Electric Discharge Machining (EDM) Service

Elimold offers a wide range of manufacturing capabilities, including EDM processing and other value-added services, to meet all of your prototyping and production needs. Our highly skilled technicians and operators use their extensive expertise and our state-of-the-art EDM machines to deliver results that exceed expectations. Contact us now for a free instant quote.

EDM Manufacturer

Elimold is a leader in precision electro-discharge machining (EDM). Whether you don’t know which type of EDM technology is best for your metal parts, or you don’t know yet that EDM is a CNC process that can reduce manufacturing costs and improve part accuracy, Elimold can point you in the right direction. No project is too big, part too complex, or tolerance too tight for Elimold, making us a preferred partner for OEM manufacturers in industries around the world. Our EDM department is comprised of highly skilled CNC machinists and engineering professionals, all of whom have decades of experience and expertise in producing precision parts with accuracy up to 1 micron. When a typical CNC machine shop can’t make it, Elimold’s manufacturing team can. And we understand that every industry has unique needs and requirements. That’s why we work closely with our customers to provide custom solutions that meet their specific needs. Our team of experts can provide guidance and advice on material selection, design optimization, and other critical aspects of the machining process.

Ultra Precision EDM Machining Factory

Elimold has many years of experience in the field of precision machining and is one of the world’s leading EDM service providers. Our in-house facility has a dedicated EDM workshop covering more than 20,000 square feet, equipped with state-of-the-art machines to meet customer requirements. We have the in-house capabilities to perform a wide range of EDM projects. We are an ISO 9001 and AS 9100 certified company. At Elimold, we have a team of highly skilled professionals who stay at the forefront of industry best practices through ongoing training and certification. Each team member is proficient in EDM operations, and our experienced engineers participate in every EDM machining operation to ensure real-time quality and accuracy. We use rigorous quality assessment methods, including hard measurement and optical comparators. Elimold has a proven track record in EDM projects and will work closely with you throughout the process. Ensuring that you are satisfied with the final product is our top priority. Our continued investment in technology, manpower and equipment has enabled us to expand our capabilities and provide a growing range of precision EDM machining services. We are a full-service EDM machining solutions provider dedicated to providing the highest quality precision machining services with fast turnaround times, competitive pricing and excellent customer service.

EDM Parts Contract Manufacturing

Elimold’s EDM contract manufacturing team is renowned for manufacturing ultra-precision parts, utilizing industry-leading CNC-controlled EDM machinery and technology to produce high-quality products with fine details and tolerances as small as 1 micron. Our expertise in enhanced processing parameters produces components with advanced surface finishes and extremely high positioning accuracy. Elimold is your source for all contract EDM manufacturing services, including wire EDM, EDM machining, EDM drilling, and laser ablation. We provide contract manufacturing for full production runs and low-volume prototypes, leveraging manufacturing services and expertise to provide customers with consistent, high-quality precision components at globally competitive costs and lead times. Our vertically integrated manufacturing process produces high-quality products with tolerances ranging from 1 to 100 microns, sometimes even 50 times smaller than the width of a human hair, allowing us to meet the tight tolerances required for a wide range of applications.

Precision EDM Tolerance Capabilities

- EDM Machining tolerances held to .0002”

- EDM hole drilling as small as .010”

- Superior ultra fine surface finishes

- EDM High Speed Drilling (EDM Hole Popping)

- 30º Tapers Up to 15” inch thick

- EDM Cuts up to 24” inch thick

- EDM Capacities to 24” thick and 2000 lbs

Manufacturability Analysis Services

The Elimold Precision Manufacturing team has extensive expertise to provide our customers with a competitive advantage. As customer needs change, our engineers can provide guidance on the best manufacturing process based on part geometry, materials and production volume, as well as detailed manufacturing design analysis to ensure that customer products are designed and manufactured to meet all quality and performance requirements. Additional finishing, coating and assembly services are available if required. We focus on building long-term business relationships with our customers and are committed to providing services that add value to our core processing and manufacturing capabilities.

