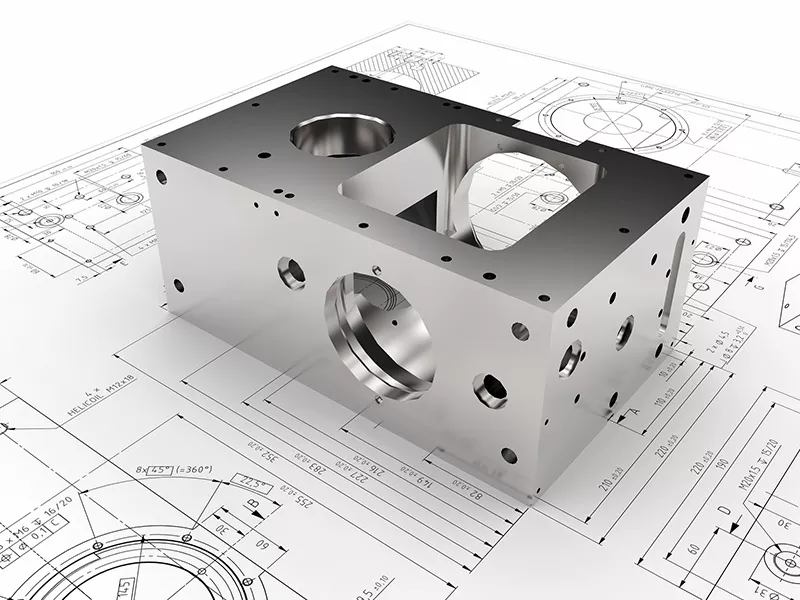

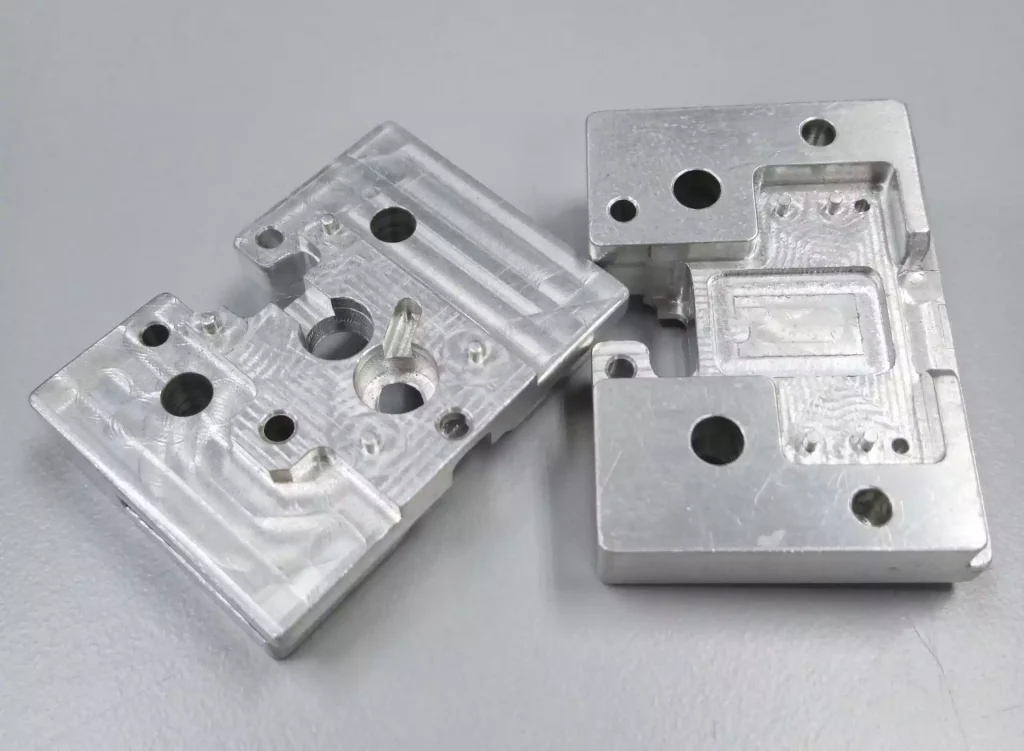

CNC Milling Services

If you are looking for a reliable, high-quality CNC milling service shop with relatively low processing costs, Elimold is your ideal choice. We are equipped with advanced 3-axis, 4-axis and 5-axis CNC milling machines. No matter the size of the project, we can provide consistent quality, tight tolerances and fast delivery speed. Tolerances can be as close as ± 0.008 mm, and delivery can be as fast as 1 day.

