Full Service Machine Shop

Elimold is a full-service contract manufacturer. We have comprehensive machining and manufacturing capabilities, ranging from design assistance, sheet metal fabrication, CNC machining services, to surface treatment and final assembly, we can meet your needs. We can quickly and efficiently complete custom part projects of all sizes, from prototypes to high-volume production. Contact us now for a free instant quote.

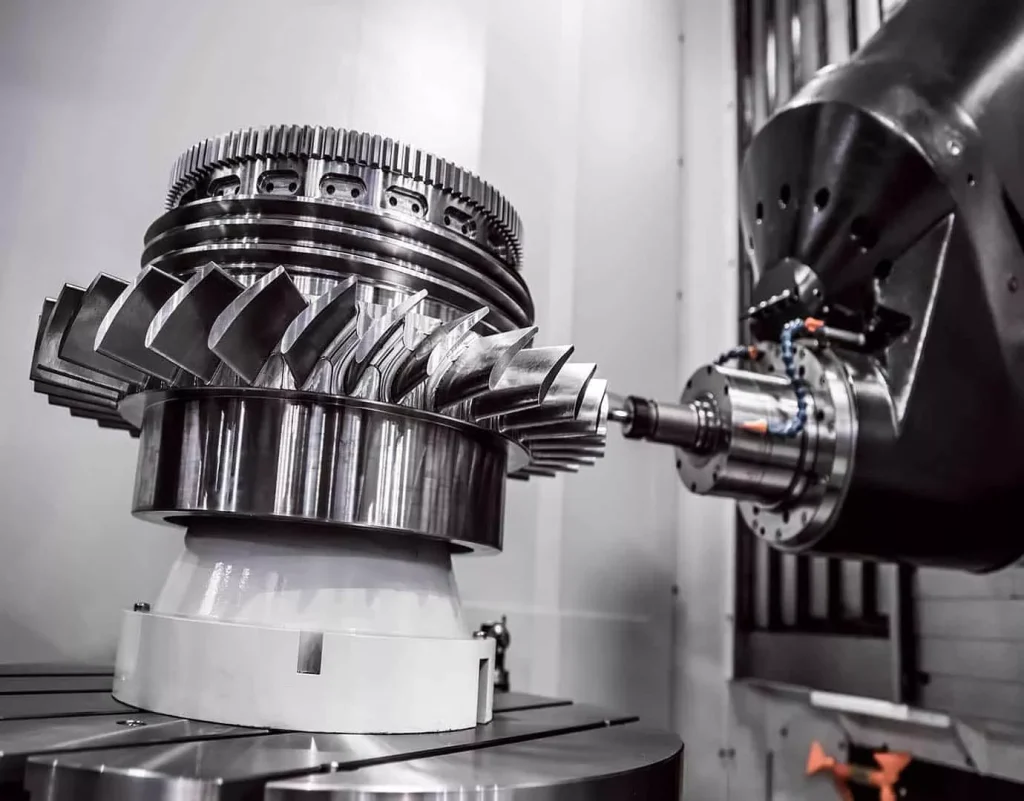

Precision Machine Shop

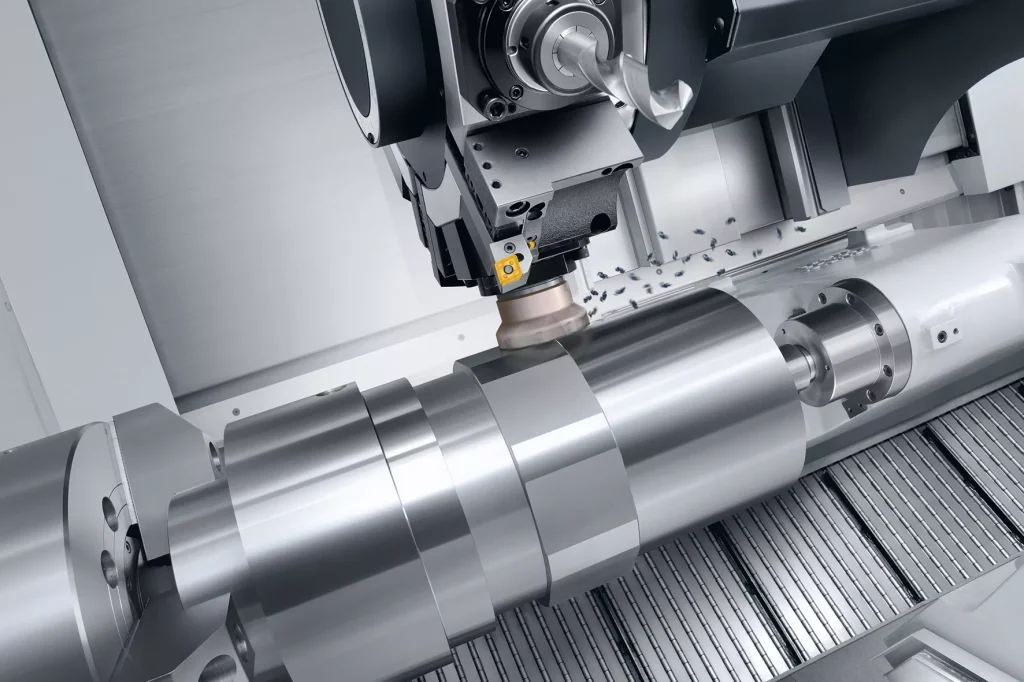

Elimold is a machining shop in China that uses the latest technology to machine parts. We have extensive precision machining capabilities, including CNC milling, large diameter turning, multi-axis machining, and other metalworking processes that meet fast turnaround times and very tight tolerances. We provide prototyping services and have equipment that can accurately handle low-volume and high-volume production.

Our skilled and knowledgeable team will take your project from concept to final completion with our strong machining capabilities and value-added services, as well as services provided in-house and by Elimold’s sister companies. Elimold’s machinery, equipment, tooling and quality processes ensure that we can meet your precise requirements and specifications for each job. We pride ourselves on always being ahead of our competitors in terms of quality, on-time delivery and price.

Elimold's in-house machine shop capabilities

