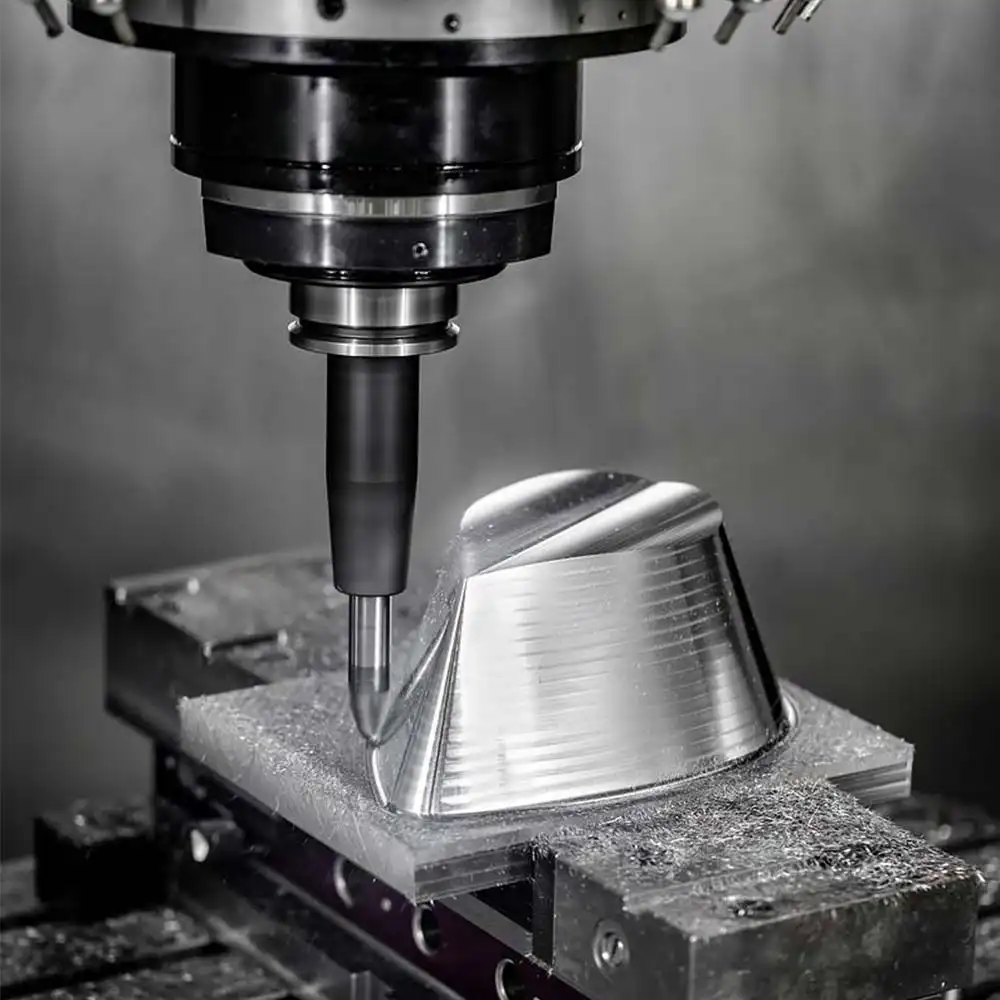

CNC Metal Machining

Elimold has been committed to providing innovative CNC metal machining solutions for all your metalworking needs. Our experienced R&D department will guide you from the initial R&D stage to meeting your low-volume prototype needs. Our extensive services meet the diverse needs of our customers, with state-of-the-art technology, equipment, a highly skilled and experienced team, and a commitment to providing the highest quality results. Turnaround time is as little as 3-4 days. Our prices are affordable, choose Elimold for precision, speed, and quality. Contact us today for a free instant quote.

CNC Metal Machining Manufacturers

Elimold is a full-service contract CNC metal machining service and material supply company founded and operated by a team of experienced practitioners. We have been committed to providing innovative CNC metal machining solutions, offering a wide range of services to meet the diverse needs of our customers, including OEM and contract parts and assembly suppliers. In addition, we understand the importance of quality parts, so we have established manufacturing processes to provide medium-volume and complex parts at the lowest cost. Our experienced R&D department will guide you from the initial development stages to meeting your low-volume prototype needs.

