CNC Machining Services

Searching for a reliable and efficient supplier of machined metal and plastic components?If yes, then Elimold is here to cater to your requirements.We offer CNC Machining services for a wide range of industries and applications. We utilize the latest in CNC technology to make high precision machined parts. Choose from 100+ materials, 60+ surface finishes. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified.

Your Reliable Partner For Custom CNC Machined Parts

Elimold provides a variety of online custom CNC machining services including milling, turning, EDM, wire EDM and surface grinding. With precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team, we can handle all types of CNC machining parts in both metal and plastic materials.

Whether you need prototypes or production parts machining, our online CNC machining service will be your best choice.Request your online quote today to get your machining parts done in as little as 5 days!

Professional CNC Machined Parts Manufacturer

Do you have unique machining needs? Complex part geometries? Tough materials? Extremely tight tolerances? Elimold’s CNC machining services take on challenging projects that other shops would balk at every day. At Elimold, it’s one of our core competencies.

If you’re looking for a manufacturing partner that can meet your needs and lead your thinking. Then, come and learn about our comprehensive CNC machining services now. We have the professional CNC machining knowledge, experience and technology to help you meet your needs faster. Partnering with Elimold, you will get the highest precision CNC technology and achieve excellent efficiency in medium and high-volume production. Whether your CNC machined parts are standard manufacturing or complex geometries with tight tolerances, they can be completed in 15 days.

Elimold In-House CNC Machining Factory

We not only have our own 215,000 square foot in-house CNC machining Factory in Shenzhen, China, but also have more than 700 CNC machines across six strategically located factories to provide comprehensive machining solutions. All machining shops are equipped with temperature, vibration and access control, as well as several large CNC machines, making it one of the most complete and advanced factories in China.

Elimold’s in-house facility is ISO 9001 certified and has extensive expertise to ensure precision every time. With more than 60 skilled employees and high-performance CNC machines, it provides processes such as milling, turning, routing, EDM, drilling and precision grinding. And it maintains 24/7 operations, delivering more than 3,000 machining projects and more than 2,000,000 machined parts per month.

Professional CNC Machining Team

We are a united team of talented and experienced engineers, machinists and technical consultants dedicated to helping solve problems related to manufacturing precision and complex machined parts, including design, product costing, quality, assembly issues, etc. Experienced engineers, programmers, QC, sales and management teams. Each member is closely connected to better complete customer orders. Engineers, programmers and workers share new ideas and skills to continuously improve machining skills. Good communication skills: Sales staff are fluent in English, proactive, have machining knowledge, and can easily understand your needs.

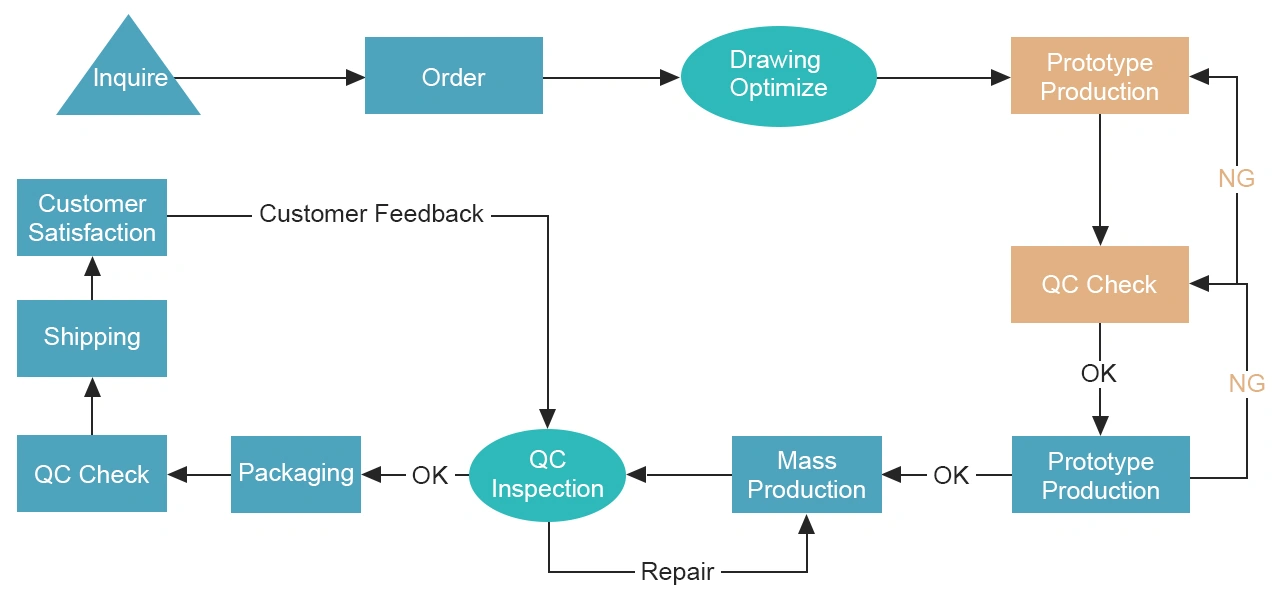

Efficient CNC Machining Order Process

Our transparent workflow ensures complete visibility throughout the manufacturing journey, whether you’re embarking on your first project or continuing a long-standing partnership.

CAD File Submission and Design Review

Material Selection and Instant Quoting

Production Monitoring & Delivery Assurance

Our CNC machining capabilities

All operations are completed in the same factory. With professional technology and advanced equipment, Elimold is able to provide a variety of processes such as milling, boring, turning, threading, tapping, thread milling, knurling, profiling, reaming, end machining, etc. Milling can produce parts up to 60 inches in length, 30 inches in width, and 30 inches in height. Turning can produce parts up to 28 inches in diameter and 48 inches in length, with bar feed lengths up to 12 feet and diameters up to 3 inches, all with tolerances as low as 0.0005 inches. These operations are all completed on 4-axis milling machines and 5-axis lathes using power tools, and all fixtures and tools are provided in-house. At Elimold, we specialize in prototyping and small-volume production, and provide expedited services.

CNC Machining Tolerances

We adopt international standards ISO 2768 To control uninjected linear tolerances of machined parts, Among them ISO 2768(F) applies to metal parts, ISO 2768 (M) is suitable for plastic parts. Normally, We can guarantee processing accuracy of ± 0.10mm to ±0.05mm. If tighter tolerances are required, You will need to provide a 2D drawing with complete annotation information, Our engineering team will communicate critical dimensional tolerances with you, and provide the highest possible processing accuracy. What’s important, due to increased scrap rates, Additional fixtures or specialized measuring tools, Tighter tolerances may result in additional costs.

CNC Machining Services for Custom Parts

Our advanced milling centers and turning equipment deliver precision with tolerances as tight as 0.001 inches. Beyond standard machining, we provide value-added services like CNC routing, EDM machining, and precision grinding, perfect for designers and product developers seeking to actualize innovative ideas with top-quality custom components. Whether the project is straightforward or complex, our equipped machine shops are ready to take it on. We guarantee not only superior quality but also rapid delivery.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5-Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Tapping

CNC Drilling

Swiss Machining

CNC Routing

CNC Grinding

Ready to Get a CNC Machining Online Quote?

Upload a 3D CAD file of your machined part and we’ll send you a manufacturing analysis report and interactive quote within hours. Modify materials and quantities in the quote and see the price update in real time.

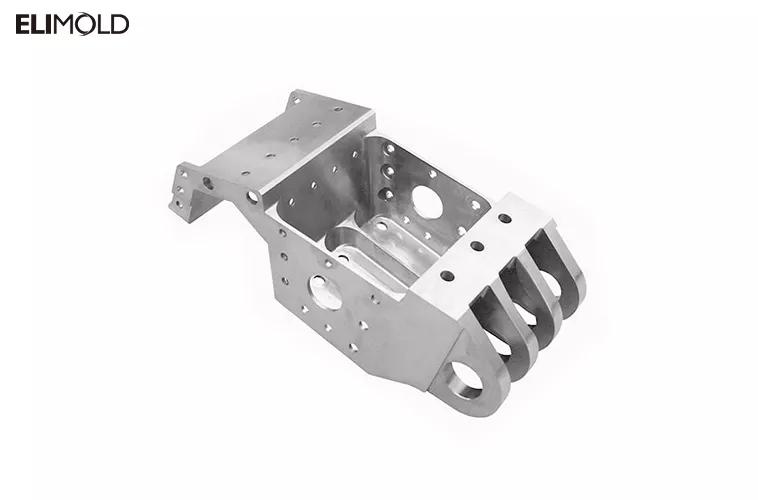

Custom CNC Machined Parts Supplier

Elimold provides custom online CNC machining services for engineers, product developers, designers, and more. Our highly qualified and certified machine shop can complete any custom design, no matter how simple or complex. We offer quick tooling, low-volume tooling, and high-volume production services, and all orders are serviced end-to-end by Elimold. Upload your CAD file to the Elimold instant quote engine to get pricing, lead times, and design for manufacturability feedback for your custom CNC parts. Our fast CNC machining capabilities cover both metal and plastic machining services, and we offer flexible production and shipping options to meet your needs at the best price and stage of product development. Your CNC machined prototype price includes duties and shipping for standard packages.

Is Your Machining Partner Reliable?

You can find plenty of CNC machining factory, but finding one you can actually count on is another story. If you’ve ever worked with an unreliable machining partner, then you know how stressful and frustrating it can be every time parts are unavailable, out of spec, or delayed.At Elimold, we believe you should be able to get the parts you need, when you need them.

Elimold provides custom online CNC machining services for engineers, product developers, designers, and more with our in-house facility. Our highly qualified AS9100D machine shop can handle any custom design, whether simple or complex. We offer quick machining, low-volume machining, and high-volume production, all with end-to-end service from our in-house facility. Send us a CAD file with relevant information or leave a message on our website to get pricing, lead time, and design for manufacturability feedback on your custom CNC parts. Our quick CNC machining capabilities include metal and plastic services and flexible production and shipping options to meet your needs at the best price and product development stage.We also provide options for part unpacking inspection, hardware traceability, material certification, and CoC to guarantee the quality of your machined parts. We accept technical drawings and have a support team to ensure you get quality CNC machined parts on time.

Elimold CNC Machining Solutions

Whether you’re creating a small batch of custom parts or scaling up for high-volume production, Elimold custom CNC machining services offer the flexibility you need.

Rapid Prototyping

Low-Volume Manufacturing

On-Demand Production and Manufacturing

Test-drive it with our prototyping services

Bridge production should not be underestimated as it reduces the risk of manufacturing parts with technical and cosmetic defects. With Elimold, you get the test pieces you need with the shortest lead time. In addition, our engineers can highlight potential improvements to your machined parts before the first production run. This allows you to smoothly enter the mass production phase.

In addition, CNC cutting is perfect for prototyping. It allows us to make prototypes with the same materials as the final product, which means you can test its functionality in a real operating environment. You can also attract potential investors to your project with CNC cutting. And for projects that only require a small number of prototypes, CNC machining is the best manufacturing method. Short lead times allow your engineers to quickly test models and make adjustments without sourcing additional materials due to unnecessary material waste during the production process.

Custom Online CNC Machining Services

Our expert engineers understand the importance of design and manufacturing collaboration at any stage of the product development process. Every quote includes a DFM analysis. Our diverse team of engineers, designers, and builders will help you find the right processes, materials, and more at every stage of product development. From design to prototyping to production validation, we are here for you. Don’t settle for just online CNC machining services. Get the engineering and design expertise you need from Elimold to make your project a success!

Design for Manufacturability and Assembly (DFMA)

Upon receiving your inquiry, our engineers will immediately review your CAD files and provide design feedback and CNC machining optimization suggestions as needed. To obtain better quality CNC machined parts and find out the CNC machining cost points that affect the unit price, thereby reducing costs. At Elimold, we support customers to quickly identify and eliminate costly or unmanufacturable features in the model in the early design stage. Eliminating manufacturability issues early in the design lifecycle ultimately helps customers improve the profitability of their new product innovations and accelerate time to market.

From 3D Model Design to Precision Machined Parts

Elimold is a full-service CNC machine shop that produces high-quality prototypes, high-volume precision metal parts, and mission-critical components for leading OEM across a wide range of industries. Our innovative team will guide you through the entire machining process. Our comprehensive CNC machining services include engineering, part design, 3D printing, advanced 5-axis machining, CNC milling and turning services, CMM inspection, and a variety of special process management. We also utilize automated production lines where machines work seamlessly together to efficiently achieve high-volume production while minimizing errors and keeping projects on schedule.

In-house Mechanical and Design Engineers

Whether you are an experienced engineer or just starting out, we can help. With a team of over 100 engineers, Elimold can help you design a wide range of products, from simple components to parts with complex geometries. With our years of experience and manufacturing expertise, we will ensure your project is completed smoothly. Our engineering and manufacturing experts will assist with every stage of your project, from design to mold making and prototyping assistance. We are here for you every step of the way. Contact our experts today to learn how we can turn your ideas into reality.