When you work with Elimold, our engineers perform the necessary manufacturing design analysis processes to produce the highest quality products. In addition, we can provide assistance with concepts, manufacturing costs, manufacturing techniques and materials as well as assist in upgrading or redesigning, re-evaluating or modernizing existing products to improve performance and/or reduce manufacturing costs. Innovation is more than just a marketing tool. It means continuously reviewing and updating the processes, products and solutions we provide to our customers. Our commitment to innovation sets us apart from the competition and helps us build long-term relationships.

Our EDM Service Types

At Elimold, we pride ourselves on being at the forefront of the ever-changing custom EDM machining industry. From state-of-the-art metalworking tools to the latest technology and software, we continually look for ways to improve our processes and capabilities for our customers. The wide variety of technologies employed in our facility allows us to take on the most challenging projects and transform them into high-quality products. Our capabilities in the custom EDM machining space allow us to meet nearly any customer need.

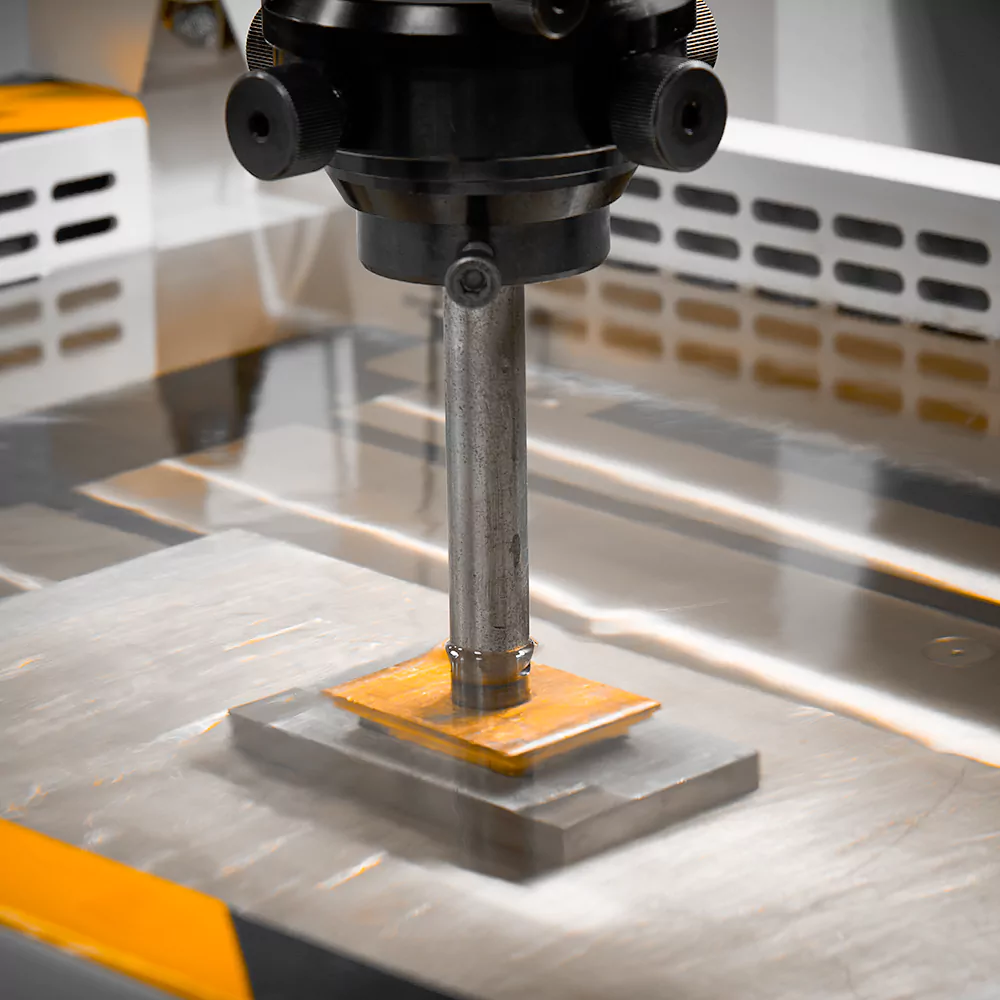

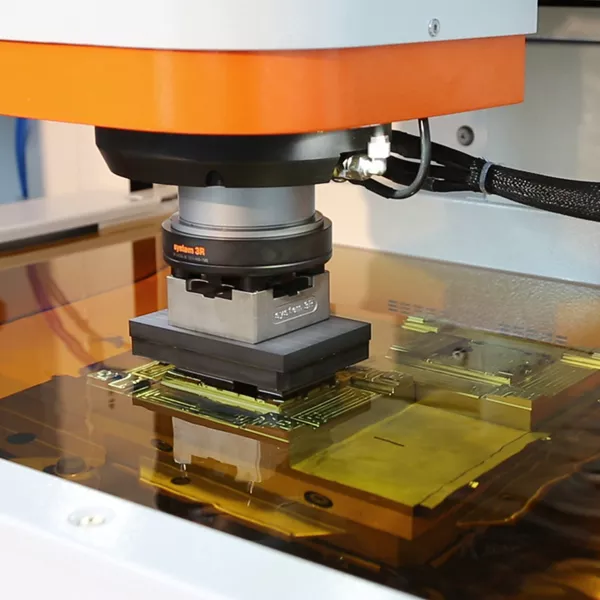

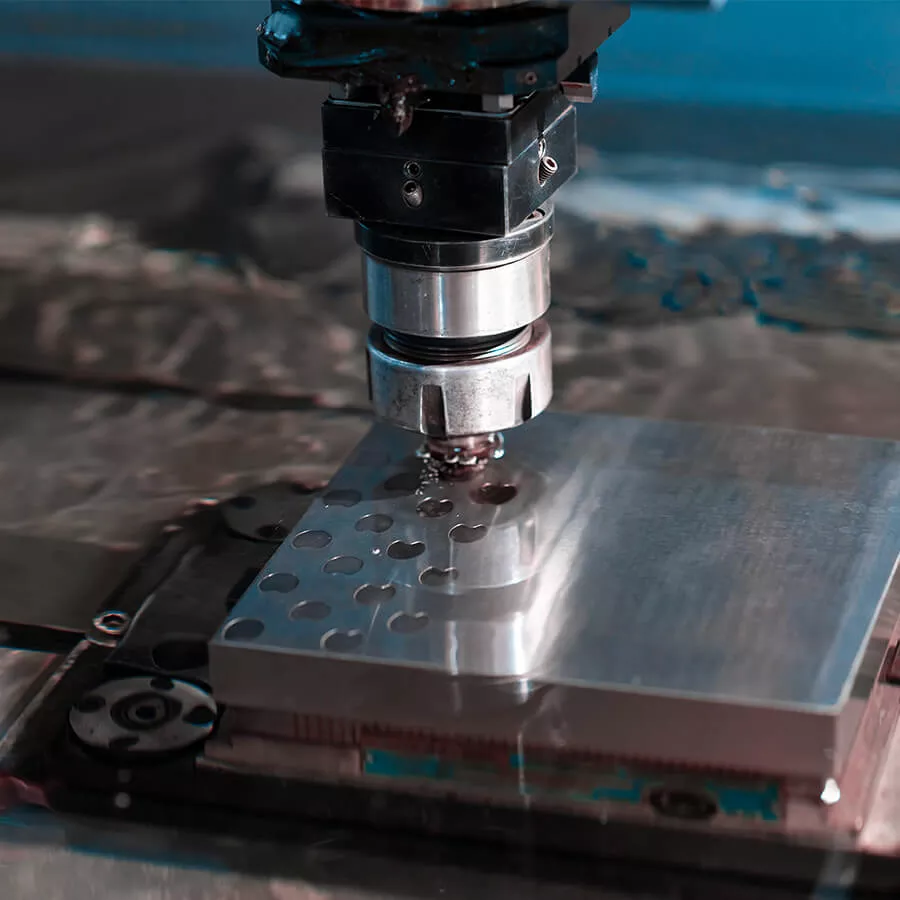

CNC EDM Drilling

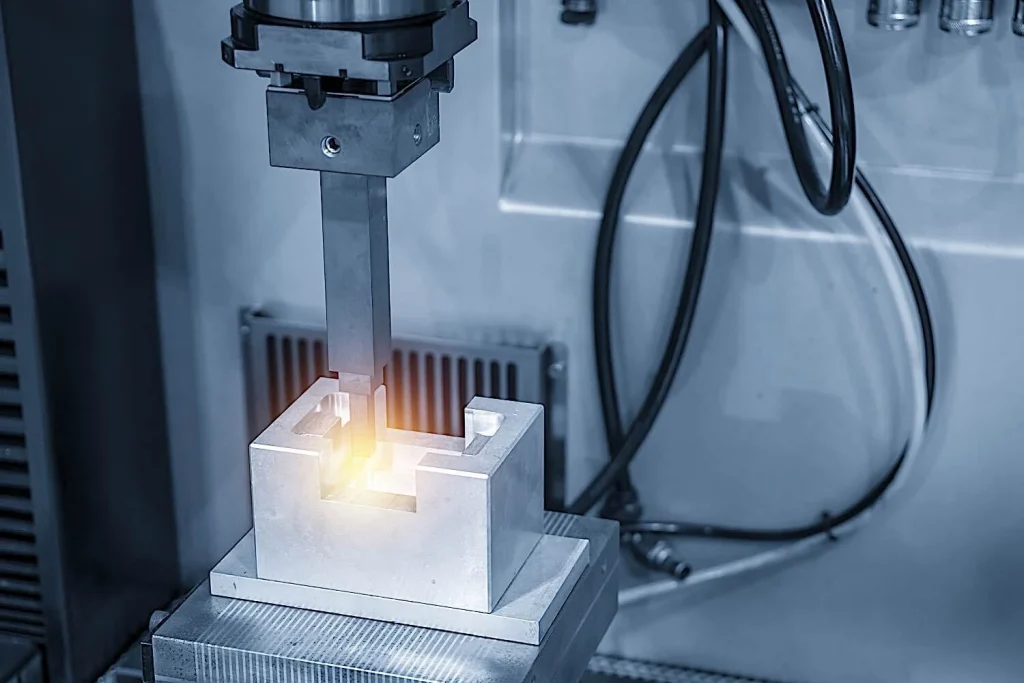

Sinker EDM Machining Services

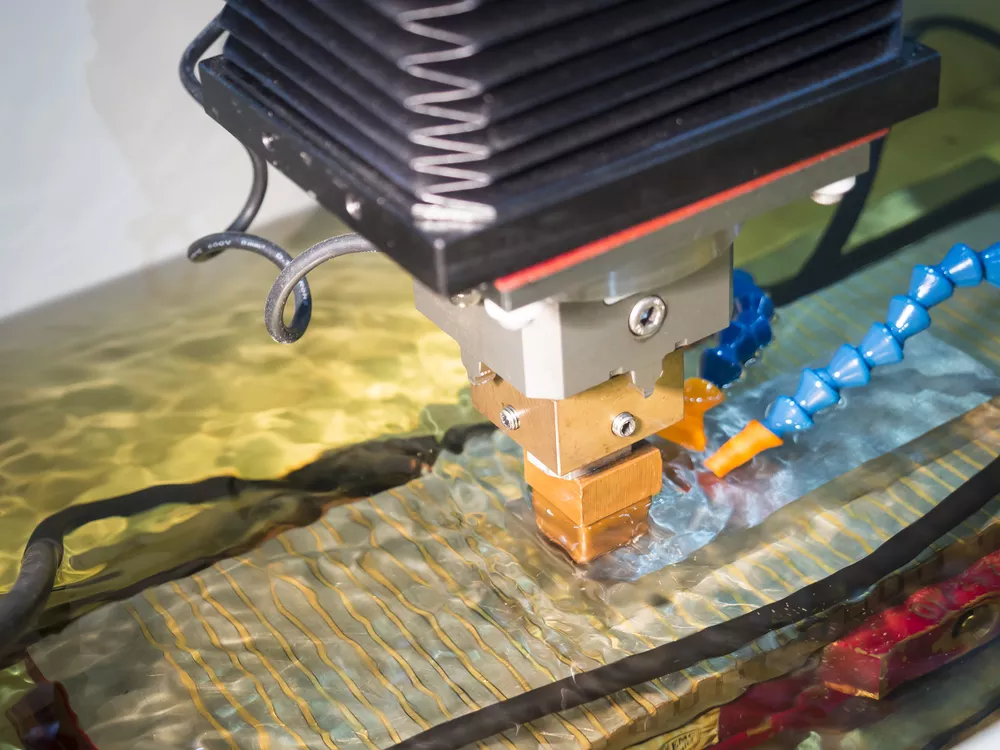

