Aluminum CNC Machining

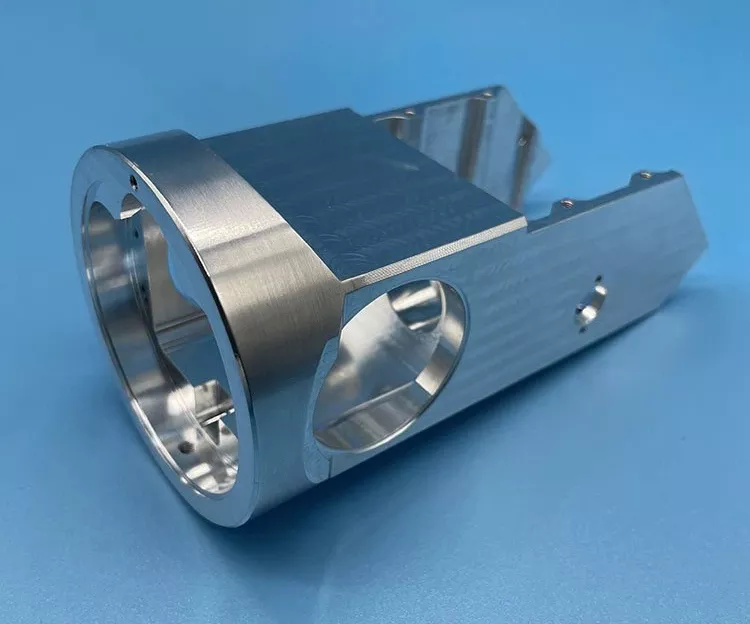

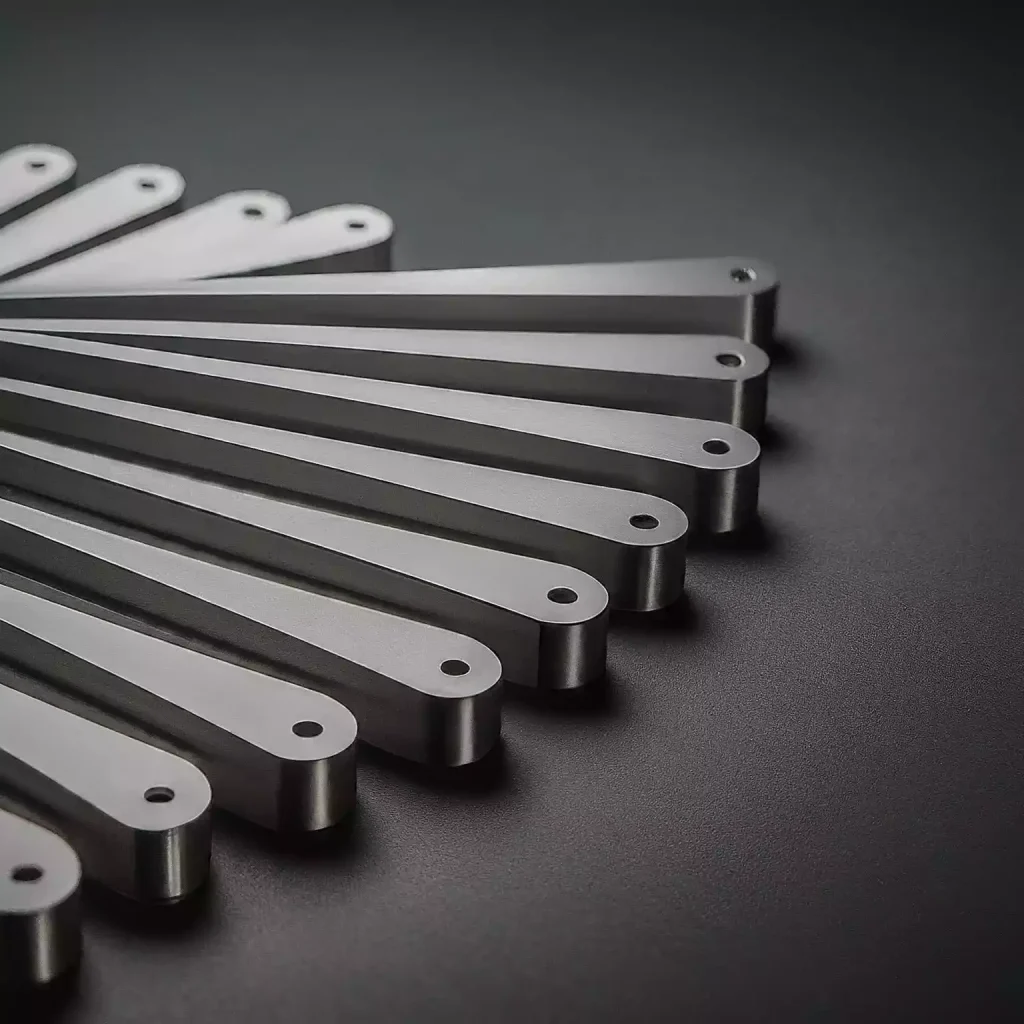

Elimold offers best-in-class aluminum CNC machining services. With cutting-edge technology and an expert team of highly skilled engineers, we specialize in providing precision aluminum alloy engineered components tailored to your exact specifications. From prototypes to high-volume production, our state-of-the-art CNC machining capabilities ensure your aluminum components are of the highest quality and precision. Trust Elimold to bring your project to life with the highest precision and efficiency in aluminum CNC machining. Contact us today for a free instant quote.

Aluminum CNC Machining Manufacturer

Elimold is a highly skilled aluminum CNC machining manufacturer with unparalleled expertise in the field. Our in-house facility offers a wide range of precision CNC machining services that can be tailored to your unique needs. What sets us apart is our relentless pursuit of excellence. We invest heavily in training our team to ensure that every aluminum machining project, regardless of complexity and size, is completed with the utmost precision and efficiency. When you choose Elimold, you get exceptional craftsmanship, attention to detail, and a commitment to achieving your project goals. Whether you need prototyping, low-volume production, or full manufacturing, Elimold has the expertise and capabilities to meet your aluminum CNC machining needs. Our commitment to machining excellence and our unwavering commitment to customer satisfaction make us the first choice for any aluminum machining need. Contact us today to discuss your needs and learn how we can help you succeed with advanced aluminum CNC machining solutions.

