CNC Prototyping

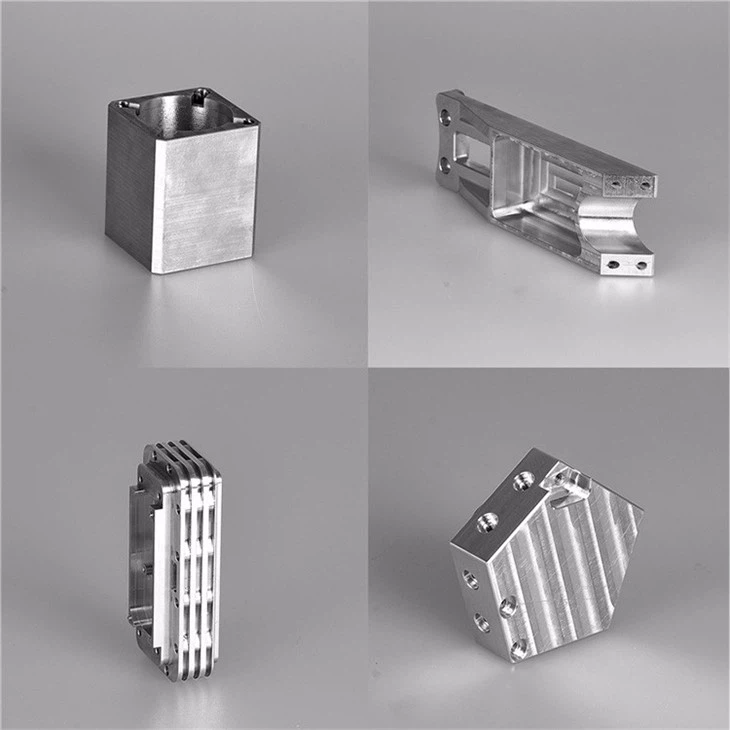

At Elimold, we use custom CNC machining services to manufacture custom prototype parts. No matter the scope of your project, we can handle everything from small, intricate components to larger, more complex designs. Since our founding, we have consistently provided high-performance, innovative solutions that set us apart and delight our customers. Contact us today for a free instant quote.