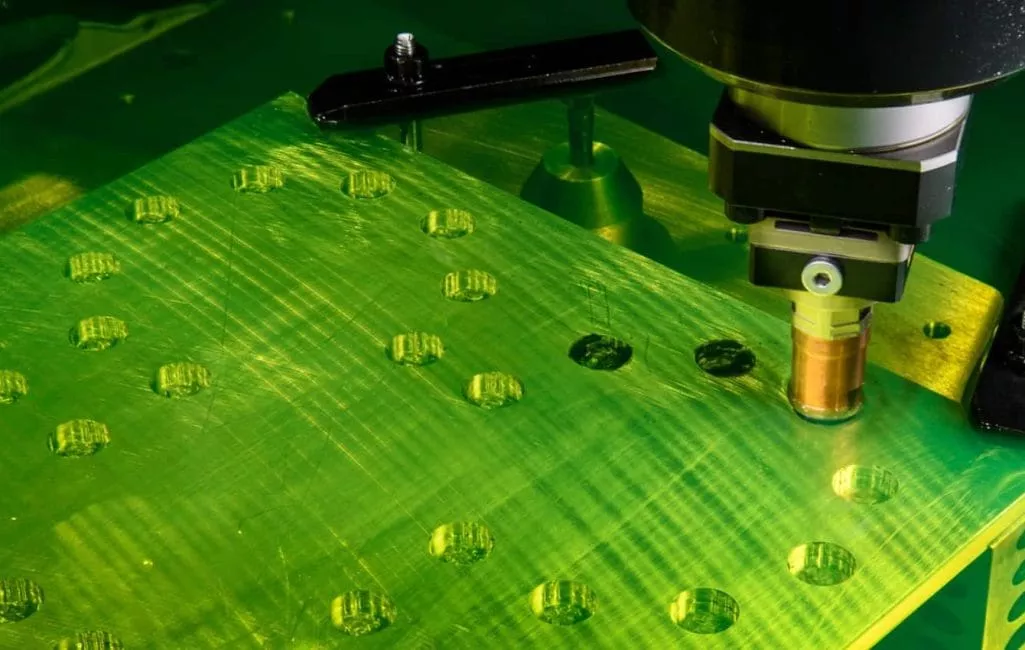

Wire EDM Machining Services

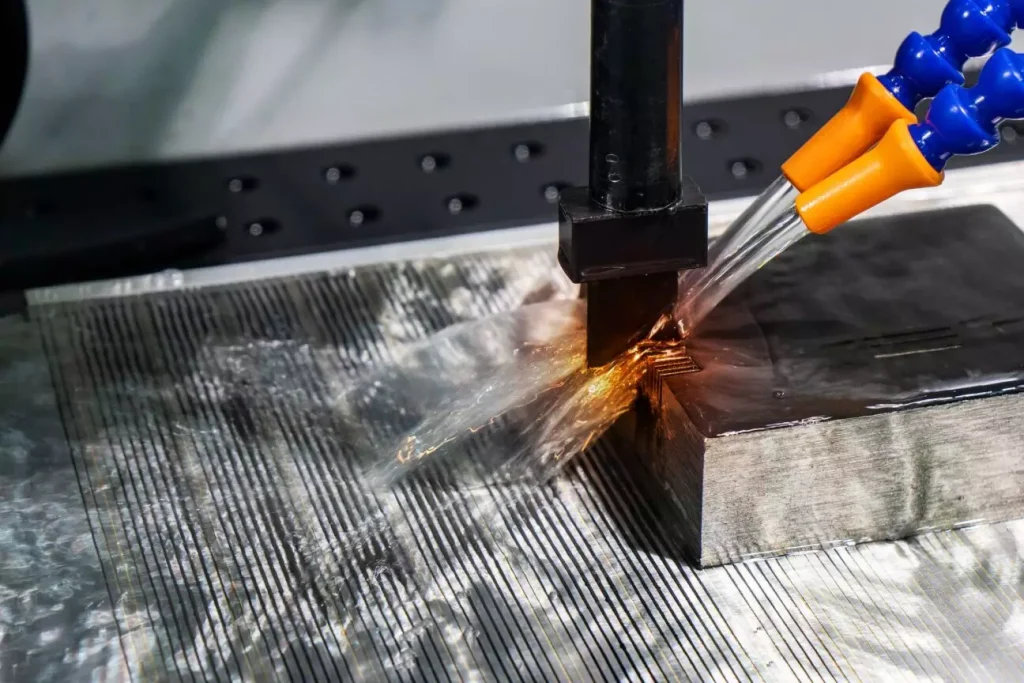

Fast Hole EDM

Full range of EDM machining solutions

Our CNC machine shop capabilities span the entire product development lifecycle and can provide comprehensive solutions to meet your needs. We use state-of-the-art technology and are staffed with skilled staff to provide precision machining services that meet your needs. From the original idea to final assembly. We provide specialized services such as wire cutting, surface grinding, and fixture grinding, always using the latest technology and best practices. We understand that each project is unique and requires a personalized approach. Therefore, we provide customized solutions to meet your needs while ensuring the highest efficiency and quality. Entrust your project to us and experience the consistency, quality, and dedication that Elimold brings. Choosing Elimold as your EDM machining partner brings multiple benefits. We provide cost-effective solutions, ensure shorter delivery times, and can use a variety of materials to provide a one-stop solution for all your EDM needs.

Our Commitment to Quality Assurance

We are committed to staying at the forefront of technological advancements in the EDM industry. To ensure this, we continually invest in new equipment with cutting-edge features and capabilities that allow us to excel in our wire cutting and EDM services. We employ state-of-the-art CMM systems and other automated inspection technologies. These systems allow us to inspect components with unparalleled accuracy, ensuring that the finished parts not only meet our customers’ expectations, but also exceed market requirements. We follow a rigorous quality inspection process that includes IQPC, QE, OQC, and use CMM, height gauges, projectors, calipers, hardness testers, spectrometer instruments for high-precision dimensional and hardness inspections. In addition, our quality personnel perform a thorough visual inspection using surface roughness gauges and microscopes to ensure there are no scratches or burrs. Every part is rigorously inspected at any stage of production to ensure that the final product fully meets your specifications and quality requirements.