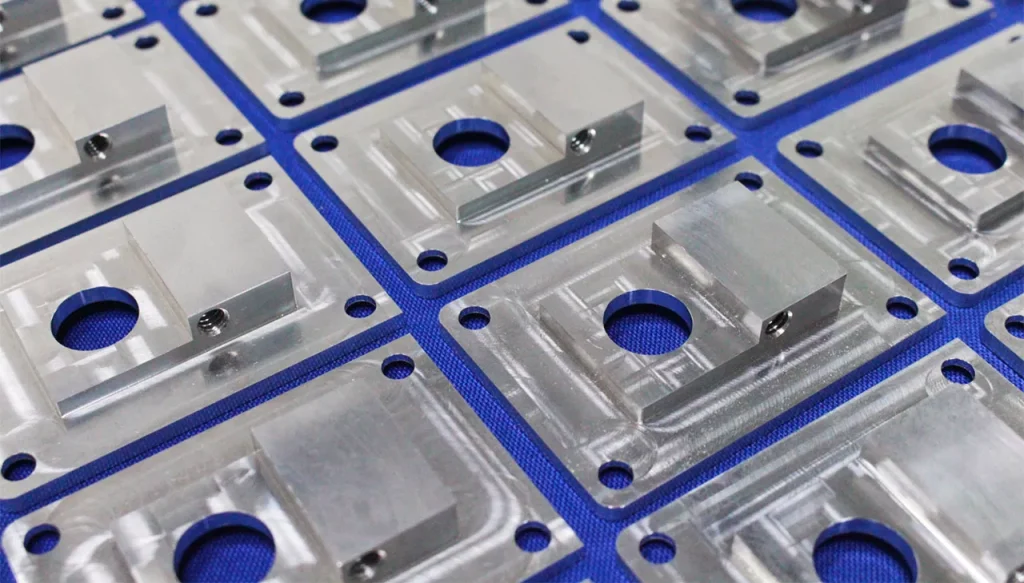

Custom CNC Milling Services

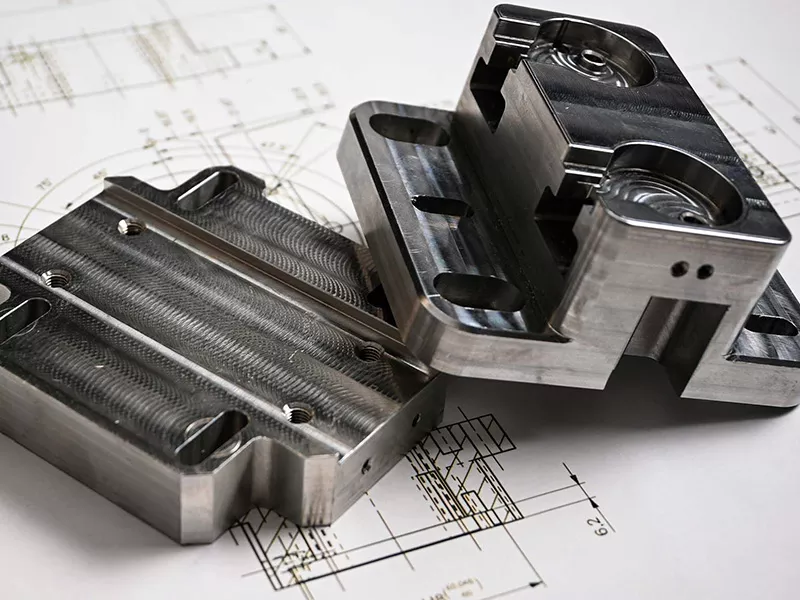

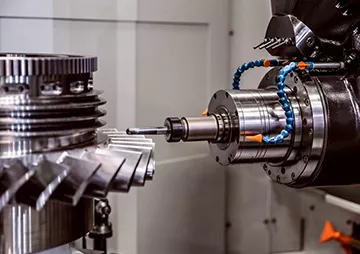

Need a quick prototype or a full-scale production part? We offer CNC milling services with accuracy up to 0.01mm and turnaround times as fast as 3 days. Whether it’s a simple 3-axis machining task or a complex 5-axis masterpiece, we can bring your design to life with exceptional precision and craftsmanship. And our quotes are both affordable and accurate because we have a team of professional mechanical engineers who carefully review every drawing. With over 20 years of experience, these engineers have deep expertise in programming, machine operation, post-processing, material properties, and more. You’re guaranteed to get an accurate quote within 6 hours. Get your CNC instant quote today!

CNC Milling Manufacturer

Elimold has an advanced quality assurance system and a team of experienced professionals ready to take on any challenging machining task for you. We understand the challenges of producing in an environment where parts must meet specific standards in order to be accepted. Everything we do is subject to rigorous quality assessments at every stage. This not only allows us to produce high-quality parts, but also allows us to critically review our processes and look for opportunities to further reduce costs and utilize turnkey solutions. With a corporate culture of continuous improvement, we are able to keep our prices competitive without compromising the quality of the product you receive.