Custom CNC Prototype Manufacturer

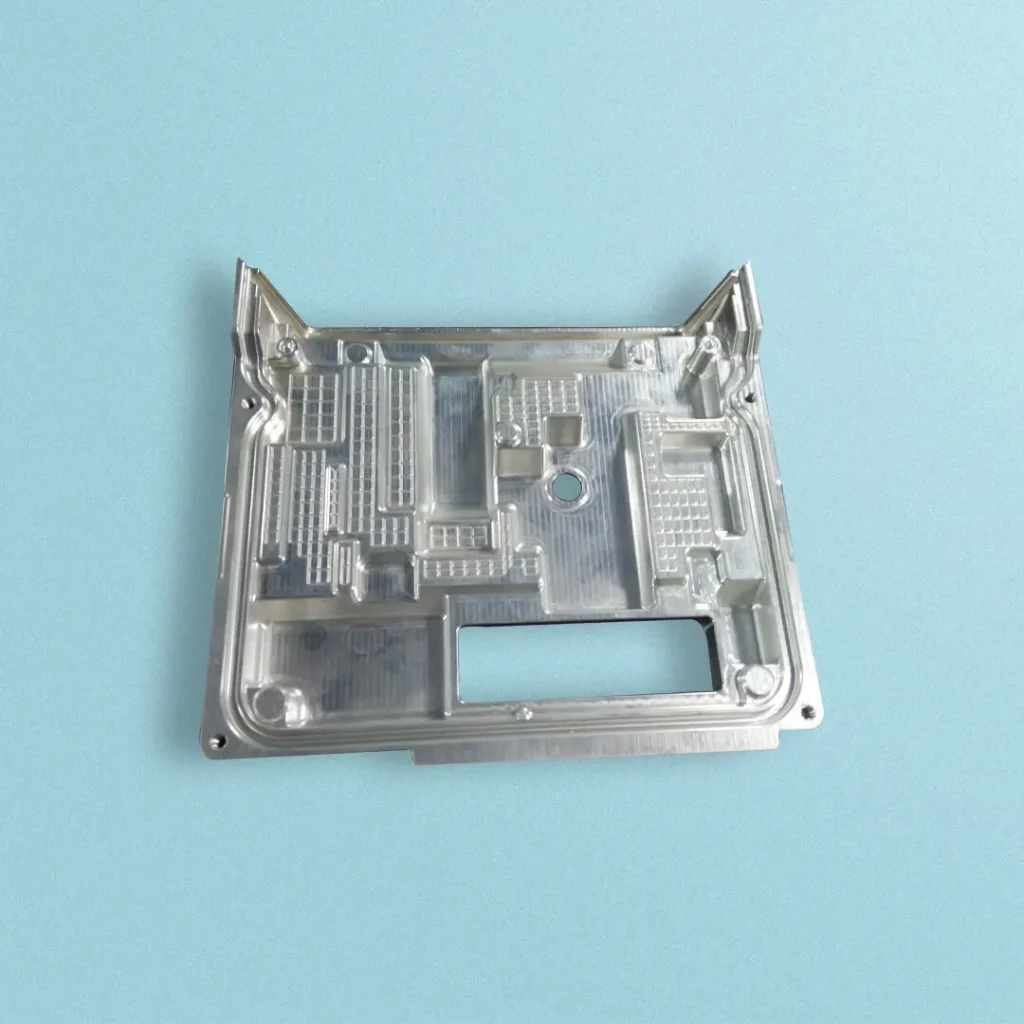

We can manufacture high-quality functional prototypes and part designs for your business with fast turnaround and dimensional stability. Elimold provides high-quality custom CNC prototyping services to produce functional prototypes, engineering models, and end-use production parts. We have extensive experience working with a wide range of engineering-grade metal and plastic materials, and have the flexibility to handle complex geometric designs, ensure high levels of precision and tolerance, and reduce lead times. Our team of highly skilled engineer experts and technicians will evaluate the design and specifications of your CNC prototyping project, recommending the best materials and methods based on industry standards and your budget. Before submitting your design for production, our automated design analysis will help you identify any difficult-to-machine details, thus avoiding costly rework later in the development process. With efficient quality control, timely service, and on-time delivery, our CNC prototyping services will provide a comprehensive and satisfying solution for your product development project.

