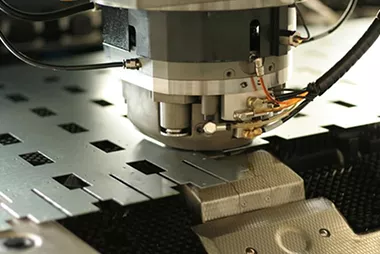

CNC Countersinking Service

With our online CNC countersinking service, we will drill tapered holes so that the hardware sits flush when joining parts, improving appearance and longevity.

Fast, accurate and affordable online countersinking services

Our CNC Countersinking allows screw heads to be sunk into the metal, rather than protrude outward from the surface. This not only allows for a flush and professional-looking finish, but it also allows for more complex parts to be assembled on the job site.

Elimold has been providing finishing services for metal fabrication projects for over 20 years. Our experts can ensure that any part has a clean, flush, and professional finish, which is exactly why we offer CNC Countersinking services.

Countersinking is one of the secondary machining operations that we offer to support our metal fabrication services. We use the most effective and reliable tools on the market to make sure your screws, rivets, and bolts lay flush with the surface of your part — so you get the exact style you were looking for.

We can also use countersinking to remove burr and smooth out any rough edges left over from drilling or tapping operations. This will remove any sharp edges and improve the overall quality of the part.

Design Considerations

When designing for countersinking, several factors must be taken into account:

- Screw Type: The countersink must match the angle and diameter of the screw head.

- Depth and Diameter: Precise measurements are crucial to ensure the screw head sits perfectly flush.

- Surface Finish: A high-quality surface finish is vital for both aesthetic and functional reasons.

Key Characteristics of Countersinking

- Shape and Size: The conical shape matches the angled profile of countersunk screw heads, ensuring a precise fit. Standardly, this is determined by the Inner and Outer Hole Diameters of the hole.

- Depth and Angle: The depth and angle of the countersink are crucial and must align with the screw specifications. Typically screw head angles range from 82 to 100 degrees. While the depth is normally proportional to the inner and outer hole diameters.

- Finish: A well-executed countersink offers a smooth surface finish, but the deburring process may generate some unwanted debris which will need to be removed.

Benefits Of CNC Countersinking

Countersinking is more than just a method to accommodate screw heads. It’s a fundamental process in manufacturing that contributes to the aesthetic, structural, and functional integrity of a wide range of products. Its prevalence is due to its ability to provide a safe, clean, and efficient way to assemble parts across various industries, making it an indispensable technique in modern manufacturing practices.CNC counterboring offer numerous benefits. Examples include:

- Increased Production Speed

- Enhanced Production Efficiency

- Improved Accuracy

- Better Repeatability

- Superior Flexibility

- Cost-Effective

- Safe

Material

We’re happy to drill, counterbore, and countersink any steel plate you desire. Grades we carry include:

Metal and Plastic

- ABS

- 7075 T6 Aluminum

- 5052 H32 Aluminum

- Delrin

- 6061 T6 Aluminum

- HDPE

- UHMW

ASTM Structural Plates

- A36/SA36 Plate

- A572 Plate

- A588, A242 Plate

- A633 Plate

- A514 Plate

- A709 Plate

- A283 Plate

- A656 Plate

ASME Pressure Vessel Plates (PVQ)

- SA516 Plate

- SA387 Plate

- SA537 Plate

Marine & Offshore Plates

- API Plate

- ABS Plate

Abrasion Resistant Plates

- AR400 Plate

- AR500 Plate

Typical Applications

The holes made from our CNC Countersinking Service are typically used for fastener insertion when joining with another part. Using CNC Countersinking parts improves quality and delivery time to market, which benefits many industries.

- Oil And Gas

- Petrochemical

- Construction

- Marine And Offshore

- Excavating And Mining

- Mold, Tool, And Die

- Agriculture

- Nuclear

Countersinking in Relation to Threading and Tapping

In CNC fabrication, countersinking, threading, and tapping are closely interrelated processes, each playing a pivotal role in the overall functionality and aesthetics of the final component. Their correlation lies in the precision with which they are executed, the sequence of operations, and the shared goal of creating components that meet exacting standards of quality and performance. This synergy exemplifies the intricate and sophisticated nature of modern manufacturing techniques.

More Manufacturing Services

Elimold has extensive experience in providing sheet metal fabrication and CNC machining services to clients across a wide range of industries.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

What is Countersinking?

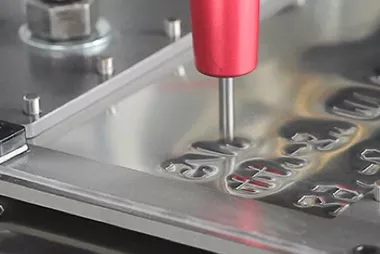

Countersinking is a machining process used to create a conical hole at the top of a pre-drilled hole. This conical hole is designed to allow the head of a flat or countersunk screw to sit flush with or below the surface of the material. The process involves a special tool known as a countersink, which is essentially a cone-shaped cutting tool that cuts into the material. This tool creates a tapered surface at the mouth of a hole, enlarging the top part of the hole to the required diameter and angle.

Countersinking is used to ensure screws and bolts lay flush with the surface

Countersinking is the process of cutting a cone-shaped hole in a manufactured object. It is commonly used in the machining and manufacturing industries, for a variety of reasons. There are a number of different tools commonly employed to cut these holes.

Countersinking is often used for ensuring any screws, rivets, or bolts that are used become flush with the surface. This can be done for aerodynamic reasons, or strictly for aesthetic purposes. These holes are often made using specially formed drill bits.

Countersinking tools can also be used for other purposes. A cross-bore countersink cutter, for instance, is used for removing any burrs that might remain after the machining process. A fluted countersink cutter is often used to create a chamfer inside an existing hole.

Request Your Free CNC Countersinking Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Countersinking parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.