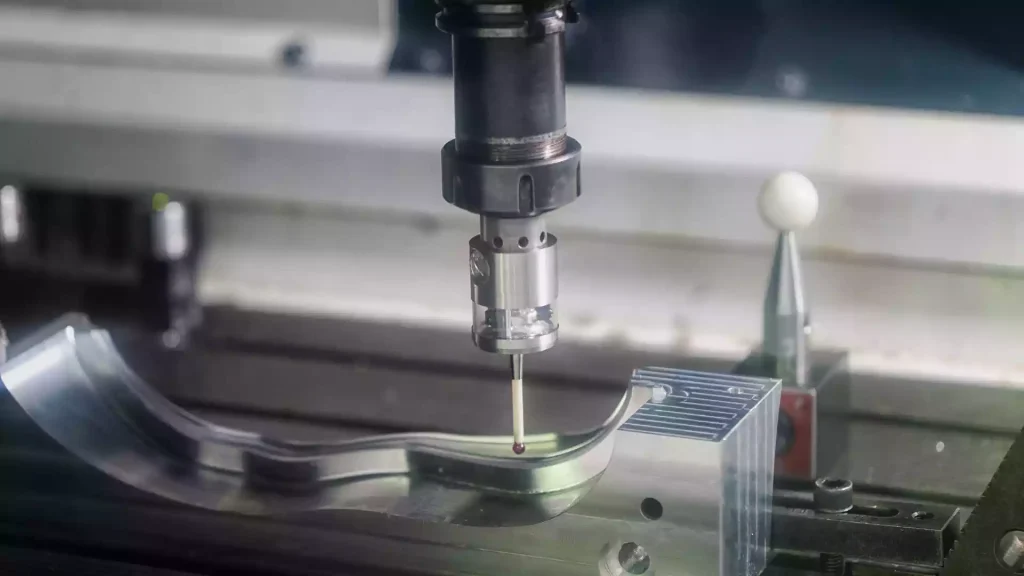

CNC Drilling

Elimold is proud to offer high-quality CNC drilling services to our valued clients. Our state-of-the-art equipment and experienced technicians allow us to produce accurate and precise holes in a variety of materials. Whether you need a single prototype or high-volume production, we can deliver the results you need on time and within budget.Contact us today for a free instant quote.

Providing high-quality CNC drilling services for precision parts

We are proud to provide the best CNC drilling services for parts manufacturing of any complexity, whether in small or large quantities. With our state-of-the-art equipment and expertise, we ensure that all your drilling needs are met with excellent results. At Elimold, we use a range of advanced CNC drilling machines, including upright, table and radial models. This diverse selection allows us to drill holes in simple and complex patterns up to 7 cm in diameter. Our services all cover a wide range of materials, including hard plastics, metals and super alloys. In addition, we strictly control the entire drilling process to ensure that strict quality standards are met every time. We combine advanced CNC drilling equipment with machining centers to perform precise and efficient drilling operations for your parts. We are a CNC drilling manufacturing solutions provider based in Shenzhen, China, specializing in turnkey machining and drilling services for OEM and their supply chain partners.

Our CNC Drilling Capabilities

Our CNC drilling services offer a typical tolerance of ±0.01mm and can drill holes up to 150mm deep, ensuring precise and consistent results every time. From standard round holes to complex geometries including blind, angled, countersunk, counterbored and threaded holes, our CNC drilling capabilities are designed to meet a variety of requirements. Regardless of the complexity, we have the expertise to process a variety of hole types with the highest level of detail. At Elimold, we are your strategic partner in precision CNC machining and drilling. Our team of CNC machinists combines elements of mechanical design, technical knowledge, mathematics and computer programming to produce close tolerance, high performance parts in a clean, professional environment. We source materials from reputable suppliers and verify compliance upon arrival. Our quality control team uses sophisticated testing and inspection equipment to ensure that every product exceeds customer specifications. Every order is audited for accuracy before shipment. With Elimold, you can rest assured that you will receive a high-quality product quickly and at a competitive price.

Rapid Prototyping

CNC drilling can be used for rapid prototyping, a process in which proof-of-concept models can be created with custom hole configurations. This feature is extremely useful in product design and development, allowing engineers and designers to efficiently test and improve their concepts. CNC drilled prototypes help visualize and validate ideas, which speeds up product development cycles and ultimately creates innovative and well-designed products.

Therefore, we provide our customers with all the necessary design and planning assistance so that they can achieve the best end result for their specific project. CNC drilling helps prototypes or parts quickly drill precise holes, threads, and handle complex hole patterns, angles, and depths. CNC drilling tolerances are basically the same, and accurate hole locations are critical for prototyping components, coordinating testing, and ensuring components work properly. Reduce the risk of errors and misalignments that can affect the performance of your prototype, saving time and resources for redesign. And our special equipment allows us to provide customers with the products they want, no matter how unique or difficult the project is. Prototyping is an important part of the design process, and we look forward to helping you develop prototypes for your metal parts or products. We are committed to serving every customer and will do our best to turn their prototypes into reality.

