CNC Turning Services

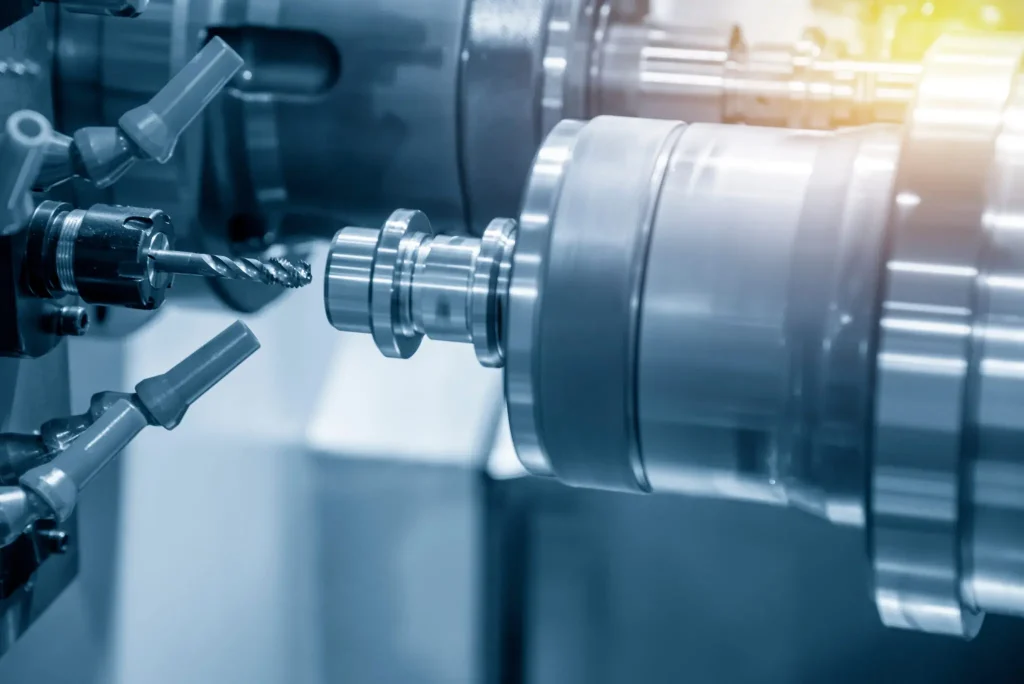

Elimold offers affordable CNC turning solutions and custom turned parts. Hundreds of lathes, Swiss lathes, and multi-axis milling machines. 50+ metal and plastic materials. 30+ surface finishes. Tolerances as low as ±.005″. Get quotes and free design analysis within hours.

Fast CNC Turned Parts Supplier

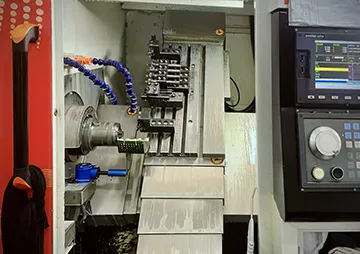

Are you looking for a reliable and fast CNC turned parts supplier? As a leading CNC turning supplier, Elimold offers a wide range of options. Our superior CNC turning capabilities help customers reduce production downtime and provide a reliable supply of parts.

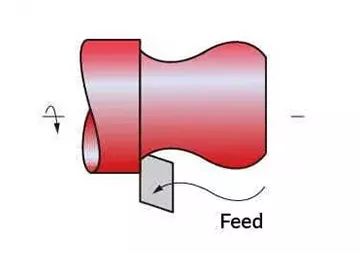

The equipment in our in-house facility is designed for high productivity and integrates the latest engineering software. We can machine parts up to 48 inches long while meeting ultra-tight tolerances. Our high-performance turning centers can be used to flexibly machine block, shaft and bar stock parts. We are committed to providing first-class CNC services to help you create your most complex products!

Start Your CNC Turning Project

In recent years, Elimold has invested heavily in our CNC turning services. This has enabled us to update our equipment and maintain our high standards. The latest automation solutions provide flexibility in our advanced manufacturing centres, enabling us to increase capacity and provide custom solutions to our customers. Our CNC turning capabilities cater to both short and long run production needs, serving a wide range of industries and are able to process a wide range of different materials, sizes and complexities to meet the most stringent requirements. Upload a CAD file and get instant quotes, lead times and DFM details for your CNC turned components. We specialise in CNC turning of metals and plastics, offering flexible production and shipping solutions to meet your product development needs.

CNC Turning With Elimold

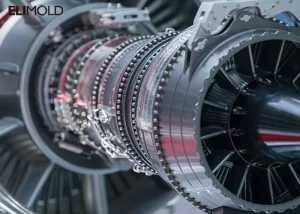

In the fast-paced manufacturing industry, precision and efficiency are critical. Elimold’s advanced CNC turning services are always at the forefront, providing unmatched turning accuracy and speed. We utilize the most advanced technology to deliver parts that meet the most stringent industry standards.

Quick Estimates

Reliable Quality

Fast Production

Engineering Support

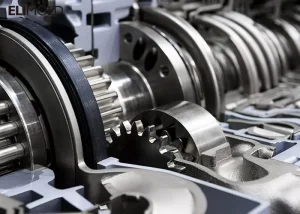

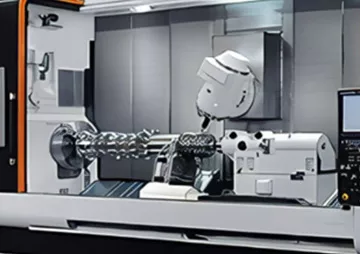

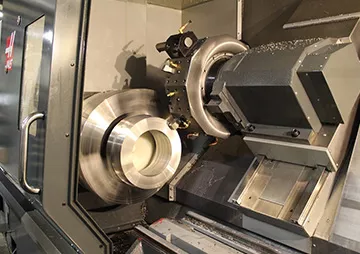

CNC Turning Factory

We have over 100 CNC and conventional machines of various types and an experienced team of skilled machinists who bring years of expertise to every project. From our engineering staff to our dedicated in-house tool design and manufacturing to our 200,000 square feet of manufacturing space with cutting-edge equipment, Elimold has the experience and capabilities to provide you with precision CNC turned parts. Our advanced equipment and state-of-the-art CNC machining technology allow Eliomld to produce tens or even tens of thousands of identical parts in a short period of time, even to the most demanding specifications. Our comprehensive quality management system enables us to complete each turned parts project in the most efficient manner, from prototyping to final shipment.

