Die Casting Services

Elimold’s die casting services are ideal for producing nonferrous metal products with high throughput, cost-effectiveness, and flexible design options. Our advanced equipment is capable of handling a wide range of designs and materials, ensuring custom, high-quality parts for a variety of industries. Get custom die cast metal parts, delivered fast. Request a quote today to get started today.

Professional Die Casting Service Provider

When looking to quickly mass produce parts without sacrificing detail and surface quality, die casting is the perfect manufacturing choice. Elimold leverages our comprehensive manufacturing capabilities to handle your project, allowing us to quickly produce any part and advance your project from prototype to production quickly and efficiently. With Elimold for your die casting services, you’ll have the support of an industry innovator and leader in die casting manufacturing services. No matter where you need your parts, our dedicated team of engineers and in-house network of facilities can serve you quickly and efficiently. Getting a quote for your custom die casting project from Elimold is now just a few clicks away, allowing you to easily and confidently start your project, backed by our commitment to high quality and fast delivery.

Full-Service Die Casting Manufacturer

Elimold is a full-service, one-stop die casting manufacturer that offers a variety of die casting processes to produce precision custom die castings. Our management and engineering teams have over 20 years of experience in die casting manufacturing, providing services from engineering design, prototyping, mold making, mass production to machining, surface treatment and final assembly. All processes are completed by our professional in-house die casting equipment, so we are able to produce high-quality products that we are proud of. We are more than just a die casting service provider, we are committed to being your true product development partner. When you work with the Elimold team, we will fully demonstrate our professional service and commitment to meet or even exceed your expectations of a die casting manufacturer.

