5 Axis CNC Machining Services

Elimold is an expert in 5-axis CNC machining production and prototyping, ready to meet your specific needs. Whether you are looking for small batches or large-scale production, we can provide you with a tailor-made service. Tolerances are as high as +/-0.005 mm. Contact us now for a free online quote!

Professional 5-axis CNC Machining Manufacturer

If you are looking for a 5-axis CNC machining manufacturer or 5-axis CNC shop to manufacture small, medium, or large custom parts in low or high volume production, Elimold is your ideal choice as an excellent 5-axis CNC machining company. Our well-trained and experienced staff manufactures custom components to the standards of customer drawings. In addition, our own in-house factory has more than 100 different types of 5-axis CNC machines, so whether your part quantity is one or tens of thousands, Elimold can provide production machining services for your company. From the beginning of the project, we work with you to ensure that the parts meet the required tolerances and are delivered on time. And our team will evaluate your challenges and recommend the fastest and best solutions.

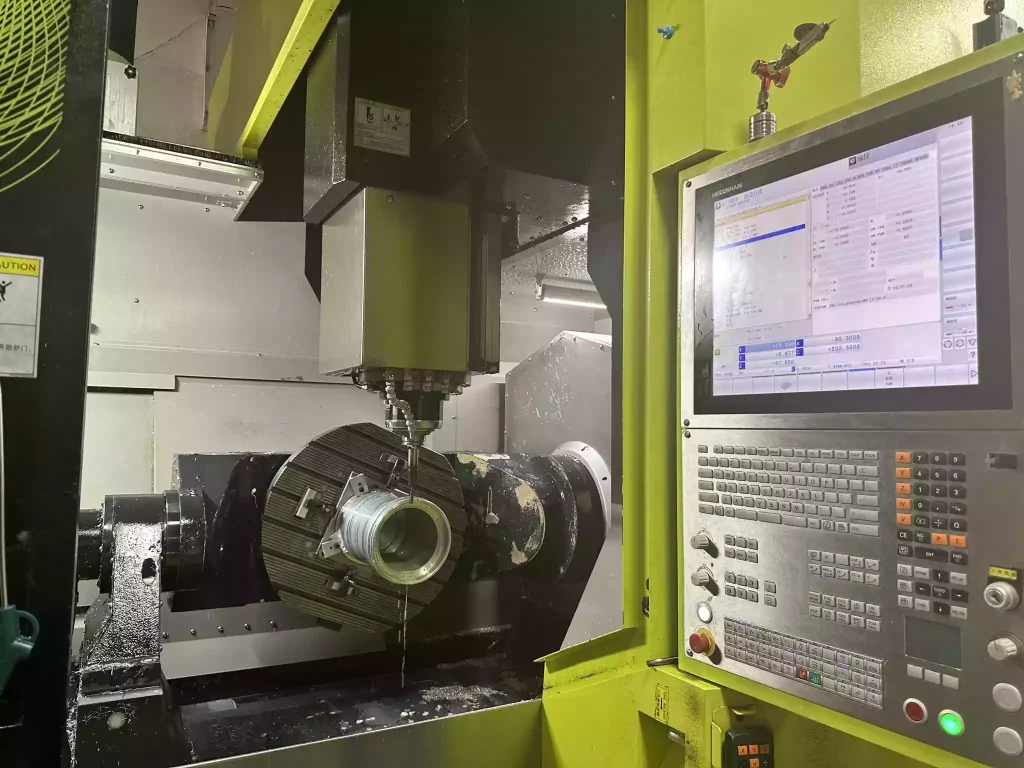

5-Axis CNC Machining Factory

Whatever type of 5-axis machining service you require, or a variety of other services, Elimold can provide you with our large facility designed to meet your needs. We have over 72,000 square feet of in-house facilities, all equipped with the latest 5-axis CNC machining technology to ensure best-in-class machining results. Our in-house 5-axis CNC machining shop has over 100 advanced machines capable of providing any number of metal and plastic parts from low-volume prototypes to high-volume production. Our team of professionals works closely with you to transform your innovative ideas into reality using advanced CNC machines and ensure timely delivery of your parts. And from a safety perspective, our employees are trained in safe working conditions. This commitment to safety is reflected in every project we undertake, ensuring the safety of our employees and customers. If you are looking for a trusted 5-axis machining partner, Elimold is the best choice for you!

Elimold's Advanced Equipment and Capabilities

Our full-featured range of 5-axis machining centers ranges from high-performance 5-axis horizontal machining centers to top-of-the-line vertical machining centers. We have over 100 5-axis CNC machines,

40 CNC milling machines and 35 drilling and tapping machines, in addition to 7 EDM machines, 6 jig grinders, 9 ID/OD grinders and over 30 surface grinders. If needed, we can continue to invest in additional equipment to expand our capacity. This allows Elimold to handle large-scale production while maintaining precision and efficiency. This advanced equipment combined with our experienced technicians enables us to meet the diverse manufacturing needs of a wide range of industries. Be confident that our services will perfectly meet your needs. Contact us for a free quote.

Elimold's Five-Axis CNC Machining Capabilities

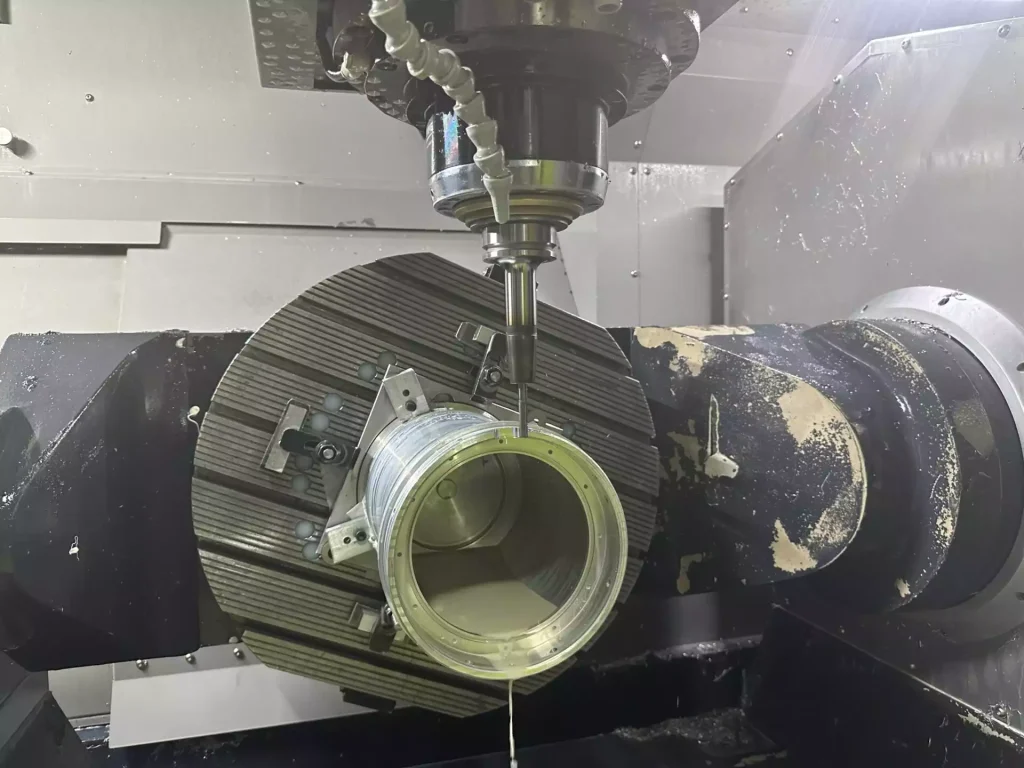

Elimold has the largest five-axis CNC machining center in Shenzhen, China. Our advanced five-axis CNC machining center can achieve precision tolerances up to ±0.0001 inches. The machining range is 204 inches long (about 5.2 meters), 114 inches wide (about 2.9 meters), and 55 inches high (about 14.9 meters), which can process large, complex and custom parts with position tolerances of ±0.003 inches (about 5.9 meters). Comprehensive machining capabilities include drilling, threading, knurling, broaching, profiling, hard cutting and hard turning. All fixtures and tools are made in-house, and tighter tolerances can be maintained as needed. This is critical for manufacturing parts with complex geometries and multiple features in one seamless operation. Ideal for customers who require complex parts with close tolerances and perfect surface finishes.

5-Axis CNC Machining Tolerances

All of our machining processes are certified to ISO 9001 standards. Elimold can manufacture parts to tolerances of less than +/-0.001 inches based on your drawing specifications and GD&T annotations. Standard surface finish is 125 Ra or better. If other surface finish options are required, they can be specified at the time of inquiry. As a result, our 5-axis machined parts are manufactured to the most stringent tolerance requirements. Unless otherwise specified, our 5-axis machined plastic parts meet ISO-2768-m standard tolerances and metal parts meet ISO-2768-f standard tolerances by default. We can also provide ISO 286 (Class 8, 7, 6) tolerance options.

Complete Five-axis CNC Machining Service

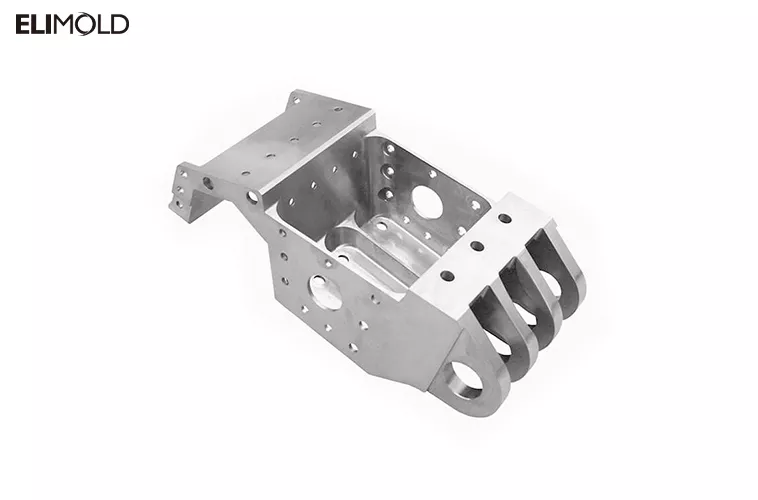

As long as you have a need for free-form surfaces and complex contours, whether the parts are large, heavy or small, Elimold can help you achieve precision machining of parts with its advanced equipment and professional and skilled machinists. One of our biggest advantages is that there is no minimum order requirement, so you can produce on demand.

Rapid Prototyping

Low-volume Production

On-demand Production

Start Your 5-axis CNC Machining Project

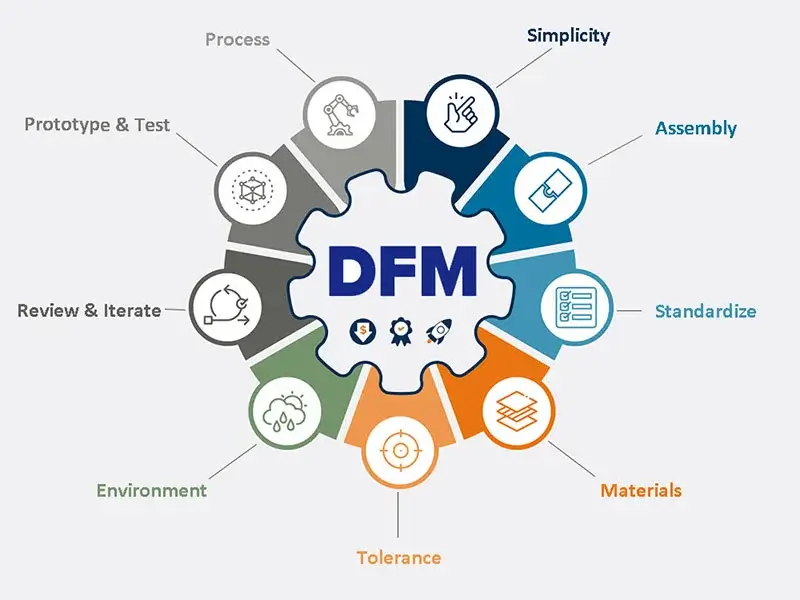

Jump start your project with our easy-to-use online quoting platform. Upload your CAD file and get instant quotes, lead times, and DFM details for 5-axis CNC components. We specialize in metal and plastic CNC machining, and offer flexible production and shipping solutions to meet your product development needs.

Advanced 5-axis CNC Machining Shop

Our programming engineers and machine operators have more than 20 years of experience and are trained annually to ensure personnel stability. The hardware facilities and personnel are first-class, which is why many large companies trust us. Elimold’s 5-axis CNC machining shop can provide automated production around the clock (24-7). We produce more than 3,000 different parts per month. In addition, our 5-axis CNC machining services are perfectly complementary to our 3D printing services, making Elimold a one-stop manufacturing supplier for all your advanced design needs. Are you ready to experience the precision and efficiency of 5-axis machining? Contact us today to discuss your project needs and request a quote. Let us show you why Elimold is a trusted partner for precision machining solutions.

Experience the Precision and Efficiency of Elimold's 5-axis CNC Machining Services

Order size is not the key, and company size is not the key. The size of the product market is more important to both of us. The sustainability of orders is a key factor in our mutual growth. Elimold’s 5-axis machining services provide unparalleled speed and flexibility. With a wide range of advanced 5-axis CNC machines and a rich selection of materials, we are able to provide the highest quality 5-axis machined parts. In addition, our experienced team and strong manufacturing capabilities can help you quickly design and manufacture complex and time-sensitive parts. If you are not sure what type of equipment your product needs to be processed, don’t worry. We can help you achieve efficient and high-quality product delivery.

Our 5-axis CNC Machining Equipment Types

Simultaneous 5-axis Machining

3+2-axis Machining

Trunnion-Style or Swivel-Rotate-Style

Trunnion-style 5 Axis Machine

Swivel-rotate-style 5 Axis Machine

Custom 5-Axis Machining Solutions

We understand that every project is unique, and we pride ourselves on providing custom solutions to meet our clients’ specific needs. Our experienced team of engineers and machinists work closely with our clients to develop optimized manufacturing strategies that maximize the potential of our 5-axis CNC machining capabilities. This collaborative approach ensures we deliver exceptional results that meet your goals and requirements. And Elimold’s capabilities extend beyond manufacturing. Our team offers 3D CAD-CAM services that can transform the simplest sketches into precision components. Whether it’s reverse engineering or manufacturing to a customer design, Elimold has the experience and capabilities to take on your next project.

DFM Analysis

Before your 5-axis CNC machining project begins, our engineers perform a DFM analysis to identify and resolve potential issues in advance. This ensures your project design is optimized and can be manufactured efficiently, with minimal defects and reduced machining costs. That’s why Elimold’s engineering team of more than 20 technicians is ready to provide you with expert advice on everything from early material selection, custom prototyping recommendations, to money-saving tips and technical reminders before 5-axis CNC machined parts are manufactured, all the way to end-use production.

CAD Engineering & Design Services

Need a new product design or help making your design manufacturable? Our CAD Engineering and Design team can help optimize your design and get it ready for production. We can also design to your ideas, reverse engineer existing products, or take existing CAD files and modify them to meet your exact specifications. We work closely with our customers to truly understand their needs and assist you with everything from component design to material selection. From the initial idea or concept, our team can guide you through the design process, ultimately producing high-quality 3D CAD models to help you turn your ideas into reality.

Reverse Engineering

We offer a comprehensive reverse engineering service. By scanning an existing part or assembly, we can generate a CAD model from the data collected, even if the original model is lost or does not exist. This allows us to accurately redesign and manufacture new products. We utilize 3D CAD laser scanning equipment and related software to understand and recreate parts that are no longer available on the market due to the original equipment manufacturer discontinuing the equipment model. The process is very in-depth and includes multiple stages: 3D modeling, data characterization and analysis. Alternatively, if you already have the part in question, please send it to Elimold and our professionals will review your existing existing parts and create new components with incredible accuracy and precision.

3D CAD Laser Scanning Services

Elimold’s 3D scanning services provide efficient solutions for a wide range of data acquisition, analysis and verification tasks. Our experienced team is fully trained to operate advanced equipment and software and will assist you at every stage of your project. With our technology, the possibilities are endless. From scanning a sculptor’s model and scaling it to the required dimensions to scanning a full-scale vehicle, we provide comprehensive 3D scanning services around the world.

This advanced technology enables us to capture extremely accurate measurements in a variety of environments. We use Autodesk Power Inspect and Artec Studio software for all scanning and inspection, which simplifies the inspection of large, complex and multi-layered parts. We use Geomagic Design X to edit scan data and mesh data, which allows us to define and shape surfaces of the highest quality.

Quality Management

Our quality inspection and testing processes are critical to the performance of your products and the efficiency of our operations. These inspections are performed by an experienced quality control team and utilize state-of-the-art technology to ensure that the products we produce meet the original computer-aided designs and exacting quality standards. Throughout the production process, our inspection procedures also ensure the most time-efficient and cost-effective development and manufacturing services are achieved. To give you complete peace of mind about the integrity of your products, Elimold supports you with comprehensive inspection processes.

Quality Inspection and Inspection Testing

Elimold has a strict quality control team, and our IQC, IPQC and after-sales service teams strictly follow ISO quality standards. These are basic quality assurances to ensure that our CNC parts are always of high quality. Our factory strictly follows the ISO9001 quality system, and each five-axis machined part undergoes strict quality inspection. When the material enters the warehouse, we will use a spectrometer to perform material analysis to ensure that the material meets your requirements. During the production process and final product inspection, we will use coordinate measuring machines (CMM), plug gauges, pin gauges and other inspection tools to check every feature of the parts to ensure that there are no scratches, burrs and other defects in appearance. The laser tracking system and coordinate measuring machine (CMM) dimensional inspection system we have are capable of measuring large machined parts with a span of more than 14 feet (about 4.3 meters) with an accuracy of ±0.00005 inches (about 0.00005 inches). Our professional processing and inspection equipment ensures that all tools and equipment meet the strict standards of various industries.

Process FMEA and Risk Management

Unforeseen risks can affect part quality, such as unexpected material behavior, thermal deformation, or fixture distortion. For complex parts, these issues may not become apparent until after machining, leading to costly rework or part scrap. Before machining a new part, Elimold performs a detailed process failure mode and effects analysis (FMEA). This predictive analysis identifies potential failure points and develops mitigation plans accordingly. We can adjust and address toolpaths for thermal expansion issues and customize fixture solutions to minimize clamping-induced distortion. Finally, real-time adjustments based on FMEA insights ensure that any risks are addressed before they affect part integrity.

Steady Delivery of 5-axis Machined Parts

Elimold fills the gaps in many manufacturing plants with expertise and experience in 5-axis CNC machining. Our team of experts has received rigorous training in all types of CNC machining, and Eliomld has invested a lot of energy in CNC technology and its applications, so customers can take advantage of our services without the sunk cost of setting up their own production plant or increasing production capacity (which may take years), and get high-quality 5-axis CNC machined parts on demand without any effort. So no matter what type of CNC machining service you need, we can meet your needs and let your company focus on product manufacturing and sales.

Ready To Get a Quote?

Elimold engineers will use our 5-axis machining technology to help you get your products to market faster and more cost-effectively. Our primary goal is to provide you with high-quality, custom, high-precision parts and products. We are committed to providing excellent engineering, design, assembly and packaging services to meet all your requirements and exceed your expectations.

Comprehensive 5-axis CNC Machining Services

We know that precision machining is just one piece of the puzzle. That’s why we offer turnkey solutions to help you streamline your entire manufacturing process. Our comprehensive services meet all your needs from a single source. Whether it’s 10 or 10,000 custom parts, we provide efficient and accurate 5-axis CNC machining services at an affordable price. Every 5-axis CNC machining production run is carefully documented and transparently shared with customers through photos and videos. You can also view the production process through video communication. Give your customers the information they need. With our seamlessly integrated process, you can count on us to deliver excellent results every time.

What is Five-axis CNC Machining?

Five-axis machining is a cutting process that uses five different axes to achieve the most efficient and accurate cuts. It allows you to create contoured parts with variable thickness in a single operation. The five axes are usually labeled X, Y, Z, A, and B. The first three axes are the same as a three-axis milling machine, that is, they control the directions perpendicular to the three planes of motion. The fourth axis allows rotation along the Z axis and completes a full 360 degrees around that line. The fifth axis moves at an angle to allow for varying degrees of motion. It is usually tilted about 45 degrees below the control horizontal plane, but can also be located above or below the XY plane. Five-axis machining has five faces and is the preferred method for making complex parts. It provides more control than four-axis machining, allowing you to do special shape machining, bevel cutting, hook face machining, punching, and many other complex functions.

5-Axis Machining Advantages

- Enhanced Precision: 5-axis YCM FX380A 5-Face Vertical Machining Center utilizes advanced software

- Boost Productivity: Machine features without the physical handling of the part in one set up

- Improved Quality: Reduce tool length and increase rigidity to obtain superior machining quality

- Added Longevity: Cutting with the belly and edge of the tool to increase tool life

- Ensured Accuracy: Reduce fixture error and lessen workpiece loading/uploading time

- Cost Effective: Saves manufacturing fixture and electrode costs

What is the difference between 3, 4, and 5-axis CNC machining?

The basic principles of all CNC machining processes are very similar. However, there are still some significant and unique differences between 3, 4, and 5-axis CNC machining that make them more suitable for specific tasks.

Three-axis machining is a traditional CNC machine that can operate on the X, Y, and Z axes. During this machining process, the workpiece remains stationary and the cutting tool moves and cuts the mold as designed. Three-axis machining has some limitations during the cutting process because it cannot rotate or spin like other four-axis or five-axis machining tools. The workpiece must be adjusted manually to machine details from different angles.

On the other hand, four-axis machines have an additional axis called the A-axis. Like traditional three-axis CNC machines, four-axis machines also have X, Y, and Z axes. But the workpiece can rotate along the additional A-axis, allowing it to be machined from different angles without changing the setup.

Five-axis machines are the most advanced of all CNC machining equipment. In addition to the X, Y, and Z axes of a traditional three-axis CNC machine, it also has two additional rotary axes. These additional axes are usually denoted by the A-axis and the B-axis. 5-axis machines are able to handle more complex designs and shapes than 3-axis and 4-axis machines. Also, 3-axis and 4-axis CNC machines cannot perform undercut designs as easily as 5-axis CNC machining machines, which can be done in a single machining setup. Five-axis machining provides better quality and surface finish for your parts. It is faster than three-axis and four-axis CNC machining due to its single setup capability.

Materials for Custom 5-axis CNC Machining

Elimold’s 5-axis machining services are compatible with a wide range of materials, from metals to plastics. You can choose from our 150+ production-grade materials based on your application needs. View our list of 5-axis CNC machining materials. You can also contact us to discuss your specific needs.

Metals

- Aluminum

- Stainless steel

- Steel

- Brass

- Bronze

- Chromium

- Copper

- Hastelloy

- Inconel

- Invar

- Manganese

- Monel

- Nickel

- Nickel nitride

- Powdered metal

- Stainless steel

- Stellite

- Titanium

- Vaspalloy

- Magnesium

Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- HDPE

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- PTFE (Teflon)

- UPE

- Bakelite

- FR-4

Surface Treatment for 5-axis CNC Machining

Elimold offers a wide range of surface treatment options to improve the surface quality of 5-axis machined parts. These surface treatments help improve the appearance, surface roughness, hardness, corrosion resistance, etc. of the parts. They can also hide visible tool marks on the product surface.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Heat Treatment

Heat treatment alters the mechanical properties of metal to increase its hardness, strength, or ductility.

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Computer Aided Machining

To ensure maximum efficiency and productivity, we use Autodesk PowerMill and Open Mind HyperMill to program machine paths. These advanced CAM packages optimize CNC machine performance and enable unattended machining. In addition, we use CGTech Vericut software to simulate NC code before machining, thus avoiding potential collisions and programming errors. After machining, we conduct comprehensive inspections in our dedicated facilities to verify dimensional accuracy. For more information, please contact us about our 3D scanning and inspection services.

Gallery of 5 Axis CNC Machining Parts

Elimold's 5-axis CNC Machining Team

We are always striving for growth and improvement. Our team is constantly evolving in terms of technology and strategies to meet the changing needs of the industry. By continuously developing solutions and alternatives, we help our customers stand out in a competitive market. If needed, we can even meet your short-term production needs. Although the size of the order is not important to us, we always stick to the principle of commitment. Elimold’s 5-axis machining shop understands the definition of extreme engineering. It is very common to encounter problems in the design and manufacturing fields before entering the various stages of production. We help our customers save precious time, energy and money by solving critical problems by ensuring a seamless transition. Our manufacturing expertise plays a key role in solving engineering challenges while also considering cost-effectiveness. Between cost and quality, Elimold strives to weigh the needs of our customers and provide them with the best solutions. By adopting the latest technology, we are committed to delivering work quickly and efficiently.

Excellent Customer Service

With our fast response time and excellent customer service, our customers value our extensive experience and precise manufacturing solutions. Elimold’s reliable 5-axis machining services can meet your large number of custom manufacturing projects and machining needs to help you move forward with your project progress.

Our team of knowledgeable and experienced engineers, workers and programmers are able to expertly machine complex shapes, internal cuts and angles, all with just one setup. We are able to work with any industry, large or small, and provide services to customers. If you need high-standard 5-axis CNC machining services, Elimold is always your best choice! Contact us and receive a quote within one business day. We are always ready to serve you.

5-axis Machining vs. 3D Printing

During 5-axis machining, a machinist uses a finishing tool to shape a workpiece in the desired way, usually removing excess material, often resulting in a significant change in the workpiece. In contrast, in the completely different 3D printing process, a software program guides the use of a powdered substrate and a dedicated computer printer to automatically build the desired shape. Today, most 3D printers use plastic materials, but metal products can also be manufactured. Because 3D printing can take a lot of time to complete, in most cases this manufacturing process cannot yet compete commercially with machining.

Other CNC Machining Services

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Jig Grinding Services

Request Your Free 5 Axis CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Five-axis CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.