No matter how you choose to work with us, our ultimate goal is to improve your profitability. We strive to recommend better ways to source materials, improve part design or processes, and manage supply and inventory solutions to save you time and money. We are proud to be your one-stop shop for all your metal CNC part manufacturing needs and will work closely with you to find the best solution for your specific requirements.

CNC Metal Machining Capabilities

Elimold invests in advanced CNC machining technology and CNC machining equipment to increase speed and capacity for mass production applications. CNC metal machining can produce parts that require tight tolerances to exacting specifications. Elimold offers different general tolerance options from 0.10mm to 0.05mm, and you can also specify available tolerances in accordance with ISO 2768-mK, or specify tighter tolerances for critical areas of the part. Our CNC metal machining capabilities allow us to produce precision metal parts with more complex shapes and tighter tolerance requirements. Multi-axis machining capabilities allow processes such as turning, boring, drilling, hex machining, milling, threading, and tapping at nearly any angle. With a wide range of capabilities, we ensure that a variety of customer needs are met with the highest precision and reliability.

Metal CNC Machining Project Management Service Capabilities

At Elimold, we understand that managing a project can be a complex and time-consuming task. Therefore, we offer comprehensive project management services to oversee and troubleshoot all aspects of a metal part or assembly. Our experienced team of professionals will work closely with you to ensure that all aspects of your project are completed efficiently and effectively. Our Metal CNC Machining Project Management services include providing detailed drawings and estimates, determining cost and manufacturing improvements, managing material procurement, overseeing machining and production, coordinating with suppliers, implementing inventory programs, and ensuring that all quality documentation is in order. We also understand the importance of meeting tight delivery schedules and will work tirelessly to ensure that your project is completed on time and to your satisfaction. With Elimold’s project management services, you can rest assured that your Metal CNC Machining project will be in good hands. Our team will work closely with you to ensure that your project is completed with the highest standards of quality, efficiency, and cost-effectiveness.

CNC Metal Machining Factory

Our in-house CNC machining factory has more than 400 advanced equipment, equipped with 3-axis, 4-axis, 5-axis CNC machines, capable of producing parts that meet most customer requirements. In addition to CNC machining centers, we can also provide metal die-casting services, with advanced fully automatic die-casting machines ranging from 300T to 1000T, with an annual output of millions of pieces. Therefore, we can provide a wide range of custom CNC metal machining solutions for prototype design engineers, whether you need a one-off prototype or an affordable small batch, we can provide fast custom metal CNC machining services for your unique needs.

In addition, we not only invest in the latest CNC machining equipment, but also invest in training and quality control methods to ensure that your project is completed on time, on budget and on specification. With our wide selection of metal materials, we can provide you with a variety of services that are suitable for your specific needs and provide shipping options that simplify inventory management, and our CNC metal machining capabilities ensure precise and consistent quality throughout the production process. Our in-house machine shop capabilities enable us to produce and finish complex parts. With equipment redundancy and an active business continuity plan, Elimold plays a vital role in the global OEM supply chain. Our expertise and fully equipped machine shop allow us to produce high-quality, fully functional CNC metal machining parts and assemblies with high efficiency and productivity. Contact us now for a free instant quote.

Different Processes for CNC Metal Parts

Our metal CNC machining services allow us to manufacture parts using a variety of CNC methods, and our facilities include multi-axis machines capable of manipulation, cutting and refining. We will work with you to determine the best equipment for your project. This allows us to offer a unique one-stop service that reduces lead times and saves costs.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

CNC Metal Machining Rapid Prototyping

CNC metal machining services are ideal for creating prototype parts to ensure the fit, form and function of a part. Our CNC metal machining rapid prototyping service is to provide manufacturers with the opportunity to test the form, fit and function of a part before committing to a final design and going into mass production. Having a prototype made of the same material as the final product and available for testing is an invaluable resource for designers. They will be able to have a finished product of the final product and test it long before it goes into production. The prototype part can then be placed in the same conditions as the final piece to ensure form, fit and function. Elimold Metal CNC Part Prototyping Service is an advantage that enables manufacturers to test new parts and make necessary changes before committing to mass production. CNC metal machining is fast, relatively low cost, and gives customers the opportunity to get a part without the expense or time of full production. Changes are also easy and low cost. Simply make a design change in the CAD file and Elimold’s CNC metal machining shop will have the modified part ready for testing in no time.

Metal CNC Parts Low-Volume Production

CNC metal machining services are a quick and efficient way to complete low-volume production. CNC machining offers many advantages over other manufacturing processes. The biggest advantage is the low cost of entry. At Elimold, we understand that time is of the essence in today’s fast-paced business environment. That’s why we offer low-volume production and fast turnaround times in CNC metal machining to meet the most demanding schedule needs. Our state-of-the-art technology and experienced team allow us to quickly respond to changing low-volume production needs, and we can adapt to your schedule, whether it’s next week, the next day, or even the same day if necessary. We offer a wide range of shipping and logistics options to ensure your parts are delivered on time, every time. Flexible production methods and a machine shop that operates 24/7 make our metal machining services ideal for low-volume production of custom metal parts. All you need to complete your CNC metal part machining project is a CAD file. Work with Elimold today and our CNC metal machine shop can complete a low-volume production and deliver it to you in a few days.

CNC Metal Machining Cost Optimization Capabilities

Our team is constantly looking for ways to help our customers become more competitive. Whether it’s value engineering part design and construction, finding ways to run components more efficiently, or analyzing materials to save time and money, we are committed to finding ways to improve our customers’ bottom line. We utilize the latest technology and software to analyze and optimize production processes in order to provide the most cost-effective solutions. In addition, our experienced team of engineers and designers will work with you to improve the design of your parts to increase efficiency, reduce costs, and improve performance.

Leading Metal CNC Parts Supplier

Elimold is a leading metal CNC parts supplier that provides on-demand metal CNC machining services. We provide high-precision machining services to customers in a wide range of industries who require high-quality metal parts to meet their product and application needs. Our metal CNC machining processes comply with all international guidelines and standards. Our team of professional engineers and machinists are on hand to support you throughout the entire process from design to delivery. As an industry-leading machine shop with many years of experience in metal machining, Elimold is able to provide high-quality and cost-effective machining services for almost all needs. And serves a wide range of customers around the world, including original equipment manufacturers and contract parts and assembly suppliers. Our skilled programmers and machinists work together to combine mechanical designs, blueprints, and mathematical elements to produce products that meet precise specifications. By taking components from design to completion, we can monitor the quality of parts at various stages to improve quality and reduce turnaround time. We also use state-of-the-art computer programming software such as Solidworks and Master cam to quickly create complex custom components based on your exact design. In addition, we also provide auxiliary services to further customize or complete your project. Therefore, we can meet all your specific requirements. We process all metals. So whether you need a single prototype or large-scale production, we have the experience and capabilities to meet your needs.

Need Metal CNC Machined Parts? Get your parts into production today!

No matter the quantity, we guarantee precision, quality and price. Our team will respond quickly to meet your needs. Contact us now for a free instant quote.

Quality Management and Certification Standards

Quality is the cornerstone of Elimold’s success. We believe that quality comes from devoting engineering resources to our quality control department. Our well-trained quality control staff ensures quality by carefully reviewing the design and certifying raw materials of custom CNC metal machining parts. Our experts perform dimensional and visual inspections after each metal CNC machining service, and then document all results in a quality control report.

We are committed to ensuring that our products meet the highest quality standards, which is why we are certified to ISO 9001 quality standards. We are also responsive to your internal quality processes and can provide you with the necessary documentation and certifications to meet your specific requirements. Our team of quality experts will work closely with you to ensure that your CNC metal machining needs comply with all industry standards and regulations. We can also provide you with detailed quality reports, certifications and documentation.

Inspection Equipment and In-house Inspections

At Elimold, quality is of paramount importance to us. We carefully monitor and measure quality throughout the CNC metalworking process, and our quality management team, combined with in-house inspections, strives to ensure that all parts and materials we produce meet your specifications. Our team of quality engineers, inspectors, and technicians use a variety of inspection equipment, including coordinate measuring machines, optical comparators, and surface roughness testers, to ensure that our CNC metalworking processes and services meet and exceed your exacting standards.

Metal Alloy Material Options

CNC metal machining services are used to manufacture a range of parts from prototypes to engineering models to production components. Elimold specializes in custom part machining and can easily process a variety of metals to meet customer needs.