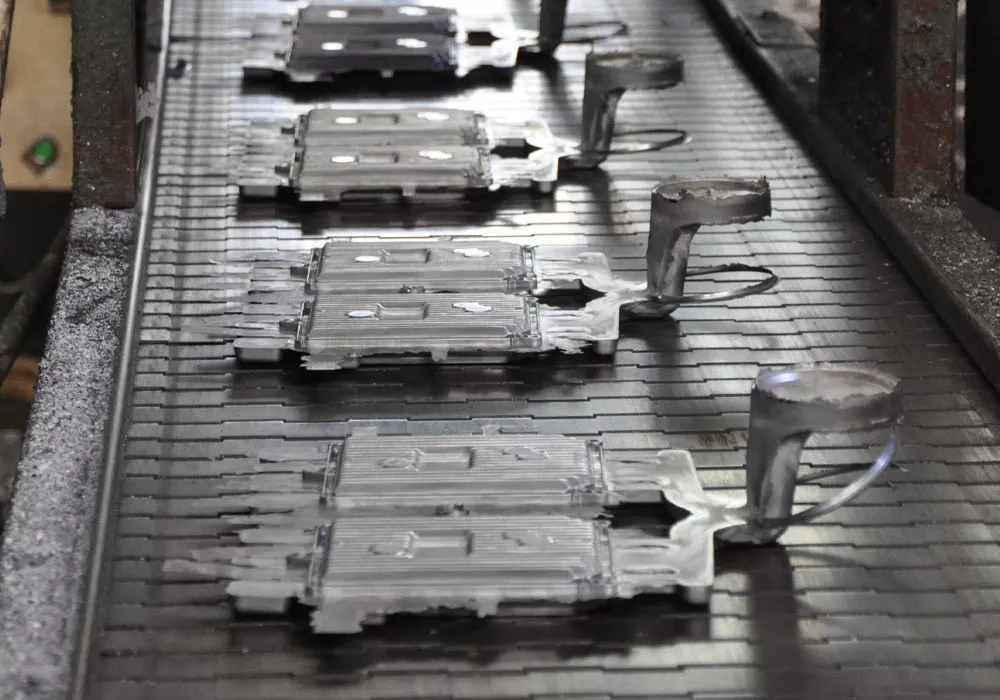

Elimold's In-House Die Casting Facility

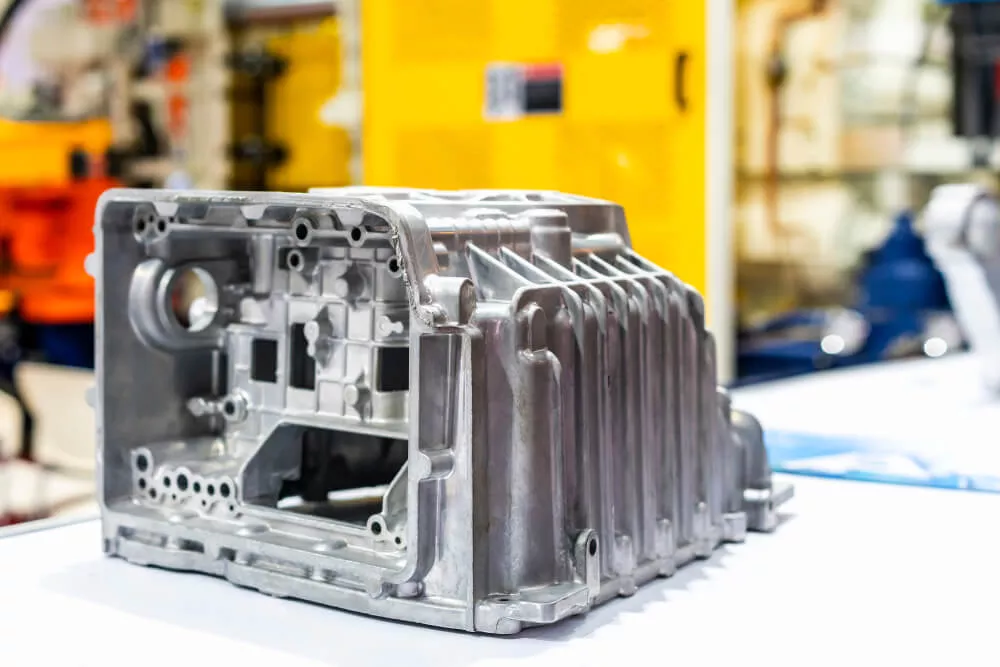

Elimold’s in-house die casting facility has the scale and experience to provide you with the highest quality parts. Our complete parts system includes casting, machining and finishing, all from a single source. We produce complex, high-quality die castings for a wide range of industries at competitive prices and on-time delivery. With over 100,000 square feet of production space, our in-house facility has large casting and CNC machining capabilities. Elimold’s dedicated team can meet your needs from project management, initial tooling and manufacturability planning, to production, finishing, assembly, and inventory management using a Kanban system. Partner with Elimold to help you create the precision parts you desire! Contact us to discuss your custom die casting part needs.