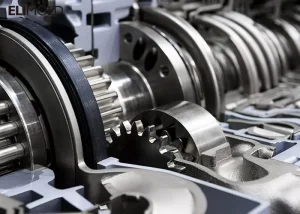

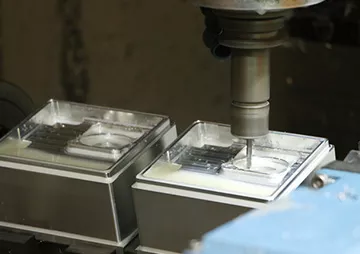

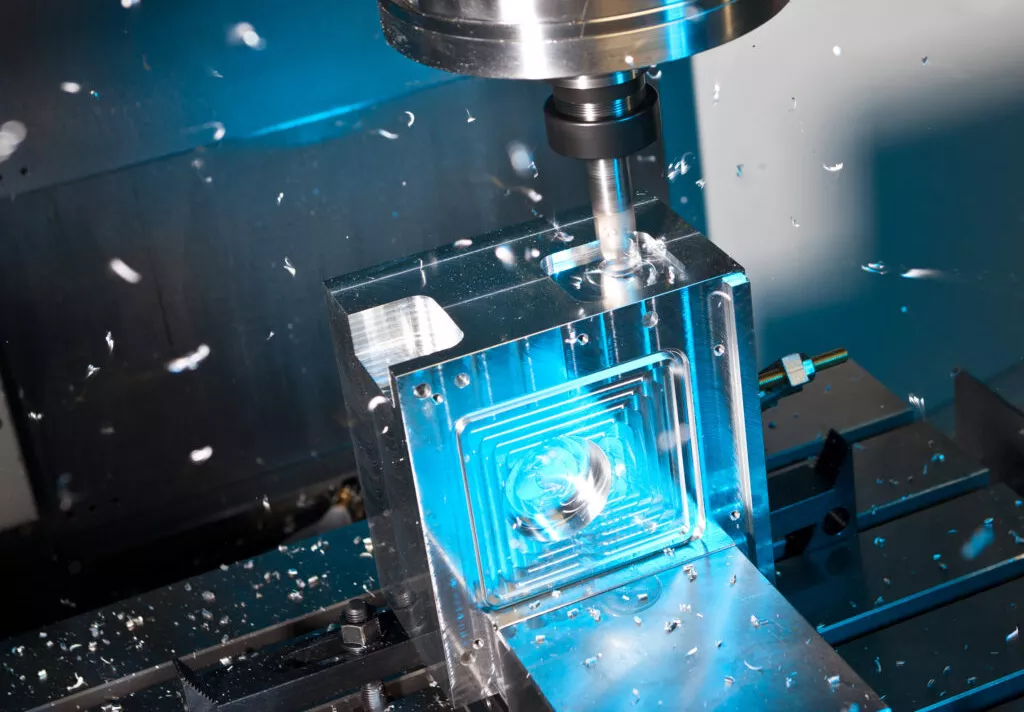

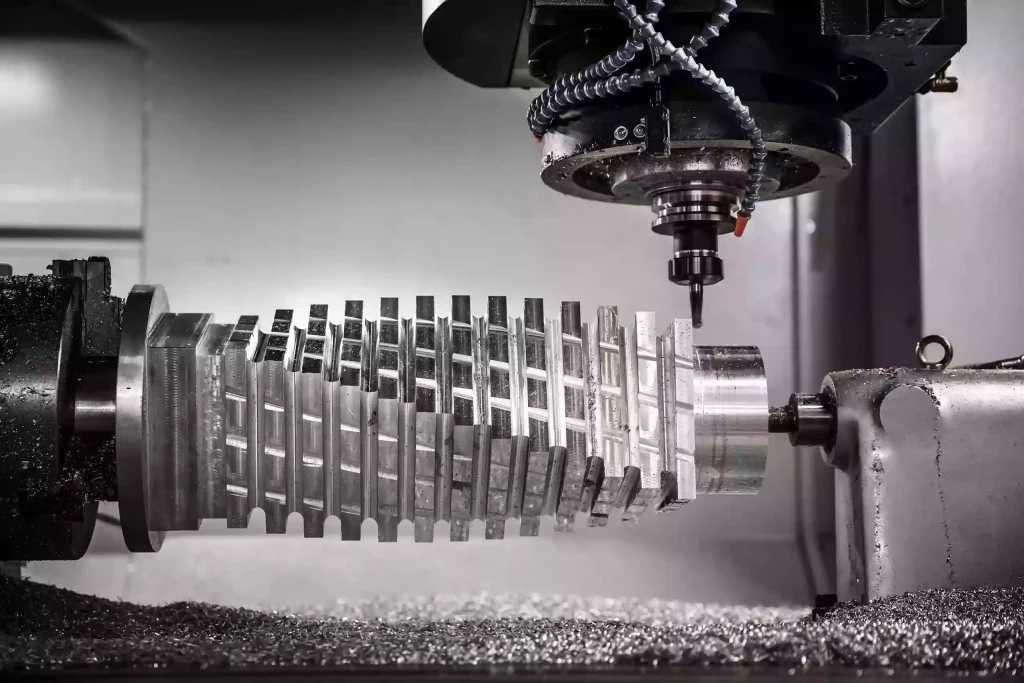

State-of-the-art CNC Precision Milling Shop

Elimold has invested in a state-of-the-art CNC precision milling shop. We have the latest CNC milling equipment as well as state-of-the-art computer programs to ensure the tightest tolerances possible. This is critical to our customers, ensuring we produce to your required part specifications. And in addition to our well-equipped facilities, we have invested in top machinists and experts in the field. Our staff ensures total quality control in all aspects of precision CNC milling, turning, manufacturing and ancillary services. From prototypes to small or large batch orders, Elimold can meet your needs. Now you can through our online quote system, you can get competitive prices and delivery times in minutes.

Our Team Advantage

Elimold’s advantage is that we have a highly skilled team of engineers, machinists and quality control experts. With extensive experience in CNC milling manufacturing, our engineers work closely with customers to optimize designs for manufacturability and reduce costs without compromising quality. Our team utilizes advanced CAD/CAM software and simulation tools to ensure accuracy from design to delivery. Continuous training keeps our employees at the forefront of CNC technology, allowing us to confidently tackle the most challenging projects.