Product Engineering Services

With over 20 years of engineering experience, we understand that technology brings endless opportunities to the engineering world. With our expertise and dedicated product engineering team, our product engineering services exceed expectations and are unique in the industry. Elimold’s team of engineers use the latest CAD software to create 2D and 3D drawings of your products. We work with customers to develop products to ensure that the forgeability and machinability of your designs meet or exceed expectations. We can then validate these designs in cyberspace using DEFORM simulation software to ensure the best success rate before actually producing the part. In addition, we are able to help customers reverse engineer products and features using portable CMM laser scanners. Our engineers and metallurgists work closely with the quality control team to ensure that each project meets or exceeds industry standards and your requirements.

Gallery of CNC Machining Parts

We make cnc machining from repid prototypes and low mini order quantity for customers from multiple industries.

CNC Machine Shop for Production Flexibility and Scalability

Elimold’s in-house CNC machine shop is designed with flexibility and scalability in mind to efficiently meet diverse customer needs. Production setups can seamlessly switch between batches, from prototype production to high-volume production, without compromising quality or efficiency. Advanced scheduling systems optimize machine utilization and workflow, enabling fast turnarounds even for complex orders. And our CNC machine shop has extensive processing capabilities to handle a wide range of materials and specifications, eliminating the need for customers to work with multiple suppliers. Efficient inventory management and just-in-time production capabilities enable it to flexibly respond to design modifications and emergency orders. Scalable infrastructure ensures that production capacity can be adjusted to growing demand while maintaining consistent quality and delivery times.

Start Your CNC Machining Project

Upload your CAD file to get instant quotes, lead times, and DFM feedback. Various materials, flexible production, and shipping options available. Get started.

On-Demand CNC Machining Services

Whether you need a small number of parts or more than 10,000 final production parts, CNC machining is the ideal manufacturing process. Our experts work closely with customers from concept to production to delivery. All design concepts are derived from our extensive experience. These concepts help improve the performance, robustness and reliability of OEM parts. Our precision OEM parts CNC machining services will help you minimize losses and increase productivity. We can provide custom engineering solutions to better serve our customers. For parts inquiries, please request a quote now. Or you can contact us today to provide your design proposal and discuss specific parts needs.

Order High-Quality CNC Machined Parts Online

We excel at developing and applying advanced manufacturing solutions to meet our customers’ complex needs and precise tolerances. We carefully plan and schedule work to meet tight deadlines and successfully handle some of the largest and most challenging projects in the industry. We have a team of highly skilled engineers who are both programmers and operators, who reduce downtime and ensure that equipment is used to its maximum potential. In addition, we believe that success comes from treating our employees as valuable assets and striving for continuous improvement. Elimold benefits from the continuous innovation and experience of our employees in an environment designed for learning and growth. We continuously upgrade our equipment and employee training to meet the ever-changing technological needs of the industry. As a result, we are able to provide a variety of services that meet or even exceed your design requirements.

High-quality CNC Machining Every Time

At Elimold, we understand that producing high-quality parts is critical to your success. Our CNC machining experts are committed to providing precision, efficiency, and consistent quality at every step of the production process. Whether your project requires simple or complex parts, in large or small quantities, we maintain a comprehensive quality control and assurance system at every stage of CNC machining. Each part is rigorously inspected using advanced equipment such as coordinate measuring machines (CMM), 2D measurement tools, XRF analyzers, gauges, micrometers, and calipers. Our team is dedicated to ensuring dimensional accuracy and functionality, and inspecting prototypes and final products. If there are any discrepancies, we will take immediate corrective action to maintain our high quality standards.

Elimold Standard—Consistently Quality Control Through The Whole Production

When you send us an enquiry with an X_T, STEP or IGES CAD file, we check it, raise any queries, then prepare a quote. We do not need 2D drawings unless you need to highlight critical dimensions, tolerances or other special features. If you accept the quote, we schedule the job, prepare the CNC program and reserve the material from our stocks or source it as necessary. Machine setups are quick thanks to the paperless process we have developed, so we can start cutting material as soon as possible. Finished parts are deburred, cleaned, degreased and inspected. Any additional finishing operations are then carried out. Finally, your parts are packaged and despatched, using our own vans for local delivery or a courier for customers further afield.

Why use Elimold for custom online CNC machining services?

Fast and Reliably Delivery

Iterate part designs quickly and accelerate product development with quick-turn parts. Our automated design analysis will help spot any difficult to machine features before your design is sent to the manufacturing floor and save you from costly reworks further down the product development cycle.