Die Casting Equipment & Capabilities

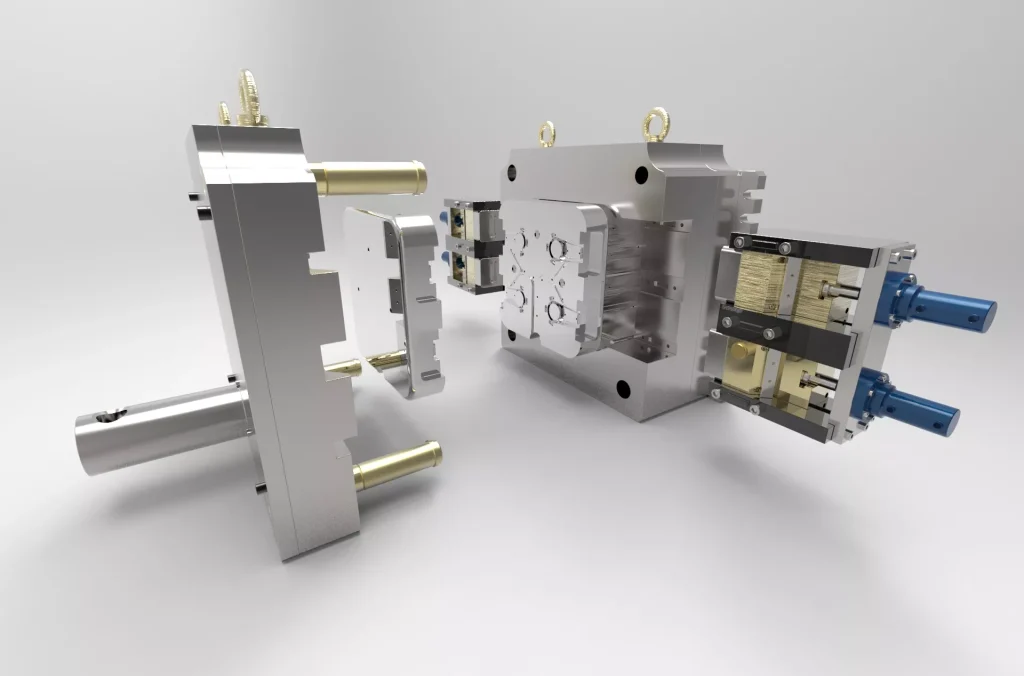

As a die casting manufacturer, we stand out for our ability to consistently deliver quality die castings. Our in-house facility focuses on a single production process so that our experienced technicians can focus on each production. Our 30+ die casting machines are each equipped with an independent furnace, with a capacity ranging from 350 tons to 2,500 tons, and can mold parts with a maximum weight of 25 kg (about 55 pounds) and dimensions of 1,500 x 1,100 mm (59 inches x 43 inches). This means we can support the production of parts of various sizes. In addition, we have our own mold shop and have full control over the entire production process. In addition to competitive pricing, high quality and one-on-one personal support, Elimold also provides professional engineering and technical support to assist in the design and development of your project.

We Provide One-Stop Die Casting Solution

We provide complete turnkey solutions from design to delivery, using the latest technology and industry-standard materials.Our metallurgical expertise ensures we use the best-suited alloys for each project to meet the toughest requirements.

CAD/CAM & Engineering Design

3D Metal Flow Simulation Technology

Die Casting Tool Manufacturing

High-Volume Manufacturing

Secondary Operations and Surface Treatment

Assembly and Packaging

Reliable Outsourcing Partner for Die Casting Projects

Elimold is the perfect combination of quality, delivery and value. At Elimold, everything we do is driven by this motto. We believe that quality products without excellent customer service are unacceptable, and this is a philosophy that every Elimold employee firmly believes in. Since its inception, Elimold has been committed to establishing, developing and cultivating long-term partnerships with customers. We stick to our strengths and produce high-quality die castings with highly competitive molds and unit prices to help our customers gain a competitive advantage and position in their respective markets. If you have a complex part design, Elimold can help you turn it into a reality. With the right equipment, strong technical knowledge and a focus on quality, from mold design to finishing to shipping, we ensure that each project is completed to a high standard and that your order is delivered on time every time.

High Quality Die Casting Services Company

At Elimold, our team of experts carefully reviews each die casting project to ensure our approach meets your specific requirements. We prioritize optimizing our production processes to ensure that each part meets high standards of durability and aesthetics. We specialize in advanced casting techniques and utilize precision die casting machines to help you achieve excellence in function and appearance, ultimately enhancing the overall value of your product. Whether you are looking for affordable standard metal parts or require custom design assistance from our experienced engineers, we can ensure you get everything you need. We oversee your project from design to final delivery, assisting with all price negotiations and product testing matters to ensure the highest quality and value. Request a free quote today to get started on your project today.

Types of Die Casting Processes

Elimold offers a comprehensive die casting service, utilizing both hot chamber and cold chamber die casting methods to meet varying material requirements and project specifications.

Hot Chamber Die Casting

Cold Chamber Die Casting

Ready to get started on your Die Casting quote?

We specialize in turning innovative ideas into reality. Our experienced team is dedicated to providing you with the support you need from concept development to production. We are committed to turning creative ideas into tangible results. Our experienced team is dedicated to providing you with the assistance you need, guiding you from the initial concept stage to production.

Low-cost Die Casting Production

Want to shorten production cycles and reduce costs on core projects? Die casting services integrate a variety of advanced technologies to streamline manufacturing processes, speed up high-volume production of machined parts, and achieve higher precision and on-time quality. Our extensive die casting equipment and comprehensive die casting technology provide strong support for our custom die casting services. Few companies can match Elimold in strictly adhering to specifications and reshaping complex geometries when producing parts in various special materials in large quantities. Whether you are preparing to submit CAD files, conduct preliminary studies, or anything else, our team is ready to help you. Our team is fluent in multiple languages and is ready to help you find the manufacturing solution that best suits your project.

Advanced Die Casting Prototyping Solutions

Rapid prototyping is often a low-cost method for manufacturing small quantities of parts, and the parts we manufacture using 3D printing can be used to create accurate and economical prototypes. At Elimold, we can provide a variety of prototyping solutions based on your specific project needs. We can use plastic or metal 3D printing or billet CNC machining, which are relatively inexpensive for small batch production because no molds are required. However, the mechanical properties of 3D printed or machined parts are very different from those of die castings. Our professional team has extensive experience and expertise in prototyping die casting parts and can transform your designs into physical components. Whether you need a small or large number of prototype die casting parts, Elimold can meet your needs.

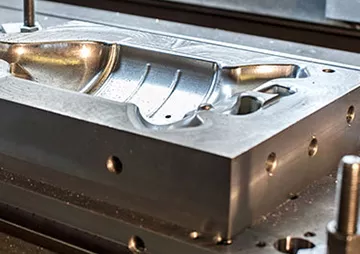

Our Die Casting Mold Making Department

At Elimold, our approach to mold making leaves nothing to chance. In addition to investing heavily in advanced equipment and a dedicated team, we always focus on customer support and communication. From design and prototyping to production, our team of experts will advise you every step of the way. With decades of experience in the industry, we know how to create consistent solutions. We have our own dedicated mold shop (no outsourcing required) equipped with the best equipment in the industry. If you are looking for a comprehensive one-stop mold making or casting service, Elimold is the ideal choice. We carefully follow specific requirements and instructions and provide advanced solutions based on the specific needs of each project.

Product Design and Engineering Services

Elimold can provide professional engineering and product design services. Our superior part design fully considers the precision required to meet form, fit and function requirements to achieve the most cost-effective product cost and maximize mold life. We use the latest NADCA (North American Die Casting Association) casting design principles. Design considerations include: parting line location, movable mold components (slide action), required tolerances, machined surfaces, finishing requirements, and secondary and assembly operations. Elimold’s team of engineers can participate in or lead product design development. We use 3D part modeling software to develop and communicate product design information to accelerate the design process. Customers benefit from our engineering support services to achieve target results.

Reverse Engineering Services

We have a team of engineers dedicated to reverse engineering projects to meet all your needs. Our team has the expertise and experience to generate 3D CAD models from existing parts using advanced scanning equipment, whether it is to determine original design intent, modernize manufacturing processes, or design new parts to fit existing products or equipment. Elimold is revolutionizing the way manufacturers think about and perform reverse engineering. We open the door to managing incomplete component design data, eliminating original design flaws or failures, improving manufacturing process efficiency, and continuous product innovation.

Quality Management

Elimold has earned a reputation for consistently providing quality die castings to customers and ensuring that customers are satisfied with the products and parts they order. Our quality team ensures that each shipment is rigorously inspected and meets our high standards.

- Advanced Product Quality Planning (APQP)

- First Non-Critical Inspection (FAI) / Production Part Approval Process (PPAP)

- Gage Repeatability and Reproducibility Procedure (GR&R)

- Corrective and Preventive Action Policy in Place

- Warranty Support Services Required by Customers

- Raw Material Element Monitoring and Certification

- In-House X-Ray Inspection

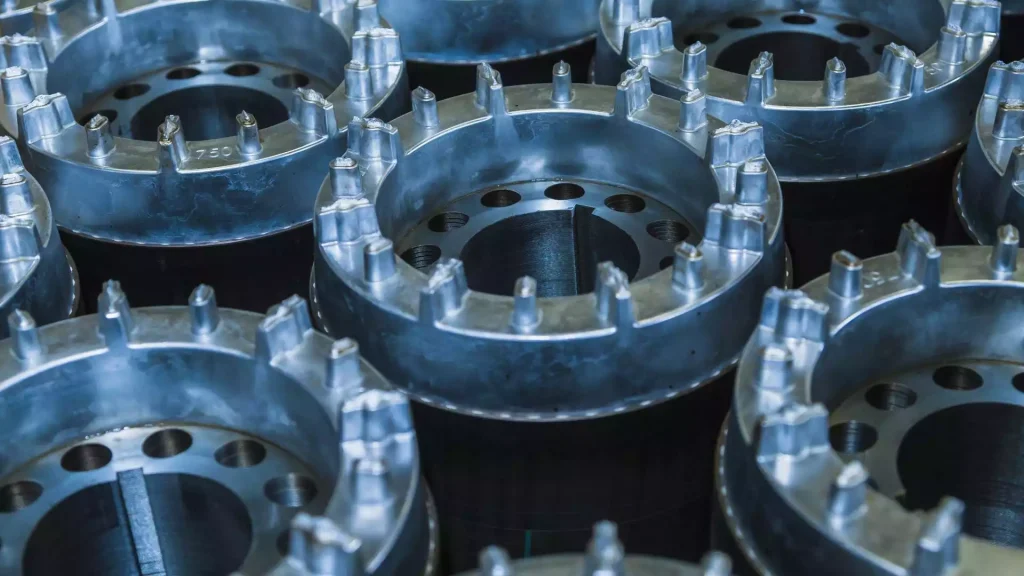

Consistency and Precision in Every Part

Why spend money on additional machining when you can work with a manufacturer that does it all once? We cast to net shape on the front end so you don’t have to do unnecessary trimming and finishing on the back end. Throughout the production process, we apply the strictest quality control standards to ensure consistency and precision in every cast part. In addition to in-process quality checks, we also provide a 1-5 level production part approval process control. From the first part to the last, every step is carefully tuned to ensure consistent quality.

Fast Parts at an Affordable Price

Need a quick turnaround? You’ve come to the right place. We streamline die casting prototyping and production processes to deliver parts even within the tightest constraints. Need a prototype die casting? We can quickly machine die castings in a variety of materials to production-quality parts. Ready to scale up? With our manufacturing locations in the U.S. and China, we have the equipment and flexibility to cast parts quickly and affordably.

Are you ready to start your next project?

With Elimold, you will receive die casting services covering a wide range of materials including aluminum, magnesium and zinc alloys. All you need to do to get started is send an inquiry and drawings to our company. After careful consideration, our managers will contact you to start the amazing manufacturing process. Our state-of-the-art facilities and cutting-edge technology ensure that each casting is a masterpiece that meets the most stringent quality standards.

What is Die Casting?

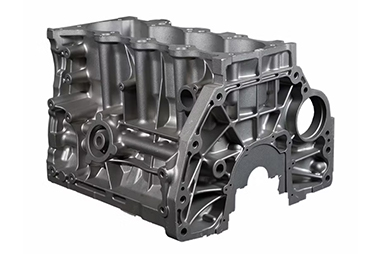

Die casting is an efficient process that can be used to manufacture fine, high-volume metal parts. The process uses specialized molds, known as die casting dies, designed to produce multiple parts simultaneously, ensuring efficiency and consistency. Commonly used for metals such as aluminum and zinc, die casting involves melting the metal and injecting it into these molds under high pressure.

The subsequent rapid cooling and solidification captures the intricate design and detail of the part, reducing the need for extensive secondary operations. While die casting eliminates all or most of the secondary operations required to manufacture metal parts; however, post-machining is common to meet tighter, function-critical tolerances. Die cast parts can also be post-processed to achieve any of the surface finishes that their respective CNC machined counterparts can achieve.

Advantages of Die Casting

Die casting services provide a number of advantages. These include:

- The capacity to design and create complex shapes with a high degree of accuracy and reliability.

- Cost savings through the bulk production of parts and components from a single design mold.

- Combining multiple components without the need for an assembly line.

- Reduction of scrap or waste.

- Faster production cycle times.

- Die casting allows for the mass production of complex parts and components in less time and at a lower cost.

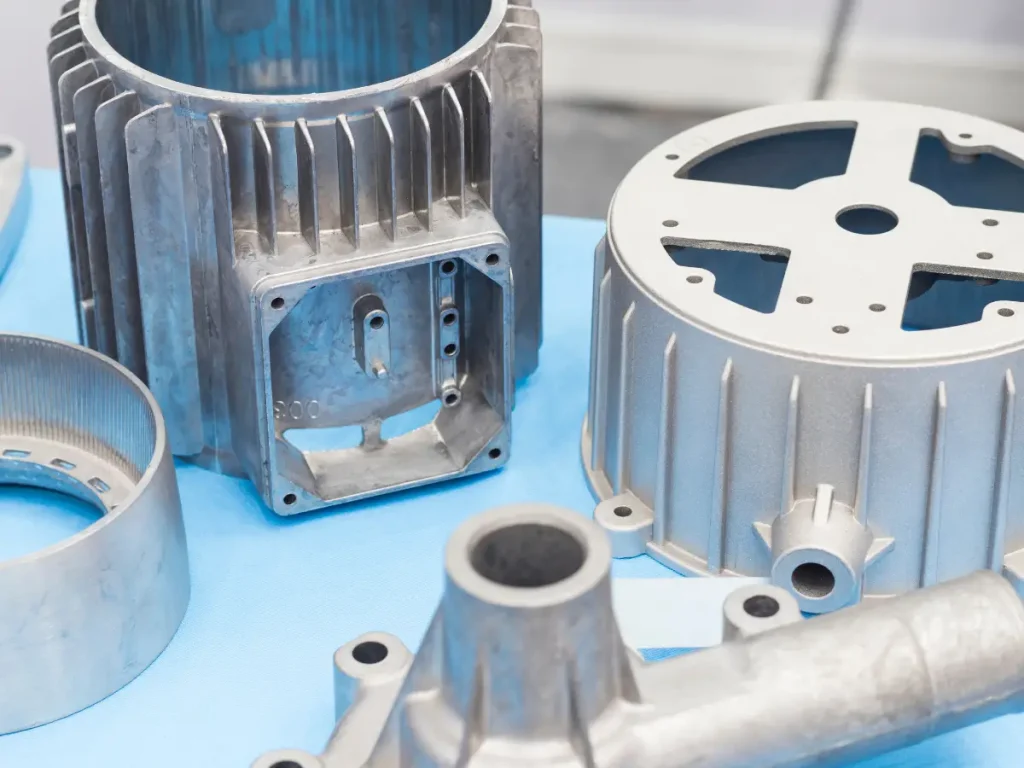

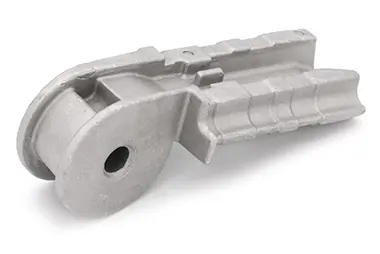

Custom Die Casting Material Options

According to the manufacturing requirements of metal die castings, different materials are selected for die casting. Each material has different characteristics, so different materials can be selected according to the industry and usage scenarios of the parts.

Aluminum Alloys

It is known for its strength, durability, and resistance to corrosion. It’s used in industries like aerospace, automotive, and medical devices for parts that need to withstand tough conditions.

Zinc Alloys

Zinc alloys are renowned for their superior strength and dimensional stability. With a high resistance to deformation and excellent casting properties, they are often used for parts requiring precise dimensions, such as automotive components and consumer electronics. Alloys like Zamak 3 and Zamak 5 provide excellent surface finishes and are perfect for high-volume production, ensuring durability and longevity.

Magnesium Alloys

Magnesium alloys are the lightest structural metals available, offering significant weight reduction without compromising strength. They have excellent machinability and good resistance to stress corrosion cracking. Common grades such as AZ91D are ideal for aerospace and automotive applications. Their superior thermal properties also make them suitable for heat-sensitive applications.

Copper Alloys

Copper alloys, including brass and bronze, provide outstanding electrical conductivity and thermal resistance. They are often used in applications that require excellent thermal management, such as electrical connectors and heat exchangers. Their high strength and corrosion resistance make them ideal for specialized industrial components, although they are less common in high-volume die casting due to higher material costs.

Lead Alloys

Lead alloys are primarily used in applications where high density and corrosion resistance are essential, such as in battery manufacturing and radiation shielding. While they offer excellent protection against radiation, their use is becoming limited due to environmental regulations. High-quality lead alloys ensure longevity and reliability in specific applications, although they are not as versatile as other materials in the die casting process.

Finishing Options for Die Cast Products

We understand that the perfect finish for your custom parts is critical. Every project has its own unique needs, such as a lustrous sheen, a tactile texture, or even a resilient protective layer. Our team is dedicated to craftsmanship, ensuring the final product is not only functional, but also meets your aesthetic expectations. Learn more about our proud array of specialized surface finishes designed to enhance the toughness, appeal, and performance of each custom die cast part.

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

Laser Cladding

Provides excellent corrosion, wear, and abrasion resistance. Laser Cladding is also effective for treating minor surface imperfections such as cavities, tiny cracks, and rust damage.

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Post-Casting CNC Machining

Elimold also offers equipment and processes for all of your post-die casting CNC machining needs. Sometimes parts require cleanup or detailed features to be machined after casting. With our expert guidance, you can choose which features to cast and which to machine. Mold flow analysis and industry-leading design software ensure that projects produce high-quality die castings. We can provide 5-axis machining centers for complex geometries as well as wire EDM and graphite machining centers for fine details after die casting.

Inventory and Production Management

Flexible scheduling, quick response, cellular manufacturing, inventory availability, inventory and kanban procedures, single minute exchange of die (SMED) concepts, automation, and a relentless commitment to Six Sigma quality are at the core of our business model. All of this allows us to think big and start small in our operations, and each element is a factor in our ability to meet shorter lead times and tighter production time windows. All of Elimold’s production is under one roof, ensuring clear, efficient, and fast communication between our engineers, sales team, and you. We have a dedicated project leader who oversees your project from start to finish, and all of our die castings are subject to strict quality control.

High-Quality Customer Service

Elimold’s focus on customer service goes beyond other production tooling suppliers. We also have the shortest lead times for die casting tooling in the industry. We provide ongoing support for your die casting project, from DFM before tooling installation to first article review to final production and finishing. You can rest assured that your die casting production project will be well managed, with regular updates on your project and access to the project management team at any time to address any questions or concerns you may have. With our strengths in stamping, finishing, and surface treatment, you will receive a well-finished, high-quality component that is ready for use.

Different Types of Casting Services

Sand Casting

Investment Casting

Low Pressure Casting

Permanent Mold Casting

Lost Foam Casting

Centrifugal Casting

Squeeze die casting

Vacuum Casting

Semi-Solid Die Casting

Is die casting right for your product?

The die casting process is the fastest option available for producing exact, non-ferrous metal products. Because this method utilizes reusable molds, it offers high-speed production of parts and has the flexibility to create a wider range of shapes and sizes than other casting methods.

Die casting can be completely automated, and its reusable molds also make it an affordable option. This technique is used to manufacture commercial, consumer, and industrial products. Die casting is ideal for medium-sized parts with more complex structures.

Alternatives to Die Casting

Elimold offers an alternative to die casting: injection molding. The injection molding process is similar to magnesium die casting, except that it uses thermoplastics instead of molten metal. Similar to die casting, during injection molding, the material is melted, pressed into a mold, and the pressure is maintained until the part is formed. Once the part has cooled sufficiently, it is ejected from the mold. Injection molding can produce parts with extremely tight tolerances (+0.004 inches). Like die casting, injection molding is an ideal method for producing large quantities of parts in a short period of time.

Try Elimold's Custom Die Casting Services

Explore precision manufacturing with die casting technology to create complex and precise parts. Our custom services turn your ideas into reality and cover a wide range of industries. We uphold excellence and prioritize custom services for each unique project. Our team of experts works closely together to handle every detail from design to production to ensure the highest quality. Share your files to coordinate specifications and pricing. DFM reports are provided before mold manufacturing, and our team will provide consultation services to ensure your needs are met. Our experts will provide personalized reviews and manual quotes to ensure you have a smooth manufacturing experience. Ready to start your die casting quote?

Request Your Free Pressure Die Casting Quote Today

After receiving your drawings, our engineers will analyze your custom pressure die casting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.