CNC Milling Factory

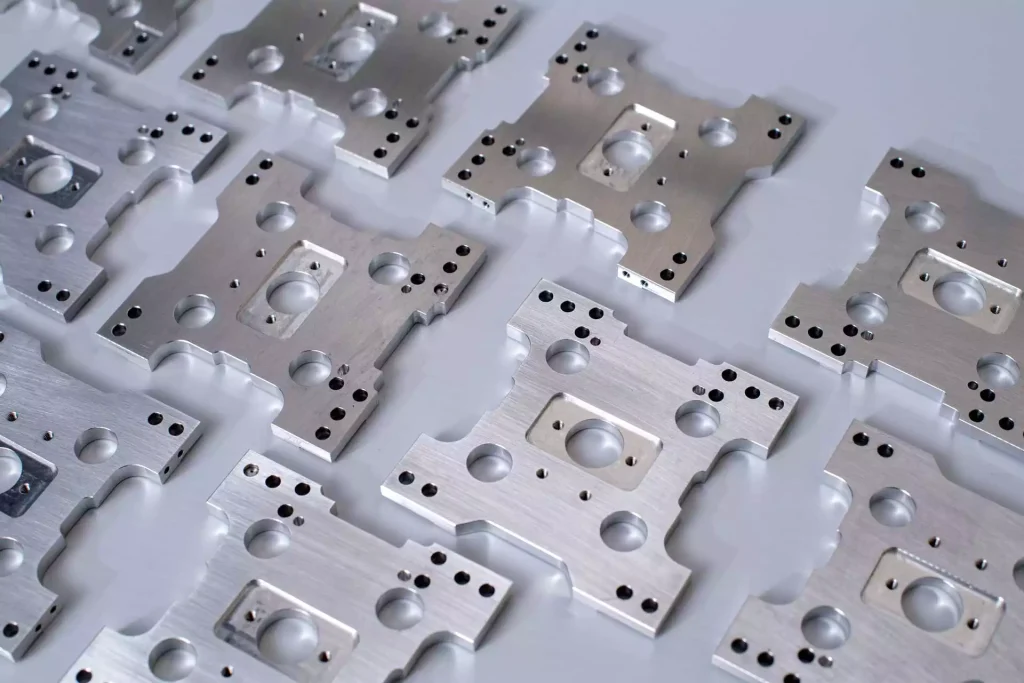

We have a complete infrastructure, with an in-house 215,000 square foot CNC machining factory in Shenzhen, China, and more than 400 advanced CNC milling machines in six strategically located facilities, supporting 3/4/5-axis CNC milling and horizontal CNC milling services, helping you quickly get custom CNC milled parts from simple to complex. Currently, we have 100 machines configured specifically for our customers’ rapid prototyping projects, as well as 2 full-time teams and outsourcing suppliers with more than 10 years of cooperation to assist customers with product development verification and rapid mass delivery. We also provide a wide range of material options to ensure that we can perfectly meet your specific project needs. Contact Elimold now to find out how we can manufacture parts in just 24 hours.

Start Your CNC Milling Project

At Elimold, our customization process is a seamless journey that begins with understanding our customers’ unique needs and ends with the delivery of a precision-engineered component or product that exceeds expectations. With our expertise in custom CNC machining, we ensure that the process from start to finish is meticulous, efficient, and effective.

Design and Engineering Expertise

Prototyping and Validation

Production and Quality Control

Delivery and Support

Ready to get started on your CNC milling quote?

Ready to take your project to the next level? Contact Elimold today to discuss your CNC milling needs. Our team is here to provide expert advice and solutions to help you achieve your goals.

Professional Milling Parts Supplier

With over 20 years of combined experience and advanced production capabilities, Elimold is able to deliver your parts on time, with superior automation and 24/7 operations. We aim to provide a one-stop service. Our highly skilled operators and programmers have a deep understanding of the machine’s behavior, able to maximize performance and produce parts with fine design features. Our work ranges from small batch production to large-scale production of a million pieces or more. We currently manufacture high-precision complex parts for a wide range of industries around the world. No matter how special the part’s complexity, geometry or material, we can process it. To learn more about our capabilities, please contact us or request a quote.

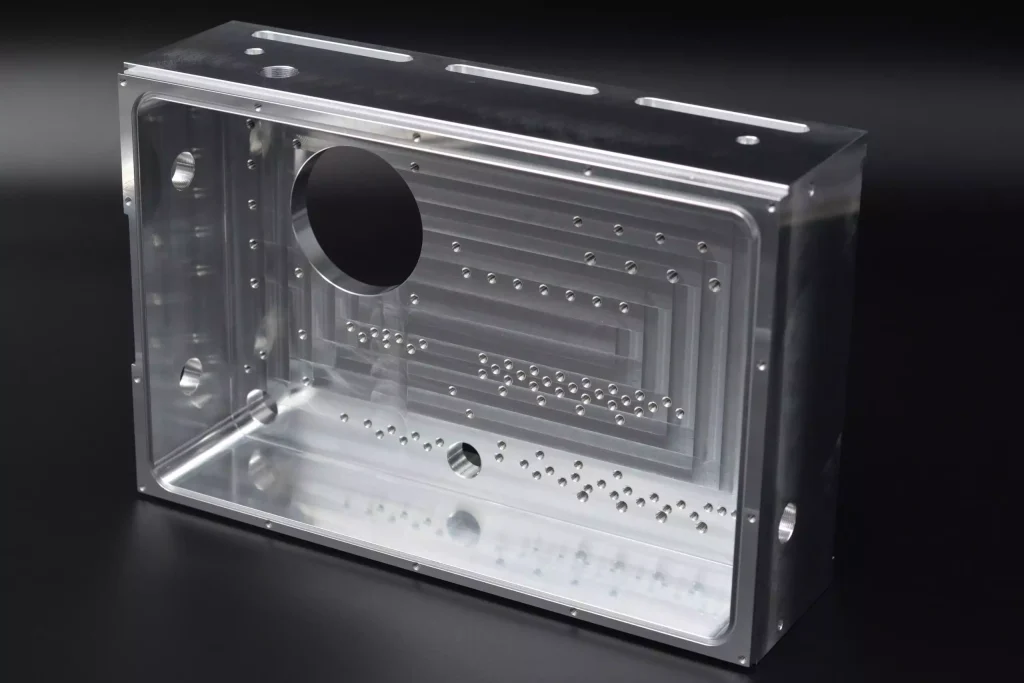

High Quality Rapid CNC Milling Capabilities

Elimold’s high-quality CNC milling services. Our CNC vertical milling machine has a working range of 142X64X27 inches. Our vertical milling equipment is able to guarantee the precision tolerance of parts of all sizes to a tight control of (±) 0.001 inches. Our well-equipped in-house facilities enable us to provide a variety of CNC milling processes, including milling, drilling, end machining, surfacing, slotting, cutting and profiling. We can also work on a variety of projects that require tapping, countersinking, reaming, profiling, thread milling and slotting. Therefore, our CNC vertical milling services are able to meet all production requirements from prototyping to large and small batch production.