Aluminum Machining Shop Capabilities

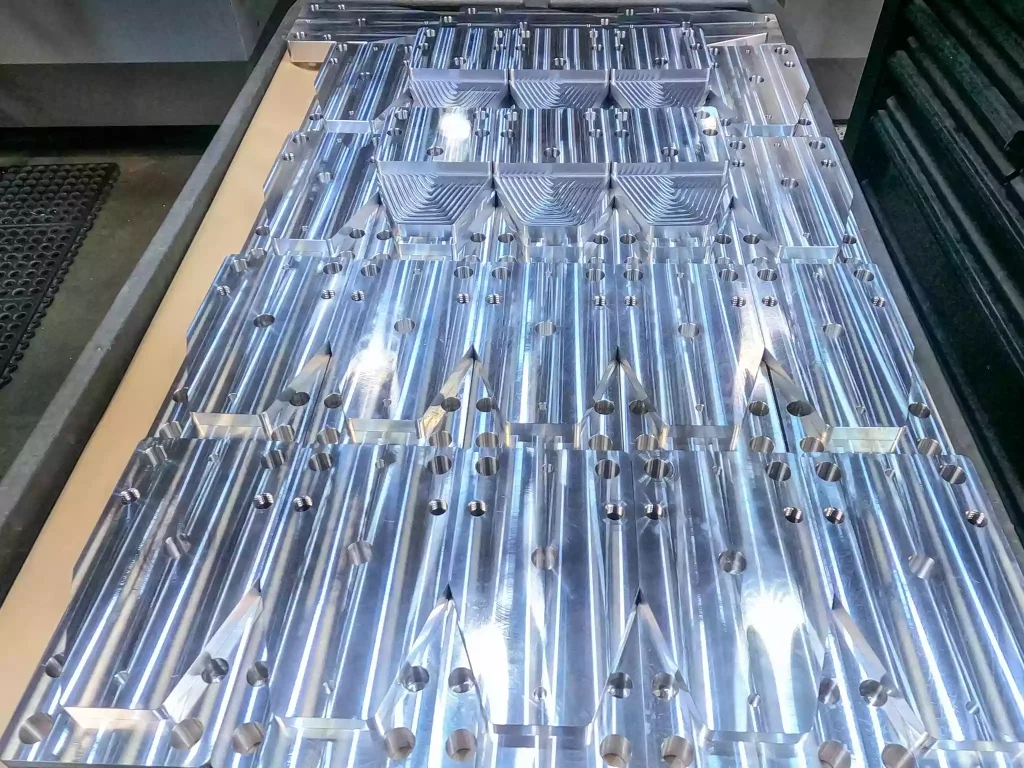

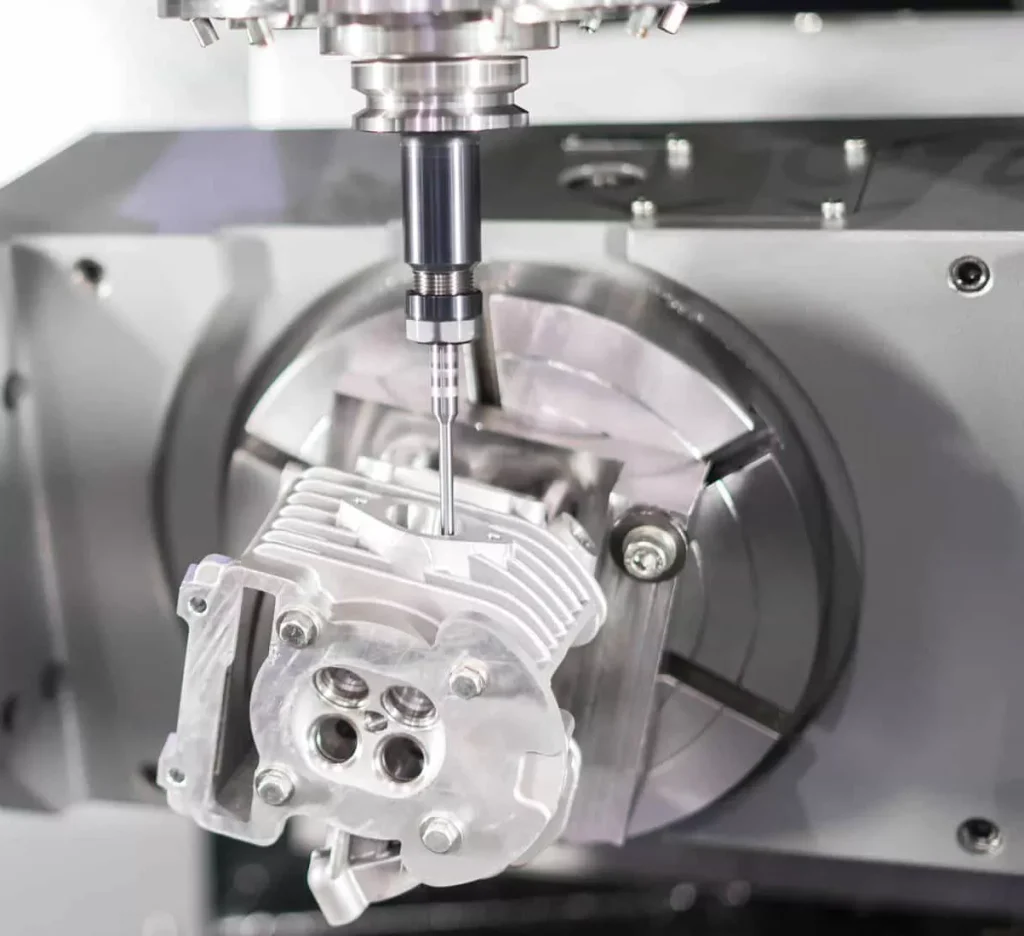

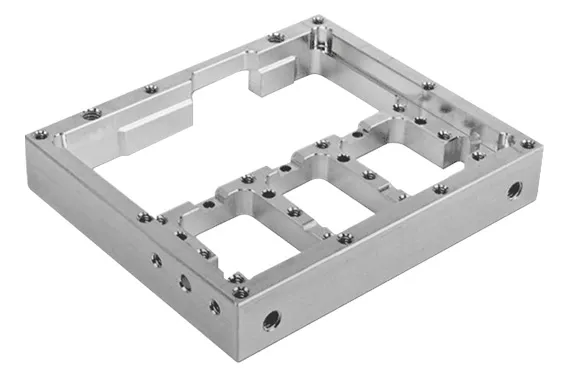

Whether you need CNC machined prototypes, low-volume production runs, or high-volume orders, our experienced technical team can handle projects of any size using advanced CNC machinery. We can produce aluminum parts with accuracies as fine as 0.0002 inches. We can manufacture aluminum parts as small as 3″ x 3″ x 3″ (or weighing less than 1 pound) to as large as 150″ x 92″ x 48″ (or weighing up to 44,000 pounds).

Elimold offers a full-service, in-house operation that reduces overall costs and delivery times while guaranteeing expert service from start to finish. With over 100 CNC machining centers and 35 overhead cranes capable of handling up to 20 tons, we can handle virtually any custom aluminum CNC machining project at our 80,000 square foot facility in Shenzhen, China.

Turnkey Aluminum CNC Machined Parts Supplier

We combine advanced equipment, well-trained personnel, and a commitment to quality to provide a full range of services to optimize the customer value chain. If you are looking for the best CNC aluminum machining services, Elimold is your best choice. With modern facilities and experienced staff, we are a leading aluminum machined parts supplier, providing services from design to manufacturing. Elimold’s innovative technology and experienced engineering and production teams enable us to manufacture parts with tight dimensional tolerances and provide assembly services. Materials are sourced from reputable suppliers and verified for compliance upon arrival. Our quality control team uses advanced testing and inspection equipment to ensure that every part produced meets customer specifications. All orders are reviewed for accuracy before shipment. Let Elimold take on these tasks and ensure accurate and reliable services. Contact us today and we can discuss how to turn your plans into reality.

Engineering Support Services

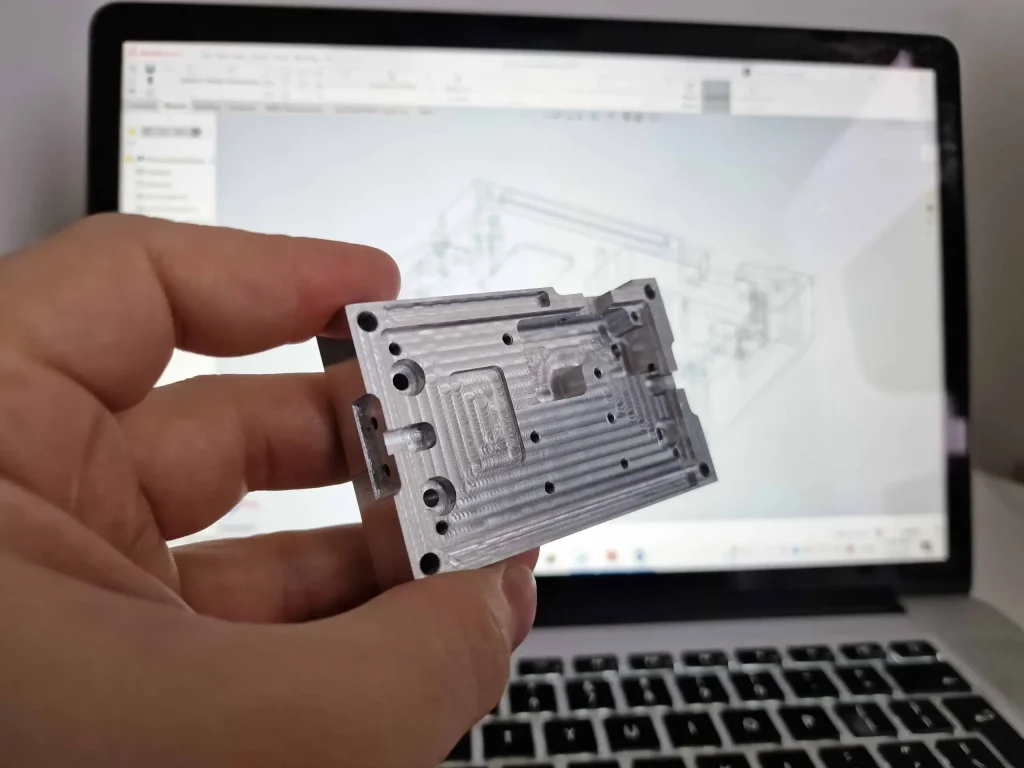

Our dedicated and experienced engineering team will help your project run smoothly from early concept to full production. Elimold’s engineering team uses advanced computer-aided engineering (CAE) tools and extensive technical expertise to optimize the design of rapid prototyping and precision-machined aluminum parts. Our engineers are proficient in applying CAE technology to improve manufacturability and product integrity. This includes using UG (Unigraphics) to verify the feasibility of product design and manufacturing, ensuring seamless integration from design to production, and proficiently processing and interpreting CAD/CAM files from various virtual systems to achieve accurate and efficient part development. As a result, Elimold can provide value-driven engineering solutions to minimize costs throughout the manufacturing life cycle without compromising quality or performance.

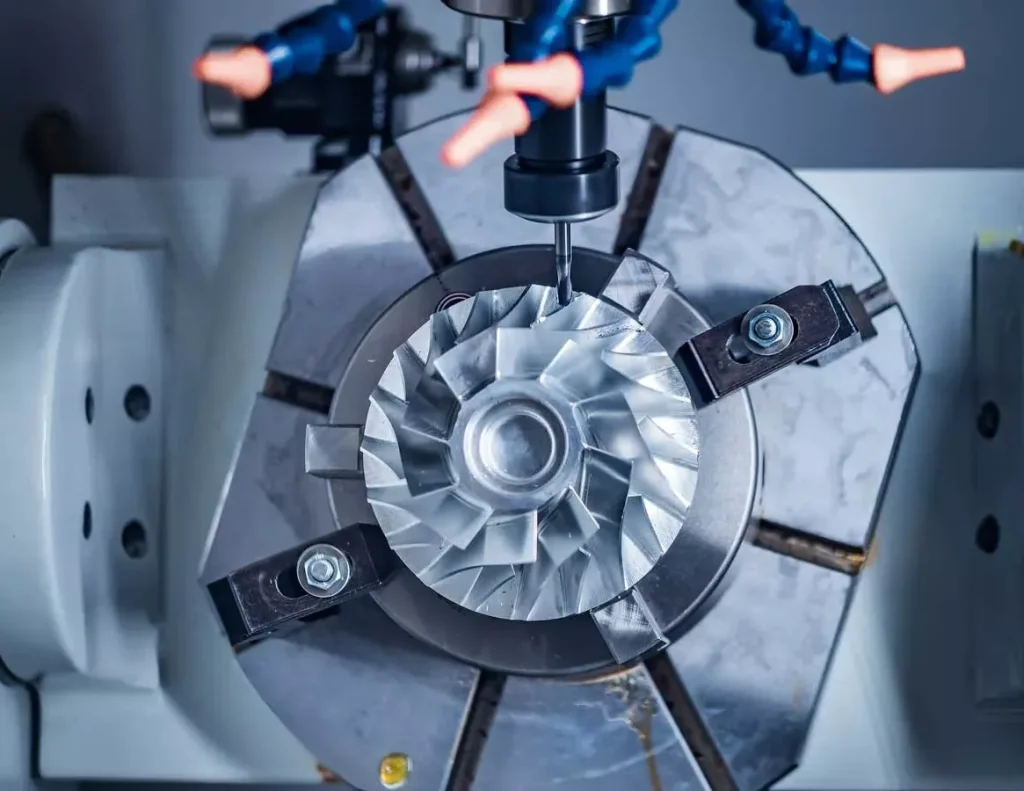

Aluminum CNC Machining Service Types

Our aluminum CNC machining services cover a variety of process types, providing flexible and diverse production and shipping solutions. Whether it is the early stage of product development or large-scale production, from flat to radial and axial holes, slots, grooves, we can meet your needs. We can meet your needs with ideal cost-effectiveness. Our professional team is at your service 24/7.

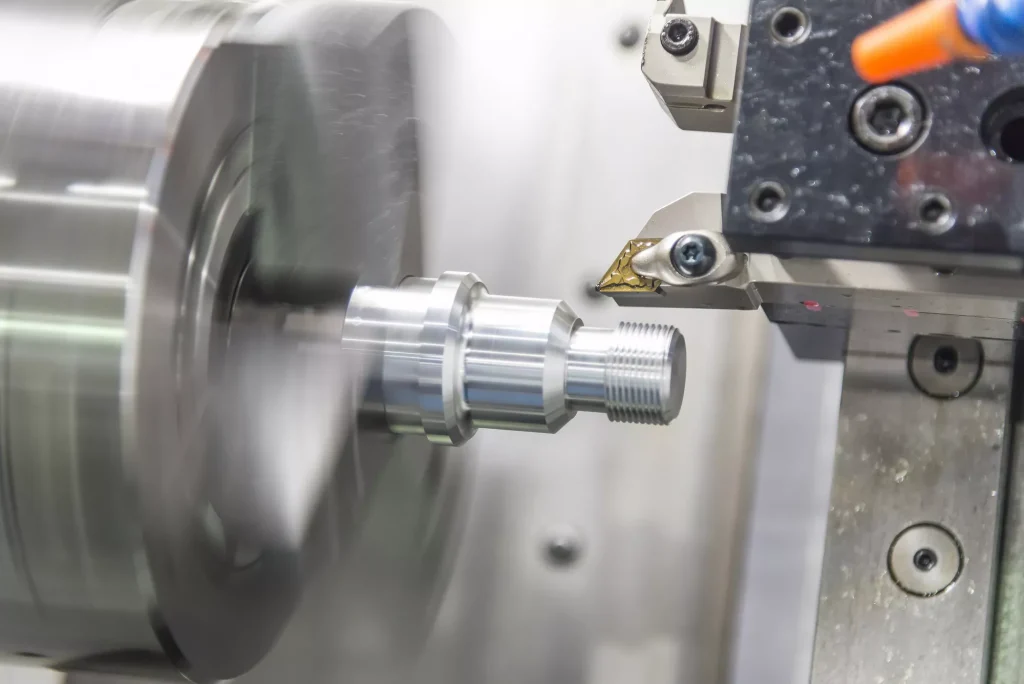

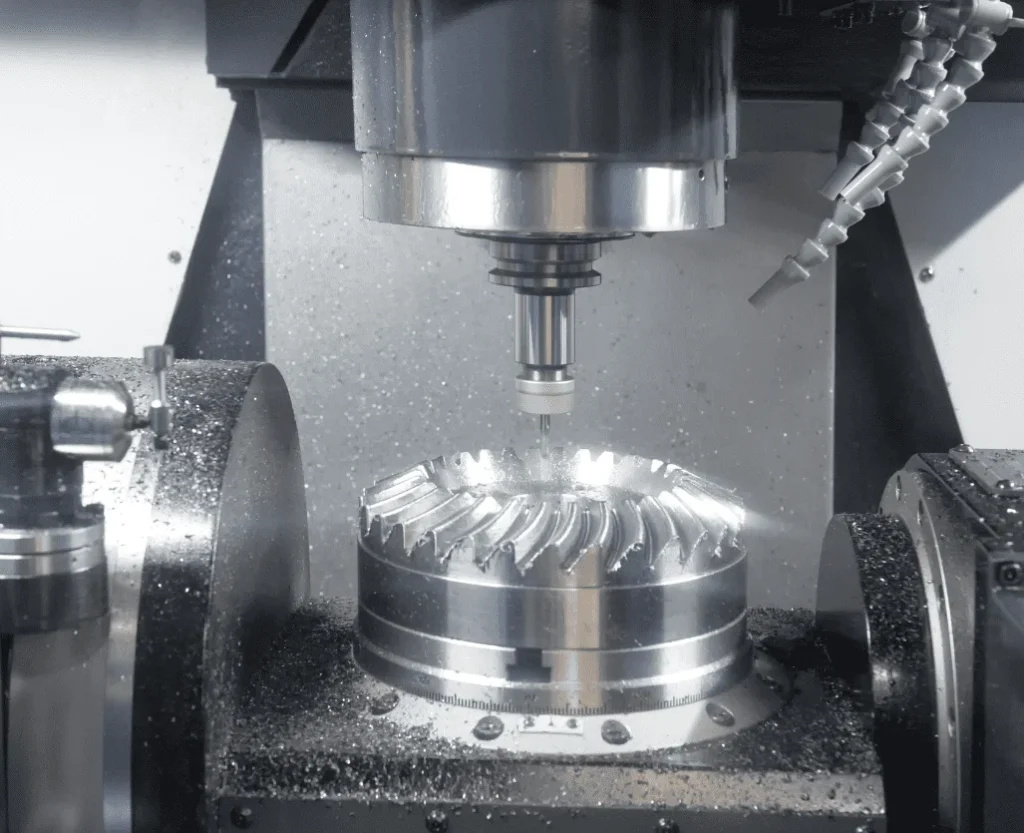

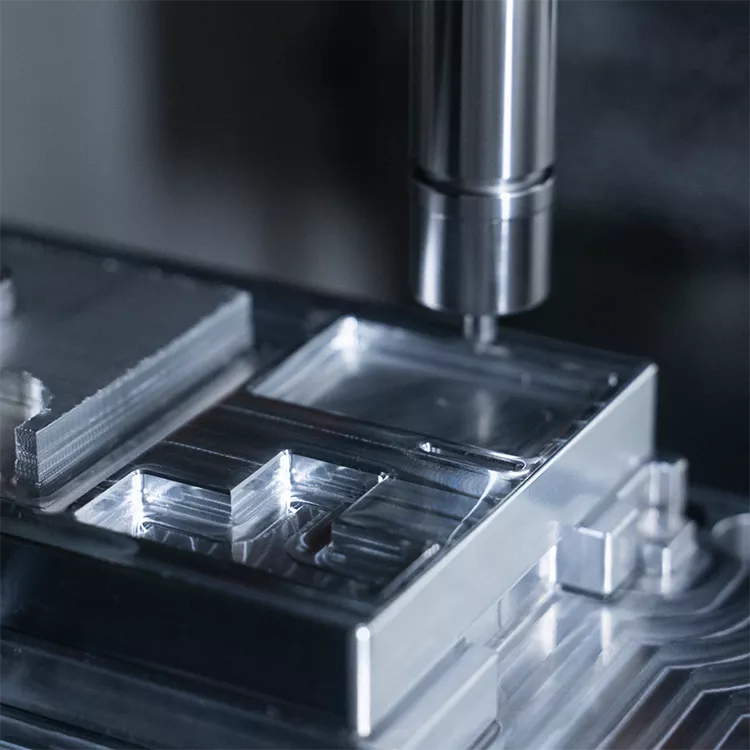

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Comprehensive CNC Aluminum Machining Services

We provide professional CNC aluminum machining services to manufacture any custom designed high-precision dimensional parts according to your mechanical engineering drawings. This helps global customers manage their operations and customized parts more efficiently. With our experienced team of engineers, our CNC aluminum machining services are not limited to large-volume orders. There is no minimum order quantity for small-volume orders, the minimum order quantity is 1 piece, and it can be completed in as fast as 3 days. Whether the project is simple or complex. We provide you with rapid prototyping, small batch processing and high-volume production services for end-use parts, as well as flexible production and shipping options. Elimold is able to meet your needs at the most suitable price and product development stage. In addition, our team of experts is on call 24/7 to answer any questions you may have or provide assistance with your project.

Custom Your Aluminum Parts Project With Elimold's Professional Services

Extensive project experience

Since the establishment of Elimold, we have produced tens of thousands of different types of aluminum parts. We have extensive experience in various aluminum grades and their corresponding surface treatments.

Dynamic Team

If you need customized aluminum parts urgently, Elimold can form a temporary team to quickly handle and deliver your project. We have sufficient production capacity to cope with urgent large-scale production needs.

Minimum Order Quantity: 1 piece

Most companies have certain requirements for order quantities. Elimold is a rapid prototyping expert, providing CNC machining services from prototype to mass production.

Favorable Price

Professional engineers save processing time by optimizing tool processing paths. Even with only one programming, we can process multiple products. With the same material cost, we can reduce processing costs.

Complete Surface Treatment

Elimold can provide complete surface treatment services, such as anodizing, electroplating, painting, powder coating and chromate passivation. So you can get the final parts directly from our factory.

Professional Packaging

If it is a common small volume part, we will pack it individually in a blister box. If it is an atypical large part, we will pack it separately with bubble cotton and anti-collision cotton.

Need CNC Machined Parts in Aluminum?

Upload your file and receive fast pricing or manufacturability feedback! Quote time for Aluminum CNC is one business day. We will contact you with any questions! STEP files are our preferred format.

Aluminum Material Grade Classification And Characteristics

Aluminum is a lightweight metal with an excellent strength-to-weight ratio, making it ideal for applications that require metal-grade strength but where weight is still a consideration. Aluminum comes in a variety of alloys, each represented by the first number in its classification. The number indicates the primary alloying element. Below is a classification of aluminum materials.

Aluminum profile series 1: (rolled material, cast non-heat-treated aluminum alloy, pure aluminum alloy

1 series aluminum content exceeds 99.00%, with good conductivity, corrosion resistance and welding performance; but the strength is low and cannot be strengthened by heat treatment. High-purity aluminum (aluminum content exceeds 99.9%) is mainly used in scientific experiments, chemical industry and special purposes.

Aluminum profile series 2: aluminum-copper alloy

Aluminum alloy with copper as the main alloying element, also adds manganese, magnesium, lead, bismuth and other elements to enhance cutting processability. 2011 alloy, pay attention to safety protection during smelting (dangerous gases will be generated). 2014 alloy is used in the aviation industry and has high strength. 2017 alloy is lower in strength than 2014 alloy, but is easier to process, and 2014 alloy can be strengthened by heat treatment. Commonly used Aviation industry (2014 alloy), screws (2011 alloy), industries with high operating temperatures (2017 alloy).

Aluminum profile 3 series: aluminum-manganese alloy

Aluminum alloys with manganese as the main alloying element cannot be strengthened by heat treatment. They have good corrosion resistance and welding performance, and their plasticity is close to that of super aluminum alloys. They are used for oil-conducting seamless pipes (alloy 3003) and tanks (alloy 3004) for aircraft.

Aluminum profile 4 series: aluminum-silicon alloy

The main component of 4 series aluminum profiles is silicon, and some can be strengthened by heat treatment. 4032 has good heat resistance and friction resistance, and a small thermal expansion coefficient. It is often used in pistons, cylinder heads, etc. 4043 has a small solidification shrinkage. After sulfuric acid anodizing, it naturally develops a gray color. It is often used for welding lines, building panels, etc.

Aluminum Profile 5 series: aluminum-magnesium alloy

5 series aluminum profiles are mainly magnesium, with good heat resistance, welding performance, and fatigue strength, but cannot be strengthened by heat treatment, and can only be improved by cold working. They are often used in lawn mower handles, aircraft fuel tank ducts, bulletproof vests, etc. 5005

The strength is the same as 3003, with good processability, weldability, and corrosion resistance. It has good finishing properties after anodizing, and the color is consistent with 6063 profiles. 5052 is the most representative alloy, with medium strength, good corrosion resistance, weldability, and formability, especially high fatigue strength and good seawater resistance. It is generally suitable for sheet metal, ships, vehicles, buildings, bottle caps, honeycomb panels, etc.

Aluminum profile 6 series: aluminum-magnesium-silicon alloy

Generally, mid-range and above aluminum materials are basically 6 series. Aluminum-magnesium-silicon alloy is composed of three metals: aluminum, magnesium, and silicon. A composite material composed of 2,4-dioxide and 2,6-dioxide, is the most widely used alloy at present. Among them, 6063 and 6061 are the most commonly used, followed by 6082, 6160, 6125, 6262, 6060, 6005 and 6463; 6063, 6060 and 6463 have relatively low strength in the 6 series. 6061 has medium strength, good corrosion resistance, good welding performance, good process performance (easy to extrude) and good oxidation coloring performance.

Aluminum profile 7 series: aluminum-zinc-magnesium alloy

7072 has a low electrode potential and is mainly used for anti-corrosion covering skins and is also suitable for heat exchanger fins. 7075 is one of the strongest alloys in aluminum alloys, but has poor corrosion resistance. 7075 is a hardenable alloy with good resistance to stress corrosion cracking, suitable for thick plates, forgings, aircraft, high-speed rotating bodies, etc.

Aluminum Alloy Grades & Specifications

We provide a variety of aluminum grades for your aluminum parts. If you have special aluminum grade requirements, please contact us.

Aluminium 1060

Aluminium 1060 is pure aluminium with an aluminium content as high as 99.6%. In CNC machining, it has good machinability and the machined surface is relatively smooth. This material is often used to make components with high conductivity requirements, such as busbars.

- Yield Tensile Strength: 30 – 40 (MPa)

- Fatigue Strength: Relatively low

- Elongation at Break: 35 – 40 (%)

- Hardness: 26 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Resistivity: 2.6 – 2.7 μΩ*cm

- Post-treatment: Simple surface treatments such as anodizing can be carried out.

Aluminium 5083 -H111

Aluminium 5083-H111 is a high-performance corrosion-resistant alloy. It can maintain good performance in harsh corrosive environments such as seawater. Its strength is moderate, and it has good machinability. It is widely used in shipbuilding, offshore engineering structures and other fields, such as hull plates.

- Yield Tensile Strength: 125 (MPa)

- Fatigue Strength: 60 (MPa)

- Elongation at Break: 16 – 20 (%)

- Hardness: 40 (Brinell)

- Ultimate Tensile Strength: 270 – 350 MPa

- Resistivity: 4.6 – 4.9 μΩ*cm

- Post-treatment: Appropriate heat treatment after cutting and welding can be carried out, as well as surface protection treatment.

Aluminum 6063

Aluminum 6063 has good extrusion performance and machinability, and is often used to make building profiles, such as window and door frames. It has good appearance quality, and after surface treatment, it can obtain a good decorative effect. Its strength can meet the requirements of general building structures.

- Yield Tensile Strength: 214 (MPa)

- Fatigue Strength: 68.9 (MPa)

- Elongation at Break: 12 (%)

- Hardness: 73 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 240 MPa

- Resistivity: 3.6 – 3.8 μΩ*cm

- Post-treatment: Anodizing, electrophoretic coating.

Aluminium 1100

Aluminium 1100 has good processing performance, is easy to form, and can adapt well to various CNC machining processes. It shows excellent corrosion resistance, especially in some non-corrosive environments, and is widely used in applications such as simple decorative parts and food packaging containers.

- Yield Tensile Strength: 90 (MPa)

- Fatigue Strength: 45 (MPa)

- Elongation at Break: 35 (%)

- Hardness: 28 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 110 MPa

- Post-treatment: Painting, anodizing and other treatments can be carried out.

Aluminium 5086

Aluminium 5086 has good corrosion resistance and machinability. Its corrosion resistance in the marine environment makes it often used to manufacture marine equipment and some structural parts with high corrosion resistance requirements.

- Yield Tensile Strength: 105 (MPa)

- Elongation at Break: 18 – 22 (%)

- Hardness: 35 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 240 – 300 MPa

- Resistivity: 4.7 – 5.0 μΩ*cm

- Post-treatment: Welding post-heat treatment and surface anti-corrosion treatment.

Aluminum 6082

Aluminum 6082 is a medium-strength aluminium alloy. Its machinability is good, and it is suitable for various CNC machining methods. The combination of its strength and toughness makes it widely used in manufacturing mechanical structural parts, vehicle components and other aspects.

- Yield Tensile Strength: 290 (MPa)

- Fatigue Strength: 105 (MPa)

- Elongation at Break: 12 (%)

- Hardness: 95 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 310 MPa

- Resistivity: 3.9 – 4.1 μΩ*cm

- Post-treatment: Quenching and aging treatment, surface treatment.

Aluminium 2017

Aluminium 2017 is a heat-treatable and strengthenable aluminium alloy. After appropriate heat treatment, its strength can be significantly improved. It has good machinability, but attention should be paid to its heat sensitivity during the machining process. This material is often used to manufacture aircraft structural parts and high-strength mechanical parts.

- Yield Tensile Strength: 275 (MPa)

- Fatigue Strength: 105 (MPa)

- Elongation at Break: 23 (%)

- Hardness: 90 (Brinell)

- Ultimate Tensile Strength: 380 MPa

- Post-treatment: Heat treatment strengthening and anodizing can be carried out.

Aluminium 5754

Aluminium 5754 shows excellent corrosion resistance, especially in some industrial and outdoor environments. It has good machinability and can be used to produce various complex shapes through CNC machining.

- Yield Tensile Strength: 110 (MPa)

- Fatigue Strength: 50 (MPa)

- Elongation at Break: 20 – 25 (%)

- Hardness: 38 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 260 – 320 MPa

- Resistivity: 4.8 – 5.0 μΩ*cm

- Post-treatment: Surface painting, anodizing and other treatments can be carried out.

Aluminum 7050

Aluminum 7050 is a high-strength aluminium alloy, mainly used in fields such as aerospace where extremely high material strength requirements are imposed.

- Yield Tensile Strength: 490 (MPa)

- Fatigue Strength: 160 (MPa)

- Elongation at Break: 11 (%)

- Hardness: 147 (Brinell)

- Young’s Modulus (Elastic Modulus): 71 GPa

- Ultimate Tensile Strength: 510 MPa

- Resistivity: 4.2 – 4.4 μΩ*cm

- Post-treatment: Complex heat treatments such as two-stage aging treatment, surface protection treatment.

Aluminum 2024 -T3

Aluminum 2024-T3 is a high-strength aluminium alloy. The T3 state indicates that it has undergone solution treatment and cold working treatment. It has high strength and is especially suitable for structural parts that bear large loads. It is widely used in the aerospace field, such as aircraft wings and other components.

- Yield Tensile Strength: 345 (MPa)

- Fatigue Strength: 138 (MPa)

- Elongation at Break: 18 (%)

- Hardness: 120 (Brinell)

- Young’s Modulus (Elastic Modulus): 73 GPa

- Ultimate Tensile Strength: 485 MPa

- Resistivity: 3.4 – 3.5 μΩ*cm

- Post-treatment: Appropriate stress relief annealing and anodizing.

Aluminum 6061

Aluminum 6061 is regarded as a general-purpose alloy. It has excellent machinability and is easy to weld. The main alloying elements are magnesium and silicon. This aluminium alloy is often used to manufacture electrical accessories, brake pistons and bicycle frames.

- Yield Tensile Strength: 276 (MPa)

- Fatigue Strength: 96.5 (MPa)

- Elongation at Break: 17 (%)

- Hardness: 95 (Brinell)

- Young’s Modulus (Elastic Modulus): 68 – 74 GPa

- Ultimate Tensile Strength: 260 – 310 MPa

- Resistivity: 3.9 – 4.1 μΩ*cm

- Post-treatment: Annealing and cold working.

Aluminum 7075

Aluminum 7075 is also a high-strength aluminium alloy. Its strength and hardness are both high. It is widely used in fields such as aerospace and military equipment, such as missile components, aircraft landing gears.

- Yield Tensile Strength: 503 (MPa)

- Fatigue Strength: 159 (MPa)

- Elongation at Break: 11 (%)

- Hardness: 150 (Brinell)

- Young’s Modulus (Elastic Modulus): 72 GPa

- Ultimate Tensile Strength: 572 MPa

- Resistivity: 4.0 – 4.2 μΩ*cm

- Post-treatment: Special heat treatments such as solution treatment and aging treatment, surface treatment.

Aluminium 5052 -H32

Aluminium 5052-H32 has good corrosion resistance, especially in corrosive environments such as the marine environment. It has good machinability, is easy to form and weld. This material is often used to manufacture some parts of ships and automobiles as well as chemical equipment.

- Yield Tensile Strength: 193 (MPa)

- Fatigue Strength: 117 (MPa)

- Elongation at Break: 12 (%)

- Hardness: 60 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Resistivity: 4.9 – 5.1 μΩ*cm

- Post-treatment: Welding post-heat treatment and surface anodizing can be carried out.

Aluminum 6061 -T6

Aluminum 6061-T6 is the state of Aluminum 6061 after heat treatment. Its strength is higher than that of ordinary Aluminum 6061, and its hardness is also greater. It is widely used in aerospace, automotive industries and other fields, such as aircraft spars, automotive suspension components.

- Yield Tensile Strength: 290 (MPa)

- Fatigue Strength: 100 (MPa)

- Elongation at Break: 12 (%)

- Hardness: 97 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 310 MPa

- Resistivity: 3.8 – 4.0 μΩ*cm

- Post-treatment: Appropriate stress relief treatment and surface treatment.

Aluminum MiC -6

Aluminum MIC-6 is a special aluminium alloy for molds. It has excellent dimensional stability and can maintain high precision during the machining process. Its strength and hardness can meet the requirements of mold manufacturing, and its corrosion resistance is also good, suitable for making injection molds and other things.

- Yield Tensile Strength: 105 (MPa)

- Elongation at Break: 3 (%)

- Hardness: 65 (Brinell)

- Young’s Modulus (Elastic Modulus): Around 70 GPa

- Ultimate Tensile Strength: 430 MPa

- Post-treatment: Surface treatments such as nitriding can be carried out to improve wear resistance.

About the Aluminum Materials

Aluminum is one of the most commonly used metals in the world because it is relatively easy to machine, making it great for CNC machining, and becoming a good choice for many industries.Aluminum has excellent properties for machining such as:

- Excellent machinability

- Low cost

- Low weight

- Overall versatility

- High strength

- Hardness

- Heat tolerance

- Electrical conductivity

- Corrosion resistance

CNC Manufacturing Of Custom Aluminum Parts

The CNC aluminum machining services provided by Elimold help businesses save costs and add value to aluminum components. Our CNC machined aluminum prototypes offer comprehensive solutions for businesses that produce a wide range of products. We have fast turnaround times and excellent customer support. CNC machined aluminum prototypes can help uncover design flaws and solve mass production issues compared to mass production. A qualified team of machinists and cutting-edge technology ensures customers receive superior finishes and precision. Our team of engineers designed our CNC aluminum rapid prototyping parts production services to meet the needs of large companies. We follow ISO-mandated quality and testing regulations when manufacturing our high-tech components. Contact us to learn how our CNC aluminum rapid prototyping machining services can benefit you.

Ready to start your next aluminum CNC machining project?

Elimold is committed to manufacturing your custom aluminum parts through our CNC machining services, with low cost, fast delivery, high precision, and no minimum quantity. Start manufacturing your CNC aluminum machined parts with us today.

Custom Aluminum CNC Machining Solutions

Need to get high-quality aluminum parts made quickly? Want help from professionals who can make even the most complex manufacturing projects a breeze? Then you should try Elimold’s aluminum CNC machining services. Because, we have the capabilities and experience needed to precisely machine aluminum parts to your unique specifications. We will take on your project with the best price, fast delivery cycle, and commitment to complete customer satisfaction. With a variety of CNC technologies and advanced equipment, we can perform complex CNC machining on a variety of different aluminum alloy materials. Our advanced machining capabilities allow us to manufacture aluminum alloy parts with the smallest tolerances and the highest precision, even down to 0.0005 inches. Elimold not only provides CNC machining services, but also a hybrid service of prototyping and additive manufacturing. If you need to make metal aluminum prototypes for more complex projects, we can help you.

CNC Aluminum Prototype to Production

Elimold provides aluminum alloy parts rapid prototyping services. Aluminum CNC prototyping is an effective way to handle complex design verification and pre-production testing before mass production of aluminum parts, which can enable you to find and solve problems faster and move towards production. We perform efficient, accurate and cost-effective processes in-house to provide excellent product results for your aluminum prototype processing. Our engineering team will review each project, analyze your design and meet any special needs. This in-depth verification ensures that you get the most effective processing process to meet your budget, time and materials.

Quality Management and Certification Standards

If you need help with a custom aluminum CNC machining project, we are one of the most capable and affordable production sources with our technology, experience and skills. Quality is our top priority. We strictly implement ISO9001 quality system standards, combined with efficient production processes and flexible custom engineering, so that we can deliver complex projects in a short time and provide excellent product quality. In addition, in order to fulfill our quality commitment to customers, we have introduced a third party to help improve our quality control management system. We have established a very effective quality control management system under the guidance of ISO.

Testing Equipment

Elimold has invested in many modern measuring instruments, such as Carl Zeiss CMM, X-ray detectors, spectrometers and cleanliness testing laboratories. To ensure that your parts are of good quality, we will continue to invest in testing instruments and employee training.

- CMM

- Spectrometer

- Microscope

- Projector

- X-ray Detector

- Cleanliness Test Equipment

- Leakage Test Equipment

- Salt Spray Testing Equipment

- Pneumatic Measuring Instrument

- Hardness Testing Machine

- Color Meter Machine

- Thickness Testing Machine

- Electronic Balance

- Density Balance

Surface Finishing Options

Elimold offers a range of surface treatments as part of its aluminum CNC machining services to enhance the quality of each custom aluminum CNC part. Each surface treatment is tailored to enhance the mechanical properties and appearance of the aluminum part.

- As Machined

- Bead Blasting

- Sand Blasting

- Anodizing

- Painting

- Plating

- Powder Coating

- Black Oxide

- Polishing

- Laser Engraving

- Passivation

- Deburring

- DLC Coating

- Quench-Polish-Quench

- Phosphate

- Grinding

- Chemical film

- Silk Screen

- Heat Treatment

- Chromate

- Brushing

- E-coating

- Alodine

- Ceramic Coating

Industries We Serve

Aluminum is lightweight, easy to manufacture, and has excellent performance, making it an ideal choice for a variety of applications. Therefore, many industries can benefit from aluminum CNC parts.

- Automotive

- Construction

- Aerospace

- Appliances

- Kitchenware

- Lighting

- Packaging

- Wiring and cabling

- Electronics

- Restaurants

- Hospitality

- Consumer goods

- Shipping

- Military and defense

- Agriculture

- Marine

Applications

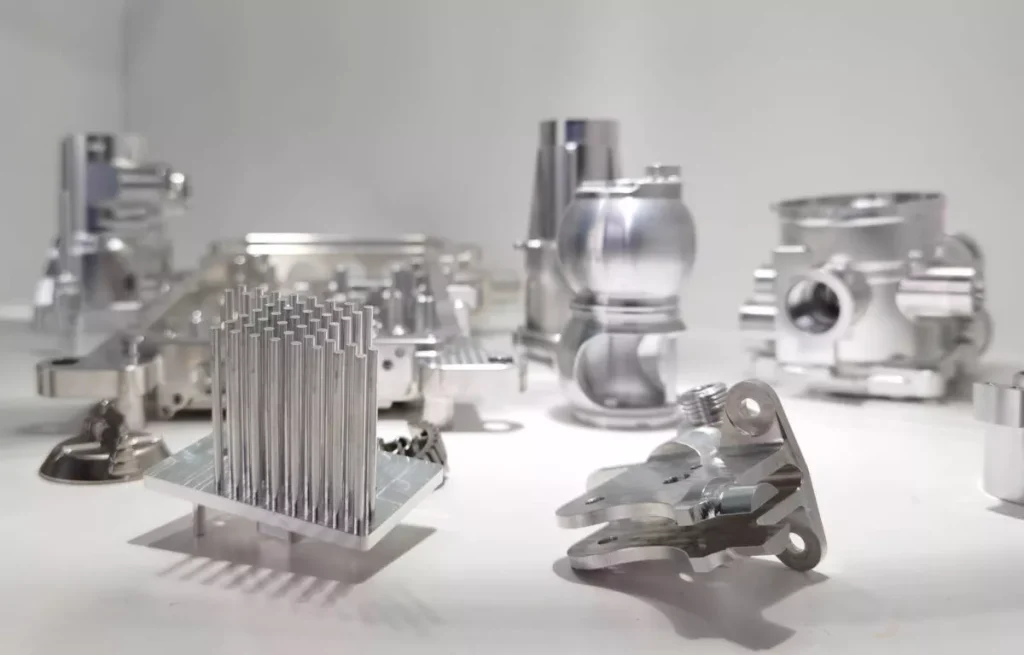

CNC machined aluminum can be used to produce a wide variety of parts and assemblies that aid in a variety of services. Today, well-machined CNC aluminum parts are becoming increasingly popular in the engineering field. We have been providing the following types of CNC machined aluminum parts to our customers.

- Aircraft parts

- Bicycles

- Sports equipment

- Highly stressed parts

- Transportation industry parts

- Rock climbing equipment

- Weapons

- Molds and tools

- Structural parts

- Pipes

- Couplings

- Covers

- Steps, floors, walkways

- Electronic components

- Aircraft parts

- Truck bodies, frames, runways

- Pedals

- Weldments

- Cookware

- Appliances

- Panels

- Food processing equipment

- Pins

- Handles

- Couplings

- Fasteners

- Marine parts

- Bearings

- Washers

- Pipes

- Lighting fixtures

- Worm gears

- Front panels

- Spline shafts

- Heat exchangers

Why is aluminum suitable for CNC machining?

CNC machining is suitable for any material that is hard enough to be easily milled, such as plastic, metal, or fiberglass. Aluminum is a lightweight metal with an excellent strength-to-weight ratio, making it ideal for applications that require metal-grade strength but where weight is still a concern. There are many types of aluminum alloys, each of which is indicated by the first number in its classification. The number indicates the main alloying element.

Due to its inherent hardness, aluminum is well suited for CNC machining mechanical parts, while the oxide layer provides effective protection against environmental corrosion. Aluminum has many properties that make CNC machining aluminum convenient and efficient. Unlike many other metals with similar qualities, aluminum is extremely machinable, with many grades being easy to cut with cutting tools, easy to chip, and easy to form. Aluminum’s high machinability allows for faster machining times, which reduces labor costs and machining time on aluminum CNC machines. It also makes it easier to machine aluminum to the higher precision tolerances required for precision products.

Professional Aluminum CNC Machining Team

Elimold is able to provide meticulous solutions and parts, and manufacture parts according to customer needs and specifications. We can not only produce large and small batches, but also undertake one-off projects, including new products and R&D projects. In addition, we can help you complete all important and complex tasks in the process of custom product prototyping and manufacturing, from initial design to small batch production, post-processing, logistics, and more. We are committed to speeding up your prototyping and manufacturing process and reducing costs. Whether it is one-time prototyping or mass production of thousands of products, Elimold can help you.

Combine with Other Manufacturing Processes

Most CNC machining shops only quote CNC machining as a stand-alone operation. But when new parts are in the hundreds or more, you need a more complete solution to achieve the best results. Some of these parts are better not milled from a solid block, but die-based machining or milling-assisted forging processes. Extrusion, casting and forging processes can all be combined with CNC machining to create better aluminum parts. Whatever the test conditions, whatever the performance requirements.

Extrusion + CNC machining

Forging + CNC machining

3D printing + CNC machining

Investment casting + CNC machining

Die casting + CNC machining

Aluminum Cutting Service

Why Choose Elimold for Aluminum CNC Machining?

We are dedicated to helping our customers meet their manufacturing needs, including producing parts that are often hard to find from other companies. Our dedication to excellence is reflected in everything we do, from the initial design phase and material certification to packaging and shipping. These measures ensure that your parts meet specifications, whether you need a small number of prototypes or large-scale production. We stand out by approaching each project with a problem-solving approach, and we often find points for improvement that lead to improved part performance, production efficiency, and cost savings. In addition to aluminum machining, we have decades of experience machining a variety of other materials, including brass, copper, rubber, and plastic.

Innovative Solutions for Aluminum Machining

We are committed to providing industry-leading aluminum machining services, making us our customers’ ideal manufacturing partner. We have been providing aluminum machining services for many years. With extensive industry experience, the Elimold team is able to contribute their skills and insights to each project. As a result, we have developed an efficient, precise and cost-effective process that delivers excellent product results. Our design and programming team not only reviews each project quickly and accurately, evaluating its cost, manufacturability and complexity, but also ensuring that we meet all the specifications of your plan. This in-depth verification process ensures that you receive the most efficient machining process that meets budget, time and material requirements. And we know that every project is unique, so we provide customized aluminum CNC machining services centered on meeting the specific needs of our customers. In addition, Elimold’s commitment to quality assurance and inspection ensures that every precision aluminum CNC machining service we provide meets the highest standards.

Request Your Free Aluminum CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Aluminum CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.