CNC Swiss Turning Services

At Elimold, we offer professional CNC Swiss turning services, a cutting-edge precision machining process designed to produce small, complex parts with exceptional accuracy and repeatability. Our team of skilled machinists utilizes advanced technology to deliver the highest quality components at an affordable price, making us your preferred supplier of precision CNC Swiss turned parts. Looking for a quote for your next project? Contact us now for a free instant quote.

One-Stop Custom CNC Swiss Turning Contract Manufacturer

Elimold is a one-stop CNC Swiss Turning Contract Manufacturer that provides comprehensive production solutions for your project. We utilize quality-assured internal and external processes to take your product from concept to finished product. We offer the experience and supply chain capabilities to virtually eliminate the need for excessive processing and the associated costs for your project. We are continually expanding our capabilities to provide high-quality products and be a one-stop shop for our valued customers. We have increased our turning capabilities to include high-volume Swiss lathe part manufacturing. Our knowledgeable staff and state-of-the-art machines keep our services at the forefront of the industry. Our in-house Swiss CNC Turning Centers continually invest in the latest CNC Swiss turning machinery and professional talent to meet high-volume orders at competitive prices.

Therefore, with our experienced team of machinists and responsive service, we are able to review initial part specifications and provide design feedback and material considerations to prevent potential manufacturability issues, ensuring you get the best value for your component. Elimold is able to use and source nearly any material specified for your project. Therefore, you can be sure that your customer’s unique specifications and requirements are met and exceeded. This commitment to custom solutions solidifies lasting relationships with customers, as Elimold has become a trusted partner in achieving product excellence.

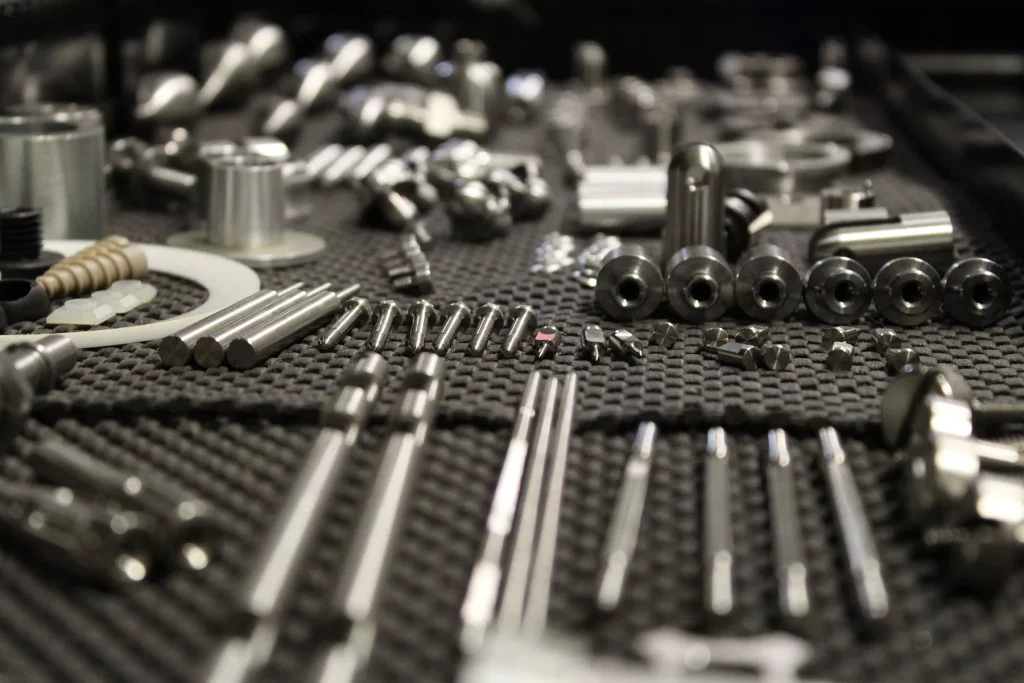

CNC Swiss Turning Capabilities

As a leading global CNC Swiss turning shop, we are passionate about medium to high volume production. That being said, a large part of our success is high mix low volume production and the ability to produce and ship in batches. We do not have minimum order quantities. And we have advanced Swiss machinery and machinists in our in-house shop, and we are constantly investing in the latest CNC Swiss turning machinery to produce high precision parts to your specifications.

We have a variety of Swiss turning styles, from 3 to 16 axis Swiss turning equipment. We also have Swiss turning centers capable of machining parts up to 32 inches long. Our precision micro machining technology is second to none. We machine parts as small as 0.008 inches in diameter and 0.015 inches in length with tolerances of 0.0001. Elimold’s full range CNC machine shop specializes in high precision, efficient Swiss turning solutions. No matter how large your batch is, we can meet your needs, whether you need 250,000 components or just a single prototype.