Advanced Capabilities

Get anodizing, tighter tolerances, and volume pricing options through our network of manufacturers at Elimold. You’ll find plating (black oxide, nickel), anodizing (Type II, Type III), and chromate coating in larger part quantities; tolerances down to ±0.001 in. (0.020mm); and cost-efficient machined parts at higher volumes to lower piece-part price.

Manufacturing Analysis and Online Quotes

When you upload your 3D CAD file to request a quote, we’ll analyze your part geometry to identify any features that may be difficult to machine such as tall, thin walls or holes that cannot be threaded.

Infinite Capacity

Eliminate downtime spent waiting for parts and safeguard in-house machining with on-demand relief and infinite manufacturing capacity.

Material Selection

We stock more than 130 engineering-grade plastic and metal materials that are suitable for various part applications and industries. Materials range from plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, platinum, and copper.

Domestic Production and Support

Work with a trusted USA-based manufacturer and eliminate the risk of sending parts overseas. You can also call or email us at any time and we’ll help with ordering parts, design feedback, material recommendations, and answer any questions.

Ready to Get a CNC Machining Quote?

Online CNC machining service for rapid prototypes and production parts in metals or plastics. Get instant quotes today, and order your custom CNC machined parts at a better price.

What is CNC machining?

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to form a design from metal or plastic stock. Standard CNC machines include 3-, 4-, and 5-axis milling machines, lathes, and routers. Machines may differ in how they cut CNC parts – the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece rotates and moves, or the cutting tool and workpiece may move together.

A skilled machinist operates a CNC machine by programming the tool paths based on the geometry of the final machined part. Part geometry information is provided by a CAD (computer-aided design) model. CNC machines can cut nearly any metal alloy and hard plastic with high accuracy and repeatability, making custom machined parts suitable for nearly all industries.

Advantages of CNC Machining

The subtractive process of CNC machining provides multiple benefits for both prototyping and production parts.

- Precision and repeatability

- Tight tolerances

- Production-grade materials

- Quick-turn parts within 1 day

- Lower piece-part price at higher quantities

- Robust post-processing to improve cosmetics and material properties

CNC Machining Material Options

Elimold offers a wide range of materials for CNC machining, including metals, plastics, and composites. All raw materials are rigorously inspected to verify their precise chemical composition and hardness. If you have special material requirements, please contact us and we can also provide you with reliable solutions.

Metals

Plastics

- ABS

- PMMA (Acrylic)

- PC

- POM/Delrin

- PC GF30

- PA(Nylon)

- PC+ABS

- PA GF30

- PP GF30

- PP

- PTFE (Teflon)

- PEI

Other Materials

- Glass

- Stone

- Ceramics

- Carbon Fiber

CNC Machining Finishes

Surface treatments are critical to enhancing the appearance, durability, and functionality of precision machined parts. As the final step in CNC machining, surface treatments are performed mechanically, chemically, or thermally to improve wear resistance, corrosion resistance, sealing, and friction properties. Browse our selection of CNC surface treatment options to meet your specific functional and aesthetic needs.

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Finishes for Plastic

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

CNC Machining Design Guide

Read our practical guide to optimize your production efficiency. Elimold experts provide instant feedback to ensure the best results from your CNC machining, helping you consistently achieve precise tolerances. Following these best practices will not only improve accuracy and shorten lead times, but also control your CNC machining service costs by reducing unnecessary complexity and rework.

Internal corner fillets

Design internal corner fillets to be 0.020” – 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii.

Floor fillets

Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior.

Tapped/threaded hole depth

Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads.

Complexity

Keep the number of small cuts to a minimum to reduce the CNC machining service cost; only design in the necessary features to balance function with aesthetic.

Fillets

Internal fillets should be as large as possible to allow a large-diameter tool to be used. The radius of the internal fillet should be greater than 1/3 the cavity depth to prevent tool damage.

Wall thickness

Metal parts typically require a minimum wall thickness of 0.8 mm, while plastic parts require 1.5 mm. Thinner walls are vulnerable to vibration and deformation.

Cavity depth

To minimize chatter, tool deflection, and other issues, the depth of machined cavities should be no more than 4x the width.

Holes and threads

Hole and thread diameters should correspond to standard drill bits and threading tools. Hole depth should generally be no more than 10x the diameter.

Undercuts

T-slot undercuts can be around 3–40 mm wide. Dovetail undercuts work best at a standard angle of 45 or 60 degrees.

Radii

In CNC machining, sharp internal corners on a workpiece will naturally form rounded corners (radii). The depth must not exceed 12 times the diameter of the drill. For end mills, the depth must not exceed 10 times the diameter of the tool.

CNC vs. 3D Printing

CNC machining is your first choice when you need strong, precision parts made from a variety of materials, while 3D printing is ideal for quickly producing complex, custom designs. Your choice depends on the material, part complexity, precision, and production volume.

When it comes to metalworking, machining is almost always preferred over printing metal. Machining allows for a wider range of materials, finer finishes, and is typically less than a quarter the price of printing metal. Machining is also a great solution for complex tools like injection molds. Plastics, on the other hand, are a little more complicated. Machining plastics is generally more expensive than 3D printing, requires longer lead times, and has more design restrictions. However, machining is available for a wider variety of plastics than 3D printing. Machining is a good option if the material you need can’t be printed.

Alternatives to CNC Machining Services

While CNC machining services are suitable for manufacturing many types of parts, they do have some limitations. It is often not possible to manufacture certain internal features of certain parts. These features can be easily achieved with additive manufacturing methods such as DMLS. For applications that require a large number of parts, manual machining may not be able to achieve the required productivity. In addition, manual machining is not practical when machining hard materials. Therefore, if you need square corners, you may want to consider wire cutting or sinker EDM. For certain types of flat workpieces, laser cutting, water jet cutting, wire cutting, photochemical etching, or metal additive manufacturing may be more efficient.

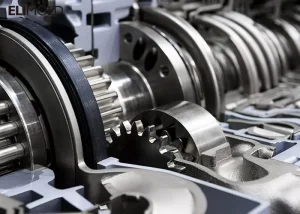

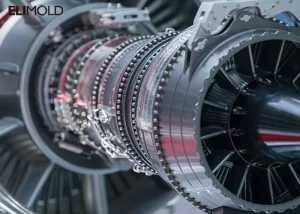

CNC Machining for Various Industrial Applications

CNC machining services are available for a vast array of applications across many industries, including:

F.A.Q.

CNC machining is a process used for designing machine parts that may either be prototypes or ready to be put into mass production. As one of the most popular processes for custom manufacturing, CNC machining can handle irregular geometries of intricate parts and is even used to produce mass production of parts once a prototype is approved.

We support many file formats to ensure we always meet the requirements of our clients. This includes popular formats of .stp, .sldprt, and .psm/.par. Moreover, we work with our clients to the end, so they get their desired results designed to perfection. This is the value we stand for.

At Elimold, not only do we have 3 axis and 4 axis CNC milling, but we also have 5 axis(HAAS) CNC milling services. These services provide excellent results, except when you need finer quality results. We suggest 5-axis CNC milling service instead of 3 axis or 4 axis milling service. Moreover, our CNC turning service employs a variety of tools and state-of-the-art software that ensures your desired components are created with accuracy and precision.

CNC machining has many benefits, including accuracy, precision, fast turnaround, the versatility of solutions, the ability to work with many materials, and being an overall economic solution compared to other solutions present in the market.

The following four factors determine the cost of a CNC machined part. 1) the time required for machining, 2) the type of material selected, 3) the geometry of the part to be machined, and 4) the startup cost of the project. Besides the client’s stated requirements, we try to make sure we take a course of action that leads to low cost without compromising the product quality. To determine the cost of your project, you can request a free quote.

Almost any rigid solid can be machined, including mild and stainless steel, aluminum, brass, copper, magnesium, titanium, and many engineering plastics. Check out our list of frequently used materials.

Our standard tolerances are 0.05 microns, which is suitable for most commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

At Elimold, we offer CNC milling (3-axis, 3+2-axis and 5-axis) and turning. Milled parts can be machined up to 2000 x 1500 x 200 mm (78.7 x 59.0 x 7.8 in.) for 3/3+2 axis CNC milling. For 5-axis milling, the maximum part size is 650 x 650 x 300 mm (25.5 x 25.5 x 11.8 in.). The maximum diameter for CNC turning is 431mm (17 in.), length is 990 mm (39 in). The minimum part dimensions recommended are around 0.39 x 0.39 x 0.39 in. (10 x 10 x 10mm). The minimum for feature dimensions is 0.5 mm.

We are limited to a 1000 mm (39 in.) maximum size for parts on our platform. You can place the request through your account manager if you need higher dimensions.

Request Your Free CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.