CNC Drilling Shapes

Elimold is the industry leader in custom, fast turnaround CNC drilling services. We can handle just about everything, but our area of expertise is efficiently machining and drilling precision shapes.

- Circular

- Square

- D-Shape

- Rectangular

- Flat Oval

- Teardrop

- Custom Shapes

Deep Hole Drilling Service

Our CNC deep hole drilling service combines precision machining with EDM technology to achieve deep, narrow holes with extreme accuracy. Ideally suited for difficult-to-machine materials, it ensures high-quality results, tight tolerances, and smooth surfaces for demanding applications. A deep hole is generally defined as a depth greater than 10 times its diameter. So a 0.25-inch diameter hole becomes “deep” when it exceeds 2.5 inches deep. (Or when a 5 mm diameter hole exceeds 50 mm.) In addition, Elimold can meet the exacting location requirements of through, blind, concentric, eccentric, angled, intersecting, and cross holes. We utilize best-in-class equipment and continue to build on our reputation for personalized service. Our team of experienced technicians will help you find practical solutions to meet your production needs. The level of collaboration Elimold offers is unmatched. As a value-added service, we get involved during the design phase to provide recommendations to reduce costs and improve the manufacturability of complex parts. Elimold is an ISO 9001–2015 certified facility specializing in precision deep hole drilling and machining of long components requiring complex internal features and tight positional tolerances. We guarantee superior quality and focus on our customers’ economic drivers, resulting in cost savings and reduced delivery times. We are committed to providing the highest level of service and on-time delivery.

Are you ready to use Elimold’s CNC drilling services?

If you are looking for a reliable CNC drilling service provider to help you achieve your business goals, look no further than Elimold. Contact us today to learn more about our services or to start placing an order!

Engineer Team and Engineering Services

Our experienced team of engineers has extensive practical and R&D expertise in CNC drilling services, providing end-to-end support from tool selection and drilling path design to fixture development. After receiving your project, Elimold’s engineers evaluate the feasibility based on the drawings and requirements, and use CAM software to simulate the CNC drilling service process and identify potential risks or areas for improvement. And any issues regarding material properties, hole tolerances or structural design will be quickly resolved. In addition, for highly specialized or challenging hole processing tasks, we will form a dedicated team to customize processing strategies to ensure that CNC drilling services meet unique project needs. Finally, we can also assist with post-processing steps such as surface treatment, tapping or assembly testing. Elimold also conducts regular internal seminars and knowledge sharing sessions to enhance our CNC drilling service team’s understanding of the latest technologies and equipment, enabling them to provide advanced drilling solutions for a wide range of industries.

Drilling Accuracy and Hole Surface Quality

In our CNC drilling service workflow, we achieve hole diameter tolerances of ±0.01 mm and maintain excellent positioning and concentricity for precision fit of critical components. By developing a careful drilling processing strategy, our CNC drilling service can reduce the surface roughness of holes in a variety of materials to Ra1.6 or higher, thereby minimizing burrs and chip accumulation. And in order to ensure consistent surface quality, Elimold’s CNC drilling service operates in a temperature and humidity controlled environment, equipped with dedicated dust removal and cooling devices to effectively remove chips. In addition, we use online measurement technology to track the depth and diameter of the hole in real time, and once a deviation occurs, it can be corrected immediately. Regular fixture and instrument calibration can eliminate potential cumulative errors in CNC drilling services, thereby ensuring the accuracy of each drilling operation. Therefore, whether using metal or plastic, our composite tools and adaptive feed strategies enable CNC drilling services to achieve first-class hole integrity, ensuring reliable product performance in assembly and end-use scenarios.

CNC Drilling Materials

CNC drilling is essential for the precision machining of a wide range of materials, each of which has unique properties that make it suitable for use in different industries. CNC drilling ensures high-quality, precise cutting and drilling in manufacturing complex applications.

Metals

- Aluminium

- Steel

- Stainless steel

- Copper

- Brass

- Titanium

- Inconel alloy

- Monel alloy

- Hastelloy alloy

- Stellite alloy

- Nimonic alloy

- Rene Alloys

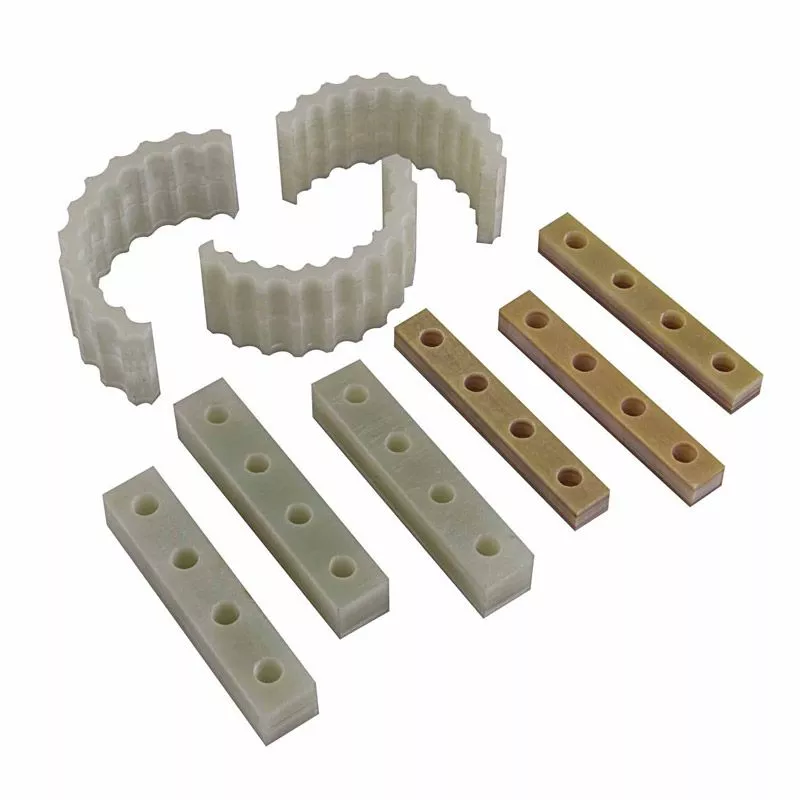

Rigid Plastics

- ABS

- Acrylic

- Industrial PEEK

- Nylon 6 / PA 6

- PC (Polycarbonate)

- PEEK glass-filled

- Polypropylene (PP)