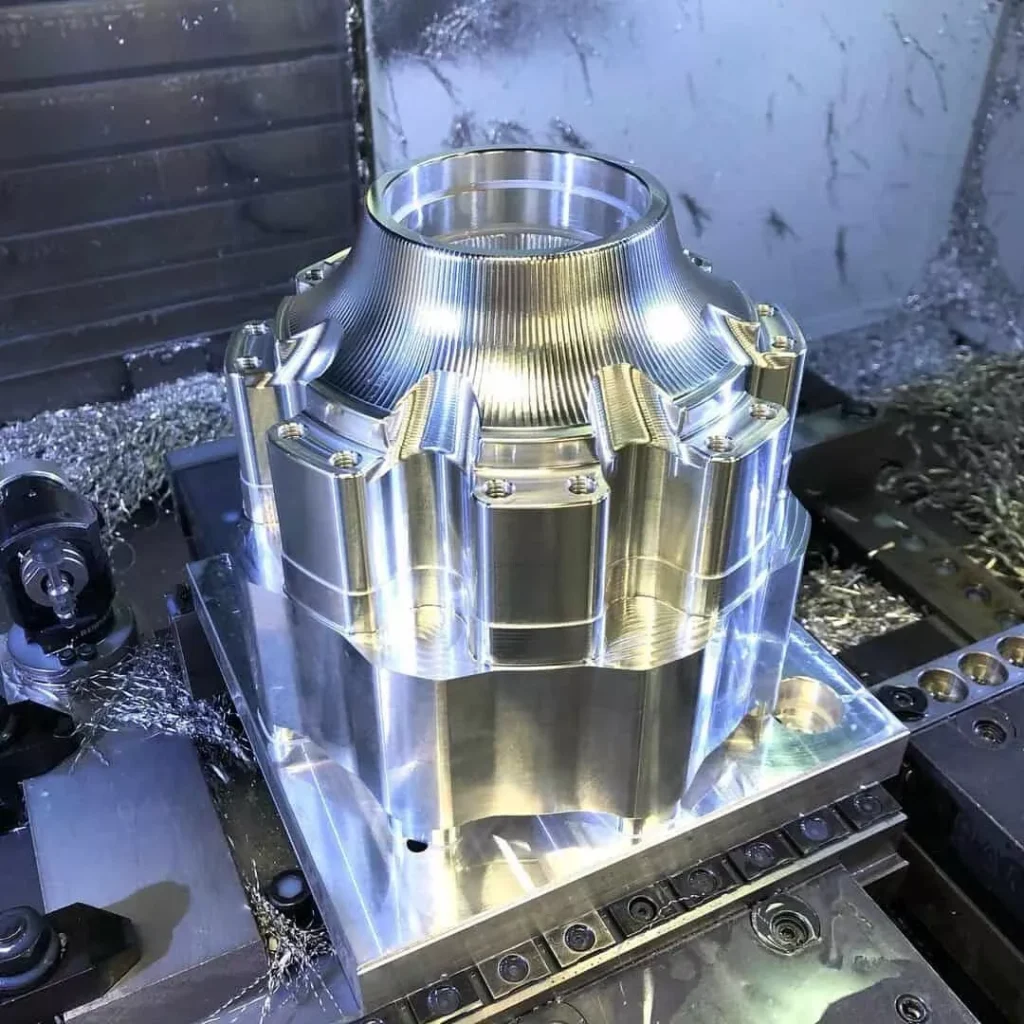

CNC Prototype Machining Factory

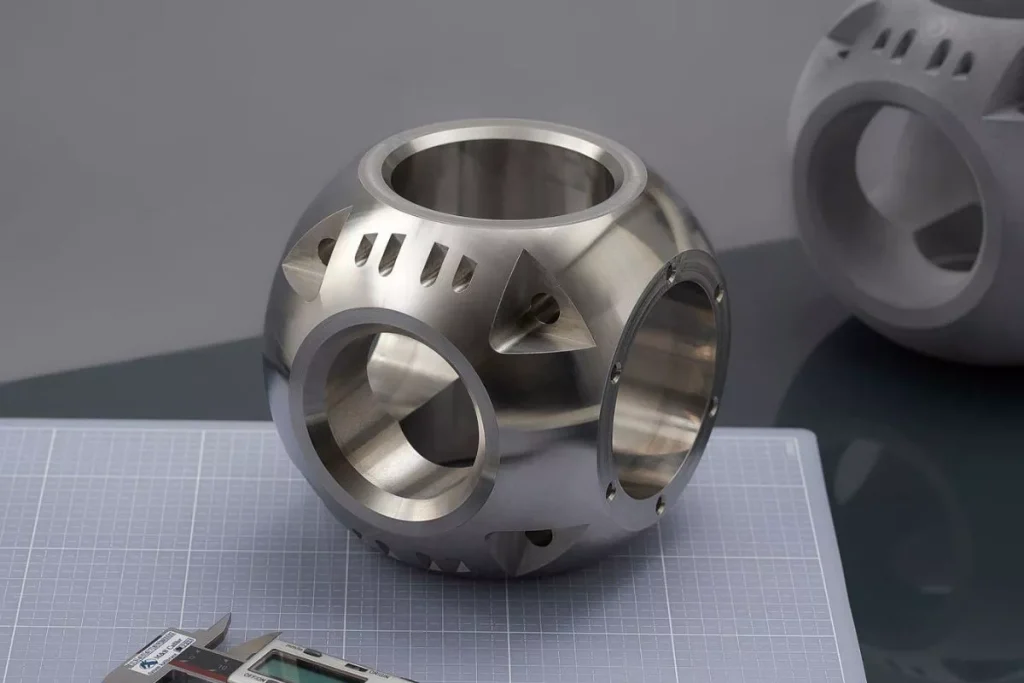

Elimold specializes in precision machining and manufacturing of a wide range of custom CNC prototype parts and undertakes rapid prototyping work in the field of R&D. Our in-house CNC manufacturing facility is 50,000 square feet and equipped with an overhead crane (with a load capacity of 20,000 pounds) and a variety of CNC machining equipment, giving us the unique ability to process large prototypes. We employ highly skilled CNC machinists who use CAD/CAM programming to produce high-precision products. Our equipment list includes high-precision 5-axis CNC machines, which allow us to machine parts with complex geometries to create your ideal prototype.

We have a proven track record in custom CNC prototyping across multiple industries, which makes us a true partner in your entire manufacturing process. Using our CNC prototyping design and manufacturing services is an excellent choice to obtain high-quality parts. With our endless options for CNC prototyping design and manufacturing solutions, Elimold is your one-stop shop. You can also get CNC prototype parts delivered directly to your door without the hassles of sourcing, project management, logistics, or shipping. Our focus is on creating high-quality prototypes for our customers in a timely manner. We also welcome one-off parts projects. Contact us now for a free instant quote.

CNC Prototyping Tolerances

At Elimold, we manufacture parts to the general tolerances of DIN ISO 2768. For metal machining, we use the fine tolerance standard; for plastics, we use the medium specification as a guide. Our custom CNC prototyping service can provide high-precision parts with a tolerance of +0.005 mm or 50 microns. For the vast majority of commercial applications, this level of accuracy is more than sufficient and makes it exactly the same as the final product. In addition, this tolerance remains consistent throughout the manufacturing process and is easy to establish for unlimited product quantities. The process of making prototypes through CNC machining is called CNC prototyping. This is currently the most common process used by Elimold among all the prototyping processes. Although it is not as fast as 3D printing, it provides the highest accuracy.