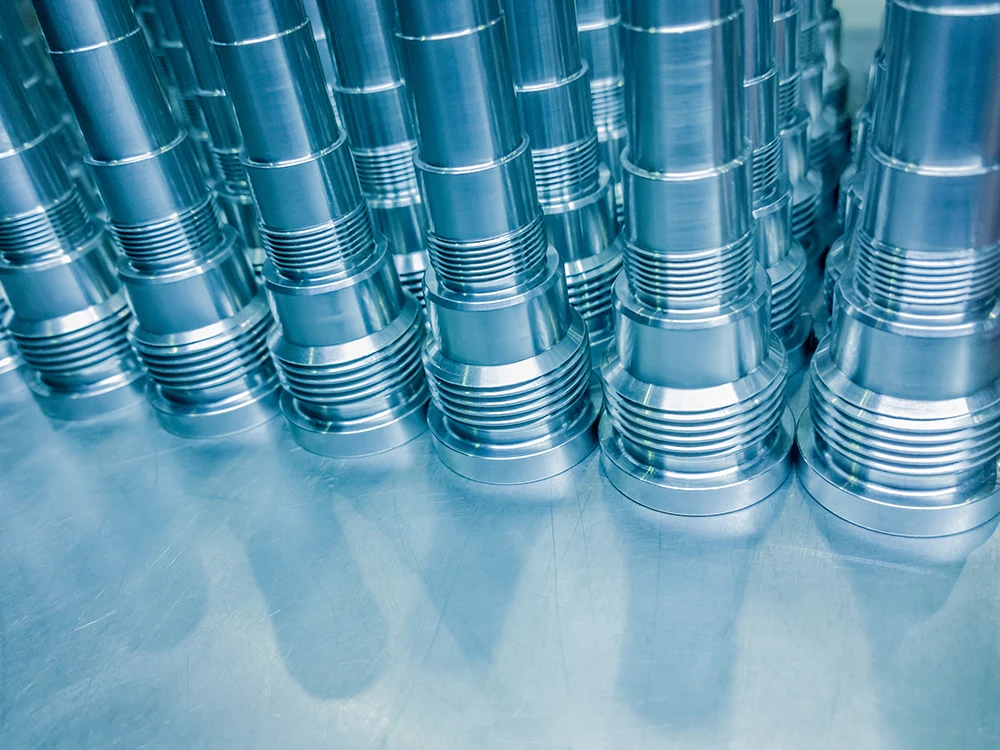

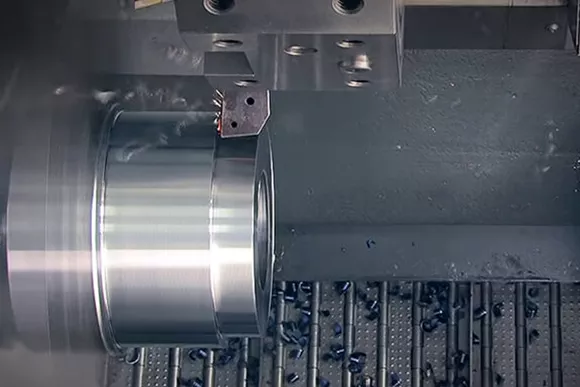

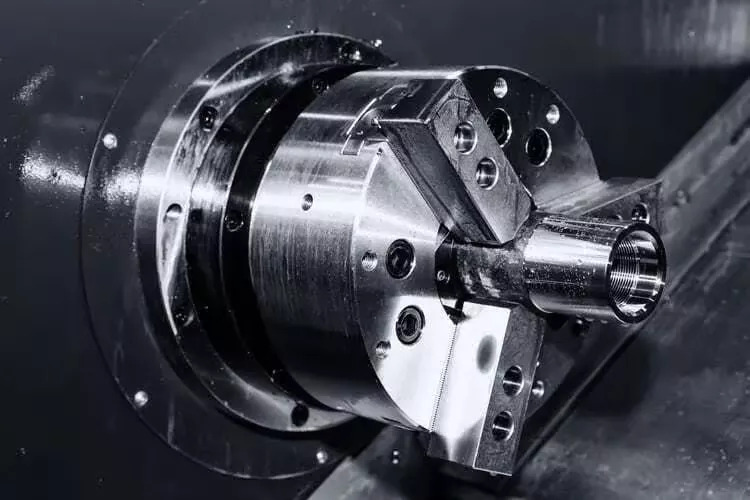

CNC Turning Capabilities

We use advanced CNC lathes to produce metal or plastic turned parts with tight tolerances for a variety of applications in a variety of industries. We can machine parts up to 12 inches (304.8 mm) in diameter, or up to 3 inches (76.2 mm) if we use a through-spindle configuration with a bar feed for automatic loading. We can machine parts up to 18 inches (457.2 mm) in length. Depending on the application, we can maintain turning tolerances of +/- .0002 throughout the entire process. We are also able to machine surfaces and planes to tolerances of ±0.0005 inches, as well as feature locations and contours to ±0.0005 inches. We can accurately replicate even the most complex or delicate part designs with perfect repeatability from the first piece to the 100,000th piece.

Tolerance Standards for CNC Turning

As an ISO 9001 certified company, we machine CNC lathe parts to exacting tolerances. Depending on your design, our CNC lathe parts can be manufactured to tolerances up to ±0.005 inches. Our standard tolerances for CNC milled metals are in accordance with ISO 2768-m and plastics are in accordance with ISO 2768-c. Whether it is a general application or a high-end product, our CNC turning services ensure that each part meets your precise specifications.

Depending on the machining process, Elimold can accept parts up to 48 inches in length. If you have a larger part, please contact our team. Also note that the tolerances listed here are ideal minimums and looser tolerances may be required depending on the process, material selection or part geometry.

CNC Turning Manufacturing for Every Stage

Manufacture precision turned parts according to your project needs, covering the production of small to large parts. With advanced technology and professional technicians, as well as customized personalized products and fast manufacturing cycle, Elimold is your trusted CNC turning service provider.

Rapid Prototyping

Bridge Production

On-Demand Production

On-Demand CNC Turning Services

Get reliable metal and plastic turned parts for your unique projects with On-Demand CNC Turning Services. Elimold’s team of dedicated technicians uses precision equipment to produce high-quality custom prototypes and end-use production parts based on your CAD or other digital design files. Our On-Demand Manufacturing services offer flexible production quantities to meet your specific needs. Whether you need low-volume or high-volume production, we have you covered. Even if you need to machine tens, hundreds, or even more parts, we have you covered. With our own facility’s nonstop production capabilities, including “lights-out” production with automated CNC technology, we also offer production services 24/6. Contact us today to learn more about our capabilities and how our team can manage the production of your custom turned parts.

Ready to get started on your CNC turning quote?

Design your next complex machined component with Elimold today. Our engineering department can help create a production plan that is best suited for your application needs and time-sensitive requirements. Contact us now, and start your project today.