CNC Milling Tolerances and Surface Finish

Elimold offers a variety of CNC machining tolerances to meet your specific design needs, including GD&T callouts. Depending on your part geometry and selected material, we offer standard and custom thread sizes with tolerances up to ±0.001 inches. Our default CNC milling tolerances for metals follow ISO 2768-m and plastics follow ISO 2768-c. However, for special projects, we can achieve tighter tolerances of +/-0.01 mm (0.00039 inches). Economy machining accuracy is IT9-IT7 with a surface finish Ra of 12.5-1.6um, and precision milled parts can reach an accuracy of IT5 with a surface finish Ra of 0.20um. If you require tighter tolerances to meet your special needs, please contact us.

Precision CNC Milling Service Production Solutions

From the early stages of parts to mass production, from raw materials to final processed products, we can provide advice, optimization and full-scale assistance. Every step is transparently shared and precisely controlled.

Rapid Prototyping

Low-volume CNC milling production

On-Demand Production

Custom CNC Milling Solutions

We know that every project is unique, so we take a personalized approach to meet our clients’ specific needs. Our team works closely with each client, providing expert guidance and support from concept to final delivery. Whether it’s optimizing the design for manufacturability, selecting the right material, or meeting tight deadlines, we are committed to providing custom solutions that exceed all expectations. When choosing Elimold as your CNC machining partner, you can count on our unwavering commitment to excellence, precision, and customer satisfaction. From prototype to mass production, we always turn your vision into reality with unparalleled quality and reliability. Experience the Elimold Difference, the perfect blend of precision and perfection.

Turnkey Custom Parts Supplier

We are committed to providing our customers with a streamlined process. As a turnkey supplier, we are able to perform multiple operations on a variety of machines to meet a variety of part manufacturing needs. We focus on the details so our customers don’t have to worry. And our CNC milling process can produce custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture more than 30 engineering-grade plastic and metal parts. With machined production parts, you can get more competitive pricing at higher volumes, in addition to First Article Inspection (FAI) reports, material certifications, and surface treatment options.

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Order CNC Milled Parts Online

To consistently produce high-quality CNC milled parts, we have built a talented milling department with an average of 16+ years of CNC milling experience. As the industry and customer needs continue to evolve, we remain relentless in our commitment to meet and exceed our customers’ expectations. New products and technologies often require new ways to mill small parts to tighter tolerances. Our goal is to make your parts as cost-effective and efficient as possible. We are happy to assist your engineering staff in determining the machinability of your parts based on material and part configuration. They work tirelessly to ensure that every part produced is of the highest quality. We understand that each project is unique, so we take the time to carefully analyze the project requirements and design a custom solution to meet your needs.

Type of CNC Milling Services

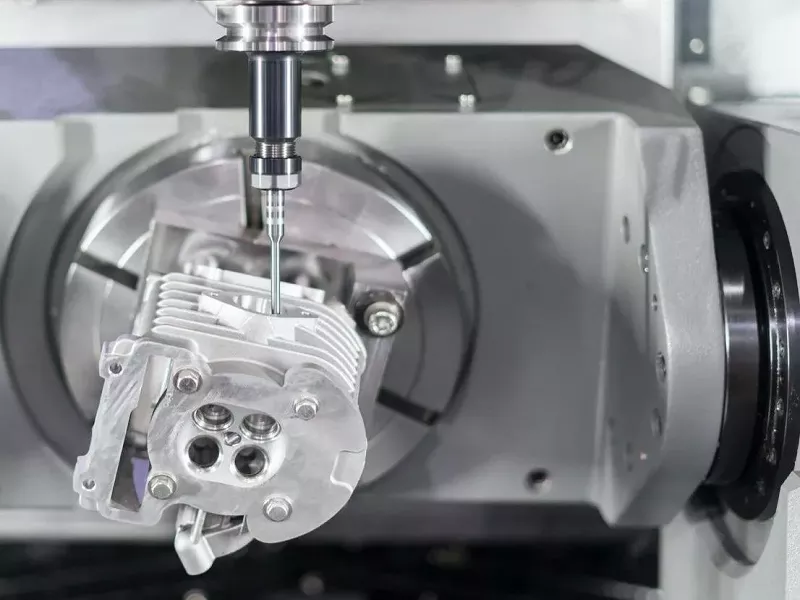

From 3-axis basics to complex 5-axis projects, our precision CNC milling brings your designs to life with unmatched accuracy and craftsmanship. Our machining team can help customers take control of their CNC milling projects and ensure custom parts meet their exacting requirements.

3-axis CNC Milling

4-axis CNC Milling

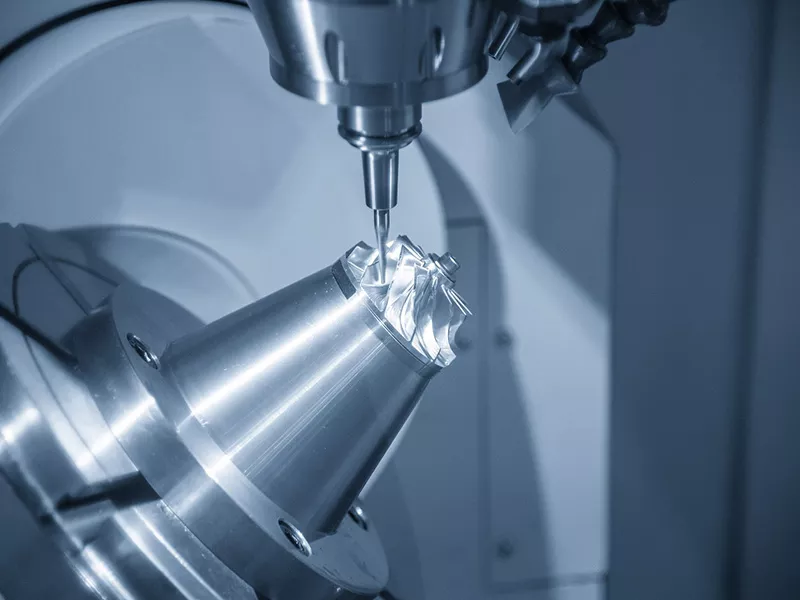

5-axis CNC Milling

3+2 Axis CNC Milling

6-Axis CNC Milling

High-Speed Milling

CNC Milling Bridge Production

Bridge production is a low-volume, high-precision manufacturing process that can create prototypes and small quantities of production parts. This is a common practice when launching new products or making modifications to existing products. It reduces costs and minimizes the risk of errors or defects during mass production. This allows us to test and improve designs, production processes and quality control measures. Bridge production typically only requires manufacturing a few dozen to a few thousand parts, depending on the project and how it is manufactured. Once completed, mass production can begin. Our wide range of services ranges from cutting complex shapes to creating complex 3D parts. With our help, you can shorten project lead times and start your project quickly and efficiently.

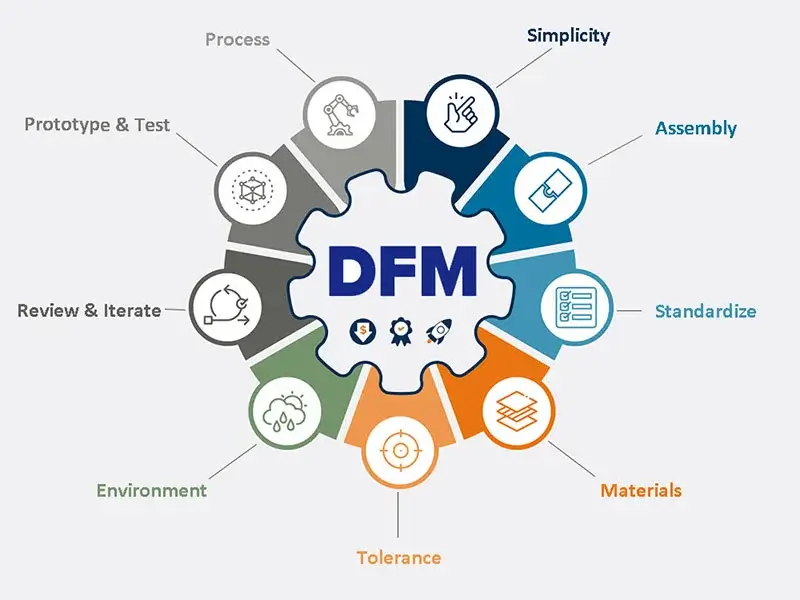

DFM Analysis

We have 10 engineers with more than 20 years of experience, who can reduce machining time and cost and provide the best machining solutions through DFM analysis and structural optimization. Free DFM analysis can be provided for all CNC milling projects to help you optimize your design and achieve cost-effective and high-quality manufacturing. After receiving your RFQ, our sales engineer will contact you within 48 hours. Our engineers will review your CAD files and provide feedback, and provide optimization suggestions for CNC machining if necessary. Our goal is to improve the quality of machined parts and find opportunities to reduce machining costs, ultimately helping you reduce unit prices.

Quality Control

We have a complete quality control management department, including IQC, IPQC, and FQC. The first inspection, inspection, and shipment reports are kept on file for two years. From the entry of raw materials to shipment, we have dedicated personnel to follow up the whole process and share transparently in real time. We have an advanced measurement laboratory equipped with high-precision testing instruments such as coordinate measuring machines (CMM), 2D projectors, height gauges, automatic inspection equipment, feeler gauges, pin gauges, etc. Our team follows a strict inspection process to ensure that there are no defects such as scratches and burrs. Each component is strictly inspected at various stages of production to ensure that the final product meets your expectations.

Professional Packaging

We will select the appropriate packaging (VCI paper) according to the size, shape and material of each component, and use clear labels on the corresponding packaging to identify the goods. The packaged components will be placed in a five-layer corrugated box or wooden box and fixed with pearl cotton to prevent transportation damage. We will attach a packing list to the outer box to facilitate your quick inspection and acceptance of the goods.

Custom CNC Milled Parts Services

Complex geometry? Tight tolerances? Difficult materials? Short-run or high-mix projects? Then come to us! The Elimold team has the expertise to help you meet your precision CNC milling requirements. We are expert problem solvers with decades of experience in meeting a wide range of machining challenges. We have the capabilities and expertise to handle your most challenging projects. If you are unsure where precision CNC milling is needed, please contact us. We will assist you with design modifications, material selection, and process and finishing decisions to ensure that the parts you require are delivered. Our success is due to our continued focus on delivering the highest “quality assurance” products at faster speeds and at always competitive prices. We guarantee that you will never be disappointed when working with the Elimold team.

Get a Milled Parts Quote Today

Upload your 3D models or 2D drawings files for instant quotes, lead time, and expert support. All data is secure and confidential.

What is CNC Milling?

A CNC mill is an automated cutting machine that uses a rotating spindle head to remove excess material. CNC mills come in a variety of sizes and with different axis configurations. The manufacturing process is primarily used to cut harder metals, but can handle a wide range of workpiece materials, from plastics and aluminum to stainless steel and titanium. CNC mills excel at contour cutting of harder materials. Like all CNC machines, CNC mills are controlled by G-codes created through CAM software. The Gg-codes instruct the machine where to move the tool head, how fast the tool will rotate, how deep to cut, how to move the workpiece, and other factors related to speeds, feed rates, and coordination. The complexity of the G-code depends on how many axes the mill has.

Types of CNC Milling Machines

Depending on the material type and product manufactured, machines running on CNC technology are categorized into various types like:

Horizontal Milling

Vertical milling

Knee-Type CNC Milling Machines

Ram-Type CNC Milling Machines

Bed-Type CNC Milling Machines

Planer-Type CNC Milling Machines

Difference Between 3-, 4-, and 5-Axis CNC Milling

3-axis milling is the most basic and commonly used method of milling parts. It involves the spindle cutting along three axes: X, Y, and Z. 4-axis milling, on the other hand, adds a rotary axis to one of the existing three on a 3-axis machine. This allows for more complex shapes to be created as the part can be rotated during CNC machining. However, 5-axis milling is considered the most advanced form of CNC milling machining services as it adds a second rotary to yet another axis on a traditional 3-axis machine. This enables even more complex shapes to be produced with greater precision and accuracy. With 5-axis milling, manufacturers can create complex geometries and intricate designs that would otherwise be impossible with other methods.

CNC Milling Materials

Elimold’s plastic and metal CNC milling solutions cover a wide range of materials, ensuring precision and durability. This wide selection allows our customers to find the best solution for their unique project, thereby improving product quality and performance.

Metals

- 18-8 Stainless Steel

- 300 Stainless Steel

- 416 Stainless Steel

- 440C Stainless Steel

- A2 Tool steel

- AISI 303

- AISI 304

- Alumina

- Aluminum 355

- ANMA

- Boron Nitride

- Elgiloy

- EN 10130

- FKM

- Garolite G-10

- Hastelloy C276

- Lennite

- M303E

- PAI

- ST37

- Stainless 301

- Stainless 304

- Stainless 304 L

- Stainless 316

- Stainless 316-L

- Stainless 904L

- Stainless A268

- Steel Plate A36

- Super Duplex

- Ti-6Al-4V

- Ti-6Al-4V Eli

- Titanium Ti 6Al-4V

- ToughMet

- ToughMet 3 AT110

- ToughMet TS

- Tungsten

- Tungsten Carbide

- Tungsten MT-17C

- Wrought Iron

- Zelux

- Zinc

Plastics

- ABS

- Acrylic

- Chirulen GUR1020

- Chirulen GUR1050

- Clear ESD Acrylic

- Crosslinked UHMW PE GUR1020

- Crosslinked UHMW PE GUR1050

- Delrin

- Delrin 100AF

- Nylon 6

- Nylon 66

- PE

- Peek (Poly-Ether-Ether-Ketone)

- PEEK 450G

- PEEK CF30

- PEI

- PES

- PET

- PFA

- PMMA

- Polyamide 6 GF30

- Polycarbonate

- Polypropylene

- POM

- POM Acetal

- POM Delrin

- PP

- PPS

- PPSU

- Propylux

- PTFE

- PVC

- Teflon

- UHMW PE GUR1020

- UHMW PE GUR1050

- Vit E Crosslinked UHMW PE GUR1020

- Vit E Crosslinked UHMW PE GUR1050

- White Delrin

Other Materials

- Ceramics

- Alumina

- AIN

- Si3N4

- SiC

- Rubber

- Glass

CNC Milling Surface Treatment

Elimold offers a variety of surface treatment options to improve the surface quality of CNC turned parts. Post-processing surface treatment can change the appearance, surface roughness, hardness and chemical resistance of the part.Other surface finishes are also available. Learn more about our metal and plastic surface finishing capabilities here.

As machined (Ra 3.2μm / Ra 126μin)

This finishing option with the shortest turnaround time. Parts have visible tool marks and potentially sharp edges and burrs, which can be removed upon request.

Smooth machining (Ra 1.6μm / Ra 63μin)

Smooth machining is similar to a ‘As machined’ finish, but with less visible machine marks. Parts are machined at a lower feed rate, with no hand polishing.

Polishing (Ra 0.8μm / Ra 32μin or better)

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment.

Bead Blasting

Machined parts are bead blasted with glass beads which results in a uniform grainy texture and reduced machining marks.

Tumbled

It is a process that tumbles vibrating media on machined parts to remove sharp edges and burrs.

Tumbling can be used to remove machine marks from exterior surfaces.

Bead blasted + Anodizing type II

The parts are bead blasted to #120 grit before being anodized type II—ideal for increasing the aluminum part’s corrosion resistance and cosmetic effects.

Bead blasted + Anodized type III (Hardcoat)

The parts are bead blasted to #120 grit before being anodized type III. Type III (Hard Coat) is thicker and adds a wear-resistant layer to Type II’s corrosion resistance, suitable for functional applications.

Black Oxide

Black oxide is a conversion coating that is used on steels to improve corrosion resistance and minimize light reflection.

Powder Coated

This is a finish of applying powdered paint to the components and then baking it in an oven, which results in a stronger, more wear- and corrosion-resistant layer that is more durable than traditional painting methods.

Chromate Conversion Coating

Chromate conversion coating is used to improve the corrosion resistance of aluminum and aluminum alloys while keeping their conductive properties. It is also applied as a base layer prior to priming and painting parts.

Plating

Include Nickel Plating, Silver Plating, Gold Plating, Zinc Plating, Chrome Plating, Tin Plating and etc, it is ideal to reduce corrosion, improve the appearance and function of solderability and electrical conductivity.