3D Metrology Systems

Elimold’s Systems Group offers automated dimensional metrology and surface roughness measurement solutions, including industrial 3D metrology centers and robotic metrology systems for in-line and near-line production measurement applications. Our CNC-based inspection machinery provides innovative solutions for engineering process development and automated quality monitoring of manufacturing and production processes.

3D Metrology Services

Elimold’s Metrology group provides in-depth non-contact 3D dimensional metrology and inspection services for parts of virtually any shape and size. 3D measurement of form, surface finish and comparison to nominal CAD models enables us to offer our customers advanced GD&T inspection services and enhanced 3D roughness parameters for even the most complex components.

Professional Packaging

We pack the products with anti-rust paper, plastic bags and foam according to the size and characteristics of the parts, and label each package after sealing with tape so that you can quickly identify the contents of the goods. After the initial packaging is completed, we will put it in a 5-layer corrugated box or wooden box and fix it with pearl cotton or fill it with bubble film to prevent damage caused by transportation. We will also attach a packing list to the outer box, which can not only effectively protect your EDM parts, but also facilitate your inspection and confirmation of the goods.

We will thoroughly review each drawing and provide an accurate free instant quote

Our quotes are both economical and accurate because we have a team of professional mechanical engineers who will meticulously review each drawing. These engineers have more than 10 years of experience and have deep expertise in programming, machine operation, post-processing, material properties, etc. Ensure you get an accurate quote within 4 hours.

Electrical Discharge Machining (EDM) Materials Options

Elimold’s EDM services can efficiently process a wide range of conductive materials, including a variety of tough super alloys, ensuring precise and durable components for demanding industries. Unlike other machining companies, we are less limited by the mechanical properties of the material (e.g. hardness, machinability). Some of the materials commonly processed by EDM include:

- Alloy Steels

- Aluminum

- Beryllium

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Alumina

- Cobalt

- Copper

- Iron

- Lead

- Magnesium

- Molybdenum

- Nickel

- Zirconia

- Palladium

- Stainless Steel

- Tin

- Titanium

- Tungsten

- Inconel

- Invar

- Silicon Carbide

- Iridium

- Kovars

- Molybdenum

- Monel

- Niobium

- Palladium

- Superalloys

- Ceramics

EDM Part Surface Finishing Options

Our EDM machining surface finishing options provide you with an exceptional experience. We offer a variety of technologies to enhance the appearance and performance of your precision parts.

- Anodizing

- BlackOxide

- Bead Blasting

- Polishing

- Electropolishing

- Heat Treatment

- Passivation

- Laser Marking

- Electroless Nickel Plating

- Nickel Plating

- Zinc Plating

- DLC Coating

- PVD Coating

- Powder Coating

- Media Blasting

- Deburring

- Glass Bead Blasting

- Brushed Finish

- Sand Blasting

- Vibratory Tumbling

Application Industry

Our engineers and machinists have extensive knowledge of best EDM machining practices and materials as they apply to many different industries, including but not limited to:

- Aerospace

- Automotive

- Computers

- Construction

- Defense

- Electronics

- Energy

- Entertainment

- Environmental

- Firearms

- Furniture

- Lighting

- Marine

- Medical

- Military

- Mining

- Retail

- Security

- Telecommunications

- Textile

- Transportation

- Jewelry

EDM Parts Production

We use a variety of EDM techniques to produce parts with precision and accuracy. Our EDM machines are equipped with the latest technology, including advanced programming and automation features, allowing us to produce parts quickly and efficiently. We can manufacture the following parts applications.

- Machine components

- Engine components

- Turbine components

- Hydraulic components

- Turbomachinery components

- Construction equipment

- Shafts

- Forgings

- Jewelry

- Valves

- Pins

- Thread rod

- Fasteners

- Spindles

- Sockets

- Bushings

- Spacers

- Fittings

- Standoffs

- Extrusion Dies

- Fixtures

- Form Tools

- Injection Mold Components

- Stamping Tools

- Control rod mechanisms

- Reactor vessel components

- High-precision seals

- Complex sensor housings

- Precision drive components

- High-accuracy tooling systems

- Micro-gears

- Precision actuators

- Custom end-effector components

- Surgical instrument molds

- Implantable device components

- Microneedle fabrication

What is EDM?

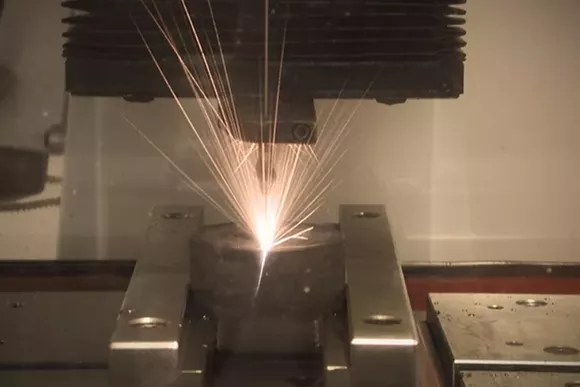

Commonly known as spark eroding, die sinking, wire erosion and wire burning, EDM is an advanced fabrication process that utilizes controlled electrical discharges to remove or erode conductive material from a blank workpiece. This process relies on a tool, called the electrode, that is either a solid shape of conductive material or a thin wire. The electrode is moved in relation to the workpiece in a motion that results in machining of the final intended shape. As the electrode gets ever closer and closer to the surface of the workpiece, and electrical arc is formed which causes the erosion of the blank material. A unique feature of the EDM manufacturing process is that the tool never actually contacts the workpiece. The electrical arc “jumps” from the tool to the workpiece in a series of rapidly pulsating discharges. This non-contact machining allows for extremely tight tolerances to be achieved.

Advantages of EDM

Compared to other precision metal cutting processes, EDM has many advantages:

- No custom tooling required,delivery times are short

- No cutting forces present, virtually no burrs generated

- Workpiece material hardness does not affect cutting speed

- Improved surface finishes, no additional finishing or polishing needed

- Tools & metal parts are machined after heat treatment,dimensional accuracy is maintained

- Highly repeatable with no deformation

- Ability to stack, string & nest multiple parts

- Ideal for delicate & complex parts

- Tight tolerances & precise fits

- Small corners & radii

- Narrow slots & thin walls

When will need EDM Machining?

EDM machining is essential when precision, intricate shapes, and the machining of hard materials are critical in manufacturing processes. Here are some use cases:

- Hard Materials: Working with exceptionally hard materials such as titanium or carbide.

- Intricate Shapes: Creating complex, detailed, or fine features.

- High Precision: Requiring exceptional accuracy in the final product.

- Heat Sensitivity: Minimizing heat-related distortion or stress on the material.

- Delicate Components: Working on fragile or thin-walled parts.

- Tool and Die Making: Crafting molds, dies, or tooling for manufacturing.

- Aerospace and Medical: Industries that demand high precision and stringent quality standards.

Other CNC Machining Services Provided by Elimold

If you’re looking for enhanced capabilities like tighter tolerances, more complexity, or high-volume production quantities Elimold in-house manufacturing delivers the solutions you need.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Jig Grinding

Custom EDM Parts Supplier

Many of our customers come from a variety of industries around the world and need our help to complete large projects or challenging components. Our focus on wire EDM contract services makes us an ideal close partner. Elimold has two precision CNC machining facilities in China and provides precision EDM services worldwide. Our team works with a wide range of companies in a variety of industries to provide high-precision prototypes, medium-volume production, and long-term, high-volume EDM component production services. Our production experience and equipment capabilities enable us to take on any size or type of project and deliver it to you on time. As an experienced custom EDM parts supplier, we understand that working with customers on the front end of a project can bring great benefits. Elimold can provide extensive design for manufacturability advice to improve production speed, accuracy, and finished part quality.

Request Your Free EDM Quote Today

After receiving your drawings, our engineers will analyze your custom EDM parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.