On-Demand Responsive CNC Swiss Turning Services

Elimold places great emphasis on its unique “Responsive Machining” consulting process, which is the cornerstone of its commitment to providing exceptional precision and accuracy on every Swiss turning project. At the heart of this approach is a thorough review of the design files submitted by the customer. The company’s dedication to responsiveness ensures that each project is meticulously reviewed, ensuring that all specifications are thoroughly understood and incorporated into the machining process. This commitment to the “Responsive Machining” philosophy is designed to benefit customers by not only meeting their expectations, but exceeding them. The iterative nature of the consulting process allows for multiple adjustments and improvements as needed, ensuring that the final product is exactly as the customer specifies. This iterative improvement not only improves the accuracy of the machined parts, but also contributes to significant cost savings on each part. And by actively engaging with customers throughout the Swiss turning project consultation process, Elimold establishes a collaborative environment where feedback is immediate and adjustments are seamlessly integrated. This approach not only streamlines the production process, but also minimizes the potential for errors or misunderstandings, ultimately contributing to a more efficient and cost-effective outcome. Customers can be confident that their project is in capable hands, and that the combination of expertise, responsiveness, and attention to detail will result in high-quality, accurately machined parts.

Custom CNC Swiss Turned Parts Supplier

By seamlessly integrating advanced CNC Swiss Turning technology and equipment, Elimold has become a leading supplier of custom Swiss turned parts. Our dedication to innovation is reflected in its advanced manufacturing processes that produce complex custom Swiss turned parts with exceptional precision and efficiency. Responsive service is the cornerstone of our operations, ensuring that our customers’ unique specifications and requirements are not only met, but exceeded. This commitment to customized solutions solidifies lasting relationships with our customers as Elimold has become a trusted partner in achieving product excellence. Have a truly unique precision requirement? Elimold can adjust the machine to produce your specific part in high volume. We are committed to providing our customers with the highest level of quality and customer satisfaction.

A One-Stop Solution for All Your Precision Swiss Turning Need

As a CNC Swiss Turning shop, Elimold has many years of experience producing high-quality parts. We have been in business for many years and have continuously adapted to the unique needs of the market. Our shop has upgraded advanced Swiss turning equipment, which helps us provide our customers with the highest quality and most accurate parts on the market today. In addition, each of our staff members has been carefully trained to meet all of your unique needs and will work hard to ensure that our processes meet your needs. With our help, you can get the CNC Swiss turning services you need for your parts. And Elimold can provide lights-out and lean manufacturing operations, and use Six Sigma practices to provide first-class and efficient CNC Swiss turning services. We also have reverse engineering, CAD design and CAM programming capabilities. Our goal is to provide you with cost-effective manufacturing solutions that benefit your business. We will work with you to maintain inventory in a way that best suits your operations, easily accommodating Kanban, JIT and integrated orders.

Ready to get started on your next CNC Swiss Turning project?

With our extensive manufacturing capabilities, we are able to reduce lead times and meet the demands of demanding specifications and highly complex parts. And our quality assurance engineers use the latest inspection equipment and training to uphold strict standards and execute to your specifications. Contact us now for a free instant quote.

Certification Standards and Quality Management

Our in-house Swiss Turning facility’s robust quality control system is certified to ISO 9001:2015, AS9100:D, and IATF 16949:2016 standards. We want to provide you with the highest quality parts when we machine your parts, so we inspect every part after every stage of production. We also require first article inspection, in-process inspection via SPC (Statistical Process Control), and final inspection after every process. Parts are inspected before and after any external process to ensure the integrity of your custom parts. We offer a variety of industry-leading quality assurance measures to help you better provide the absolute best results for every part we produce, no matter the size of your project. When you work with our planning and development team, you’ll find that they can work with most file formats and are always available to help you guide you through the setup process for your order. We are also able to meet the most stringent turnaround times. Companies need Swiss turned parts they can trust and a Swiss turning partner they know will help them, help them grow, and get the job done right the first time.

Quality Testing Equipment

Elimold verifies the quality of each part with a series of inspections. We are able to inspect tolerances to 0.0001”. Our quality-control room includes:

- (4) TESA digital height gages

- Micro-Vu CMM

- Beta LaserMike laser micrometer

- Deltronic optical comparator

- Rockwell hardness tester

- Profilometer (surface roughness tester)

Swiss Turning Material Options

We can machine complex and smallest components from a variety of materials. Elimold’s Swiss Turning lathes can produce precision Swiss turned parts using the following materials.

Metals Materials

- Alloy Steels

- Aluminum

- Austenitic Stainless

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Iron

- Lead

- Magnesium

- Martensitic Stainless

- Nickel

- Phosphor Bronze

- Stainless Steel

- Stellite (Hardfacing)

- Tin

- Titanium

- Zinc

Exotic & Precious Metals Materials

- Gold

- Hastelloy™

- Inconel

- Invar

- Iridium

- Kovar™

- Molybdenum

- Monel

- Niobium

- Palladium

- Platinum

- Silver

- Superalloys

- Tantalum

- Ceramic

- Composite Materials

- Fiberglass

- Glass

- Graphite

- Polyester

Plastic Polymers Materials

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal

- Acrylic

- Delrin®

- Fiberglass Reinforced Plastics

- Nylon

- Phenolic

- Polyamide-Imide (Torlon™)

- Polycarbonate (PC)

- Polyetheretherketone (PEEK)

- Polyetherimide (PEI)

- Polyethylene (PE)

- Polyphenylene Sulfide (PPS)

- Polypropylene (PP)

- Polystyrene (PS)

- Polysulphone

- PolyTetraFluoroEthylene (PTFE)

- Polyvinyl Chloride (PVC)

- Polyvinylidene Fluoride (PVDF)

- Ultra-High-Molecular-Weight Polyethylene

Surface Finishing and Secondary Operations

Elimold can also provide a variety of surface finishes and many secondary operations for your custom Swiss turned parts to improve their appearance, function or durability.

