CNC Multi Spindle Machining

Elimold offers multi-spindle machining capable of delivering the highest quality and precision in the industry. Our team can efficiently and quickly manufacture large volumes of parts while still maintaining consistent quality and precision. At Elimold, we remain committed to investing in the latest technology to continually improve our manufacturing processes and services to provide our customers with high-quality, tight tolerance components. Contact us today for a free instant quote.

Your One-Stop Manufacturer for Streamlined CNC Multi-Spindle Machining Services

Elimold has a complete turnkey factory in-house. Our precision CNC machining factory offers over 200,000 square feet of streamlined manufacturing space equipped with over 400 production machining centers. Our versatile manufacturing technology includes a variety of CNC multi-spindle machining equipment to handle your high-volume machining runs with unparalleled quality and consistency. In addition, our trained design team will review your design and assist with any specific changes required before the production process. We are committed to providing excellent customer service and providing the highest quality CNC parts at the most competitive prices. In addition, Elimold can provide assembly services, and once the parts are assembled, Elimold can also meet your warehousing needs and ship directly to your customers when necessary. We respect your deadlines and can guarantee that your orders will be shipped on time.

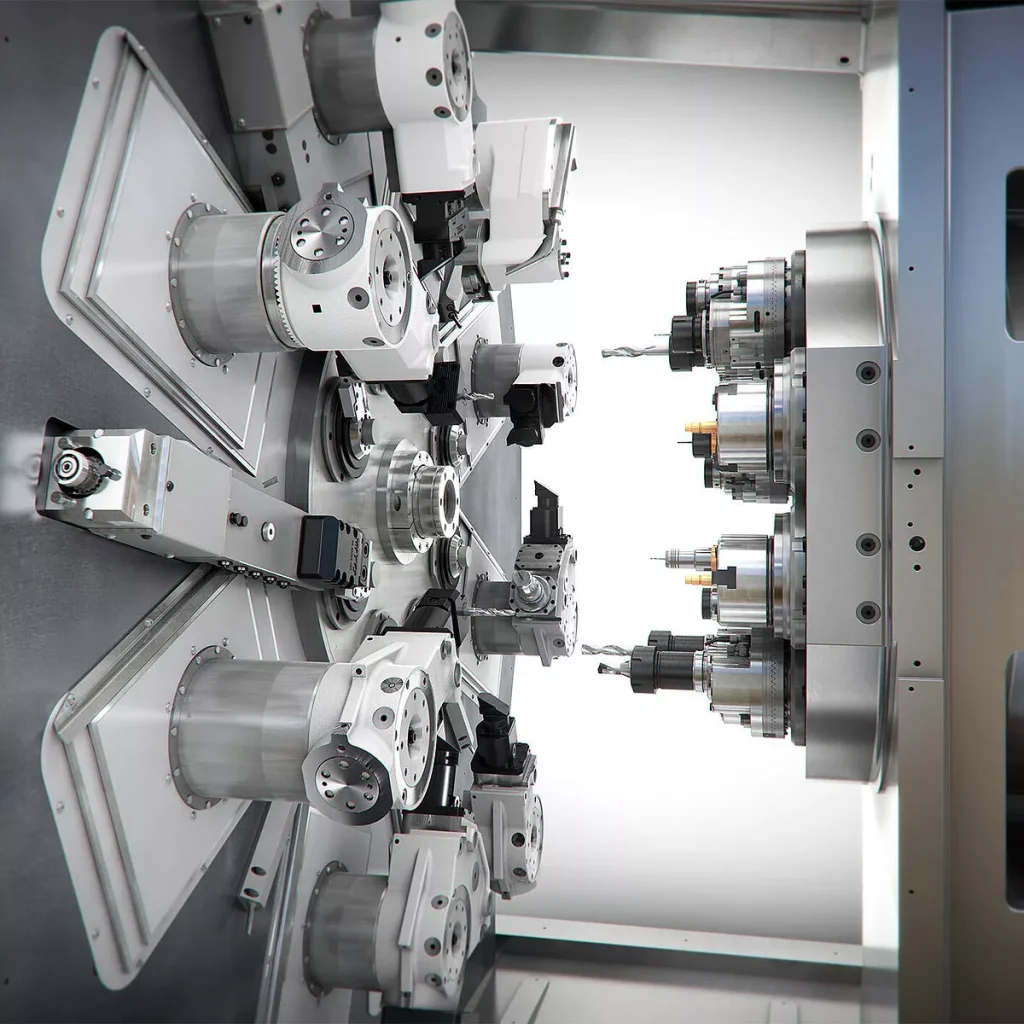

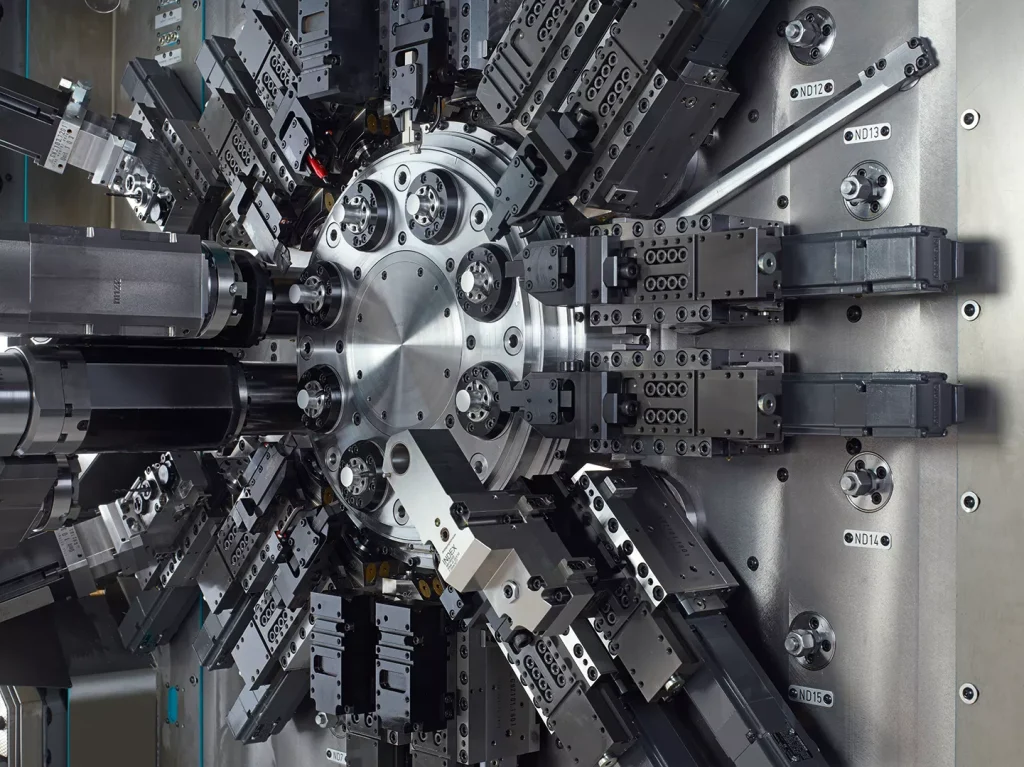

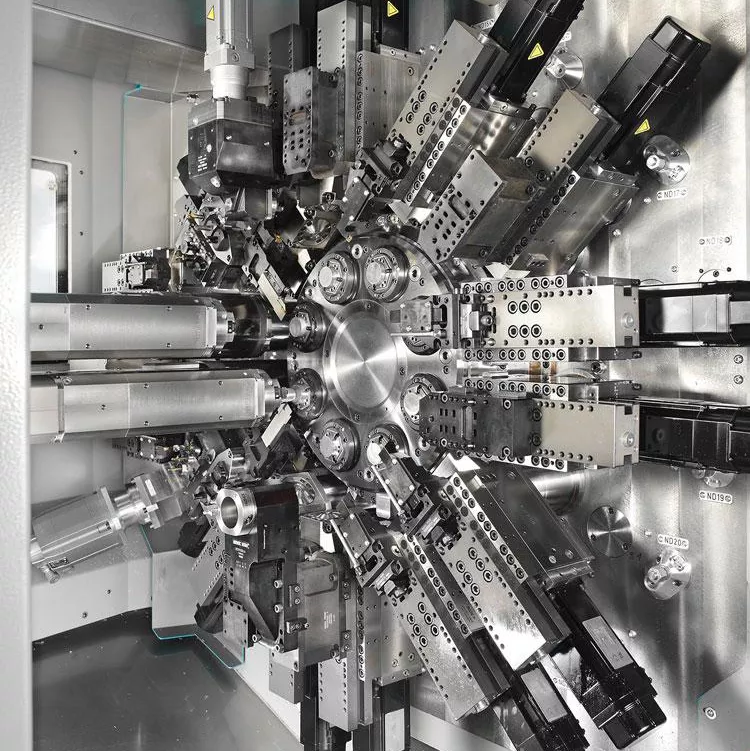

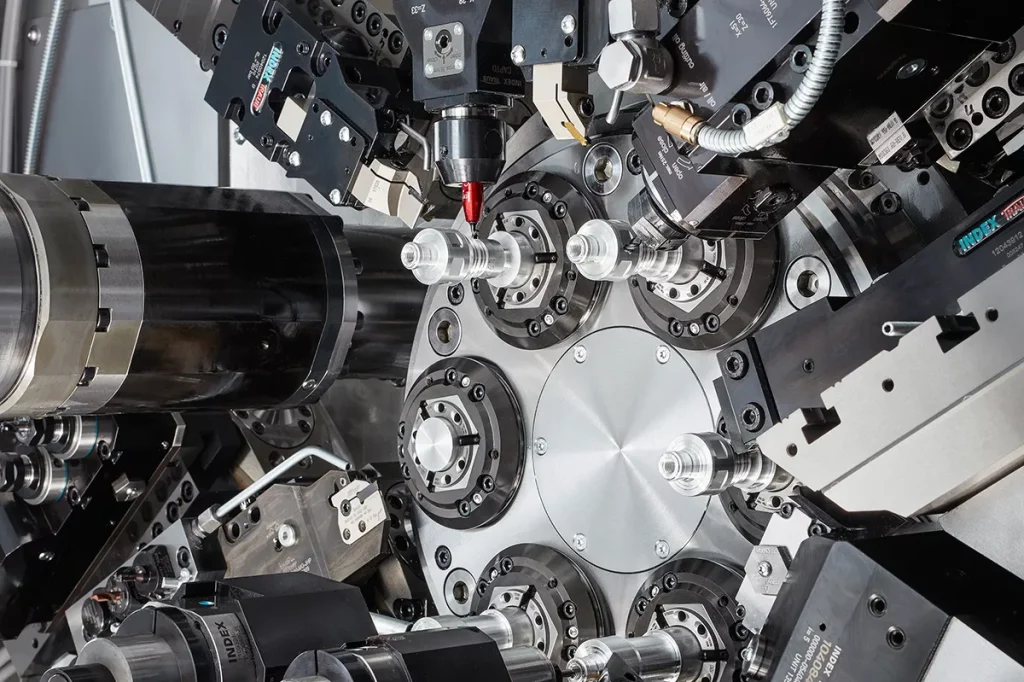

CNC Multi-Spindle Machining Capabilities

In keeping with our mission to provide the most cost-effective solutions for precision parts, Elimold’s in-house CNC multi-spindle machining facility features state-of-the-art equipment including 5-axis, 6-axis, 8-axis and 17-axis precision CNC machining centers. Our multi-axis automatic machines are equipped with capabilities such as threading, thread rolling, picking, back finishing, tapping and broaching. As a result, our multi-spindle machining services produce complex parts with excellent surface finishes in sizes ranging from 0.500” to 4” (12.7 mm to 101.6 mm) long and 0.125” to 1” (3.175 mm to 25.4 mm) OD, all with tolerances of ± 0.001”. Complex turned parts up to 2-5/8” in diameter can be produced. Cycle times are reduced by 80% compared to single-spindle machines, allowing production rates of up to 400 pieces per hour. Our in-house CNC machine shop specializes in high-volume production of over 10,0000 pieces and is able to provide customers with high-quality parts at very competitive prices.