Elimold is a full-service machine shop and offers custom part manufacturing services 24/7/365. Our machine shop features 58,000 square feet of shop space with ample overhead cranes to handle both routine and special machining projects. The shop is equipped with lathes with a 32-inch swing radius and 52-foot center spacing, as well as vertical and horizontal boring mills that can machine up to 18 feet in diameter. At our company, we have an unwavering commitment to providing machining excellence. Our team of highly skilled engineers and technicians utilize the latest cutting-edge technology to ensure that each project meets the highest standards of accuracy and reliability. Our adherence to industry best practices and obsessive commitment to quality means that when you choose Elimold for your machining needs, you can count on us to pay meticulous attention to detail and consistently exceed your expectations.

Advanced Machine Shop

Our spacious CNC machine shop is equipped with cutting-edge CNC machining equipment, including 5-axis milling machines, 4-axis lathes, large lathes, and 3D printing capabilities. We focus on efficiency. Therefore, Elimold has invested heavily in building a factory management system in our internal factory, from machine tool layout, shop organization/warehousing solutions, tool and coolant usage, process flow, documentation to shop management system, striving to stay ahead in machining capabilities and production. We also like to accept challenges. We have advanced technology, sufficient manpower and sophisticated processes to ensure that your high-volume machining projects are delivered on time. If you need specialized machining or other production solutions, we are ready to serve you. We will work with you to fully understand your needs and specifications. We will look for opportunities to improve the manufacturability and quality of your products.

Machining Service Types

Looking for machining services? Our China-based company specializes in precision machining services. With state-of-the-art equipment and a team of highly skilled machinists, we are able to provide exceptional quality and precision for your most demanding projects. Whether you need a small precision part or a large, complex part, we deliver on time and on budget. Trust our experienced team to deliver the highest levels of precision and accuracy for your next project.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Your One-Stop Machine Shop

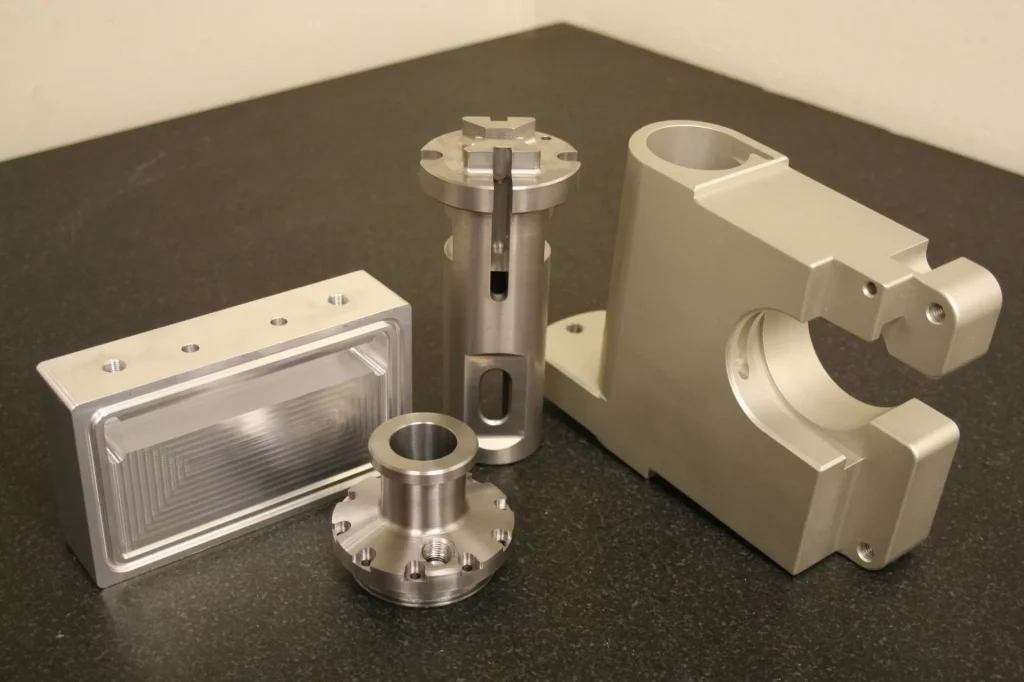

Elimold offers a wide range of services in China. Each custom manufacturing service is tailored to specific business needs. Our engineering and design teams work closely with our customers, applying their technical expertise and innovative thinking to transform concepts into reality. Our in-house machine shop’s manufacturing services are high-tech, producing high-quality parts and tools that meet exacting standards. The dedicated EDM department uses precision electrical discharge machining technology to shape carbide, while the CMM inspection department uses the finest coordinate measuring machines to ensure absolute accuracy and compliance. Custom machining and delivery services provide tailor-made solutions, from the manufacture of unique components to on-time delivery, reflecting Elimold’s commitment to comprehensive, end-to-end solutions.

Tolerance Capabilities

We have experience manufacturing a wide variety of parts for a wide range of industries. We excel at handling tight tolerances, difficult to machine parts, and we can process anything from plastic to titanium! We can provide general machining accuracy up to +/- 0.002 and wall thickness as thin as 0.015. Our extensive experience allows us to better understand your needs as a customer. With our understanding of the industry, we will help you achieve your manufacturing goals. With our focus on excellent craftsmanship and attention to detail, our team will help you achieve the success of your project.

Milling Tolerance Capabilities

We offer 3-5 axis CNC milling with accuracies up to +/- 0.0005 inches for materials ranging from aluminum alloys to heat resistant super alloys. Complex 5 axis machined parts up to 20 inches in diameter. 3 axis machined parts up to 40x20x20 inches in size. Supports low, medium and high volume production.

Turning Tolerance Capabilities

We have extensive CNC turning capabilities. We can machine parts up to 9 inches in diameter and as small as 0.08 inches in diameter. We offer 2-4 axis CNC turning with accuracies up to +/- 0.0001 inches for materials ranging from aluminum alloys to heat resistant super alloys.

Other Tolerance Capabilities

In metalworking, we can also machine parts from sheet, formed or expanded materials using bending, stamping, cutting and welding techniques. CNC precision machining can achieve tolerances as low as +/- 0.005. We offer popular and cost-effective options for small, medium and large batch production.

Reach Out To Our Machining Experts Today!

Got a problem part or a component that can’t be delivered? Need it done quickly? Contact Elimold’s dedicated team. We excel at handling complex parts and meeting tight deadlines.

One-Stop Machining Services

Our in-house facility is equipped with the machinery and technical skills to meet these needs, and our team of machinists and fabricators are available 24 hours a day, 7 days a week to provide efficient service. Elimold’s in-house facility has highly skilled employees, strong system capabilities, and effective customer problem-solving methods to help you tackle complex automation projects. Our team provides a one-stop service for turnkey design, manufacturing and assembly of automation systems, and can replicate designs as many times as your multi-location operations require. No matter where your project is, machine shop services can help you. From reverse engineering to mass customization of parts, we can provide services for you.

In-house Large Parts Machining Shop

Our large parts machining shop offers 31,200 square feet of production space, equipped with 3-ton and 5-ton bridge cranes with a lifting height of 20 feet (about 6 meters). And the special shop for heavy parts machining covers 14,400 square feet (about 13,600 square meters) and has three crane cabins. The customized central crane cabin houses a 30-ton bridge crane with a lifting hook height of 30 feet (about 9 meters). We have a wide variety of large horizontal milling machines and lathes, ready to serve you. With us, your parts will be machined according to the drawings and delivered as promised. We are committed to building customer relationships by delivering quality components on time. Contact us to learn more about our large parts machining shop services. Our team will be happy to discuss our custom processing and manufacturing capabilities with you in detail.

Rapid High-Quality Prototyping and Engineering Support

At Elimold, we provide best-in-class rapid prototyping and production part services with advanced custom machining capabilities to meet our customers’ needs. Our experienced team of engineers and technicians use cutting-edge technology to ensure the highest precision, efficiency and reliability in every project we undertake. Whether your needs are well-designed parts or critical components, we have the knowledge and facilities to quickly and cost-effectively transform your concepts into reality. Alternatively, if you need assistance with part design or prototyping. We can confidentially process your models in Solidworks or Inventor for manufacturing or provide DFM (Design for Manufacturability) support to your engineers. Our 3D printing technology is ideal for prototypes and end-use production parts.

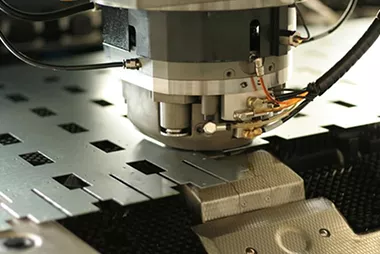

Sheet Metal Machine Shop Services

Elimold also provides exceptional sheet metal machining services. We know your business depends on high-quality custom machine shop services, so we are committed to providing high-quality services. We are your one-stop custom mechanical parts supplier.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

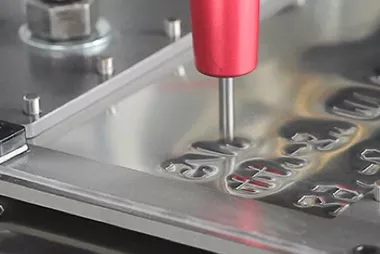

Fast, Reliable Prototype Processing

Elimold focuses on custom part processing for our customers, and our highly automated, full-service machine shop has a dedicated shop for fast prototype part processing. Our high-tech machine shop provides a clean, temperature-controlled environment with machinery for high-volume production, and a reverse-flow air handling system to control debris and fumes for efficient processing of composite and polymer materials. Our machine shop is air-conditioned to maintain a constant temperature year-round.

All of our prototype parts are processed on-site, eliminating delays caused by third-party processing. Our focus on precision ensures excellent tolerances, which ultimately leads to excellent testing results. Elimold can produce small-scale specimens and custom fixtures for testing finished parts and special geometries in addition to processing standard specimens to ASTM, ISO, MIL, AWS and ASME codes. In addition, we offer in-house welding capabilities for custom fabrication.

Quality Control Machining Services

Our cutting-edge precision components are ready for final assembly. Instead of outsourcing to multiple downstream suppliers, we provide end-to-end services to meet all your needs. Our sophisticated CNC machining process ensures strict supervision every step of the way. Our in-house part inspection capabilities increase efficiency. We have a metrology laboratory with NIST traceability, advanced scanning probe coordinate measuring machines (CMM), camera inspection systems and other advanced equipment. Our quality department is capable of handling even the most complex parts.

In-house Value-Added Services

You get a full-service experience. Before machining begins, our engineers will evaluate your drawings and part designs and provide recommendations to optimize production efficiency. Our staff is well-versed in machining, so you can rest assured that your parts will meet your requirements. You can save time by getting all of our contract machining services with a single purchase order. With a single purchase order, we can source raw materials, machine parts, perform heat treatment, coating, assembly, inspection and verification, identification, and packaging. In addition, we are able to provide warehousing and logistics services to our customers. Our team can work with you to develop a production plan to ensure that critical parts are always available when you need them.

Want to discuss a machining project with us?

Whether you need a same-day quote, have questions about our processing capabilities, or just want to say hello, contact us today!

Excellent Customer Service System

We always strive to establish and develop long-term cooperative relationships with our customers and let them experience firsthand our emphasis on quality, innovation and excellent customer service. We look forward to meeting your challenges and becoming the preferred supplier for all your design, development and processing needs. We constantly remind ourselves that we are committed to providing our customers with excellent products and services. Whether it is timely delivery of quality products or finding answers to technical questions, we can help you. We believe that sincere and timely communication is the key to our success.

Elimold provides reliable and high-quality services. Our team of engineers has extensive experience in their respective fields and ensures that all customers receive excellent service. In addition, our commitment to quality and unparalleled customer satisfaction. We use modern, high-precision machines to manufacture parts that meet or exceed customer specifications. Elimold is also flexible and willing to meet customers’ unique needs, making it an ideal choice for custom and fast processing services.

Material Options

At Elimold, we proudly offer a wide variety of high-performance composite, plastic, and metal materials for your project through our state-of-the-art CNC machine shop. Our team carefully selects and evaluates custom materials to ensure they meet the unique needs of your project. Whether you need corrosion-resistant materials or conductive materials, we have you covered! We consider factors such as durability, precision, and finishing needs to provide tailored solutions for projects of any size and complexity. In addition, our strong focus on quality and attention to detail ensures that each project is completed on time and exceeds the highest industry standards, giving you confidence in the reliability and performance of the final product.

Metals

- Aluminum

- Steel (carbon, alloy, stainless)

- Brass

- Bronze

- Copper

- Titanium

- Inconel

- Hastelloy

- Magnesium

- Nickel alloys

- Cast iron

- Monel

Plastics

- Delrin (Acetal)

- Nylon

- PTFE (Teflon)

- Polycarbonate

- PVC

- UHMW

- ABS

- PEEK

- Polypropylene

- Acrylic

- HDPE

- PVDF

Other Materials

- Ceramics

- Composites

- Graphite

- Foam

- Phenolic

- Fiberglass

- Quartz

- Mica

- Refractory materials

- Bakelite

- Micarta

- Resin-based materials

Surface Finishing Options

Custom parts often require surface treatment to improve corrosion resistance, appearance or performance. The right surface treatment is essential for custom parts projects to ensure the parts are fully functional, beautiful and free of defects. We can provide a range of surface treatment services. It is important to choose the right surface treatment based on the material and intended use. If you have any questions about the surface treatment options we offer, please feel free to contact us.

Metals

- Anodizing (Type I, II, III)

- Electroplating

- Electropolishing

- Powder Coating

- Painting

- Passivation

- Black Oxide

- Sandblasting / Bead Blasting

- Polishing

- Heat Treating (case hardening, nitriding)

Plastics

- Vapor Polishing

- Flame Polishing

- Bead Blasting

- Painting

- Silk Screening

- Pad Printing

- Texturing (via mold or post-process)

- Ultrasonic Polishing

- Solvent Smoothing

- Clear Coating

Other Materials

- Sanding

- Painting

- Clear Coating / Lacquering

- Resin Impregnation

- Sealing

- Polishing

- Texturing

- Flame Treating

- Surface Grinding

- Plasma Spraying

Industry Services

- Oil and gas

- Power generation

- Transportation

- Entertainment

- Mining

- Hydropower

- Solar

- Medical

- Military

- Marine

Custom Components for Critical Applications

Our expertise extends beyond manufacturing precision parts; we specialize in manufacturing critical components for critical applications. The projects our clients commission require us to deliver unparalleled precision and reliability. They rely not only on the accuracy of our components, but also on their ability to perform reliably in critical situations.

- Shafts

- Gears

- Bushings

- Flanges

- Housings

- Couplings

- Brackets

- Mounting plates

- Pins

- Rollers

- Valves

- Pistons

- Cylinders

- Manifolds

- Spacers

- Adapters

- Sleeves

- Fasteners

- Dies

- Molds

- Fixtures

- Jigs

- Tooling components

- Engine components

- Bearing blocks

- Pulley systems

- Levers

- Heat sinks

- Nozzles

- Custom enclosures

Why Choose Elimold?

Quality

Elimold is quality-based, ISO 9000 compliant, and applies statistical process controls when needed to ensure parts are machined to the tightest tolerances and reduce scrap/waste.

Pricing

The efficiency of our production and processes allows us to offer very competitive pricing. New customers will be pleasantly surprised when they contact us for same-day pricing. If you are looking for an alternative to a local Las Vegas machine shop, consider Elimold!

Fast Turnaround

Tight deadlines? The Elimold team is on call 24/7, Monday through Friday. While most other machine shops are resting, we are working flat out to ensure our customers’ expectations are exceeded.

Flexibility

We are committed to your success and can handle any task you throw at us. Need a small machined part? Need a long run? Need a special material? Need machined part finishing services or heat treatment? Need design assistance? We have you covered.

Service

The entire Elimold staff is dedicated to providing you with unparalleled service in the machining industry. From same-day machining quotes, to fast, on-time delivery, to a satisfaction guarantee, working with Elimold makes a world of difference.

Predictability

When it comes to precision machined parts, predictability is critical! Need a specific part machined to the exact same quality and tolerances as it was last week, last month, or last year? No problem. With Elimold, you get reliable, predictable quality.

Tooling, Machining and Related Engineering Capabilities

Elimold prides itself on its diverse CNC machining capabilities. We offer contract manufacturing services, handling both large and small projects with equal proficiency. Prototype tooling services offer your business the opportunity to create, test and refine designs before full production. With our expertise in tooling, we have the expertise to develop durable, high-precision tooling. Laser scanning is another advantage, enabling the precise digitization of components for quality control, reverse engineering or further processing. Finally, custom inspection services ensure that each product meets the company’s high quality standards, demonstrating our commitment to excellence in every project.

Request A Free Quote For Your Next Custom Project Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.