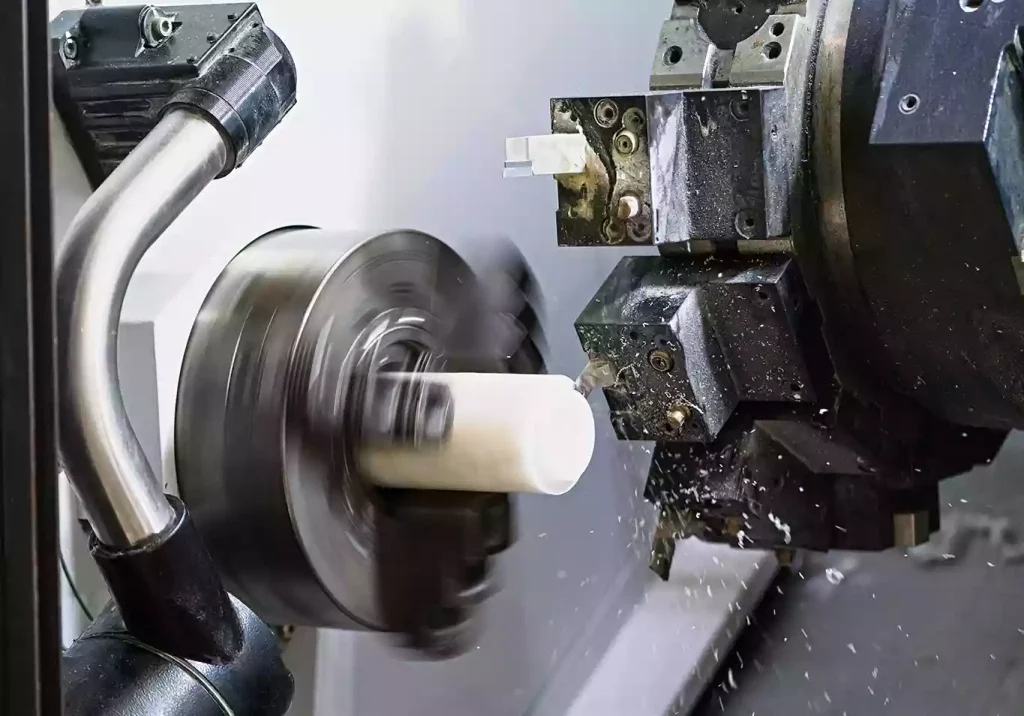

CPVC CNC Machining Services

Elimold has extensive experience in machining CPVC parts, capable of producing to your specifications or assisting you in designing parts to meet your needs. CNC machining and manufacturing of CPVC parts are carried out in a fully controlled environment, with complete product records maintained. We strive for excellence, infusing superior quality into every part we machine. Get a quote now.

Looking for a Professional CPVC CNC Machining Service Provider?

We possess state-of-the-art machinery, a spotless machining workshop, and a professional quality control team, enabling us to achieve superior CPVC CNC machining processes, capable of handling even the most challenging tasks.

What truly sets Elimold apart is our team’s unwavering pursuit of excellence. We are a group of experienced craftsmen, each meticulously refining the quality and craftsmanship of our CPVC CNC machined products. With our ISO-certified machining technology and in-house processing capabilities, we cover a wide range of machining needs, from specialty and traditional materials to complex and standard products.

What is CPVC?

Chlorinated polyvinyl chloride (CPVC) plastic is made by increasing the chlorine content in polyvinyl chloride (PVC) through heating or ultraviolet irradiation. This makes it slightly heavier and more expensive than PVC, but its applications are just as wide. Compared to PVC, CPVC has better ductility and higher resistance to high-temperature corrosion.

Moreover, CPVC’s properties and advantages are basically the same as PVC. CPVC is a high-strength material with excellent corrosion and chemical resistance, high-temperature resistance, low moisture absorption, and good electrical and insulating properties. It also has good flame retardant properties. CPVC has good dimensional strength and compressive strength, is easy to mold, process, and weld, and can achieve high precision.

CPVC Material Properties

Chronicated polyvinyl chloride (CPVC) shares most of the same properties and performance as polyvinyl chloride (PVC).

- It is easy to process, including machining, welding, and molding.

- CPVC exhibits excellent corrosion resistance at high temperatures.

- CPVC can be used at temperatures up to 200°F (93°C).

- CPVC can be bent, molded, and welded.

- CPVC has a wide range of applications in various processing techniques.

- It possesses excellent fire resistance and chemical resistance.

Comprehensive CPVC CNC Part Manufacturing Solutions

Whether you require custom CPVC CNC part design or reverse engineering, our superior service and efficient production ensure timely delivery and high-quality service. In addition to part design and reverse engineering services, Elimold also offers value-added manufacturing solutions such as emergency manufacturing and delivery, rapid prototyping, and low-cost high-volume production services.

Comprehensive Production Support Team

We have a team of experienced manufacturing experts working behind the scenes to fulfill your production orders. We manage the entire process and keep you updated on the latest progress.

Account Manager

Application Engineers

Logistics

Quality Control

Precision CPVC Plastic CNC Machining Services

Elimold is dedicated to setting industry standards in the machining of complex CPVC plastic parts and precision components. We understand the unique challenges of CNC machining and manufacturing plastics that conventional equipment cannot handle. Therefore, with over a decade of expertise in the plastics field, we ensure on-time, high-quality, and compliant solutions. Whether you bring us meticulously designed final drawings or undeveloped concepts, Elimold treats every project with the same critical attention to detail required by our clients.

Elimold: A One-Stop CPVC Parts Manufacturing Solution Provider

When you are designing custom CPVC CNC machined parts or products, contact Elimold. Our staff will assist you throughout the entire lifecycle, from requirements and design, prototyping, fixture manufacturing to final production. We will also suggest improvements to your CPVC CNC part drawings (new or old projects) to facilitate production and installation. Furthermore, even in emergency situations, we can produce, assemble, package, and ship parts on time, making Elimold your one-stop CPVC parts manufacturing solution provider.

Precision CPVC CNC Part Dimension Control

Our advanced CNC machining capabilities allow for precise part machining, maintaining tolerances of ±0.005 inches for critical dimensions and thread depth. Additionally, we possess threading, drilling, grooving, and tapping capabilities, enabling mass production of parts and prototypes.

CPVC CNC Machining Factory

Our in-house CNC machining workshop, located in Shenzhen, China, covers 136,000 square feet and is equipped with over 100 advanced machines of various types, including milling machines, lathes, five-axis machine tools, multi-axis machine tools, Swiss-style machine tools, and engraving machines. Furthermore, after years of development, Elimold’s CNC plastics machining workshop has assembled over 20 precision machining experts.

Comprehensive Quality Management for CPVC Parts

Quality control in CPVC CNC machining is the most critical aspect of our business. It’s more important than metalworking or plastics manufacturing because it’s the only way to ensure your products meet extremely high precision standards. Our team understands that every product we produce is part of a larger whole. Our internal quality management philosophy allows no room for error; every product must be manufactured with unparalleled precision. Large-volume orders undergo quality inspections at the beginning, middle, and end of production.

FAQ

Material selection depends on your fluid chemistry, operating temperature, and pressure requirements. PVDF offers the broadest chemical resistance in corrosive environments. CPVC performs well in chlorinated water and hot water systems. Polypropylene provides cost-effective resistance to common acid and alkali corrosion. Our engineering team will help you select the appropriate material based on your specific application needs.

We machine all common thread standards: NPT (American National Standard Pipe Thread), sizes from 1/8 inch to 4 inches; BSPT (British Standard Pipe Thread); M6 to M48 metric threads; and custom threads to match your existing fittings. Thread depth and pitch are compliant with 2A tolerances to ensure proper seal engagement.

Yes. Our reverse engineering service can obtain your worn or discontinued parts, restore thread specifications and dimensional details, and modify them according to the application environment. We will create CAD documentation and machine an identical replacement part.

Get Quote For Your Next CPVC Project

Ready to bring your design to life? Elimold makes it easy to get started. Share your project details and our team will work closely with you.