Multi-spindle machining of complex parts

Our multi-spindle machines are the most technologically advanced equipment in the industry, allowing us to run the most complex parts in a single operation. They also allow us to hold tight tolerances, perform multiple machining functions, and make quick changeovers during medium to high volume runs. By offering multi-spindle machining speeds for complex parts, our production capabilities have been increased. Our multi-spindle equipment can easily handle a wide range of materials for a variety of applications. When you need to precision machine complex parts quickly and accurately, Elimold provides you with state-of-the-art equipment and experienced, knowledgeable professionals. And for high-volume production of less complex metal parts, Elimold’s multi-spindle machining capabilities can provide high precision for machined parts at a much faster rate than other machining methods. Multi-spindle machining offers unique advantages in speed and quality compared to traditional CNC machines, including fast production cycles for high volumes, superior accuracy, and cost-effective results.

Part Design and Manufacturing Process Optimization

Multi-axis machines can be set up to specific design parameters, making it possible to simultaneously manufacture a wide range of components with different sizes, thread patterns and other special features. This flexibility is critical for industries that require custom components for specific applications, where standard sizes and shapes are not sufficient. That’s why Elimold offers precision multi-spindle machining solutions with engineering efficiency. Our engineering team develops efficient and cost-effective manufacturing processes based on the specific requirements of your custom parts: physical size and shape, design and tolerances, and production quantities. When it comes to high-volume production machining, our multi-axis turning capabilities provide a level of precision and efficiency that meets the most demanding industrial part production. At the same time, manufacturing consistency is guaranteed through our integrated quality control system.

Ready to start your next CNC multi-spindle machining project?

Elimold operates a modern precision machine shop dedicated to providing our customers with cost-effective manufacturing solutions and exceptional service. We have a team of highly skilled people who are committed to efficiently and economically designing and producing parts with speed, precision, and quality. Contact us today to get a detailed quote for your next project.

CNC Multi-Spindle Machining Supplier

Elimold has established itself as a full-service CNC multi-spindle machining parts supplier. In addition to full-service and timely production, we can meet your warehousing needs through inventory management and Kanban programs, and ship directly and discreetly to your customers with your needs and assistance. We value your deadlines and can guarantee your orders are shipped on time. Through our collaborative approach, our team of well-trained and experienced engineers can review your specifications for the most efficient manufacturability while pursuing the lowest cost production processing.

At Elimold, we are committed to providing excellent customer service and the highest quality products at the most competitive prices. Our services can provide not only custom manufacturing services, but also assembly services and in-depth quality control testing. Our capabilities range from small orders to industrial-scale orders. Contact us today to learn more about Elimold’s multi-spindle machining services.

Quality Assurance

We offer extensive quality assurance measures to ensure the highest quality CNC multi-spindle machined parts. We are ISO 9001:2015 certified and our processes include comprehensive reporting and tracking. We have a strong quality department that fully inspects every part we produce. Our experienced team of quality assurance engineers inspect each part before shipment. Equipment includes: CMM, roundness machine, 10 different vision systems, pneumatic gauges, pin gauges and any basic instrumentation required.

CNC Multi-Spindle Machining Material Options

Multi-spindle machining is versatile, meaning it is compatible with a wide range of materials, from harder materials to softer metals, plastics and other composite materials.

Metal Materials

- Alloy Steel

- Carbon Steel

- Stainless Steel

- Brass

- Aluminum

- Monel

- Titanium

- Stainless Steel

- Bronze

- Copper

Plastic materials

- Acetal

- Delrin

- Nylon

- Polycarbonate

- Lexan

- Acrylic

- PVC

- Teflon

- UHMW

- Garolite

Surface Finishing and Post-Processing Services

In addition to machining, Elimold also provides comprehensive finishing services. Our vertically integrated operations simplify machining and finishing, and further save costs and time. Our customers can rely on us from computer-aided design to assembly and delivery of the final product.

- Anodizing

- Brazing

- Plating

- Burnishing

- Passivation

- Grinding

- Knurling

- Press-Fit Assembly

- Heat Treatment

- Sand Blasting

- Welding

- Surface Grinding

- Cylindrical Grinding

- Welding

- Tumbling

- Mechanical Assembly

Full range of CNC multi-spindle machining services

At Elimold, our business is designed to be tailored to your operation. We understand that our customers have unique and customized needs, so we provide unique and customized solutions. Our multi-spindle services are just one way we can meet your needs. We can also provide a variety of boring, turning, chamfering, tapping, grinding, drilling, cross drilling, knurling, reaming, threading, thread rolling and milling services for CNC parts in various materials. To maximize the potential of our first-class equipment, Elimold’s experienced team of engineers utilizes in-house custom designed and manufactured tooling and automation equipment. Our significant capital investment and deep machining expertise allow us to work flexibly and provide high-quality, cost-effective services. We are able to provide a comprehensive manufacturing experience with additional value-added services, and all of our services are under one roof for each task. We manufactured and shipped millions of parts last year, and we are happy to take on your project as well. All of our products and processes meet the highest industry standards.

Related CNC Precision Machining Services

Elimold offers a wide variety of CNC machining services and equipment, with our expertise in comprehensive CNC machining services to meet your needs for complex or simple custom CNC parts.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Ready to get started?

Elimold is a global strategic market leader in precision machined parts while also providing outstanding customer service, delivery and quality. Contact us today to learn how we can meet your multi-spindle needs with our equipment, or if you are ready to get started, request a quote using our online form.

Multi-Spindle Machining Industries and Applications

At Elimold, we specialize in providing fast turnaround and unmatched quality to manufacturers across a wide range of industries. Our priority has always been to provide precision CNC parts for any industry.

Industries Served

- Aerospace

- Agriculture

- Automotive

- Communication

- Construction

- Dairy

- Electrical

- Electronics

- Energy

- Firearm

- HVAC systems

- Hydraulics

- Injection Molding

- Instruments

- Marine

- Medical

- Military/Defense

- Government Contracts

- Packaging

- Railway

- Refrigeration

- Robotics

- Satellite

- Transportation

Applications Served

- Appliances

- Archery

- Controls

- Door & Window Hardware

- Fiber Optic

- Fluid Power Systems

- Furniture/Office Equipment

- Instrumentation Components

- Lawn & Garden

- Machinery

- Molded Inserts

- Motion & Control Systems

- Musical Instruments

- Pumps

- Recreational Products

- Semi-Conductor

Components Manufactured

- Adapters

- Axles

- Blocks

- Bolts

- Bosses

- Bushings

- Cages

- Clamps

- Collars

- Couplings

- Dowels

- Electronic Connectors

- Fasteners

- Fittings

- Gears

- Hardware

- Housings

- Hubs

- Inserts

- Knobs

- Manifolds

- Mounting Plates

- Nozzles

- Nuts

- Pistons

- Plugs

- Plungers

- Pulleys

- Retainers

- Rifle Firing Pins

- Rings

- Rods

- Screws

- Shafts

- Sleeves

- Spacers

What is multi-spindle machining?

Multi-spindle machining is a manufacturing process that uses machines equipped with multiple spindles to produce parts simultaneously. Unlike traditional single-spindle machines that process one part at a time, multi-spindle machines can handle multiple workpieces at the same time. This makes them a preferred solution for high-volume production and complex geometries.

Depending on the complexity of the task, these machines can have anywhere from two to dozens of spindles. They are generally divided into two types: fixed headstock (automatic bar feeders) and rotating headstock (transfer machines). Each spindle is programmed to perform a specific operation on the workpiece, such as drilling, turning, or tapping. By sharing the workload between multiple spindles, these machines significantly reduce production time, making them indispensable equipment for industries such as automotive, aerospace, and electronics. The key to multi-spindle machining is efficiency, precision, and scalability.

Benefits of CNC Multi-Spindle Machining Services

CNC multi-spindle machines maximize our production efficiency. This advanced technology offers many benefits for increased productivity and cost-effective solutions. With these features, we can deliver expertly machined parts on time while optimizing efficiency and minimizing costs.

- Increased Production Capabilities: CNC multi-spindle machines allow us to handle medium to higher volume production runs, efficiently meeting our customers’ needs.

- Versatile Machining Capabilities: With up to 48 axes of motion and unlimited quick-change options, we can perform complex machining operations quickly and accurately.

- Precise and Reliable Performance: The machine features 6 spindles and a rotating synchronized spindle, ensuring precise machining and maximum rigidity.

- Wide Range of Applications: From disc milling to gear cutting, CNC multi-spindle machines offer the flexibility to handle a wide range of machining tasks.

Request Your Free CNC Multi Spindle Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Multi Spindle Machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.