FR-4 (G-10) CNC Machining Services

Get an immediate quote for machining services on your materials using our online FR-4 (G-10) CNC machining service. Our advanced technology and professional team ensure that parts are precisely tailored to your most demanding requirements.

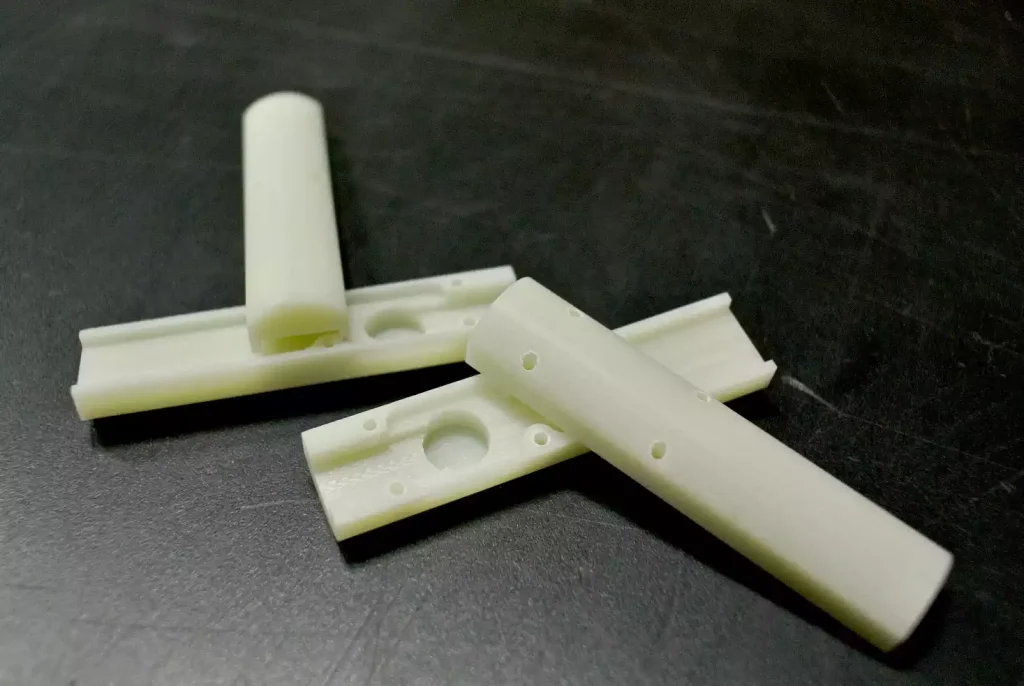

One-Stop CNC Machining Service for FR-4 (G10) Parts

To meet the needs of our diverse clientele, Elimold offers a one-stop CNC machining service for FR-4 (G10) parts. Whether for rapid prototyping or mass production, we can customize parts to your specifications, drawings, or samples. Our team has extensive experience and utilizes advanced equipment to produce high-quality, precision FR-4 (G10) parts for you. Elimold’s in-house CNC workshop is certified to ISO 9001:2015, ISO 13485, and AS9100D. As a partner to all, we are committed to matching the best solutions for our clients and projects.

What is G10/FR4?

G10/FR4 is an electrical grade epoxy resin, also known as G10 glass fiber, FR4 glass epoxy resin, or FR4 glass cloth. It possesses extremely high strength, dimensional stability, and creep resistance, even at high temperatures. In CNC machining, the stability and durability of G10/FR4 enable the production of complex and precision components. It is particularly favored in the electronics industry because it can withstand high temperatures and has extremely low moisture absorption, ensuring stable performance under various environmental conditions. This composite material is also commonly used in printed circuit boards (PCBs), electromechanical equipment insulation, and other similar applications.

As a thermosetting material, G10/FR4 cannot be melted or reshaped. If heated above its maximum operating temperature, it undergoes chemical decomposition and loses its original properties upon cooling. Therefore, G10/FR4 cannot be injection molded. CNC machining is the only method for manufacturing complex parts made from this material.

What are the differences between G-10, FR-4, and Garolite?

G-10, FR-4, and Garolite are different names, but they essentially refer to the same material: high-pressure fiberglass laminate, a composite material. This material is made by impregnating multiple layers of fiberglass cloth with epoxy resin, resulting in a material with extremely high strength and excellent electrical insulation properties. This plastic composite material is rare, combining high strength, excellent electrical insulation, outstanding dimensional stability, and chemical resistance. Because of its excellent performance in harsh industrial environments, it can be considered as a metal alternative in non-conductive applications.

Available Material Grades

FR-4 also has many different names, all ultimately referring to the G-10 type used. At Elimold, we offer several different options:

G-10 Standard

This is a high-strength material best suited for general structural applications and robotics. It is not flame-retardant but has good moisture resistance.

FR-4

FR-4 is a flame-retardant version with slightly lower mechanical strength but meets the UL94 V-0 flame retardant standard. This material is ideal for aerospace and medical projects.

Garolite XX

This paper-based phenolic laminate has excellent dielectric strength and is suitable for low-load electrical applications. While it is more difficult to process and its strength is not as high as G-10, its electrical properties are superior.

Garolite CE

This version of Garolite uses cotton fabric, making the material easier to process, but its dielectric properties are somewhat reduced. Therefore, it is more suitable for mechanical parts or bushings.

Garolite LE

Garolite LE is a low-friction, high-strength laminate. Although more expensive, it can be used as a surface for low-wear bearings.

Garolite G11 (FR5)

Garolite G11 (FR5) is similar to G-10, and is also a glass epoxy resin laminate. G11 offers better thermal insulation than G-10, allowing it to withstand higher operating temperatures. This makes it ideal for mechanical or electrical applications in high-temperature environments.

Key Characteristics of FR4 and G10

- G10 has a flame retardant rating of HB, while FR4 has a flame retardant rating of V-0.

- The thermal conductivity of G10 and FR4 are 0.25 W/mK and 0.28 W/mK, respectively.

- Both materials exhibit excellent mechanical strength.

- G10 has a dielectric strength of up to 550 V/mil, while FR4 has a maximum dielectric strength of 900 V/mil.

- FR4 is more cost-effective than G10.

Comprehensive Production Support Team

We have a team of experienced manufacturing experts working behind the scenes to fulfill your production orders. We manage the entire process and keep you updated on the latest progress.

Account Manager

Application Engineers

Logistics

Quality Control

CNC Machining Capabilities for FR4 (G10) Material

We offer CNC machining services for G10 or FR4 sheet metal with an accuracy of ±0.005 inches. We can cut or machine according to your CAD drawings. From 5-axis machining centers to milling machines, we can quickly and easily machine G10 FR4 sheet metal to the precise dimensions you require. As a special material, there are not many machining plants capable of processing G-10/FR-4. We offer G-10 CNC machining services to meet the needs of your most challenging projects.

In-house CNC Machining Workshop and Equipment

Elimold, a leading manufacturer of CNC-machined FR-4 (G10) parts with over 10 years of experience, has an in-house workshop of over 136,000 square feet in Shenzhen, China, equipped with over 100 CNC machining centers of various types, including 35 five-axis machining centers, 45 three-axis machining centers, and 20 mill-turn machining centers, as well as other equipment. This equipment enables us to produce FR-4 (G10) parts in prototype, small-batch, and high-volume production. Currently, we produce over 500 different products monthly for orders from corporate clients worldwide, with highly mature technology and quality control systems. Our production capacity is almost always sufficient, and our prices are highly competitive.

Surface Finish Options

We offer several different surface finish options for machined G-10 parts. Most G-10 parts remain as is, but you can choose the appropriate surface finish based on the part’s aesthetics, performance, and/or durability.

Sandblasting

This uses fine particles to blast the surface of the G-10 part. These particles remove tool marks, resulting in a more uniform surface.

Engraving or Laser Marking

Engraving can be used to add part numbers, labels, instructions, or logos to the part.

Surface Sealing

We can also provide surface sealing for your G-10 parts. Adding a layer of sealant or epoxy coating improves moisture resistance, reduces dust, facilitates cleaning, and enhances the part’s durability.

Painting

This surface finish is suitable for metals and plastics and can be matte, glossy, or textured, with color matching available.

Strict Quality Control

As an ISO 9001:2015 certified quality management system company, all our teams, materials, and equipment are in a state of high-quality assurance, ensuring that things are done right the first time. This is not only a responsibility to ourselves but also to our customers. We inspect and maintain our machines daily. At any stage of parts production, our quality control team frequently checks dimensions, and the production and quality control managers check dimensions again. Finally, our quality control department performs a final inspection using a coordinate measuring machine. We conduct 100% inspection on all parts, paying particular attention to threads and surface finishes.

FAQ

Elimold offers a variety of customization services for G10 and FR4 materials, including CNC machining, cutting to specific dimensions, and creating special shapes for various industrial applications.

Our experienced team can help you refine your design based on your application needs. We can guide you through the material selection process and recommend the best option for your project.

G10 is a strong and tough material that is not easily broken or cracked under normal operating conditions. However, like any material, it can fracture under extreme stress or impact. Its fracture resistance depends on thickness, design, and the specific load or force applied.

G10 has extremely high heat resistance, with a melting point much higher than most thermoplastics. However, like any material, it has a temperature threshold below which it begins to soften.

Yes, we can not only CNC machine G10, but also 3D print G10 plastic, choosing the appropriate processing method based on your project requirements.

Yes, we can offer expedited service. We may be able to complete the CNC machining of expedited orders within 2-3 days. Expedited orders require expedited shipping (express delivery costs borne by the customer) to meet tight delivery deadlines.

Absolutely. Installing threaded inserts in FR-4 test fixtures, tooling, and mechanical components is a very common requirement. We can also tap directly on FR-4 (M2 to M20 threads), but this is less suitable for applications with frequent assembly/disassembly, high stress loads, or torque requirements.

FR4 is known for its rigidity rather than flexibility. The combination of glass fiber and epoxy resin creates its strong and stable properties, therefore its flexibility is not as good as some other plastics.

Ready to Start Your FR-4(G10) CNC Machining Project?

Whether you need a single prototype or full production volumes, Elimold delivers precision CNC machined FR-4 and G10 parts that meet your exact specifications. Upload your CAD files today for a detailed quote within 24 hours.