- Anodising

- Hard Anodizing

- UV-proof Hard Anodizing

- Chemical Plating

- Deburring

- Electroplating

- Glass Bead Blasting

- Hardening

- Laser Engraving

- Sand Blasting

- Spraying

- Polishing

- Powder Coating

- Welding

- Sub-assembly

- Custom Packaging

Industries Served

The Swiss turning process can be used to manufacture a wide range of standard and custom cylindrical parts such as fittings, screws and shafts. Its precision and accuracy make it ideal for the production of critical components, including industries with stringent quality standards.

- Medical

- Dental

- Automotive

- Aerospace

- Outdoor Recreation

- Plumbing

- HVAC

- Pumps and Valves

- Electrical and Electronics

- Pneumatics and Hydraulics

- Oil and Gas

- Workholding

- Material Handling

- Agricultural Equipment

Application of CNC Swiss Turning Center

Elimold provides Swiss turned components with unmatched precision and reliability. As a trusted partner for custom CNC Swiss turned parts manufacturing, Elimold is committed to providing innovative and cost-effective high-precision Swiss turned parts production solutions that meet your needs.

- Pins and shafts

- Orthopedic implants

- Valves

- Bone screws

- Connectors

- Forceps

- Fittings

- Clamps

- Contact pins

- Springs

- Fuel injectors

- Valves

- Connectors

- Sensors

- Transmission components

- Drive shafts

- Brake components

- Steering system components

- Screws and fasteners

- Watch components

- Hydraulic valves

- Landing gear components

- Shafts

- Connectors and fittings

- Pressure sensors

- Temperature sensorse

- Flow meters

- Terminals

- Shafts and diaphragms

- Standoffs and spacers

Extensive CNC Manufacturing Services

Our precision CNC machine shop’s state-of-the-art equipment not only ensures your precision Swiss turned parts are manufactured quickly and to exacting tolerances, but also offers a wide range of CNC manufacturing services. Elimold has a team of experienced CNC machining professionals who are dedicated to providing you with the highest quality custom CNC manufacturing services.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

What is CNC Swiss Turning?

CNC Swiss Turning is a machining technique developed specifically for producing complex parts with tight tolerances. A Swiss-type lathe differs from a conventional lathe in that it uses a sliding headstock and guide bushings. The sliding headstock allows the workpiece to move along the Z axis while the cutting tool remains stationary, allowing small, complex parts to be machined with precision by supporting the material with the guide bushings throughout the process; this prevents deflection and provides a more controlled, stable environment for machining.

How Does Swiss Screw Machining Differ From Traditional CNC Turning?

Swiss screw machining differs from traditional CNC turning processes in several ways. A key distinguishing feature is the sliding headstock and guide bushing that supports and guides the workpiece. This custom sliding and guiding feature, working in tandem with a collet to secure the workpiece, enhances cutting accuracy, tool accessibility, and reduces cutting vibrations.

Swiss screw machining’s multi-tool capacity also differs from other CNC turning models. Our machine shop can equip multiple tools to shape the workpiece such as drilling, milling, and turning tools, allowing for a range of complex part dimensions to be shaped in a single run.

Advantages of Swiss Turning Processes

Swiss turning offers many advantages over other machining and manufacturing processes.

Greater Design Versatility

Swiss turning machines can make components that would be too expensive or impossible to make with traditional machining and manufacturing techniques, such as very small or complex screws with multiple surface features. In Swiss turning operations, the distance between the workpiece support and the cut is minimal, which results in less workpiece bending and cut surface deflection. This process quality enables manufacturers to achieve tighter tolerances in machined components.

Wider Material Applicability

The Swiss turning process is applicable to a wide range of metallic and non-metallic materials, all of which can be formed with extremely high precision. In addition, the same machine can be configured and reconfigured to machine different materials depending on part and production specifications. This versatility allows customers to be selective with their material choices and choose the material that best suits their project.

Greater Production Efficiency (High Volume)

Once configured and loaded, Swiss turning machines can run automatically, minimizing operator involvement. Because the machine can contain multiple spindles and cutting tools, a single pass is often sufficient to make near-net components. The Swiss turning process allows for high-volume production of precision components, often with little to no secondary finishing required.

Higher Levels of Control

Swiss turning machines can incorporate a variety of cutting tools to perform different machining operations and achieve different elements on the workpiece. While the Swiss turning process itself allows for the manufacture of precision parts and products, integrating CNC technology into the equipment enables manufacturers to achieve tighter tolerances and reduce the potential for production errors.

Request Your Free CNC Swiss Turning Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Swiss Turning parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.