From Prototype to Production

Whether you need a prototype for initial testing or full-scale production, our CNC turning services can meet your needs. Our efficient processes and advanced equipment allow us to seamlessly transition from prototyping to production without compromising quality. Whether you are a startup launching your first product or a global manufacturer in need of a reliable partner, Elimold can provide expert engineering, fast turnaround, and competitive pricing for your CNC turning project. With our best-in-class equipment, technicians, and support team, we are able to deliver high-quality products quickly, reduce lead times, and always go the extra mile for our customers. Contact us today to learn more in person.

Types of CNC Turning Services We Provide

As a leader in precision manufacturing, we offer a range of manufacturing solutions that support rapid prototyping as well as low-volume and high-volume production needs. Our expertise ensures efficient delivery of complex, high-quality parts with unmatched accuracy, speed and reliability.

Standard CNC Turning

Multi-Axis CNC Turning

Mill-Turn Machining

Swiss-Type Turning

Large CNC Turning Services

CNC Lathe Services

Complete Turnkey Turned Product Development Solutions

Which service do you need? There may be other specifications and issues to consider when deciding on a specific CNC turning process, and if you are not sure, Elimold’s consulting professionals can help you determine which method is right for you and your business. With over 20 years of experience, our CNC turning capabilities enable us to provide turned parts of consistent quality. In addition, Elimold has a temperature and humidity controlled workshop and uses only the finest machine tools and imported cutting tools. Of course, each step is carefully inspected to ensure that it meets your specifications. Our complete in-house manufacturing and finishing services further improve your CNC turned parts. We are proud to provide you with a complete turnkey product development solution using precision CNC lathes and turning centers.

Vertical and Horizontal CNC Turning Services

As a leading CNC lathe shop, Elimold offers a full range of vertical CNC turning and horizontal CNC turning services. Our experienced technicians use advanced CNC technology to produce precise and reliable parts tailored to your industry.

CNC Horizontal Turning

CNC Vertical Turning

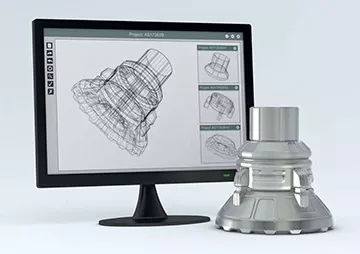

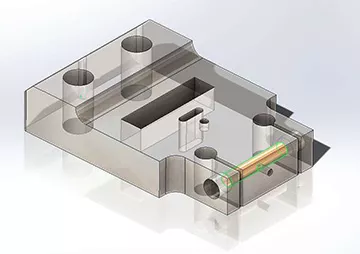

Make to Model and Make to Drawing

We can produce parts based on 2D drawings or 3D models. Our advanced CAD/CAM software ensures that every detail is captured accurately, whether we are working from a detailed 3D model or interpreting a 2D print. However, we understand that some projects may require new, specialized equipment, depending on the size and quantity. We have the resources to procure the most efficient equipment solution for your project. Once the project is confirmed, if a revision of the drawing is required, our team of drawing experts (led by a project manager) will begin processing your technical drawing revision request. Our experts will design your technical drawings using the latest software. We will deliver your technical drawings within 5 working days. If you require further revisions, we will provide revision suggestions until you are satisfied.

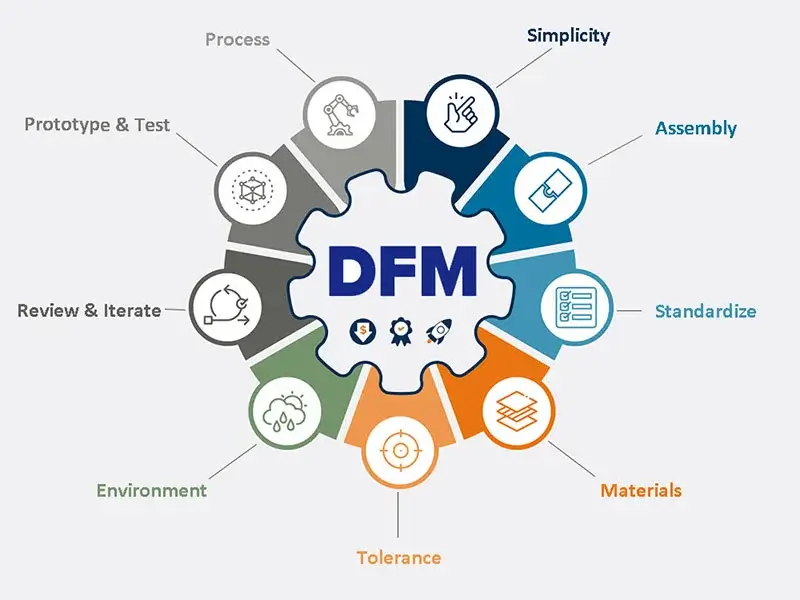

Engineering Support Services

When you work with Elimold, our team of engineers will work closely with you to review and optimize the design of the part to be machined. They may make recommendations for design improvements to improve manufacturability, reduce costs, and enhance performance. This may include adjusting tolerances, selecting the right material, or optimizing geometry to make it easier to CNC machine. If your project requirements are special, our engineers will also help select the material that is best suited for the specific application, taking into account factors such as material strength, durability, weight, and cost. In addition, we will help you perform a tolerance analysis on your project to ensure that the specified tolerances can be achieved during the CNC turning process. The analysis helps define tolerance areas and ensures that the design meets manufacturing capabilities.

Prototyping Phase

If you already have a final design ready for prototyping, that’s great, we’re happy to turn your design into reality. However, if you run into any issues during the design phase of your prototype part, we’re here to help. If needed, we can review your design and provide helpful suggestions for reducing weight, lowering costs, or improving functionality. Over the years, Elimold has worked with a wide variety of materials and assisted numerous industry professionals with their designs. Whether you have a sample, model, drawing, or just an idea, our staff can help you get your prototype ready for machining. We use GibbsCAM, AutoCAD, and Catia software to create all the necessary machining drawings or models.

Design for Manufacturing (DFM) Services Tailored to Your Needs

Our DFM and process development services make it easy to get the precision parts you need. Elimold’s experts can work from your CAD/CAM design or reverse engineer your existing parts using our inspection technology. As needed, we can develop entirely new processes, including automation and support, to help us deliver parts that meet your exact specifications. In our experience, we’ve found that the earlier we get involved in our customers’ development process, the easier it is to find the balance of quality and cost they need. We achieve this balance by meeting your cost targets as efficiently and accurately as possible. Elimold’s DFM services help you produce parts faster, easier, and at a lower cost. Our engineering team will work with you as needed to optimize your design for improved manufacturability without changing the fit, form, or function of the turned part.