Different Types of CNC Prototype Manufacturing Techniques

Elimold is more than just a custom CNC prototype shop. We have developed unique and innovative methods that take advantage of a wide range of CNC machining techniques to produce metal and plastic prototypes. Our advanced equipment can achieve extremely complex geometries, resulting in fully functional mechanical parts. Our experienced team is well versed in a wide range of CNC prototype machining techniques, helping us achieve tighter tolerances, faster turnaround times, and more versatile prototype projects.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

CNC Prototype Suppliers

Elimold places more emphasis on quality and customer support than your average CNC prototype machine shop or service shop. Our experience with a vast array of products from a variety of industries makes us the best choice for your CNC prototype project. We welcome small batch custom CNC prototype part manufacturing and deliver with the high quality standards we embody. We are happy to study your design and understand the scope of your prototype project. Once we have determined how your part will look and work, we can apply our knowledge to select the right tools and strategies to turn your idea into reality. Our goal is to turn your CNC prototype part into reality in record time. It may be necessary to rethink one or more elements in your design. The purpose of a prototype run is to create a part for a product that serves as a model to replicate the product. At Elimold, we recognize the inventive process and will work with you until we achieve the results you envision. We will invest as much time as you need, and your prototype will be treated with the respect and confidentiality you deserve. With a well-planned and versatile equipment format and the support of a highly curated network of partners, Elimold is the best choice for your CNC prototype machining project. With continuously open capacity, you can expect competitive pricing and short delivery times; plus, the tolerances of your drawings will be met! We are happy to provide a quote for CNC prototyping and production.

CNC Prototype Design Service

If you already have a final design ready for prototype machining, that’s great, we’d love to make your design a reality, our team of professional project engineers is dedicated to reviewing and refining your project ideas. With their extensive knowledge and expertise, they assess the feasibility of your design and determine the most efficient way to create final prototypes and production parts. So, no matter what issues arise during the design phase of your prototype parts, we’re here to help. If needed, we can review your design and make helpful suggestions to reduce weight, reduce costs, or improve functionality. Over the years, Elimold’s team of engineers have worked with a wide variety of materials and assisted many industry professionals with their designs. Whether you have a sample, model, drawing, or just an idea, our staff can help you get ready for prototype machining. We use GibbsCAM, AutoCAD, and Catia to create any and all drawings or models required for machining.

Mechanical Engineering, Reverse Engineering and 3D Scanning

We are able to make prototypes from drawings, by reverse engineering existing components, or if you have neither drawings nor prototypes, but have an idea, we can help you with the early stages. Re-manufacture your parts through 3D scanning, CAD modeling, improve designs and quickly manufacture your replicas. Our experienced engineers can take your instructions or take over your next project. When we work on your prototypes, accuracy is of the utmost importance. Our team will work with passion and precision to ensure that your prototype is as accurate as possible before it goes into production. And we combine our extensive experience in subtractive manufacturing with state-of-the-art manufacturing processes to create quality prototypes. Our experts always make design suggestions that help our customers reduce manufacturing costs without compromising quality. We help our customers make an easy transition to the production stage.

Service support from prototyping to mass production

At Elimold, we understand the urgency of getting your product to market quickly. With our advanced CNC machining factory capabilities, we provide CNC rapid prototyping services to efficiently meet your needs. Whether you have an existing design or need guidance, our team will work closely with you to create an accurate prototype.

Concept and Feasibility

At Elimold, we are committed to nurturing new product concepts into clear projects with clear milestones and end goals. As a foundational step in the development cycle, our goal is to refine and build these concepts to a manageable scope, ensuring a comprehensive understanding of the purpose and key details of the CNC prototype project.

Prototype Improvement Solutions

Whether you have just completed proof of concept or are about to start the final build, we are ready to assist you in quickly bringing your product to market. When the concept is validated and the specifications begin to take shape, it is time to truly test the feasibility of the product. This stage often involves an iterative process before success can be achieved. By carefully evaluating technology and prioritizing features during these initial stages, we can minimize iterations and ensure efficient mechanical product development.

Perfecting the Details

We leverage insights from the prototyping phase to enhance performance and functionality while incorporating DFM and DFA principles. Our multidisciplinary team scrutinizes every aspect of the project for quality assurance and validation prior to the pre-production phase. These builds are the final dress rehearsal before production, providing the last opportunity for design refinement.

High-Volume Production

During this critical phase, we begin first production, a moment that everyone eagerly awaits. As designs are finalized, drawings are formally released, and configuration control is put into place, our priority is to maintain best-in-class quality standards. With production volumes ramped up and quality controls in place, projects are moving toward a major milestone in their journey toward high-volume production.

Adequate communication ensures efficient cooperation

Developing a new product launch plan is only part of the challenge; no matter what your industry is, finding a capable prototype CNC machining contract manufacturer is equally important because timing is critical in new product development, especially in prototype CNC machining, CNC machine shops vary greatly, and it is difficult to find the best shop for CNC prototype machining. To ensure that you choose the best partner for your project, please consider answering the following questions when consulting us to ensure project success.

- What is the intended application of this component?

- What purpose does this component serve?

- What is the urgency of the component’s requirement?

- Has the component been designed for efficient manufacturing and assembly?

- Is the product easily scalable for mass production?

- What will be the volume of production batches?

- Are any revisions needed for the technical drawings?

- Can the design of the product be further enhanced for efficiency?

Comprehensive Design Services for Your CNC Prototype

With an unmatched combination of experienced technicians and top-notch customer service, we have solidified ourselves as a leader in our field, consistently delivering exceptional results for businesses and manufacturers, no matter the requirements of the project. Whether you need to produce complex geometries or have a simpler task at hand, we pay equal attention to detail and precision to achieve outstanding results. For precise prototyping of products or components, our CNC prototyping technology is the best production method, as its advanced technology strictly adheres to design guidelines and produces parts in a short period of time. CNC prototyping is an ideal choice if the products your company intends to produce have short windows for human error and very specific requirements. With on-demand assistance and unlimited production capacity, you can minimize downtime waiting for components to be completed. Our efficient prototyping and manufacturing services can significantly save you on production costs while accelerating your time to launch. Contact Elimold for a seamless process for developing prototypes for your business.

Ready to start your next CNC prototyping project?

With its domain expertise and problem-solving approach, Elimold has become a leading CNC prototyping service provider to an international client base. Contact us now for a free instant quote.

Benefits of Creating High-Quality CNC Prototypes

Copy Your Actual Product

A CNC prototype can serve as your initial unit. Its purpose is the same as your intended final product.

Understand the technical specifications of your product

A CNC prototype can quickly verify whether your idea meets the production constraints. It can specify the part quality of the final product.

Collect Feedback from Potential Customers at a Lower Cost

You can get feedback from your customers through CNC prototypes to perfect your product.

Enables You to Plan Strategically

CNC prototypes allow you to do markup studies, and you can plan more strategically.

Quickly and Easily Created

Thanks to CNC machining, CNC prototypes can be made very quickly and with high quality.

Allows Quality Assurance and Design Modifications

Once a CNC prototype is made, you can check its quality and make design modifications as needed.

Quality Assurance and Certification

Elimold is committed to providing high quality products and services. We are ISO 9001:2015 certified and have a strong quality management system throughout the organization. And we prioritize thorough inspections throughout the entire production process. Our dedicated Quality Control (QC) team conducts comprehensive inspections at each stage, including material inspections, workmanship inspections, and finished product inspections. All precision machined products we can provide are RoHS-5 or RoHS-6 compliant unless otherwise requested. RoHS compliance certificates are available upon request.

Second-to-None Customer Service

We believe precision is more than just a technique; it’s a commitment to excellence that permeates our entire organization. From the moment you work with our team, you’ll notice our relentless focus on detail, accuracy, and reliability on every project. This ethos drives our ongoing investment in emerging technologies and skilled professionals, continually seeking to stay ahead of industry trends and advancements. You, the customer, are at the center of everything we do, and in addition to creating best-in-class custom CNC prototypes, we are committed to building lasting partnerships based on open communication, transparency, and responsiveness. From initial consultation to project completion, our dedicated team listens to your needs and delivers solutions that align with your vision. We specialize in proactive support, aiming to anticipate your needs and keep you informed every step of the way so that your experience working with us is smooth and enjoyable.

Multiple Material Options

Choosing the right material is an important step in manufacturing your CNC prototype project. Elimold offers a wide range of CNC prototype parts material options to meet different project requirements. The material options we offer include a variety of metal and plastic materials. With our team’s extensive material expertise and focus on quality, we ensure that your CNC prototype parts are manufactured to the highest standards and meet your specific needs.

Metals

- Aluminum

- Steel

- Stainless Steel

- Magnesium

- Titanium

- Zinc

- Brass

- Bronze

- Copper

- Inconel alloy

- Monel alloy

- Hastelloy alloy

Plastics

- ABS

- PC

- PP

- PS

- POM

- PMMA

- PAGF30

- PCGF30

- Teflon

- LDPE

- HDP

- PEEK

Finishing and 2nd Operations

Elimold provides the perfect surface finish for your CNC prototype parts. We offer a range of options. Enhance the aesthetics and functionality of your parts with our professional surface finishing services. Trust us to provide superior quality and attention to detail for your CNC prototype surface finishing needs.

- Anodize

- PAA + BR127

- Powder Coat

- Paint

- Chem Film

- Alodine

- Chromate

- Heat Treating

- Black Oxide

- Zinc Plating

- Polishing

- Bead Blast

- Electropolish

- Gold Plating

- Silver Plating

- Brushing

- Vapor Polish

- Teflon Impregnation

- Park Marking

- Logo Work

- Hardware Installation

Applications of CNC Prototyping

Almost any industry that requires precision machined parts can benefit from CNC prototyping. In most of these industries, there is always a need for a working prototype, or at least a model that can show how the final product will function. CNC prototype parts are widely used across industries because it is often the first choice for functional prototypes that require strength, mechanical stability, or other qualities that additive techniques cannot provide.

- Automotive

- Defense and Military

- Medical

- Aerospace

- Energy & Power

- Electronics & Semiconductors

- Robotics & Automation

- Education

- Industrial Manufacturing

- Research & Development

- Consumer Products

- Agriculture

What is CNC Prototyping?

Prototyping is an effective method of producing high-quality prototypes in small batches using CNC machines. Product designers and engineers often create prototypes for future production runs. The CNC machining process helps create a physical and functional representation of the final part. Therefore, prototyping demonstrates a physical manifestation of the digital design. Manufacturers can easily detect and eliminate design flaws through prototyping before mass production begins. Moreover, eliminating design flaws during the prototyping phase can make production more cost-effective. This technique is essential to the manufacturing industry because it enables them to develop product prototypes and other items that meet specific requirements. While there are other prototyping methods, such as 3D printing, CNC prototyping can use a wider variety of materials. Moreover, this technique is best suited for complex mechanical parts. CNC milling, CNC turning, and CNC screw matching are a few examples of CNC prototyping techniques. Each technique makes full use of computer control technology to produce highly specific and detailed prototypes.

Comparison of CNC Machined Prototypes and Injection Molded Prototypes

While both prototyping methods are designed to provide a visual representation of the final product, they exhibit distinct differences. Part tolerances for injection molded prototypes are typically ±0.1 to 0.7 mm. The limited tolerances are due to material shrinkage after injection molding. In contrast, CNC machined prototypes have an extremely high tolerance level of ±0.01 mm, reflecting the precision and accuracy inherent in the machining process. Compared to injection molded prototypes, CNC prototyping requires no additional tooling. This helps eliminate any initial investment costs and lead times during the new product development phase. The only equipment for CNC milling and turning is the hardened metal cutting blades for the spindle. The various cutting blades and shapes perform different cutting operations on the equipment, but when properly arranged on an automated turntable, these tools can be switched and exchanged in seconds. If you need to produce several prototypes, CNC machining is the most cost-effective option. Compared to injection molding, which can take months to prepare the molds and tolerances, CNC prototype machining can begin immediately within days after the layout and tolerances are determined.

Comparison of CNC Machining Prototypes and 3D Printing Prototypes

While both methods can serve as prototyping methods, they exhibit significant differences in both approach and results. Each method has its own unique advantages, disadvantages, and ideal applications. In terms of material usage, 3D printing stands out for its minimal waste. This is because 3D printing consumes only the necessary material during the manufacturing process. In contrast, CNC machining carves away excess material from the block to obtain the desired shape. Another thing is that CNC machines have excellent accuracy, with tolerances of up to ±0.001 mm. In contrast, advanced 3D printing technology offers a slightly lower tolerance accuracy of ±0.1 mm. In addition, parts produced through CNC prototyping tend to be stronger and more durable than those printed by 3D. However, there are some prototyping projects that can utilize 3D printing for rapid prototyping. One of the benefits of 3D printing for prototyping is that it provides a cost-effective option when you are only looking for a prototype for demonstration purposes.

Elimold's Advantages in CNC Prototyping Services

Flexible Tooling and Design Adaptability

No need for complex tooling. If there is a need to change the shape and size of a part, only the machining program needs to be modified, which is suitable for the development and modification of new products.

Stable Quality and High Precision

Elimiold’s prototype processing is stable in quality, with high machining precision and high repeatability, meeting the processing requirements of high-precision products.

High Production Efficiency

In the case of mass production, our production efficiency is relatively high, which can reduce the time for production preparation, machine tool adjustment, and process inspection.

Complex Surface Machining Capability

Our CNC prototyping service can process complex surfaces that are difficult to handle with conventional methods, and even some processing parts that cannot be observed.

Request Your Free Prototyping Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Prototyping parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.