Automotive Lighting Injection Molding

Experience the excellence of Elimold’s plastic injection molding solutions for the automotive lighting industry, highlighting the superior quality of the car with superior design, performance and efficiency. Driving the automotive lighting industry forward with cutting-edge plastic injection molding technology.Contact us now for a free instant quote.

Professional Automotive Lighting Injection Molding Manufacturer

Elimold is a professional automotive lighting product injection molding manufacturer, specializing in the production of automotive lighting plastic parts and automotive lighting plastic molds. Our goal is to provide a full range of injection molding solutions for automotive lighting products. We specialize in providing high-quality, short-cycle, and cost-competitive lighting plastic parts injection molding manufacturing services for the automotive industry. Elimold is committed to producing first-class automotive lighting injection molds that meet the needs of the global automotive market. If you are looking for a reliable partner to meet your automotive lighting plastic parts injection mold needs, Elimold is your best choice. We provide high-quality, reliable products and injection molds that meet global automotive industry standards, and have a capable and experienced team of professionals who work tirelessly to ensure that our customers receive the best quality products and services. In addition, our extensive experience in the automotive industry ensures that we can provide professional OEM and ODM services, as well as the best solutions for automotive lighting product injection molds. Our in-house injection molding factory has advanced technology and equipment to ensure that our products meet customer requirements and have the highest quality. And we also offer a short-cycle production mode, which enables us to complete your project in the shortest possible time while maintaining the highest quality standards. We strive to provide you with competitive costs and build long-term relationships with our customers.

Your Trusted Automotive Production Partner

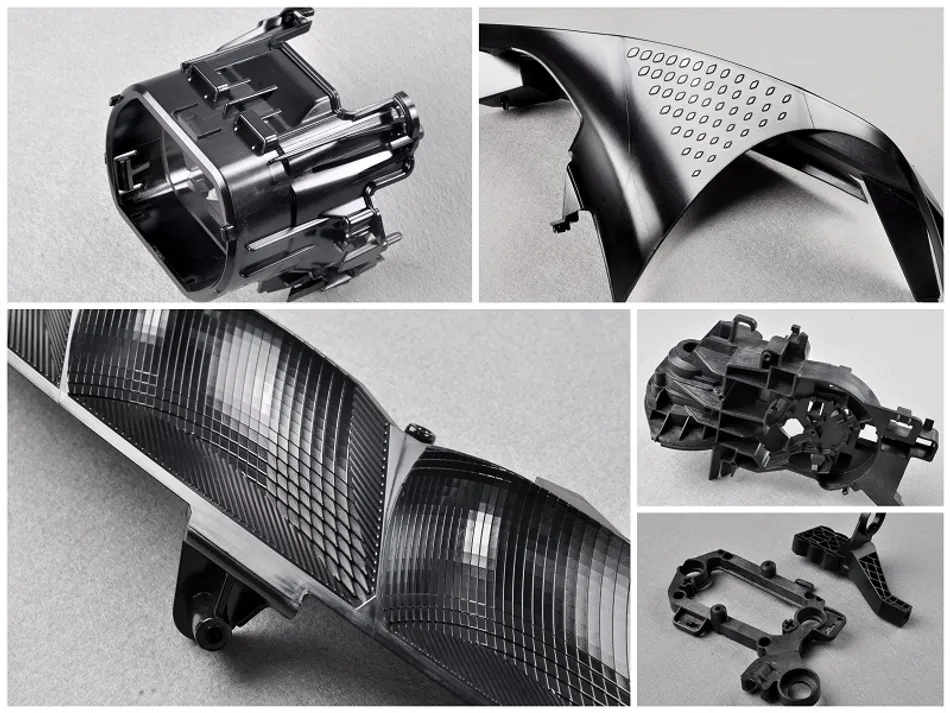

Elimold offers a wide variety of interior and exterior molded parts for the automotive lighting market. Our high quality standards and knowledge of lens grade materials have made us a top supplier to the headlamp, signal, and rear lamp markets.

We currently supply standard, reflector, and LED style lenses to several automotive customers. Our lens molding capabilities include polycarbonate and acrylic type lenses molded in clear, amber, and red. Elimold has developed specific and dedicated lens manufacturing cells with parts that utilize automated technology to eliminate all defects associated with contamination and handling. Our full range of lens manufacturing services includes all in-house photometric testing and protocols via our Hoffman SAE-010 reflectometer system.

Automotive Lighting Injection Molding Factory Capabilities

At Elimold, we have assembled a team of professional engineers, designers, machine operators, and project managers with amazing combined experience in the expertise, technology, and processes involved in automotive lighting injection molding. We have built an excellent reputation not only on product quality, but also on customer service. We can provide services such as development product design, prototyping, and mass production, and our methods and processes are based on mutual trust and collaboration. You will be informed of what is happening at every stage of the project.

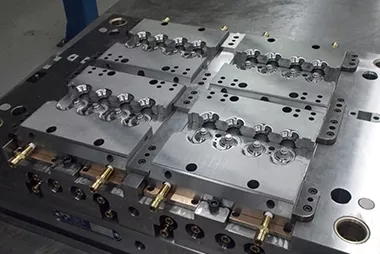

In our in-house injection molding facility, we have more than 70 advanced machines with clamping pressures ranging from 40 tons all the way up to 3,000 tons. We are ISO 9001 certified for quality management and take a collaborative approach with each of our customers to ensure the ideal results for each project. Plus, our in-house facility also has a full-service in-house tooling department, which means you can avoid the hassle and headache of working with multiple service providers for your automotive lighting injection molding needs. We work with you from start to finish on each plastic injection molding project to keep it moving forward quickly and efficiently, saving you time and money. Moreover, Elimold’s in-house injection molding facility is fully digitally managed, and we use the latest project management software to plan and coordinate the workflow of your project through our facilities. You will be able to track the progress of the entire process. A designated project manager provides monitoring and can update the project status at any time according to your needs. Updates can also be made via email, including digital photos of the mold and product and Gantt charts to help you track project milestones.

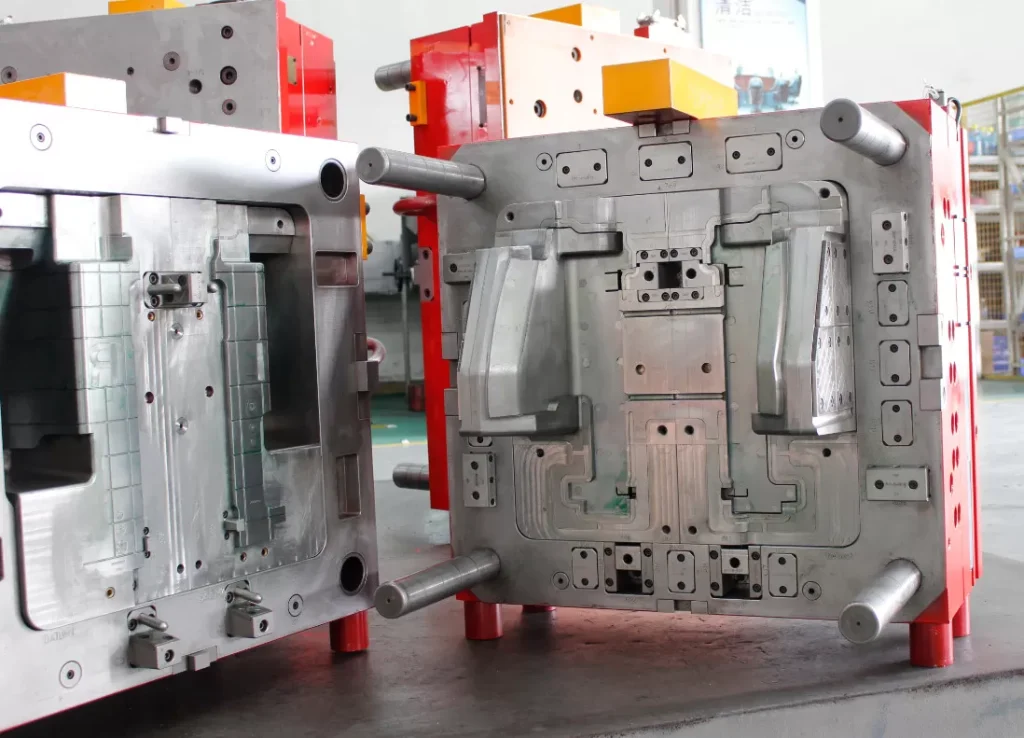

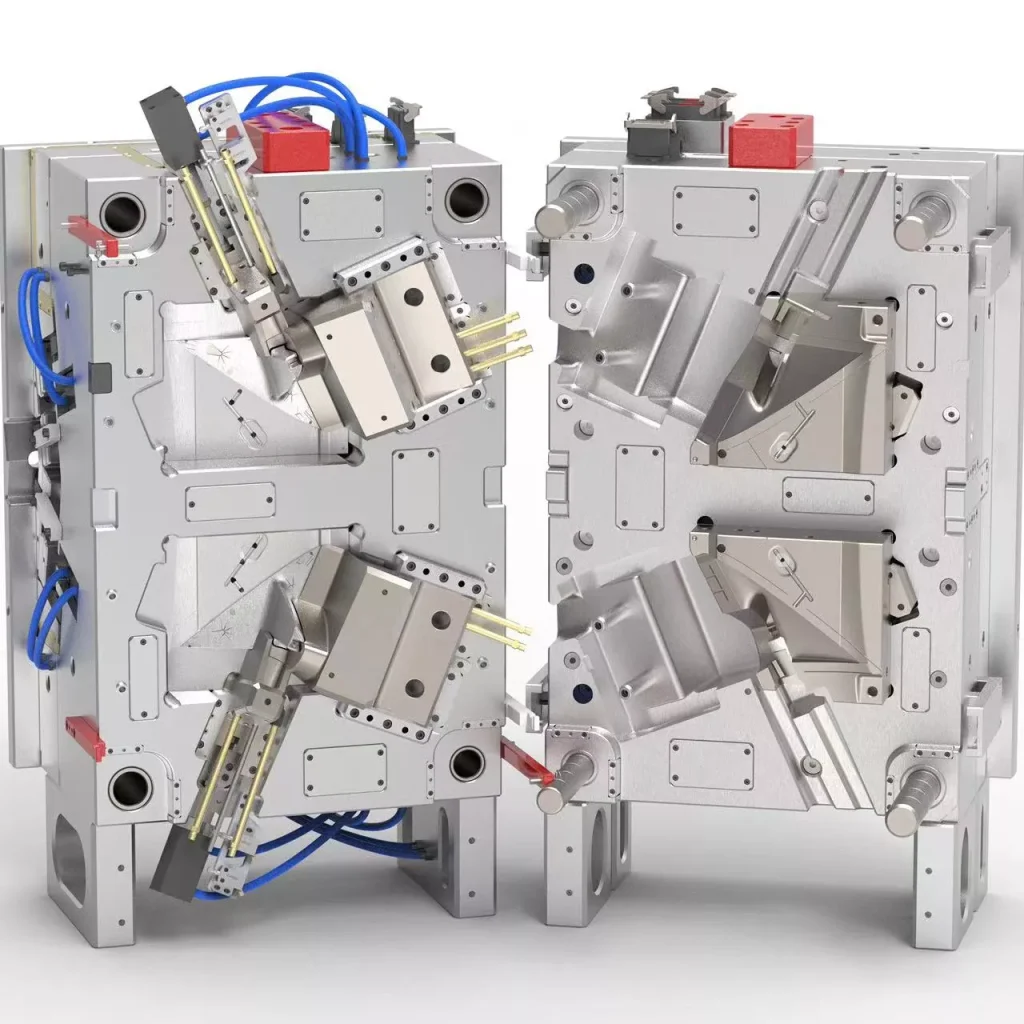

Automotive Lighting Injection Mold Manufacturing

Molds play an integral role in the injection molding of automotive lighting plastic parts. At Elimold, we offer a comprehensive service including mold manufacturing and mass production of injection molded parts within our in-house injection molding factory. At the same time, we understand that some customers may have their own injection molding factory and just need our expertise in mold manufacturing. The injection mold manufacturing workshop at our in-house factory is fully equipped to provide excellent automotive lighting mold manufacturing services to meet your specific needs. Whether you need complete mold and mass manufacturing services for automotive lighting products or independent mold manufacturing, we can provide you with the best quality solutions.

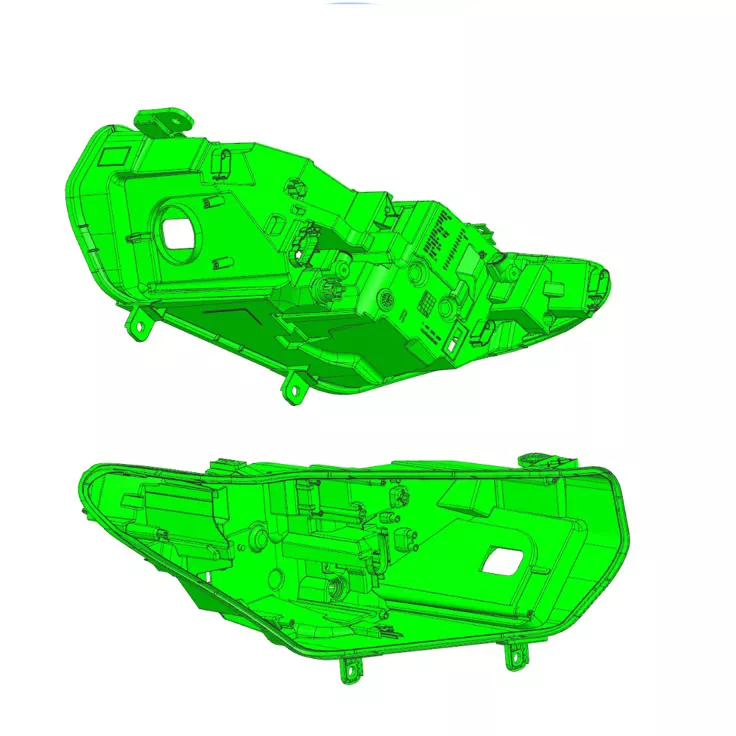

DFM service for automotive lighting product injection molding projects

At Elimold, we provide design for manufacturing (DFM) services for automotive lighting products. Our team of engineers works closely with you to ensure that product design is coordinated with efficient and cost-effective production, improving product quality, performance and overall efficiency to achieve the highest standards in all aspects. Our skilled team of engineers will carefully prepare a comprehensive DFM report for your automotive lighting injection molding project, which contains meticulous details, from parting lines and gates to ejection mechanisms and wall thickness. Elimold has an unwavering focus on optimizing the design for manufacturability (DFM) process to address the complexity of automotive lighting product design and ensure optimal manufacturability. We are committed to seamlessly integrating design and manufacturing to take tooling processes and product mass production to new heights.

Automotive Lighting Injection Molding Project Management Capabilities

Elimold is able to manage the entire process from concept start to perfect completion. This means higher efficiency, lower cost, shorter delivery time and better overall operation control. We will develop a detailed production plan and schedule, and strictly follow up by project managers who are experienced in mold design, tool manufacturing, injection molding process management. Each project is individually managed by a project manager. He is also responsible for all business and technical communications with customers about the project. We will keep customers informed of the details of the project through weekly reports and digital pictures. Customers can easily manage projects at the same time. We will provide high standards of customer service through self-improvement. Just a phone call or an email, you will find that we are at your service 24/7. We have established an efficient team to ensure a smooth transition of project development from engineering to production or customers.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own factories and extensive manufacturing network, we are able to efficiently deliver complex and high-quality automotive lighting plastic parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Insert Molding

Rapid Tooling

Production Tooling

Automotive Lighting Rapid Prototyping

One of the key benefits our injection molding technology can bring to you is rapid production of prototypes. Elimold provides a seamless customer experience from initial design to post-production support. With extensive knowledge and advanced equipment, we ensure that your lighting components meet the highest standards of quality and durability. By using processes such as 3D printing and CNC machining, we can produce your prototype automotive lighting plastic parts in the shortest possible time. One of the main advantages of our injection molding rapid prototyping technology is the very short delivery time.

Whether you need automotive lighting product concept development and design or mass production of products, our team works closely with you to create innovative designs and manufacturing plans based on your needs. Using advanced CAD tools and prototyping and mold manufacturing, we ensure the performance and production efficiency of the design are optimized. Simply provide us with the precise specifications and dimensions of your plastic automotive parts, and we can produce your products in record time.

Automotive Lighting Plastic Parts Supplier

Elimold serves automotive and parts customers worldwide, and over 10 years of experience enables the Elimold team to provide customers with fast development time and consistent quality, ensuring that new projects run smoothly. At Elimold, our team of engineers can provide a seamless customer experience from initial design to post-mass production support. With rich knowledge and strong skills, we can build and manufacture premium automotive lighting plastic injection molded parts for our customers. As a premium automotive lighting injection molded parts supplier, we have the resources to optimize your business process through a focused mindset and state-of-the-art equipment. In addition, our in-house mold manufacturing plant can produce more than 300 sets of molds per year and supply them worldwide. This capability has earned us a reputation for being able to complete any order, no matter how large the order is. No matter how large the order is, we have the full capacity to complete it. When customers contact us for molds and product mass production for automotive lighting products, we respond quickly within 6 hours, which is the standard time frame for production mold quotes. However, we are committed to improving efficiency, and if it is a simple structure product, we have managed to shorten the response time to 6 hours or even less. This fast service reduces customers’ waiting time and gives them more valuable evaluation time.

Automotive Lighting Low-Volume Injection Molding Contract Manufacturing

We have the ability to provide rapid tooling and low-volume injection molding of automotive lighting plastic parts to deliver your end-use molded parts within 2-5 weeks. We provide cost-effective and reasonable advice from design, materials, production processes, manufacturability and other aspects. Elimold is committed to providing customers with the highest quality, beautiful and precise parts. Our quality assurance team strictly supports the industry’s Production Part Approval Process (PPAP). Adherence to this process ensures the reliability and consistency of all parts we manufacture. We have a team of experienced technicians who can handle customer-specific product design requirements and provide complete manufacturing support. Our automotive plastic injection molding process is capable of rapid design, processing and injection molds. We are very careful and serious about the production of interior and exterior lighting molds. Even new lighting molds can be easily produced and assembled. Elimold is a leading supplier of comprehensive plastic contract manufacturing solutions for automotive lighting products, providing end-to-end services from initial concept to final product delivery. With years of experience, we can turn your ideas into reality with efficiency, precision and excellence. Work with us to experience the difference of Elimold in plastic contract manufacturing.

Rigorous Quality Control

At Elimold, the quality process begins at the very beginning of each project. We demonstrate this commitment by providing high-quality tools that are designed and manufactured to give our customers the best value. We define quality as complete customer satisfaction. This drives us to strive for excellence in all aspects of our business while continuously improving our strong workforce and processes.

Once the CAD data is received, the molds are manufactured, molded, tested, and inspected using an in-house coordinate measuring machine (CMM). Each part is scrutinized and every detail is meticulously compared to the 3D model to ensure that the dimensions are accurate and within tolerance. Our comprehensive inspection includes running dimensions, lighting evaluation, seal testing, and more. All of these activities are performed in our in-house facility by our experienced staff under strict quality control guidelines to ensure that the specific requirements of our customers are met.

How Injection Molding Is Used in Automotive Manufacturing

The plastic injection molding process is very important in the automotive industry because consistency, safety, and quality are important parts of accident prevention. Molten plastic is injected into existing molds for signal lights, interior lights, and other automotive lights and lenses, then cooled and hardened. After the plastic solidifies, the manufacturer removes the product and checks its quality before shipping it to the customer.The challenge of the plastic injection molding process in automotive and other industries is to create reliable, well-designed molds. Poorly designed molds can cause defects and create errors during assembly. Before manufacturing begins, each mold is checked for integrity and quality to prevent this from happening.

Advantages of Injection Molding in the Automotive Lighting Industry

- Precision and Repeatability: High precision and repeatability are crucial in automotive manufacturing, which is the core reason why the automotive industry favors injection molding.

- Complex Shape Design: Injection molding produces complex parts through a process called “screw injection”, which helps to manufacture delicate and complex parts.

- Fast and Efficient Manufacturing: The fast production process ensures that automotive manufacturers can meet their component needs efficiently.

- High Surface Finish Quality: Parts produced through injection molding have excellent surface finish quality, providing a smooth and flawless surface.

- Color Variety: Injection molding allows the production of parts with a variety of textures and colors without the need for post-molding coloring processes.

Automotive Lighting Material Options

Modern automotive lighting is becoming more and more complex and diverse. To realize all these innovative lighting systems, high-quality molds and reliable material solutions are required. Elimold has very close cooperation with companies in the field of automotive lighting systems and has accumulated rich experience in material application. The following are the material options we can provide.

- Polycarbonate (PC)

- Acrylic (PMMA)

- Acrylonitrile Butadiene Styrene (ABS)

- Polybutylene Terephthalate (PBT)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- Polyamide (PA, Nylon)

- Thermoplastic Elastomers (TPE)

- Styrene Acrylonitrile (SAN)

- Polyoxymethylene (POM)

- PC-ABS blends

- PMMA-PC blends

- Liquid Silicone Rubber (LSR)

- High-heat resistant Polyamides (PA46, PA4T)

- Thermoplastic Elastomers (TPE, TPU)

- UV-stabilized Polycarbonate

- Diffusion-enhanced PMMA

- Flame-retardant PBT

- Optical-grade Liquid Crystal Polymer (LCP)

- High-reflectivity Polyesters

Automotive Lighting Injection Mold Surface Treatment Process Options

Plastic parts for automotive lighting fixtures often require a high-gloss surface treatment. During the mold making process, the mold maker applies the appropriate injection surface treatment to the mold. This surface treatment is then transferred from the mold to the surface of the molded part during the molding process. The high-gloss surface treatment standards commonly used in the automotive industry are defined by two associations, the Plastics Industry Association (SPI) and the Association of German Engineers (VDI). In North America in particular, high-gloss surface treatments that meet SPI standards A-1, A-2, and A-3 are required. Therefore, Elimold has the ability to provide surface finishing processes to the above standards.

Value-added services

Whether it is the manufacture of transparent automotive lighting injection molding parts or other plastic structural parts of automotive lighting related products, different surface treatments or other post-processing processes may be required. Elimold provides one-stop automotive lighting product injection molding services, so we can provide a variety of value-added services.

- Vapor Deposition (e.g., Physical Vapor Deposition – PVD)

- Vacuum Metallization

- Electroplating

- Spray Painting (e.g., UV-cured coatings, solvent-based coatings)

- Pad Printing

- Hot Stamping

- Laser Etching

- Hydrographics (Water Transfer Printing)

- Silk Screen Printing

- Texturing (via Mold Surface Etching or Secondary Processing)

- Ultrasonic Welding (for surface fusion and finishing)

- Clear Coating (for scratch resistance and UV protection)

- Matte or Glossy Finishing (via Chemical or Mechanical Methods)

Automotive Lighting Injection Molding Application

Elimold has extensive experience in automotive lighting plastic parts injection molding, serving major automotive parts manufacturing companies that require high-quality plastic automotive lighting parts and components. We do not “specialize” in any one area, which allows us to accumulate experience and provide professional support for any of your projects or components. From beginning to end, we provide the same quality, expertise, engineering, design and customer service to each customer.

- Headlamp housings

- Headlamp lenses

- Taillight housings

- Taillight lenses

- Turn signal light housings

- Turn signal light lenses

- Fog light housings

- Fog light lenses

- Reflectors

- Light guides

- Bezels

- Diffusers

- Mounting brackets

- Gaskets (if using overmolding)

- Sealing components

- Decorative trims

- Bulb holders

- LED modules (plastic casings)

- Inner light shields

- Ventilation components

- Projector lamp housings

- DRL (Daytime Running Light) housings

- DRL lenses

- Optical light pipes

- Adaptive front-lighting system (AFS) components

- Multi-layer lens assemblies

- Hybrid reflector structures

- Inner structural frames

- PCB holders for LED lighting

- Heat sink covers

Request Your Free Automotive Lighting Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Automotive Lighting injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.