- Aluminum

- Titanium

- Copper

- Brass

- Steel Alloy

- Low Carbon Steel

- Tool Steel

- Inconel

- Invar

- Bronze

- Kovar

- Cast Iron Zinc

Surface Treatment and Post-Processing Options

CNC metal machining is the process of removing excess from raw metal materials to create metal parts of the desired shape. Visible tool marks are left on the surface of machined metal parts. To help improve the functionality and aesthetics of CNC machined metal parts, Elimiold supports a one-stop surface treatment service for CNC machined metal parts. We offer a variety of surface treatments for these metals, including:

- Standard (As-Milled)

- Bead Blast

- Tumbled

- Anodized (Type II Or Type III)

- Titanium Anodize

- PTFE Impregnated Hard Anodize

- Chem Film (Chromate Conversion Coating)

- Passivation

- Powder Coat

- Electropolishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Zinc Plating

Metal Machining Aplication

- Automotive Manufacturing: Used for producing automotive components such as engine parts, transmission systems, and braking systems.

- Aerospace Industry: Utilized in manufacturing structural components and engine parts for aircraft and spacecraft.

- Medical Device Industry: Applied in manufacturing medical equipment and instruments such as artificial joints, surgical tools, and implants.

- Electronics Industry: Employed in manufacturing metal enclosures, connectors, heat sinks, and other components for electronic products.

- Defense Industry: Utilized in manufacturing weapon systems and components for military equipment such as tank parts and missile components.

- Energy Industry: Used in manufacturing equipment and components for energy production, including generator parts and oil drilling rig components.

- General Manufacturing: Encompasses various manufacturing sectors including mold making, machining, and tooling production.

What is Precision CNC Metal Machining?

CNC or Computer Controlled Machining is a modern manufacturing method that utilizes computer-controlled, automated, high-speed cutting tools to remove layers of material to form complex shapes. Tool paths are programmed using CAD (Computer Aided Design) and machine commands are translated using CAM software. These tool paths precisely mill, cut and shape materials by mounting cutting tools and materials or both. This process is most accurately accomplished using CNC (Computer Numerical Control) machines, which can produce nearly any three-dimensional object designed using CAD (Computer Aided Design) software. State-of-the-art metal CNC machines, like the ones we use, are capable of cutting complex features on parts with high precision while maintaining tight tolerances. For design engineers, R&D teams and manufacturers who rely on part sourcing, precision CNC metal machining can create complex metal parts without the need for additional machining.

How CNC Metal Machining Works

The CNC machining process starts with the design of a 2D or 3D CAD part. The finished design is then exported to a CNC-compatible file format and converted into a CNC machine program through CAM software, which instructs the machine’s operations and the movement of tools on the workpiece. Before running a CNC program, the operator must first prepare the CNC machine by attaching the workpiece to the machine’s work surface (table) or workholding device and attaching a milling cutter or turning tool to the machine. Depending on the specifications and requirements of the machining process, the CNC machine will use different cutting tools, such as milling cutters and drills. When the machine is ready, the operator starts the program through the machine interface, instructing the machine to perform the machining operations. The part is then cut on the X, Y, and Z axes, achieving complex geometries that are almost impossible to achieve with traditional machining. The CNC system can control the machine tool to automatically change tools, select spindle speed, feed rate, etc. according to different metal machining operations, so that drilling, boring, milling, reaming, tapping, etc. can be completed continuously. CNC machines cut parts with extremely high precision. Each successive part will be exactly the same as the first, allowing for quick and easy copying.

Technical Advantages of CNC Metal Machining

Customers choose Elimold because we are committed to providing speed, accuracy, and expertise in CNC metal machining, grinding, and other related services. Our state-of-the-art technology, highly skilled team, and commitment to quality set us apart from the competition. Trust us to meet your metal machining needs on time, on budget, and to the highest standards

- Fast Turnaround Time: We understand that time is of the essence to our customers, which is why we prioritize fast turnaround time for on-demand parts.

- Eliminate Variation: We pride ourselves on our ability to eliminate variation and maintain batch-to-batch quality, reducing the need for on-site inspections.

- Reduce Costs: Our proven track record of reducing costs is another reason so many customers return to us.

- Reliable Quality: We maintain reliable batch-to-batch quality on CNC metal machining, eliminating the need for on-site inspections.

- Single Point Project Management: Our single point project management approach ensures accountability and control of the entire process from initial estimate to delivery.

Request Your Free CNC Metal Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Metal machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.