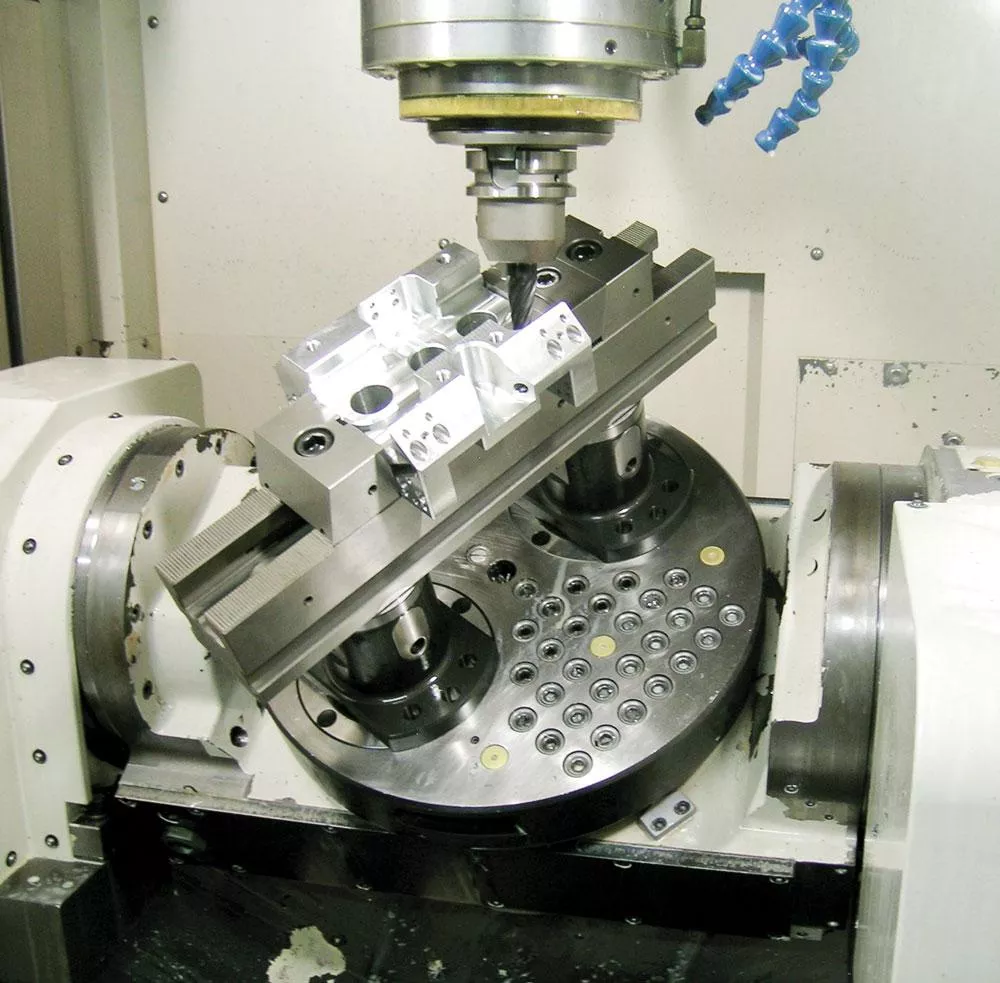

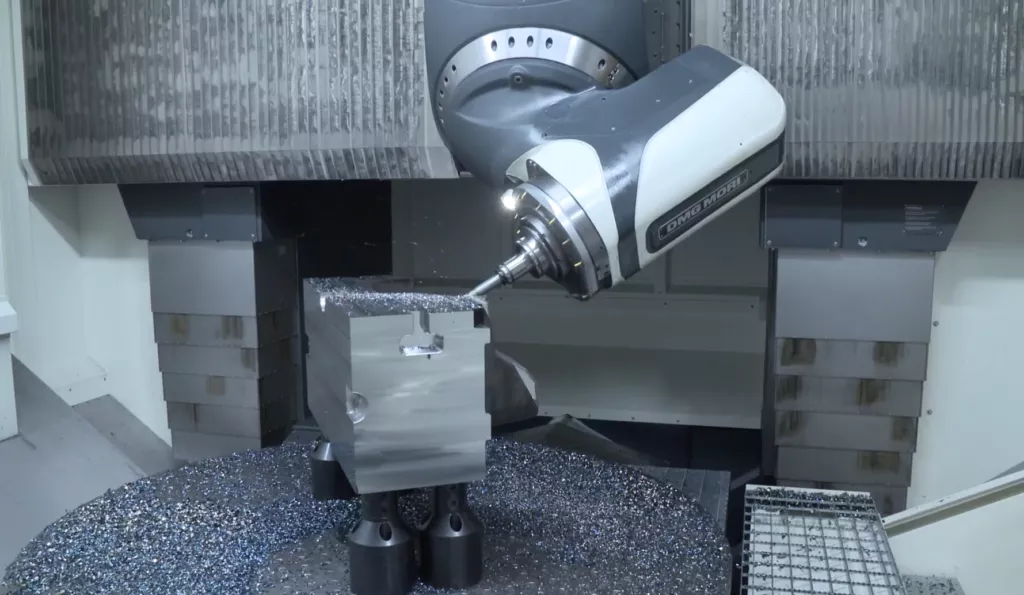

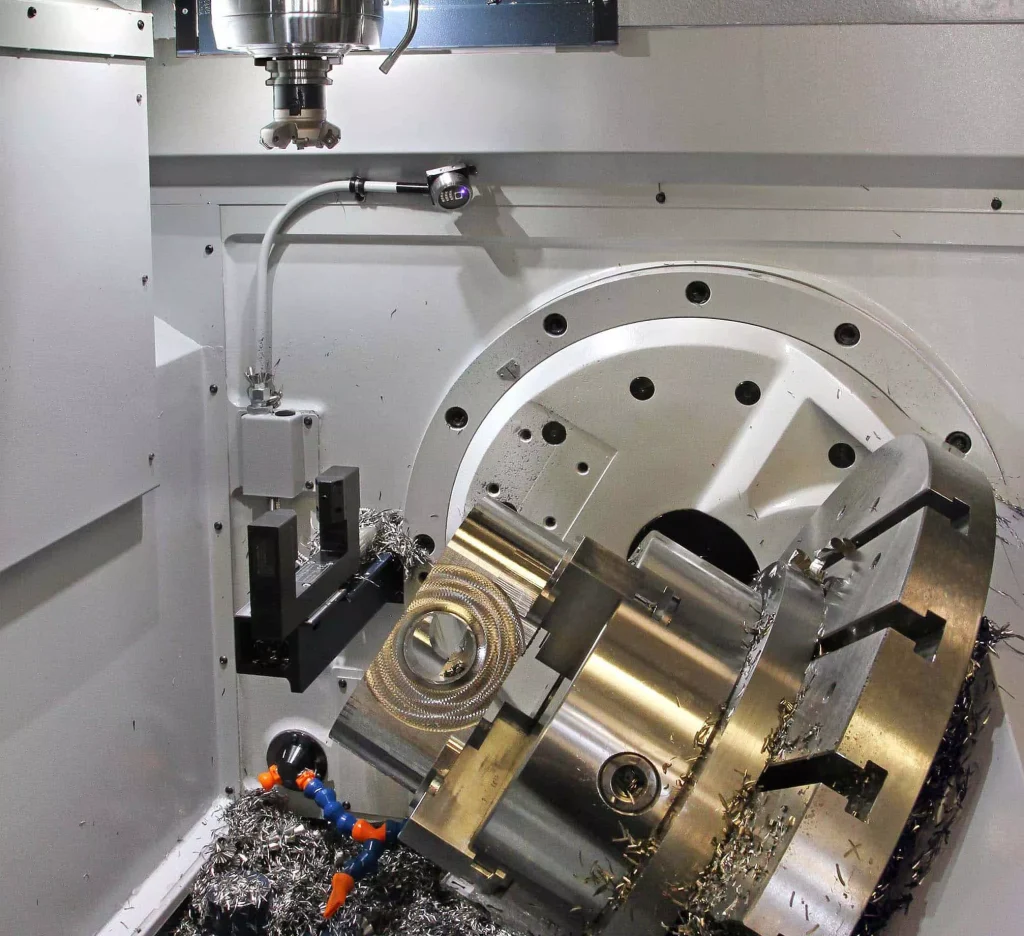

Elimold offers advanced 5-axis milling services that greatly increase the possibilities of designing and manufacturing parts of all shapes and sizes that work on complex and tight surfaces. We are an experienced 5-axis milling company that can provide custom solutions to help you achieve your most difficult manufacturing goals. Using 5-axis milling can increase the accuracy of details on different sides or planes of an object. Our computer-controlled milling process includes specifications such as +/- 0.001-inch tolerances and the ability to machine a 36-inch cube. We can also machine workpieces up to 80 to 120 inches in size, drill holes as small as 0.005 inches, and provide thread milling capabilities. As a result, our capabilities can meet the ever-changing needs of our customers. Our machines are equipped with advanced tools and accessories that enable us to achieve precision and efficiency in every project. Whether it is complex geometry, tight tolerances, or challenging materials, we have the expertise and technology to exceed your expectations.

Comprehensive 5-axis CNC Milling Solutions for Your Manufacturing Needs

Elimold offers 5-axis CNC milling and machining services that reduce setup time and achieve the tightest tolerances. We provide tight tolerance 5-axis milling services to manufacture the most complex parts with high repeatability. Elimold’s engineers and machinists are the best in the industry. We manufacture low-volume and high-volume components to exacting standards, regardless of complexity, to provide our customers with the most cost-effective, high-quality parts. We understand that precision machining is only a small piece of the puzzle. That’s why we offer turnkey solutions to streamline your entire manufacturing process. From 5-axis milling to EDM, welding, and assembly, we offer a comprehensive range of services to meet all of your needs from a single source. With our seamlessly integrated process, you can trust us to deliver exceptional results every time. Ready to experience the precision and efficiency of 5-axis milling? Contact us today to discuss your project needs and request a quote.

In-House 5-Axis Milling Machining Factory Capabilities

Elimold has over three decades of expertise in manufacturing precision 5-axis milled parts, including providing 5-axis milling CNC machining services to a wide range of regional and national customers. Our team is dedicated to finding solutions for many different manufacturing needs. We have extensive in-house capabilities and extensive project management support, which allows us to complete your parts quickly and correctly the first time. We have invested in equipment and a highly skilled workforce to operate state-of-the-art equipment in our 4,500 square foot shop, which can produce parts of various shapes and sizes. Elimold’s integration of 5-axis milling machining into your manufacturing workflow can increase efficiency and reduce costs. And you can ensure that your components have the precision, strength and durability required to meet the needs of your specific application. Our experienced team of engineers are knowledgeable in various industries and will help you manufacture parts that perform as required.

5-Axis Milling Rapid Prototyping

Our roots in rapid prototyping have helped us develop and continually improve our skills in machining the most complex parts. Our extensive background in production and automation allows us to optimize processes for reliability and maximum productivity. Whether you need one part or thousands, we can exceed your expectations! For complex and time-sensitive machined parts, our 5-axis CNC machines offer unmatched flexibility and speed. Elimold’s experienced team can help you turn your ideas into reality, from rapid prototypes to end-use parts for safety-critical applications. Our 5-axis milling capabilities allow us to deliver precision parts with complex geometries.

5-Axis Milling Parts Supplier

Elimold offers state-of-the-art 5-axis CNC milling services. We specialize in extremely precise custom parts, and our in-house facility is virtually guaranteed to meet or exceed your expectations for quality and accuracy. With ten individual CNC milling machines in our in-house CNC machine shop, we can guarantee you that at least one will meet the specifications you and your prototype require. Plus, we can handle any number of orders, from up to 250,000 individual parts to a single precision milled prototype. We have decades of experience working in the custom manufacturing industry, and we are happy to put that wealth of expertise to work for you. And, our philosophy and quality management capabilities ensure that you always get the highest quality products from our machines. To achieve this, we first carefully inspect the schematics of every new part we receive. During the inspection process, we ensure that each schematic, and subsequently each part, is produced with the best quality and highest manufacturing efficiency.

Turnkey 5-Axis Milling Shop

Elimold is an online machine shop that manufactures custom parts using 5-axis milling technology. We offer one-stop shopping for all your machining needs for all your custom part production. We strive to complete your parts extremely quickly to keep your supply chain in order and on track to market. Our high-performance 5-axis milling capabilities support our customers’ most demanding components, many of which require us to hold extremely tight tolerances on complex geometries. Our expertise comes from years of hands-on experience machining parts made from exotic materials for mission-critical applications in a variety of industries around the world. And, partnering with our customers throughout the product cycle is the essence of our company and corporate culture, from initial design review, prototype development to full-speed production, working directly with your engineers to provide the highest quality, most cost-effective and most efficient manufacturing process possible. In addition, Elimold has a deep understanding of 5-axis technology (including software, machines, cutting tools and fixtures), as well as decades of hands-on experience doing prototype development and first-article work, so we can provide consistent benchmark quality and on-time delivery at a competitive cost. Elimold’s 5-axis milling technologies include trunnion, articulating spindle, high speed and vertical machining centers. Most of our large milling machines are also equipped with precision turning capabilities to machine large parts in one go.

Quality Management and Certification Standards

Elimold is proud to be ISO 9001:2015 certified, which allows us to give our customers complete confidence in our control over materials and workmanship. Because we can guarantee that our services meet industry quality standards. Our pursuit of precision goes beyond these standards with our experienced and talented staff, cutting-edge CNC machines, and facilities designed to handle high-volume production. And we also require first-article inspection, in-process inspection through SPC (Statistical Process Control), and final inspection at every operation. Our quality assurance engineers use the latest inspection equipment and training to uphold strict standards and enforce your specifications. All parts we manufacture are inspected after milling to ensure their integrity and to check that they meet our strict quality standards. If we discover potential defects or inaccuracies in your parts, we will go back and re-evaluate the operation of our machines before milling the rest of the batch. We do this before and after every process in your product development phase to ensure smooth and on-time delivery in the future. At Elimold, we will not tolerate poor quality or inaccuracies in our machined parts, and we know you won’t either.

Testing Equipment

- Coordinate Measuring Machine (CMM)

- Optical Comparator

- Surface Roughness Tester (Profilometer)

- Digital Height Gauge

- Bore Gauge

- Calipers (Digital, Vernier, Dial)

- Micrometers (Outside, Inside, Depth)

- Laser Scanner

- Hardness Tester

- Thread Gauge (Plug and Ring)

- Optical Micrometer

- Ball Bar Test Equipment

- Vibration Analyzer

- Ultrasonic Thickness Gauge

Ready to start your next 5-axis milling project?

Provide free 5-axis milling solutions for your products. Our rich manufacturing processes and experience can meet your production needs, help you simplify the supply chain and achieve “one-stop” ordering of the entire project. Contact us now for a free instant quote.

Wide Range of CNC Machining Process Types

Elimold offers a wide range of CNC machining processes to meet your many needs. Our goal is to help you find the most appropriate process to meet your design and production needs. We work with you to understand your production process, the materials required for the part, and any design complexities that may affect machining.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

5-Axis Milling Manufacturer

At the heart of our operations is a team of highly skilled machinists and engineers who can utilize design data and our own fixturing programs to handle complex parts that require careful process design. We also use robotic manipulation in our machine’s pallet automation system to maximize capacity and minimize quality deviations. All of this is managed through our volume management system and MES/ERP system to minimize touches and speed quote-to-delivery. Precision and innovation are made easy with Elimold’s advanced 5-axis milling services. We deliver exceptional precision, efficiency, and versatility to take your machining projects to new heights. We use state-of-the-art equipment and material removal techniques to deliver value to our customers with the most stringent quality requirements. Utilizing the best technology available, we can produce your parts faster, more reliably, and more economically than our peers.

What is 5-axis CNC milling?

5-axis CNC milling involves an advanced CNC machine that can manipulate a tool or workpiece along five different axes simultaneously. This advanced capability allows complex geometries to be produced efficiently and with high precision. Unlike traditional 3-axis machines that move along linear paths along the X, Y, and Z axes, 5-axis machines introduce two additional axes of rotation. These axes, commonly referred to as the A-axis (rotation about the X-axis) and the B-axis (rotation about the Y-axis), allow the tool to approach the workpiece from multiple angles simultaneously in a single setup. The versatility of a 5-axis CNC milling machine enables the creation of complex and delicate designs that would be difficult or impossible to achieve with traditional machinery.

5-Axis Milling Material Options

We offer a wide variety of metal and plastic material options for applications across a wide range of industries. Ideal for one-off prototypes and end-use custom parts.

Metals

- Alloy Steels

- Aluminum

- Beryllium Copper

- Brass

- Bronze Alloys

- Carbon Steel

- Cobalt

- Copper

- Hasteloy

- Inconel

- Invar

- Kovar

- MP35N

- Nickel

- Nickel Iron

- Nitronic 80

- Nitronic 60

- Stainless Steel

- Stellite

- Titanium

- Tungsten

- Zicronimum

Plastics

- ABS

- Acetal

- Acrylic

- Fiberglass Reinforced Plastics

- Nylon

- Phenolic

- Polyamide-Imide

- Polycarbonate (Delrin)

- Polyetheretherketone (Peek)

- Polyetherimide

- Polyethylene

- Polystyrene

- Polysulphone

- PTPFE (PilyTetraFluoroEthylene)

- PVC (Polyvinyl Chloride)

- PVDF (Polyvinylidene Fluoride)

- Teflon

5-Axis Milling Surface Finish Options

We support high-quality surface treatment needs, and improve the performance of parts by selecting high-quality surface treatments to improve the roughness, hardness, chemical resistance and aesthetics of finished parts. And can provide data such as film thickness, hardness, color, salt spray test and adhesion report.

- Chrome

- Brushed Nickel

- Brushed Bronze

- Oil-Rubbed Bronze

- Brushed Gold

- Titanium Brushed Stainless

- PVD Coating

- ED Coating

- Anodizing Plating

- Hard Anodizing Plating

- Electricizing Treatment

- PTFE Coating

- Molybdenum Disulfide Coating

- Sandblasting

- Oxidation

- Electroplating

- Electrophoresis

- Baking Paint

- Chemical Conversion Coating

- Passivation

- Polishing

- Blackening

- QPQ

- Any Customized Finishing

Industries Served by 5-Axis Milling

Our 5-axis milling shop serves many industries around the world, custom manufacturing parts for a variety of precision applications for numerous companies.

- Aerospace

- Automotive

- Medical

- Defense

- Energy (Oil & Gas, Renewable)

- Marine

- Electronics

- Robotics

- Industrial Equipment

- Semiconductor

- Jewelry

- Architecture

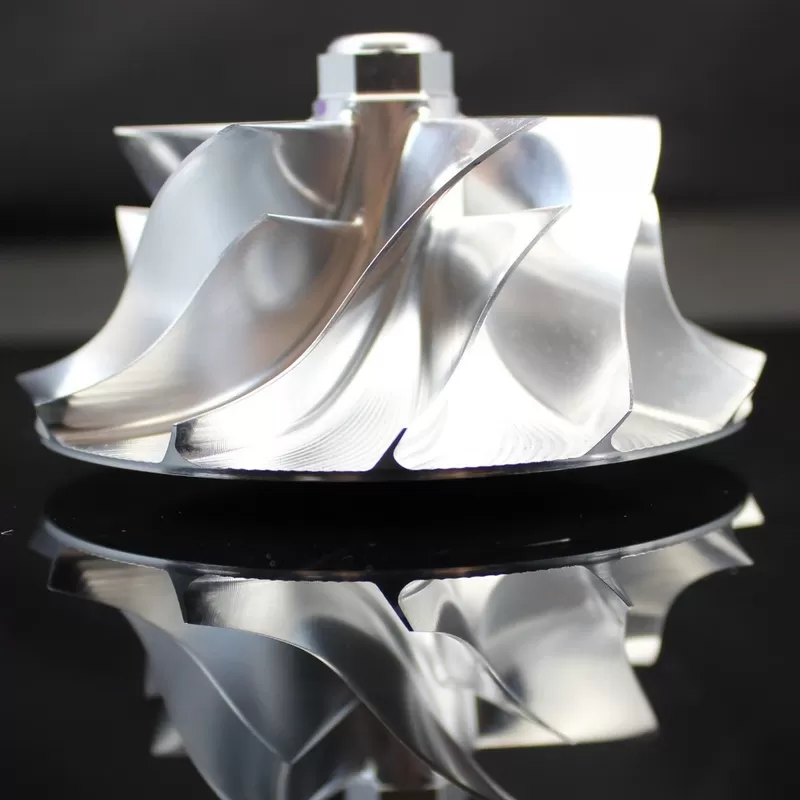

5-axis Milling Applications

The following are typical parts that Elimold 5-axis milling can custom and manufacture. We process parts with high feature count and complexity, including specific operations or to manufacture specific types of parts.

- Turbine Blades

- Impellers

- Engine Components

- Manifolds

- Prosthetic Implants

- Bone Plates

- Aerospace Brackets

- Satellite Components

- Optical Housings

- Heat Sinks

- Heat Exchanger Plates

- Electronic Enclosures

- Custom Gears

- Complex Automotive Brackets

- Cylinder Heads

- Marine Propellers

- Robotic Arm Components

- Aircraft Fuselage Components

- Suspension Components

- Medical Surgical Instruments

- Hydraulic Manifolds

- High-Precision Bearings

- Custom Fasteners

- Aerospace Engine Mounts

- Microfluidic Devices

- Optical Lens Holders

- Precision Valves

- Satellite Antenna Brackets

- Drone Frames

- Missile Guidance System Components

- Fuel Injection Nozzles

- Electric Motor Housings

- Wind Turbine Hubs

Request Your Free 5 Axis CNC Milling Quote Today

After receiving your drawings, our engineers will analyze your custom 5 Axis CNC Milling parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.