DLC (Diamond-Like Carbon) Coating

DLC (Diamond-Like Carbon) coating is a hard, wear-resistant coating made of a carbon-rich material that exhibits some of the properties of diamonds.

Alternatives to CNC Milling

While CNC milling is a popular and versatile machining process, there are several alternatives depending on your specific project needs. CNC turning is ideal for cylindrical parts like shafts and bushings because it rotates the workpiece rather than the cutting tool. For complex designs or thin materials, laser cutting offers greater precision and speed, making it ideal for machining sheet metal and custom patterns.

Laser Cutting

Waterjet Cutting

3D Printing

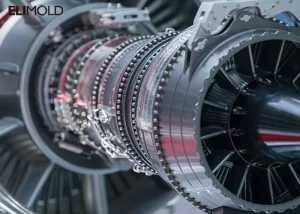

Industries We Serve

The CNC milling process is applicable to many industries as it is highly efficient, accurate and eliminates the need for manual labor. Whether it is for prototypes or a full production runs, machine shops and their services are a critical step in the manufacturing process.

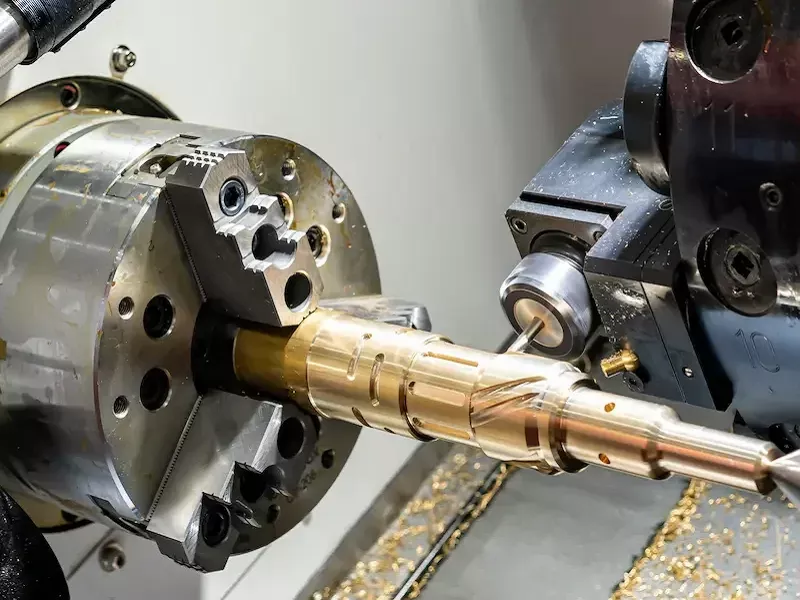

Difference between CNC milling and CNC turning

CNC milling and turning both are capable of producing accurate custom parts from metals, plastic and other materials. The main difference is that while the cutting tools rotate for milling, the raw material rotates for turning. For that reason, turning is mostly used for machining custom cnc round parts such as shafts, pins, balls, etc. Another difference is that while basic milling machines have three axes of motion, a lathe or turning machine needs only two. In a mill, the cutter usually moves up and down while the workpiece moves horizontally in two directions. In comparison, turning requires only that a non-rotating cutter move left and right on one hand and forward and back for the second axis. The fact that turning has only two axes in its simplest form, constrains the variety of shapes it can produce. For example, turning can produce a shaft, chess pawn, a cylinder with a rounded end, etc. Turning normally can’t produce even a simple enclosure box. However advanced turning centers can have more than two axes and therefore can produce a wider variety of shapes.Elimold’s services are not limited to CNC milling and include hybridized manufacturing that leverages CNC milling, prototype fabrication, additive manufacturing and more.

Why choose CNC milling?

CNC milling is ideal for machining a wide range of shapes such as bevels, grooves, chamfers, holes, curves, and planes. CNC milling is able to quickly and accurately remove large amounts of material while achieving a good surface finish. Milling can be used for any rigid material, but we primarily machine metals and plastics. Of all the CNC machining processes available, milling is the most versatile.

Milling is not only used to manufacture finished parts, but also for making molds for plastic injection molding and die casting. Setup time is minimal, and it takes only a few hours to transform a CAD file into a finished part. Since there is no need to manufacture additional specialized tools, you are not subject to minimum order quantities, making the process very cost-effective and virtually waste-free.

Other CNC Machining Services

With Elimold’s online CNC machining services, you’re investing in more than just a machine. We promise to provide you with impeccable precision, tight deadlines, and the support of experienced professionals for all your custom CNC machining needs.

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Jig Grinding Services

What is the difference between a CNC router and a CNC mill?

A CNC router is used to cut materials like wood, plastic, foam, and sometimes soft metals like aluminum. It has a larger work area and typically moves faster. The router’s cutting tool, called a spindle, is designed to cut flat surfaces and intricate patterns, similar to a high-speed engraving machine. CNC routers are often used in woodworking, sign making, and other applications that require large, flat materials to be processed quickly and with high precision.

A CNC mill is more durable and versatile, capable of handling harder materials like steel, brass, and titanium. It can withstand the force and precision required to cut these materials. The cutting tool in a CNC mill, called an end mill, can move in multiple directions, allowing the machine to process more complex shapes and designs.

CNC Milling vs. EDM

Unlike CNC milling, electrical discharge machining (EDM) is a non-shear cutting method. It uses a workpiece and a cutting tool, and in a dielectric device, a high voltage creates an electrical discharge, and an electrode forms the workpiece by electro-eroding the material. Electrical discharge machining (EDM) is a technology specifically used for micro-machining, such as machining small holes, slots, cavities, etc.

Get Your CNC Milling Project Started Today

With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements.