Copper CNC Machining

Whether you need prototyping or mass production, we can provide high-quality custom copper parts to your specifications. We manufacture exactly to your drawings and specifications. Fast delivery and highly competitive prices.

What is Copper?

Copper is a naturally occurring element. Its bright orange-red appearance is highly recognizable, and even after natural oxidation, forming a bluish-green patina in the environment, it remains aesthetically pleasing. Copper is represented by Cu (atomic number 29) in the periodic table. It is an excellent conductor of electricity and heat, second only to silver in both. Commercially available copper typically has a purity exceeding 99%, with the remaining 1% usually consisting of impurities such as oxygen, lead, or silver. Copper is renowned for its excellent electrical and thermal conductivity. It possesses strong corrosion resistance and is inherently antibacterial. Due to its superior thermal and electrical conductivity, copper is widely used in various electrical applications. In CNC machined copper parts, the raw metal is meticulously sculpted to create the desired shape or object. However, it should be noted that copper generally has poor weldability.

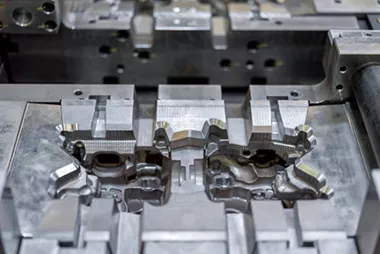

Copper CNC Machining Services

Elimold provides high-quality copper CNC machining services to engineers, manufacturers, and original equipment manufacturers (OEM) worldwide. Our in-house factory utilizes advanced technology and ISO 9001:2015 certified processes to deliver custom copper parts with exceptional precision. Whether you need prototyping or mass production, our copper machining services ensure reliable results. In addition to producing parts in various copper sizes, Elimold also machines parts from other materials such as aluminum, brass, bronze, plastics, and steel.

Copper Grades We Process

At Elimold, we can process copper of various grades. Below are some common copper grades we frequently process, along with their material properties.

Pure Copper (C110, C101, C102)

Pure copper grades C110, C101, and C102 are among the best electrical and thermal conductors. This material exhibits excellent corrosion resistance, making it suitable for a wide range of industrial applications. Its good ductility allows it to be easily machined into various shapes. However, its mechanical properties are lower than many other metals, resulting in poorer resistance to harsh environments. The tensile strength of pure copper (210-310 MPa) is lower than that of brass (340-580 MPa) and bronze (350-690 MPa), limiting its use in structural applications.

Brass (C260, C360, C464)

All brass grades, including C260, C360, and C464, offer excellent machinability and sufficient strength. This material has strong corrosion resistance, making it suitable for a wide range of industrial applications. Brass has lower electrical conductivity than pure copper. Adding zinc enhances the strength of brass, improving its structural durability.

Bronze (C932, C954, C863)

A range of bronze materials, including C932, C954, and C863, possess excellent wear resistance, high strength, and corrosion resistance. This material can withstand harsh application environments such as heavy loads and friction. Bronze’s thermal conductivity is within its range, but its overall efficiency is lower than pure copper. Adding specific elements such as tin, aluminum, or manganese to bronze can enhance its strength, making its wear resistance superior to almost all other copper alloys.

Tellulose Copper (C14500)

C14500 tellurose copper has excellent electrical properties and is easier to machine than ordinary copper. Adding tellurium helps produce higher-quality chips, minimizing tool wear and simplifying material processing. This material has good corrosion resistance, thus performing optimally under a variety of working conditions. The advantages of C14500 material are mainly reflected in its lower conductivity deviation compared to pure copper and its excellent machinability.

Beryllium copper (C17200, C17500)

The C17200 and C17500 series of beryllium copper offer excellent fatigue resistance and high strength, making them ideal for industrial applications. This material exhibits exceptional corrosion resistance, enabling its use in harsh environments. Beryllium copper has a conductivity approximately 20-25% that of pure copper (IACS 22%, compared to 100% for C101), thus making it suitable for specialized applications. Its stress-dependent strength retention makes it ideal for high-performance component applications.

Copper CNC Machining Services for Custom Parts

Our CNC copper machining capabilities encompass 3-axis and 5-axis machining centers, equipped with 24/7 automated operating systems. We support a wide range of part designs, from complex to simple, and offer quick fixture changes to ensure production flexibility. You can trust Elimold with our fast turnaround times, repeatable quality assurance, and clear communication throughout the project. Our copper CNC machining technology produces parts that combine electrical conductivity, strength, and aesthetic appeal. Furthermore, we offer design consulting services to reduce costs and improve manufacturability.

Copper Parts Machining Tolerances

We can provide machined copper parts with tolerances of ±0.0005 inches or higher. Our standard parts typically have tolerances from ±0.05 mm to ±0.1 mm. Custom precision parts have tolerances ranging from ±0.01 mm to ±0.02 mm. Our copper CNC machining technology ensures perfect repeatability from the first part to the last, and we can meet your needs regardless of quantity.

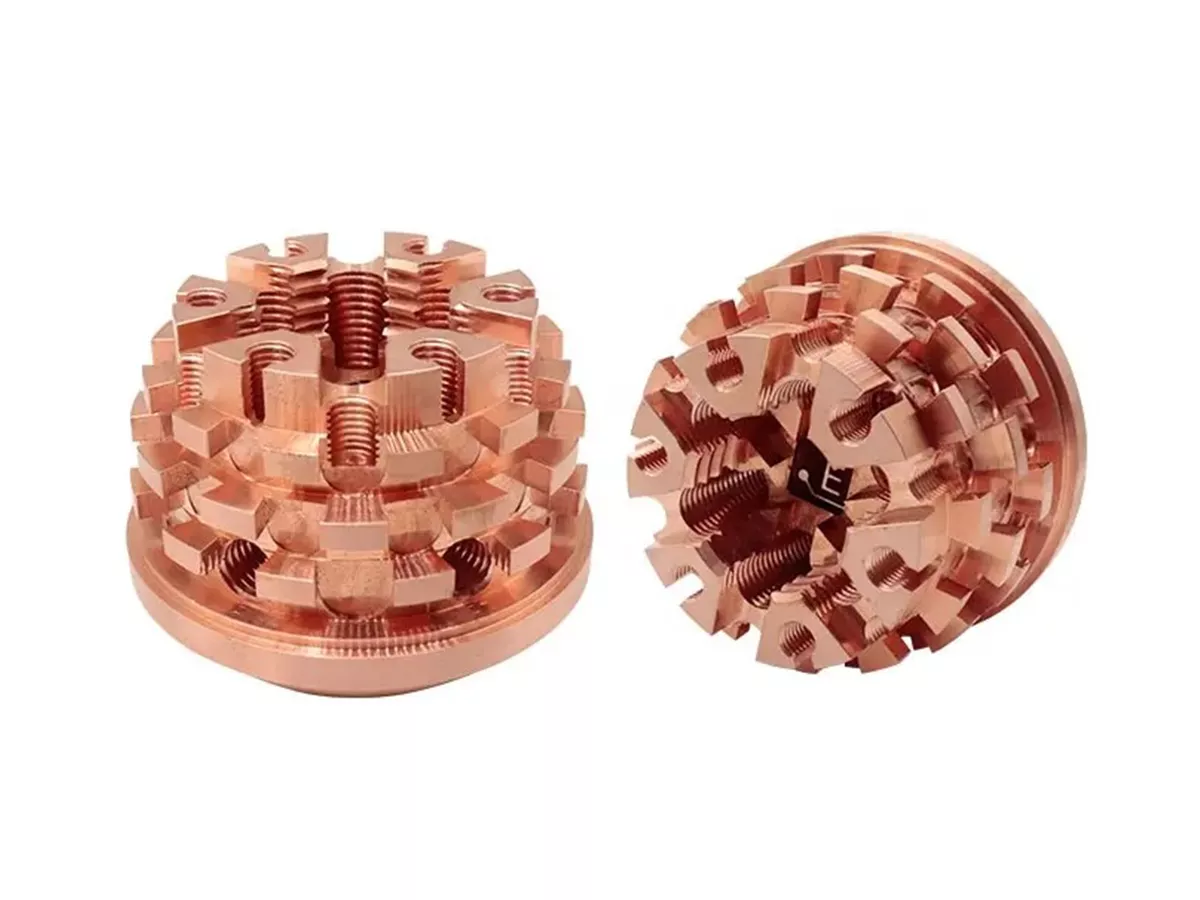

Types of CNC Copper Parts We Produce

Please see some of our recently produced copper parts. These samples demonstrate our expertise in CNC machining of copper, precision tolerances, and high-quality surface treatments. From design to production, each part is custom-made to customer specifications.

Copper Surface Treatment Solutions

Elimold offers comprehensive surface finishing services for custom CNC copper parts, employing various processing techniques to meet the specific needs of diverse applications. This ensures that custom copper parts meet requirements in terms of performance, aesthetics, and durability.

As machined

This option leaves copper with visible tool marks from machining.

Polishing

This option leaves copper with visible tool marks from machining.

Sand Blasting

Sandblasting can be applied to copper to give it a matte or textured finish.

Tumbling

Tumbling smooths and cleans up copper surfaces, leaving a matte finish.

Electropolish

Electropolishing can enhance the surface of copper, giving it a bright, reflective finish and improving corrosion resistance.

Alodine

Though mainly used for aluminum, Alodine can sometimes be applied to copper for light corrosion protection.

Heat Treatment

Heat treatment can alter the appearance of copper through oxidation, giving it different colorations or surface textures.

Black Oxidize

This process can create a darkened surface on copper, offering some protection against oxidation.

Electroless Nickel

This finish is suitable for copper to improve wear resistance and corrosion protection.

Chrome Plating

This process can be applied to copper for a shiny, durable surface finish.

Brushed Finish

Brushing can give copper a textured, matte finish with fine, directional lines.

Our Machining Services

CNC Milling

CNC Turning

Design for Manufacturing

Tailor-made Copper Component Solutions for All Industries

Copper CNC components are widely used in numerous industries and applications. Their excellent thermal and electrical conductivity makes them ideal for high-power electrical applications. The rapidly growing electric vehicle (EV) industry is also increasing the demand for copper CNC components. We can serve the following industries and applications.

Start Your Copper Machining Project with Experts

Project planning requires meticulous preparation and attention to detail. Not only technical aspects but also economics must be considered to ensure the project is efficient and cost-effective. The tasks to be solved must be clearly defined, the methods determined, and a project scope statement developed. Furthermore, it is necessary to select a contractor, evaluating their experience, qualifications, technical equipment, reputation, and past performance.

Elimold provides manufacturing services including cnc machining, turning, and laser cutting. We possess advanced equipment and experienced staff, enabling us to efficiently solve a wide range of complex problems. We understand the importance of completing projects on time and within budget, therefore we provide customized solutions for each project.

Our Other Copper Processing Services

Laser Cutting

Forging

3D Printing

Die Casting

FAQs

We provide certification for materials, dimensions, and surface treatments.

If your parts are anodized, you can paint them.

Most CNC machining orders can be completed within 20 business days after order placement.

Please send us your drawings or requirements, and we will reply with a quotation within 12-24 hours.

Due to its soft texture and high ductility, machining copper can be extremely challenging. This can cause copper to adhere to the cutting tool, resulting in poor surface finish and accelerated tool wear. Therefore, specialized tools and machining techniques are required to achieve optimal machining results.

Costs vary depending on various factors, such as the complexity of the design, the type of copper used, the number of parts, and any additional machining steps required. For a detailed quote, please upload your design files to our quotation platform.

For purely mechanical parts, using ultra-pure copper (such as C101 with a purity of 99.99%) is not cost-effective. However, if conductivity requirements are not high and the machining volume is large, C110 may be a better choice.

Pure copper, such as C101, has excellent electrical conductivity but is softer and more difficult to machine. Copper alloys, such as C110 and C145, offer superior machinability, hardness, and strength while maintaining good electrical conductivity. Material selection depends on the application and required properties.

CNC machining can provide high-quality surface finishes for copper parts, ranging from polishing to improve conductivity to more textured surface treatments to meet aesthetic or functional requirements. Post-processing techniques such as silver or gold plating can further enhance conductivity and prevent oxidation.

Choose Elimold for your copper CNC machining needs

Elimold offers the industry’s most efficient and precise copper machining services with advanced CNC equipment. We pride ourselves on world-class customer service and exceptional technical expertise, advantages few competitors can match. Contact us now for a quote.