- POM / Delrin acetal

- PTFE / Teflon

- PVDF / Polyvinylidene fluoride

- UHMW PE / Ultra-high-molecular-weight polyethylene

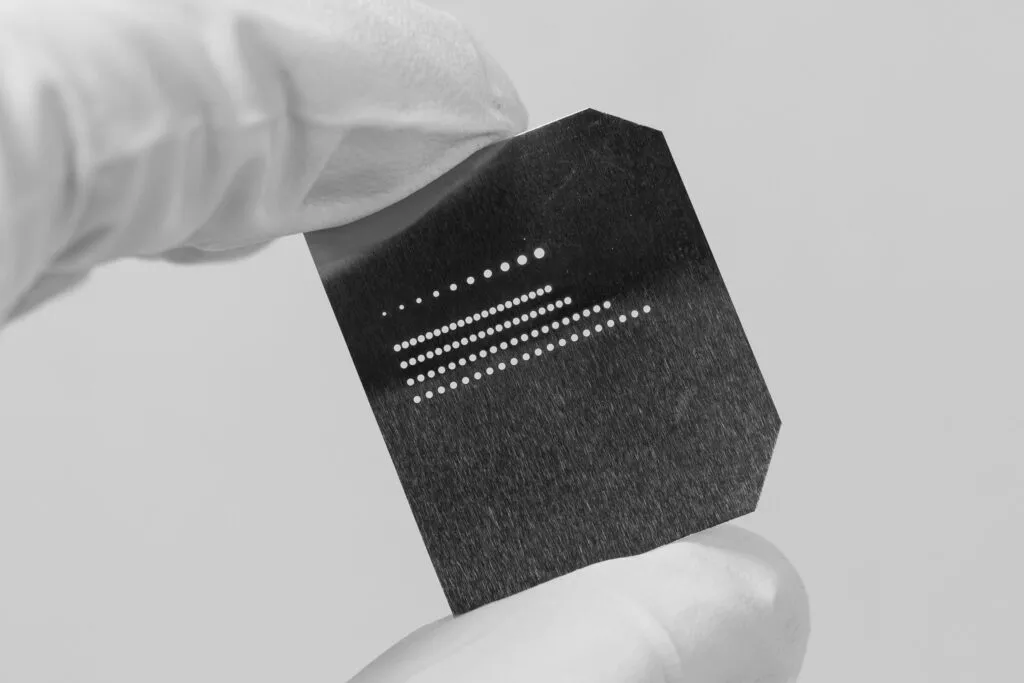

Ceramic

- 99.6% Alumina

- Glass

- Fused Silica

- Quartz

- Sapphire

- Crystals

- Silicon

- Macor

- Geranium

- Filter Glass

- A1ON

- Ferntec

Surface Finishing Options

- Anodizing

- Brushing

- Matting

- Polishing

- Blasting

- Painting

- Powder coating

- Heat treatment: +NT; +QT

- Plating: zinc, nickel, chrome

Quality Management and Certification

To guarantee reliable results from our CNC drilling services, we fully adhere to the ISO 9001 quality management system, recording and tracking every step from incoming material to final inspection. Our entire CNC drilling service uses statistical process control (SPC), continuously monitoring critical hole diameters and distances so that we can promptly adjust cutting parameters when deviations occur. We invest in core inspection equipment: coordinate measuring machines, optical projectors, and roughness testers, which can thoroughly verify the characteristics of each hole in our CNC drilling services. In addition, our regular quality training ensures that operators and engineers maintain a keen awareness of the key factors that affect CNC drilling services, thereby enhancing overall execution and consistency. Through continuous PDCA cycles and continuous improvement, we steadily reduce scrap rates in our CNC drilling service operations and improve product consistency, ultimately providing our customers with reliable drilling solutions.

Elimold CNC Drilling Services supports various industry sectors

Elimold CNC Drilling Services produces CNC machined parts for many sectors. With our expertise, flexible facilities and experienced skills, we provide customers with drilling services for different components with tight tolerances and excellent finishing.

- Aerospace and Aviation: Fuel injector nozzles, Turbine blade cooling holes, Aircraft structural components

- Power Generation: Steam turbine shafts, Rotor cooling holes, Boiler tubes

- Oil and Gas: Drill pipe holes, Valve body channels, Hydraulic component holes

- Consumer Products: Injection mold cooling channels, Electronics housing holes, Plastic component cavities

- Medical Device: Surgical instrument holes, Bone screws and implant channels, Medical device housings

- Agricultural Machinery: Hydraulic valve holes, Gear shaft lubrication holes, Pump body channels

- Automotive: Engine block oil passages, Fuel injection system channels, Transmission component holes

- Robotics: Actuator component holes, Gearbox shaft passages, Robot arm pin holes

- Automation: Pneumatic cylinder holes, Actuator mounting holes, Control valve passages

- Industrial Equipment: Hydraulic cylinder passages, Gearbox oil holes, Pump body channels

- Nuclear: Reactor coolant channels, Fuel rod holes, Pressure vessel cooling passages

What is CNC drilling?

Before starting a drilling operation, it is important to carefully consider the capabilities of the equipment. In CNC drilling operations, productivity, drill availability, thread form, and material properties can vary greatly. The feasibility and efficiency of production also depends largely on the expertise of the machinist.

Drilling refers to the cutting process of moving the tool so that the tool center is aligned with the hole center, and the workpiece does not move while the tool rotates. CNC drilling is mainly performed on CNC machine tools, including CNC milling machines and lathes. CNC drilling is generally used for the creation and modification of round holes, machine screws and bolts. Drilling can process parts of hard plastics, metals, wood, and most other rigid materials.

Other Drilling Services

Manual Drilling

Manual drilling involves the use of a manual drill and is a simple alternative for simple drilling tasks. It is often the first choice for low-cost machining applications where precision and high productivity are not important. Manual drilling is often used in woodworking and small-scale manufacturing scenarios. However, it lacks the precision, speed, and automation provided by CNC drilling machines.

CNC Milling

The milling process can be an alternative to CNC drilling when the goal is not just to drill holes, but to create complex shapes, grooves, and contours. CNC milling machines excel in precision drilling, so they are the first choice when tight tolerances are required. CNC milling has the versatility to process a wide range of materials, including: metals, plastics, and composites. It is particularly valuable for industries that require complex component designs, such as the aerospace and automotive industries.

Laser Drilling

Laser drilling technology provides a non-contact machining method that can replace traditional drilling methods. It is particularly suitable for applications that require high-precision small hole drilling. Laser drilling has the following advantages: minimal material deformation, reduced tool wear, and the ability to create extremely fine holes. However, the heat affected zone (HAZ) must be considered when using laser drilling, as excessive heat can affect the properties of the material. Laser drilling can be applied in aerospace, electronics, and medical device manufacturing.

Waterjet Cutting

Waterjet cutting is a versatile cutting method that uses a high-pressure stream of water or a combination of water and abrasive particles to cut a variety of materials. Abrasive waterjet cutting is ideal for materials that are difficult to process with traditional tools, including heat-sensitive materials such as plastics and composites. High-pressure waterjet cutting is used in applications that require precision and speed. Waterjet cutting is able to create complex shapes, contours, and fine details without changing tools. It is commonly used in the following industries: architectural design, automotive, and stone and tile cutting.

Other CNC machining services

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Jig Grinding Services

Request Your Free CNC Drilling Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Drilling parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.