CNC Turning Rapid Prototyping Services

Before a product goes from design to production, most customers will typically build a prototype first. Especially for high-volume production, prototype parts can identify any design or performance issues in advance, avoiding expensive rework or even replacing the part later. 3D printing has become a popular choice for prototype parts, but there are still some limitations in terms of available materials and surface finish. Prototyping allows test parts to be made from the same material as the final production product, which makes them more suitable for any physical testing that may be required. At Elimold, we closely follow the development of 3D printing technology. We always strive to stay ahead of the curve and provide the best solutions for our customers.

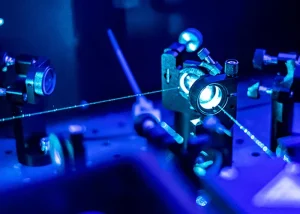

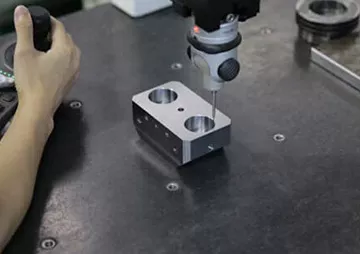

Our Quality Inspection Equipment

Elimold has a strict quality control system to ensure that all products meet customer requirements. Before delivery, we will conduct comprehensive tests on customer products to ensure that they meet the specifications, including dimensional accuracy, surface finish, hardness and precision. We use computer measurement equipment to verify key dimensions to ensure that every product we produce is of the highest quality. Our smart oscilloscope vision system and Zeiss coordinate measuring machine (CMM) ensure that all parts meet the strictest precision machining tolerances. We have a full-time quality team trained in geometric tolerancing, drawing reading and inspection equipment use, and maintain the latest calibration systems to ensure that all machinery and inspection equipment are operating properly. Our commitment to quality ensures that every customer receives products on time, with the highest accuracy and in accordance with their requirements.

Quality and Process Control

Our quality control team inspects parts throughout the production process to ensure they meet customer specifications. Our ISO 9001:2015 certified quality system maintains consistent standards from first article to volume production. Documentation includes material traceability, inspection reports, and First Article Inspection Reports (FAIR) upon customer request. A comprehensive quality management process demonstrates our commitment to robust, repeatable processes, continuous improvement, and documented quality assurance. Quality control is more than just the last step. Our dedicated team performs in-process inspections throughout production, verifying key characteristics and ensuring consistency from first to final part.

One-Stop CNC Turning Services

We offer a one-stop CNC turning service for all your machining needs. We pride ourselves on offering a wide range of machining services that can cater to projects of any size and complexity. Whether you require precision parts for a small project or large industrial production, we have the capabilities and expertise to meet your needs. Our Advantages In addition to our in-house facility, we have a large network of local suppliers that are rigorously vetted to ensure the highest quality and reliability. This network enables us to efficiently source materials, components and services to provide you with cost-effective solutions without compromising quality.

Ready for Your Project with A Free Quote?

Get top-quality CNC turned parts with unmatched accuracy, speed, and reliability. Upload your design files for a free quote and experience fast, hassle-free production. Our expert team ensures precise prototyping and superior craftsmanship for both prototypes and large-scale manufacturing. Start your project today with seamless ordering and on-time delivery!

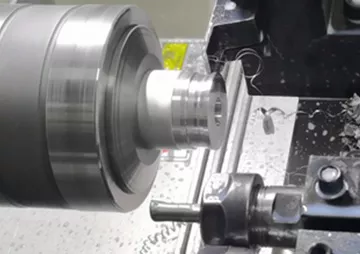

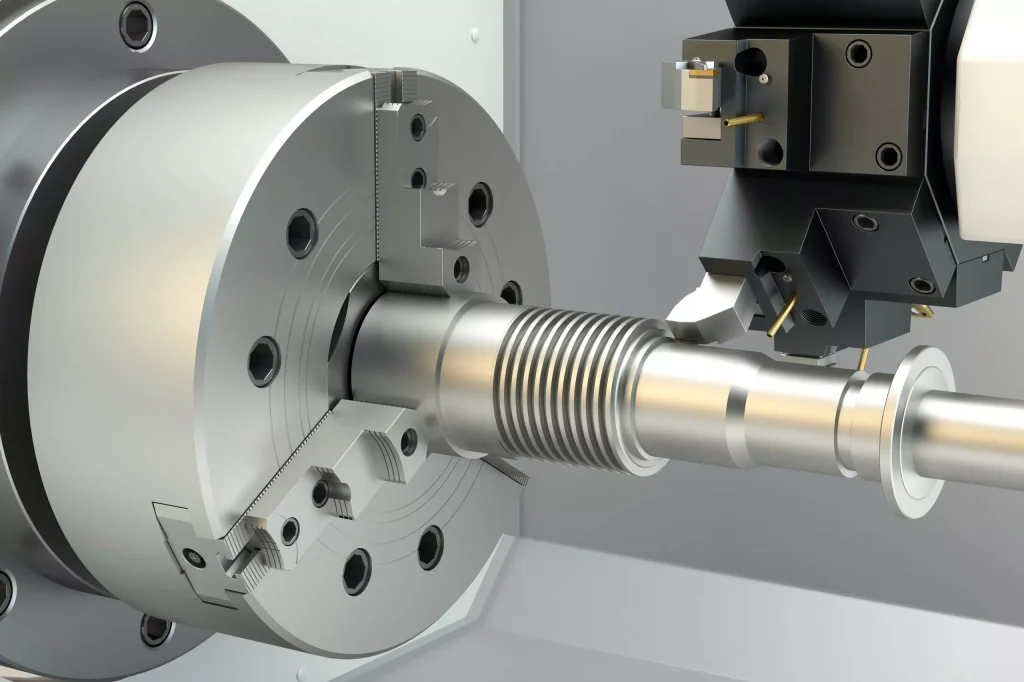

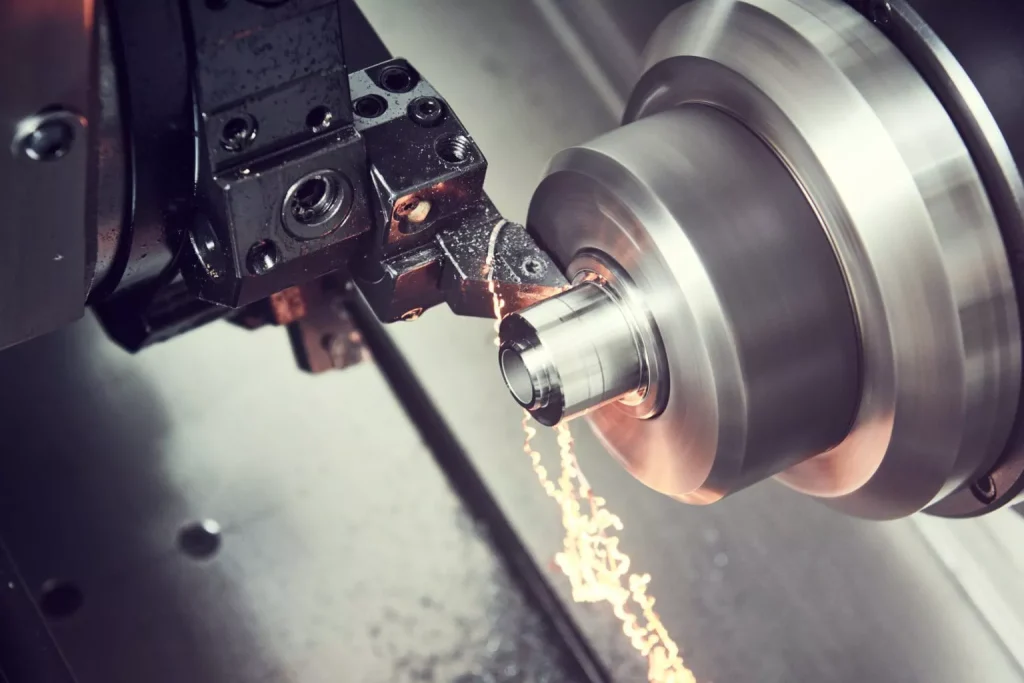

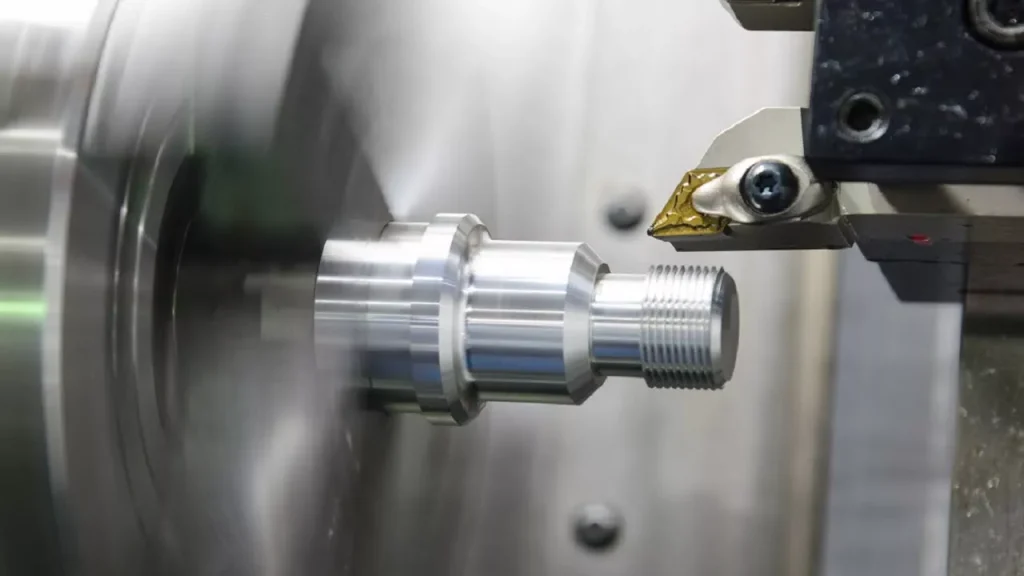

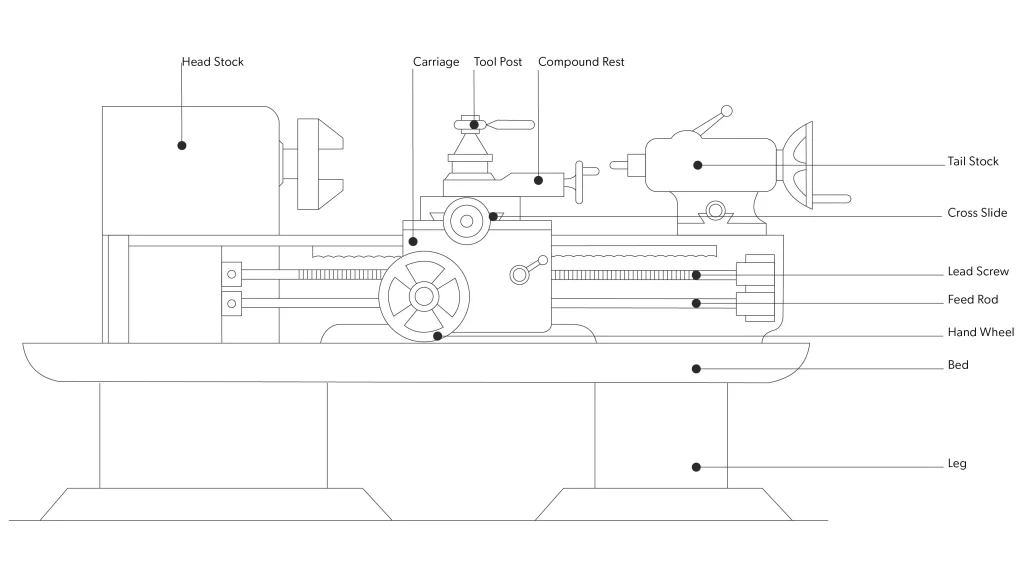

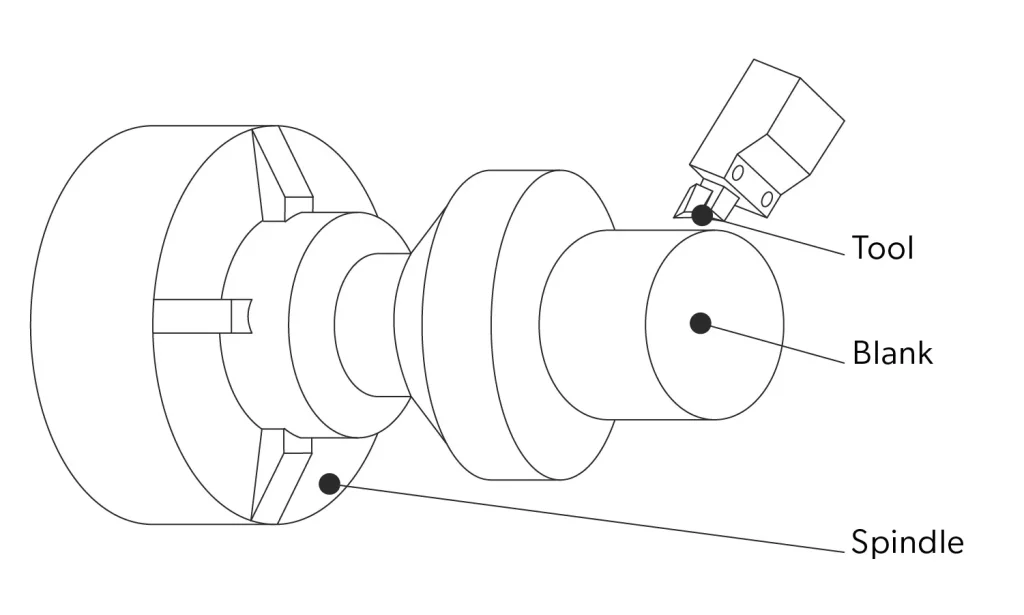

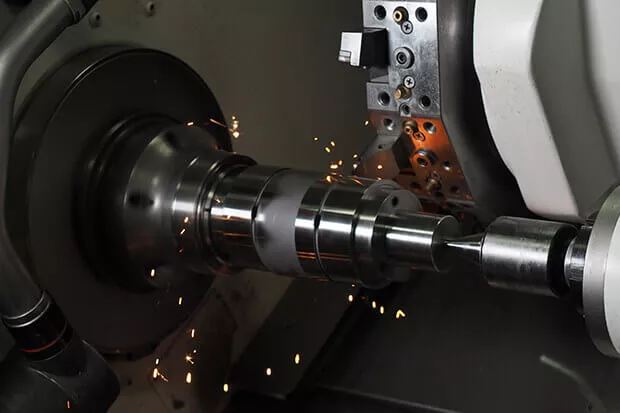

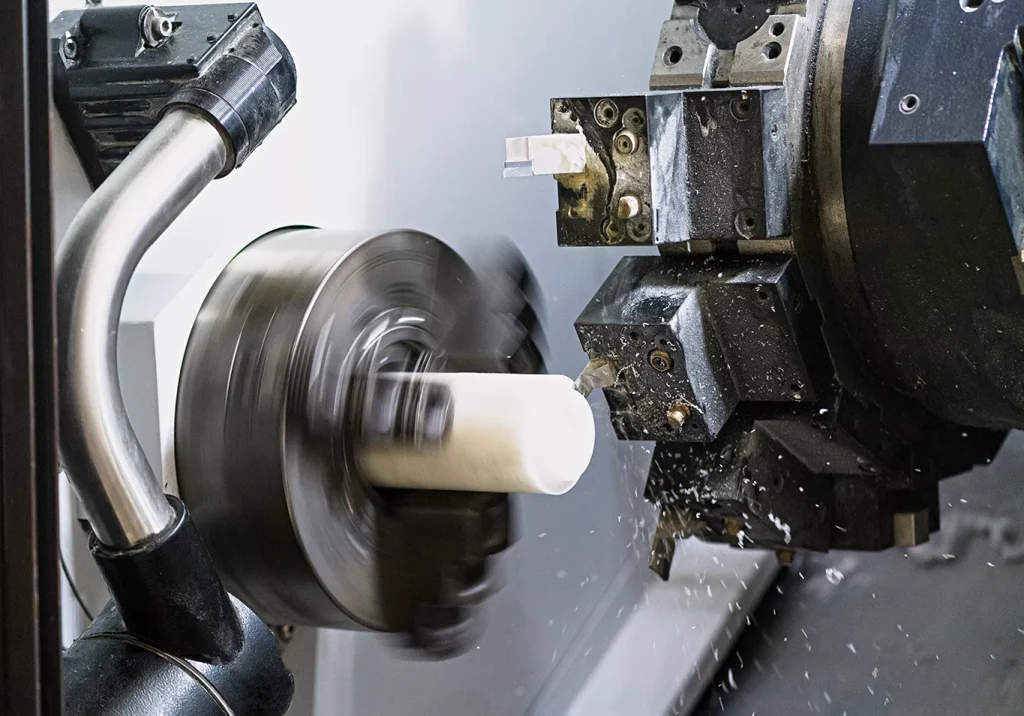

What is CNC Turning?

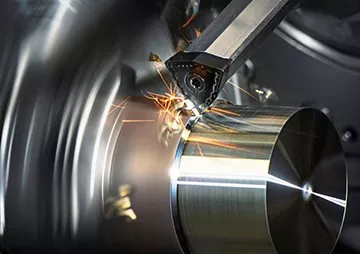

CNC lathes, also known as powered lathes, are ideal for cutting any symmetrical cylindrical or spherical parts. Characteristically, the lathe rotates the workpiece on a vertical or horizontal axis while a fixed forming tool moves around the workpiece in a more or less linear path. The operation of cutting a workpiece on a CNC lathe is called turning.CNC lathes use a subtractive approach to create the desired shape. After the G-code is created, a blank piece of stock material is loaded into the chuck of the lathe spindle. The chuck holds the workpiece in place while the spindle rotates. When the spindle reaches a rotational speed, the fixed cutting tool engages the workpiece to remove material until the desired geometry is achieved.Many operations can be performed on a powered lathe, including facing, thread turning, knurling, drilling, boring, reaming, and taper turning. Different operations require tool changes, which increases costs and setup time.When all machining operations are completed, the part is cut from the stock for further post-processing. The CNC lathe can then repeat the operation with virtually no setup time in between.

How does CNC turning work?

CNC turning is a manufacturing process in which a stationary cutting tool removes material from a rotating workpiece, shaping it into a cylindrical, symmetrical object. The process is performed using a computer-controlled machine tool, known as a CNC lathe or turning center. The CNC lathe then moves the cutting tool along the workpiece according to the shape and dimensions programmed into its software. The CNC turning process typically begins with the raw material being secured to the lathe spindle, which spins the material at high speeds. The cutting tool removes small amounts of material until the desired shape and size are achieved. The removed material is known as chips and is cleared by the machine tool. Once the turning process is complete, the finished machined part is inspected and any necessary finishing or polishing is completed.

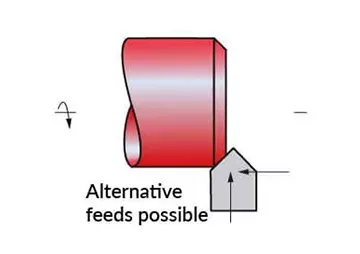

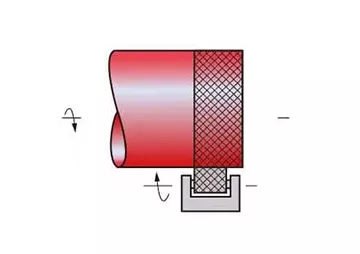

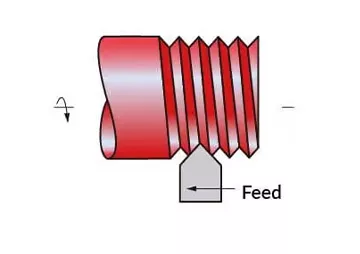

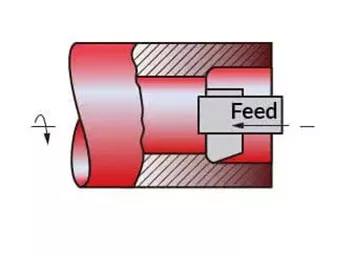

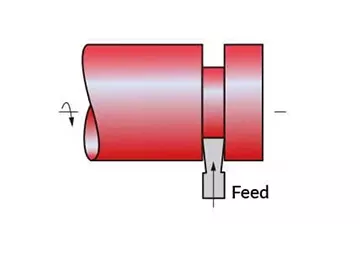

Basic Types of CNC Turning Processes

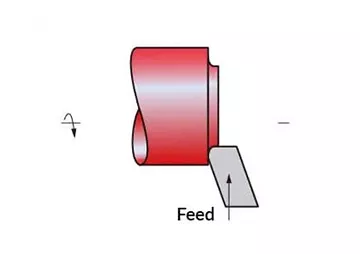

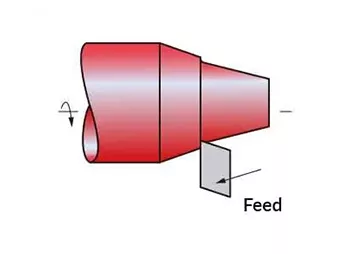

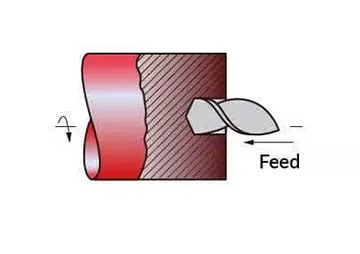

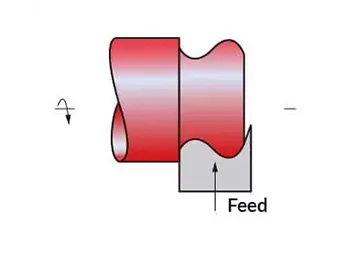

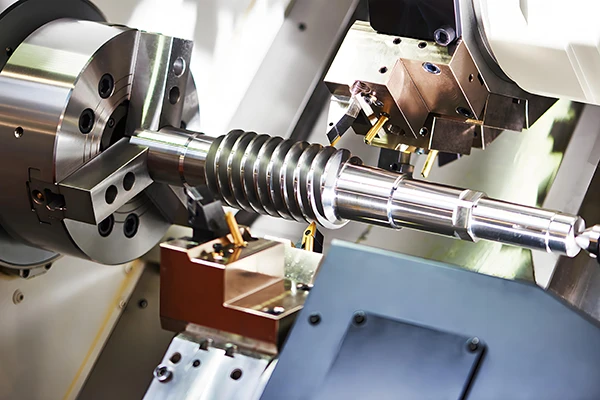

Turning processes have a wide range of applications and can complete various types of surface processing for internal and external rotating bodies, such as external turning, internal turning, conical turning, cutting and grooving, facing, boring, reaming, drilling, knurling, threading, etc.

Facing

Taper Turning

Drilling

Form Turning

Chamfering

Knurling

Threading

Boring

Cutoff

Contour Turning

Benefits of CNC Turning Services

Fast & Efficient Production

These machines can run 24 hours a day, seven days a week without human supervision, while maintaining a high degree of accuracy.

Quick Production Changes

Changing over from the production of one part to another only requires the loading of a new CNC program. Many CNC machines are equipped with a rotating carousel that can carry multiple tools. This enables it to automatically switch tools during milling and machining processes.

Cost-Effective Production of Prototype Parts

Because CNC turning machines can process parts quickly, they can be used to cost-effectively produce small numbers of metal and plastic prototype parts.

Reduced Production Costs

Compared to manual turning, CNC turning provides efficient, scalable production while minimizing material waste. These factors result in the cost-effective production of parts.

Complex Parts

Swiss turning can be used to produce small, intricate parts quickly, with tight tolerances. Because of their guide bushing system, Swiss lathes can process long, slender parts and cut intricate details more effectively than conventional CNC lathes.

Extremely Tight Tolerances

Swiss CNC machines firmly support the workpiece adjacent to the point of operation throughout the machining process. Because the piece is supported so close to the tooling operation, the part remains steady, virtually unaffected by the force of the tools. This ensures precision within extremely tight tolerances—even when machining very small parts.

Improved Surface Finishes

Swiss lathes usually operate at higher RPMs with no vibration. This enables faster machining times and improved surface finishes.

Eliminate Secondary Operations

Swiss turning lathes can mill, drill, ream, saw and do many other operations, eliminating the need to do them separately as secondary operations.

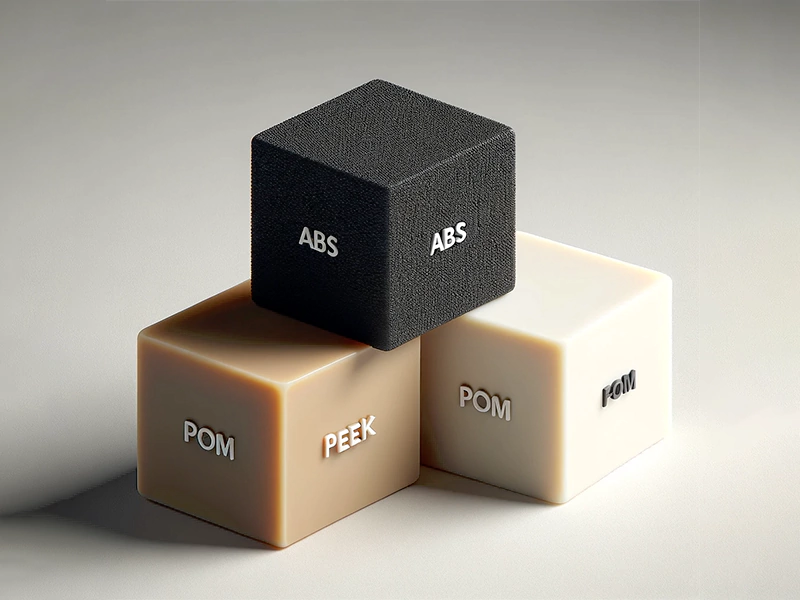

Turning Material Options

Our CNC turning processes are suitable for a wide range of materials, including machine-grade metals and plastics. Whether you need precision turned aluminum or other materials, we can produce accurate rapid prototypes and low-volume production to meet your needs. Check out some common materials for your CNC turning projects. If your project requires a material that is not listed, let us know! We can accommodate other material needs, but quotes may take more time while we source the materials.

Metals

- 18-8 Stainless Steel

- 300 Stainless Steel

- 416 Stainless Steel

- 440C Stainless Steel

- A2 Tool steel

- AISI 303

- AISI 304

- Alumina

- Aluminum 355

- ANMA

- Boron Nitride

- Elgiloy

- EN 10130

- FKM

- Garolite G-10

- Hastelloy C276

- Lennite

- M303E

- PAI

- ST37

- Stainless 301

- Stainless 304

- Stainless 304 L

- Stainless 316

- Stainless 316-L

- Stainless 904L

- Stainless A268

- Steel Plate A36

- Super Duplex

- Ti-6Al-4V

- Ti-6Al-4V Eli

- Titanium Ti 6Al-4V

- ToughMet

- ToughMet 3 AT110

- ToughMet TS

- Tungsten

- Tungsten Carbide

- Tungsten MT-17C

- Wrought Iron

- Zelux

- Zinc

Plastics

- ABS

- Acrylic

- Chirulen GUR1020

- Chirulen GUR1050

- Clear ESD Acrylic

- Crosslinked UHMW PE GUR1020

- Crosslinked UHMW PE GUR1050

- Delrin

- Delrin 100AF

- Nylon 6

- Nylon 66

- PE

- Peek (Poly-Ether-Ether-Ketone)

- PEEK 450G

- PEEK CF30

- PEI

- PES

- PET

- PFA

- Polycarbonate

- Polypropylene

- POM

- POM Acetal

- POM Delrin

- PP

- PPS

- PPSU

- Propylux

- PTFE

- PVC

- Teflon

- UHMW PE GUR1020

- UHMW PE GUR1050

- Vit E Crosslinked UHMW PE GUR1020

- Vit E Crosslinked UHMW PE GUR1050

- White Delrin

- PMMA

- Polyamide 6 GF30

CNC Turning Surface Treatments

We offer high-quality surface treatment options to enhance the appearance, performance, and durability of your CNC turned parts. Surface treatments can improve corrosion resistance, increase surface hardness, reduce roughness, and help eliminate visible tool marks from the machining process. For surface treatments not listed here, please contact us and we will help you find the right solution for your application.

Metals Post Processing

- As machined

- Smooth machining

- Tumbled

- Plating

- electrophoresis

- Anodizing

- Bead Blasting

- Chromate Coating

- Electroless Nickel Plating

- Part Marking

- Passivation

- Brushed + Electropolishing

- Powder Coating

- Press Fit Hardware

- Silk Screening

- Brushing

- Polishing

- Black Oxide

Plastics Post Processing

- Mold texturing

- Threaded inserts

- Pad printing

- Laser engraving

- Basic assembly

- painting

- electroplated

CNC Turning vs CNC Milling

CNC milling and turning allow users to create patterns and add detail to metals that are impossible to do by hand. However, CNC Milling and CNC Turning are very different processes that usually end up with entirely different results. They both use computer programming to achieve their end results, but the differences lie in the way their finalized parts are created.

For example, CNC milling drills and turns its material along an axis to cut its materials to their specified dimensions. Conversely, CNC turning uses a single-point cutting tool that maintains a parallel insert to cut its intended material. Furthermore, the material is rotated at changing speeds at which the cutting tool traverses to make its specified cylindrical cuts. The form, shape and dimensions of the finalized product will dictate whether CNC milling or CNC turning is appropriate for your given project.

CNC Turning Design Guidelines

Radii

Minimum internal radius of 0.5 mm recommended. Larger radii (up to 3 mm or more) can improve tool access and reduce stress concentrations in the part.

Threads and Tapped Holes

External and internal threads can be precisely cut. Standard thread sizes from M1.6 and larger are feasible. Ensure a minimum thread length of 1.5 times the diameter for stability.

Minumum Wall Thickness

Maintain a minimum wall thickness of 0.8 mm for metals and 1.5 mm for plastics to ensure structural integrity without compromising the machining process.

Text

Engraving should have a minimum character height of 2 mm and a depth of at least 0.5 mm to ensure legibility after machining.

Holes

Minimum hole diameter of 0.5 mm. For deep holes, maintain a diameter to depth ratio of 1:10 to avoid tool deflection and ensure hole quality.

Choosing a CNC Turning Manufacturer for Your Next Project

When choosing a CNC turning manufacturer for your project, it is important to consider the quality of parts it produces, the secondary surface treatments it can withstand, turnaround time, and customer service support. It is important to ensure that the manufacturer is up to date with the latest technology and has the necessary CNC machines to produce the parts you need in a cost-effective and reliable production process. Additionally, it is important to ensure that the manufacturer is experienced in the various types of processing required for your CAD design, such as tooling assembly, raw material procurement, and equipped with CNC mills to accommodate any advanced features. Finally, you should ensure that the cost of the part is within your budget and competitive with other quotes you have received.

Are you looking for an Accurate price for your parts?

Our dedicated experts are ready to review your specifications and provide a detailed evaluation within 4 hours, ensuring all your needs are met.

Does Your Parts Require CNC Turning?

We consider a variety of factors when determining if your part requires CNC turning. These include the number of parts you will need in the short and long term. If you need to produce a large number of parts quickly, a CNC lathe is a good choice. Another factor is the size of the parts needed. Smaller parts can be produced quickly and in succession, but larger parts may require more time and individual processing. Our innovative team is here to guide you through cost-effective design and manufacturing processes. Our goal is 100% customer satisfaction, providing quality machined products that meet quality certifications, resulting in excellent lead times, on-time delivery, and unparalleled customer service.

Custom Contract Turned Part Manufacturing Capabilities

We have custom contract manufacturing capabilities that provide tailor-made solutions to meet the specific needs of your business. With advanced technology and flexible methods, we provide high-quality, cost-effective production services for a wide range of products. And we can provide Kanban programs for JIT (Just in Time) delivery, our dedicated team ensures efficient work, providing customers with the turnaround time they need, and even rush service for your urgent orders. No matter how unique or demanding your project requirements, Elimold always provides you with precision CNC turning services and ensures that the final product meets your exact specifications and delivery deadlines.

Professional CNC Turning Company

In today’s world of groundbreaking R&D and cutting-edge technology, everyone is racing for efficiency to expand the scope of productivity. To stay ahead, Elimold offers CNC rapid prototyping services to manufacture parts quickly and efficiently. Our professional CNC turning services are designed to push boundaries and continue to leverage our regular investment in technology. This means we are able to serve a wide range of applications and industries, reducing costs, raising standards, and providing flexibility and greater capacity through automation. This allows us to provide fully customized solutions to customers seeking CNC turning services. In addition, our commitment to quality, precision and efficiency makes us the first choice for companies in a wide range of industries.

Other CNC Machining Services

Whether you need a small number of parts or more than 10,000 final production objects, CNC machining is the ideal manufacturing method. Below are the various types of customized CNC services we offer.

CNC Milling

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Jig Grinding Services

Are You Ready To Start Your Next CNC Turning Project?

With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file for a free quote, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements.