Fused Deposition Modeling (FDM) 3D Printing Service

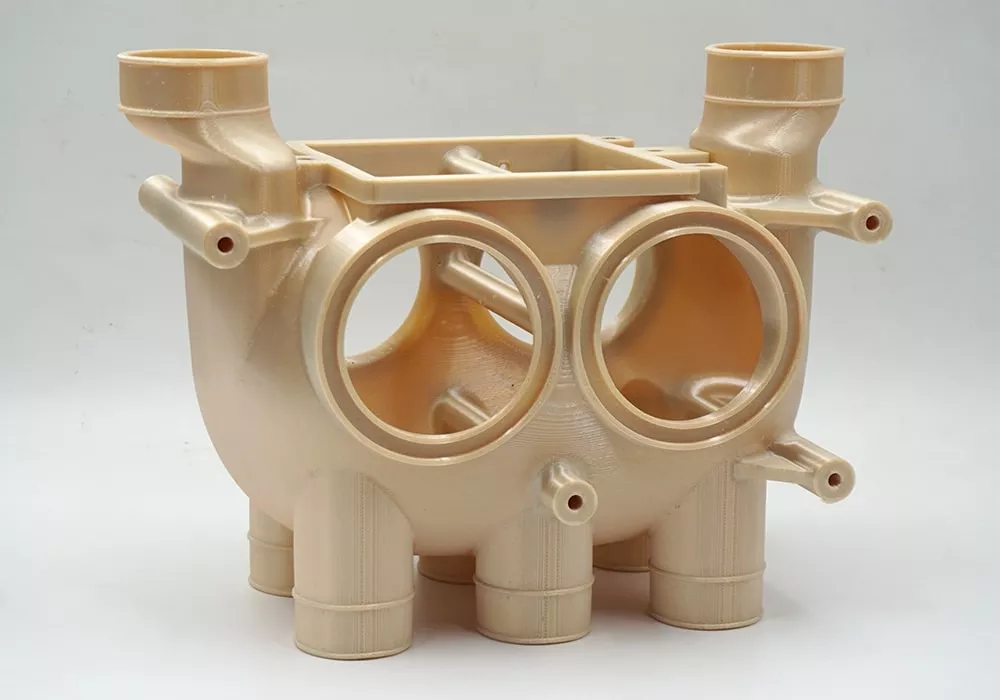

Fused Deposition Modeling combines the unparalleled design freedom and fast lead times of 3D printing with production-grade thermoplastics to create durable parts with excellent mechanical properties. The technology is ideal for functional prototypes, durable manufacturing tools, and low-volume end-use parts.Contact us now for a free instant quote.

Professional Fused Deposition Modeling (FDM) 3D Printing Service Provider

Do you need to get 3D printed parts quickly to verify your prototype design? Do you also need to produce production parts? Do you want them to withstand harsh environments? Do you need to print large parts with high precision? Elimold has professional Fused Deposition Modeling (FDM) technology that can provide 3D parts for small batch production. Choosing us, you can get the ideal product prototype and take advantage of our innovative solutions to deliver your products quickly. And FDM technology has significant efficiency improvements compared to traditional manufacturing methods, which can help you reduce production costs while shortening delivery cycles, so as to enter the market faster. Our rich material portfolio covers a wide range of applications from functional prototypes to end-use parts. In addition, Elimold has rich experience, well-trained professionals and in-house facilities to support FDM printing and provide high-quality parts and prototypes that meet your needs.

Professional FDM 3D Printing Manufacturer

Elimold is a professional 3D printing, 3D scanning and CAD design service company in China. We have the best talent to help you transform any complex 3D model into a physical entity. Whether you need to print a brand new design or already have a 3D model, just contact us or upload it to our website to get a free quote for FDM 3D printing services. Our designers and engineers are able to use their creativity and engineering capabilities to add color to your products. We provide exclusive 3D printing solutions that have been thoroughly researched. With our streamlined online services, you can easily purchase FDM parts. When you contact us, you can choose from a range of advanced thermoplastics customized to your application needs. And we can provide instant quotes and consult our FDM experts for material recommendations and design optimization solutions to ensure fast delivery of high-quality parts.

From Rapid Prototyping to High-Volume Production

Whether you need a prototype or high-volume production, our FDM manufacturing technology can meet your needs. With years of experience and the support of the latest 3D printers, we are able to provide you with high-quality products. We offer more than 45 industrial-grade materials for you to choose from, helping you turn your ideas into reality. Our engineers have extensive experience in rapid prototyping and low-volume production, and use FDM technology. We use the latest 3D printers to manufacture parts according to your needs, with the materials and surface treatments that meet your needs. Elimold provides excellent fused filament fabrication services to help you innovate strongly and gain a competitive advantage in the industry.

FDM 3D Printing Factory

At Elimold, we are committed to providing an exceptional customer experience by bringing your vision to life through innovative 3D printing solutions. Today, we offer hundreds of FDM 3D printers in different sizes, for different materials and applications, with unmatched capacity, professional engineering support and cutting-edge technology. With over 70 industrial-grade printers, we offer fast delivery times and scalable production capabilities, whether you need a single prototype or a full production run. And like all of our additive manufacturing machines, FDM runs 24/7, but with simpler operation and post-processing, resulting in low-cost parts and fast turnaround in just 1-2 days. Whether you are working on a personal project, creating a prototype, or producing custom parts for your business. We can turn your ideas into reality, providing fast, efficient service and high-quality results.

Fused Deposition Modeling 3D Printing Capabilities

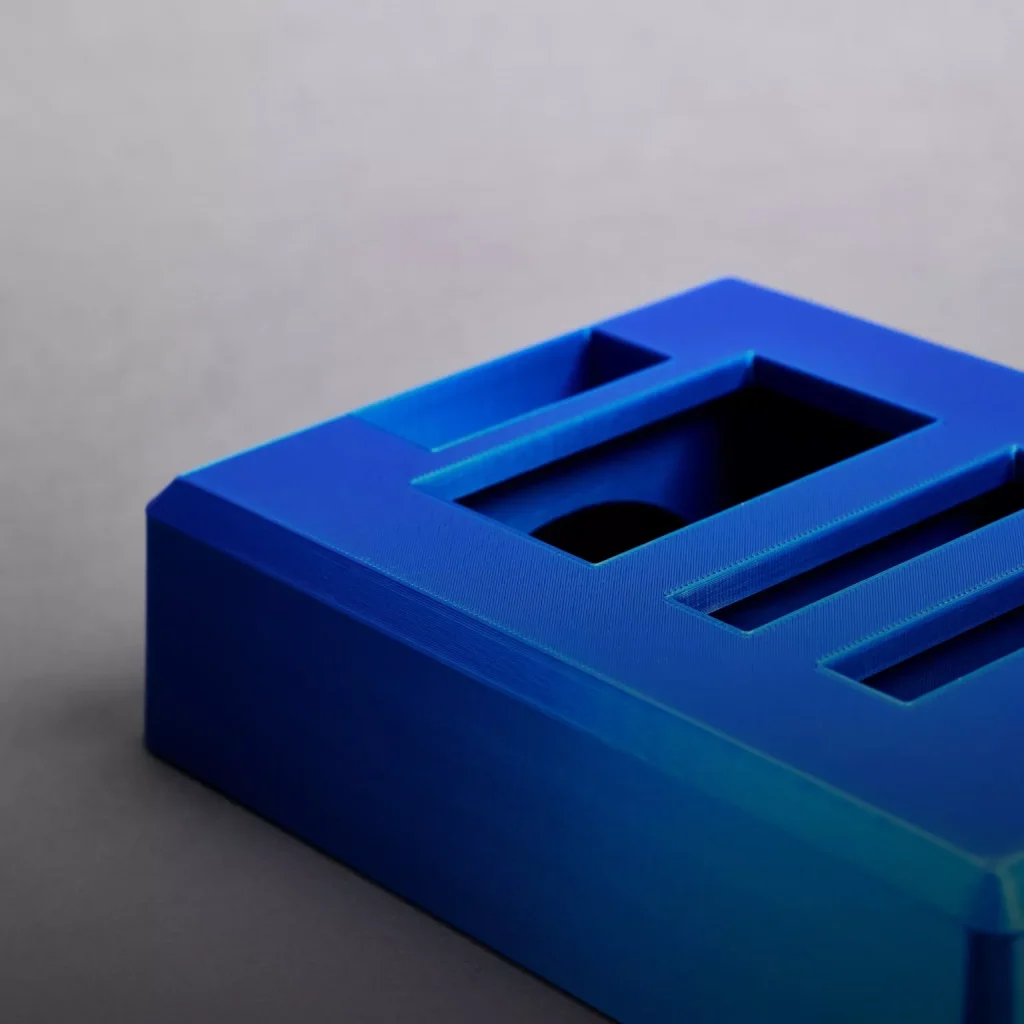

Elimold’s FDM 3D printing is able to hold part tolerances to +/- 0.005” for the first 5” and +/- 0.001” per inch thereafter. The same part can be printed repeatedly to +/- 0.001” accuracy. FDM 3D printed models can be up to 36” x 24” x 36” (914mm x 610mm x 914mm). Large models of almost any size can be cut up and glued together after completion to produce very large components.

Elimold has a variety of FDM machines to choose from depending on the project requirements. Each machine has its own advantages depending on the material and part type required for your job. These machines can build parts at different levels depending on the selected material and part requirements (e.g., surface finish, cost, quality, etc.).

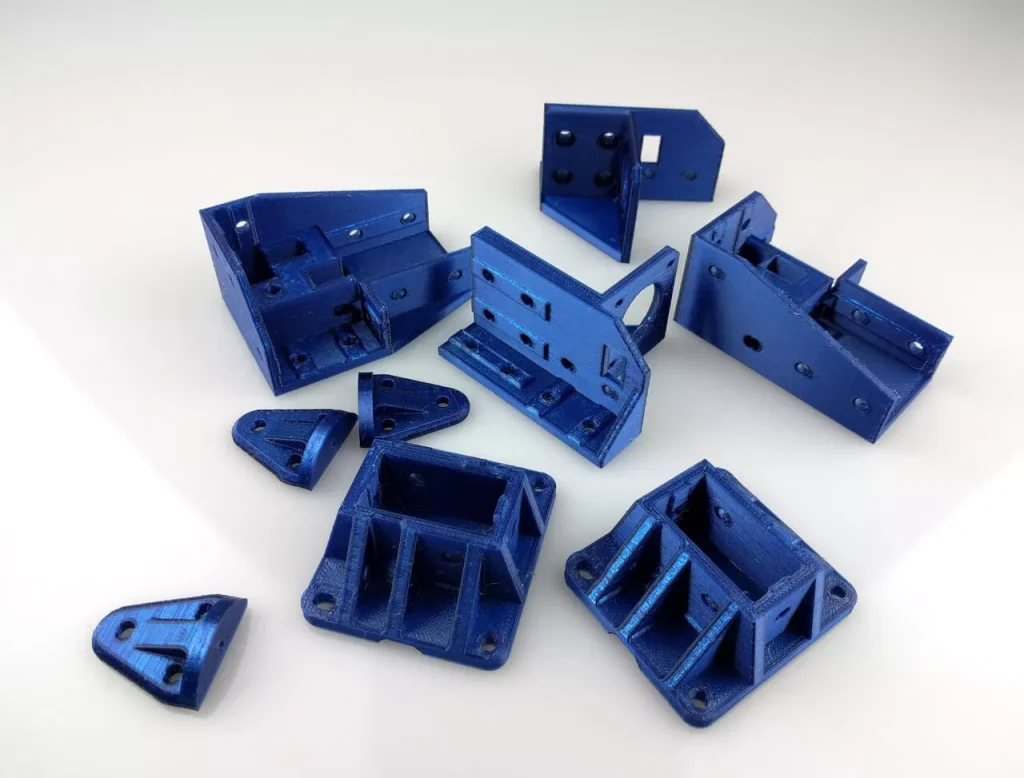

Applications of FDM 3D Printing

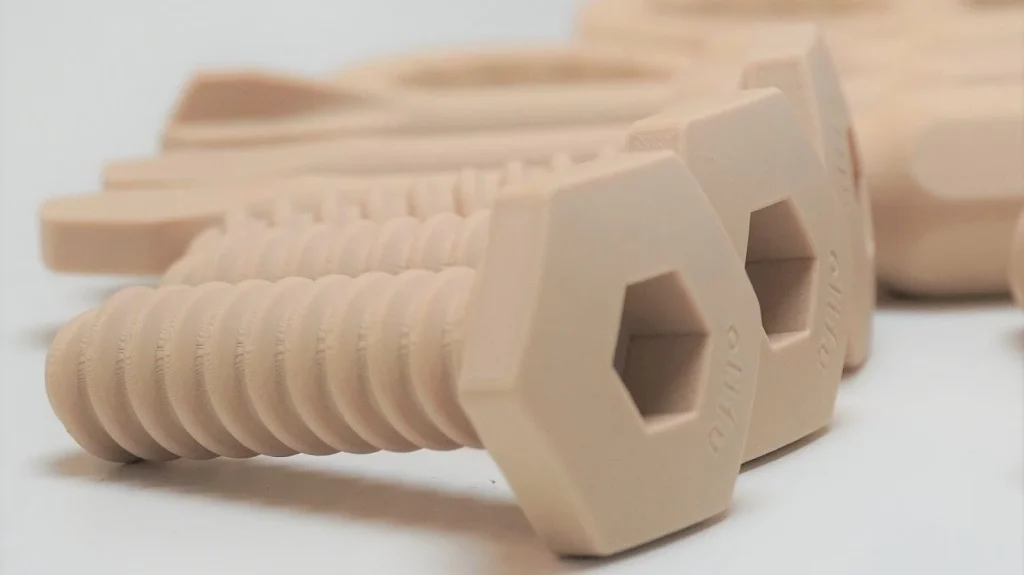

FDM is a popular additive manufacturing method, but it also has its own unique advantages. Due to the availability and low cost of desktop 3D printers, FDM is more widely known and more affordable than HP MJF or Carbon DLS. Here are the best uses for FDM.

Rapid Prototyping

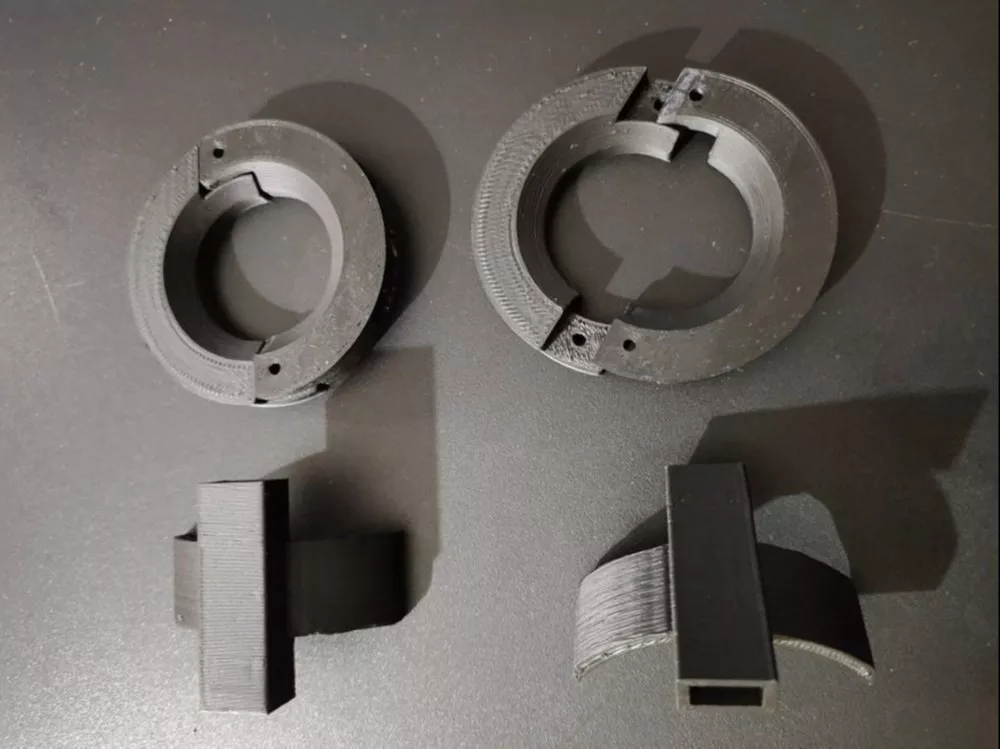

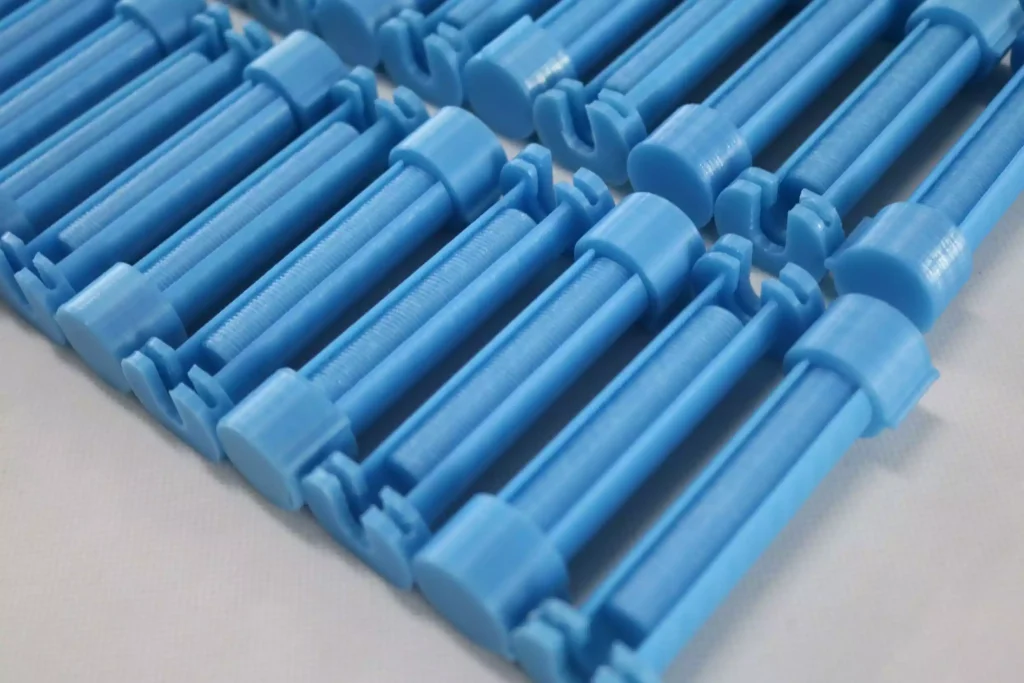

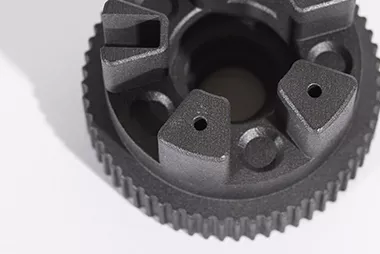

Composite Tooling

Jigs & Fixtures

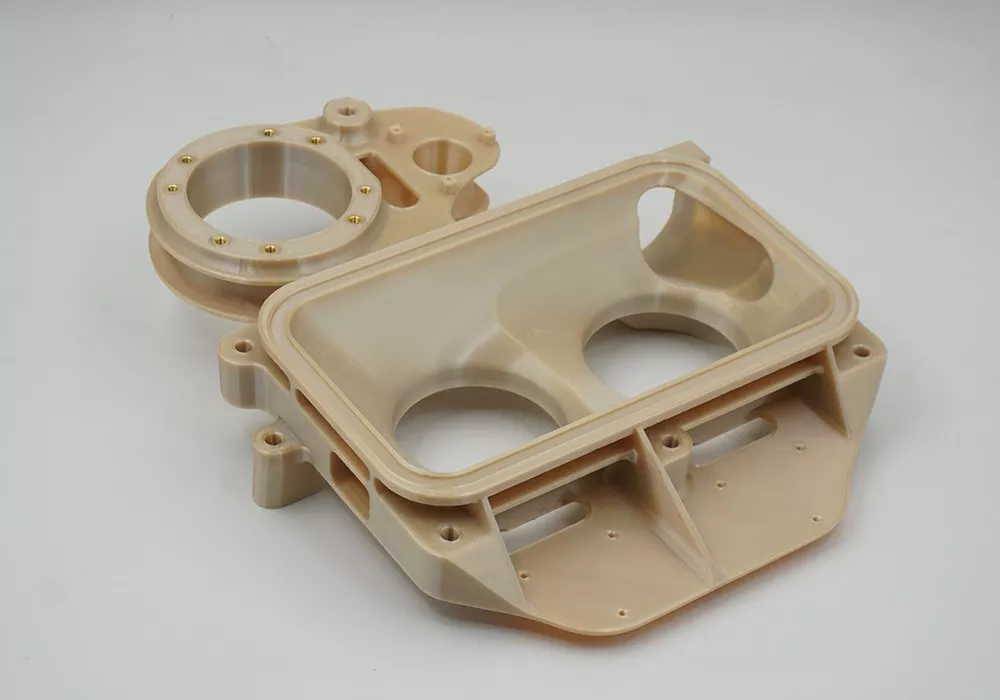

Production Parts

Full Range of FDM Printing Services

We are committed to making the FDM 3D printing process simple and easy. It all starts with discussing your project with you. Whether you want to create a functional prototype, manufacture a custom part, or just try a new design, we will take the time to understand your goals. Once we understand your goals, you can send us your 3D file and our team will carefully review it to ensure it is optimized for printing. We will help you choose the best material for your project based on factors such as durability, flexibility and budget. Then, we begin the printing process. Our advanced FDM printers print layer by layer, accurately building your design. Throughout the process, we perform quality checks to ensure that everything is perfect. After printing, we provide optional post-processing services such as sanding, painting or assembly as needed to ensure that your part is perfect. Finally, we will deliver the finished part for use. No matter the size of your project, we will ensure that the entire process goes smoothly from beginning to end.

Get Started with FDM 3D Printing

Ready to turn your ideas into reality? Contact Elimold to start using our FDM 3D printing services. Whether you want to prototype a new product, create a custom component, or bring a personal project to life, we are here to help. Contact us today to get a free quote and learn how we can help you achieve your goals with professional FDM printing solutions.

Full-Process FDM 3D Printing Service

Elimold has made a name for itself by using FDM technology to 3D print a wide range of three-dimensional objects. Our dedicated in-house team focuses on the key aspects of design (customization), manufacturing, machining, verification, and post-processing, taking care of the entire 3D printing process. Every member of our team is passionately committed to providing customized, high-quality 3D printing services. We help customers print products and models using a variety of 3D printing plastic materials. In addition, we simplify the 3D printing process with easy-to-use and highly reliable FDM 3D printers. Elimold can be trusted to print any product or object in the lowest time and cost.

Rapid Prototyping Solutions

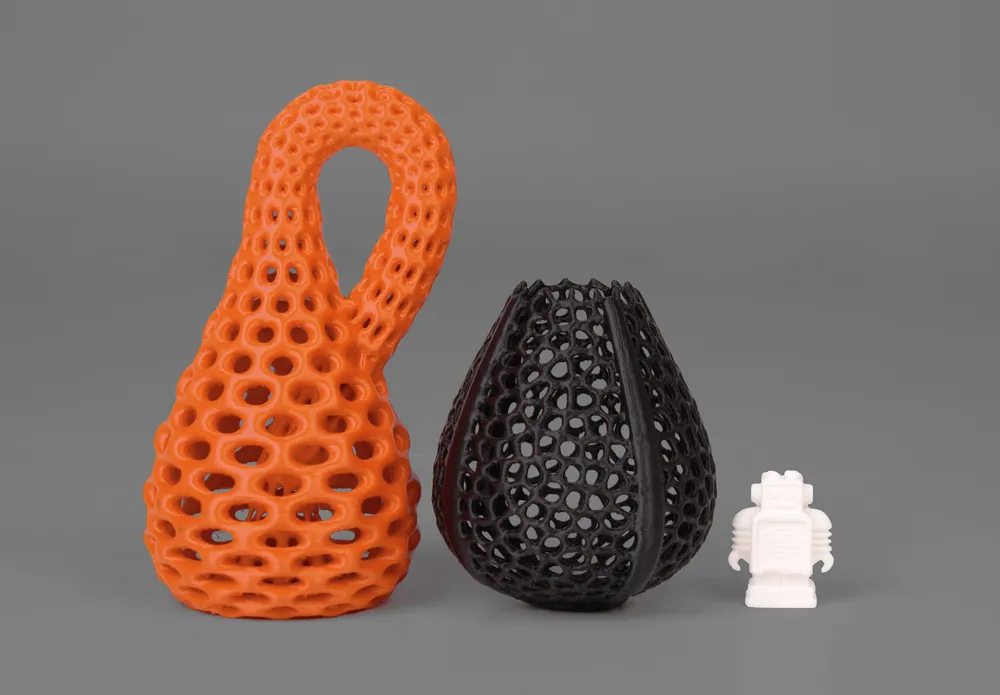

If you’re into rapid prototyping, FDM is the ideal solution. It allows you to quickly create and test designs, which is essential when you need to iterate and improve your product before committing to mass production. Not only that, FDM prints are durable and reliable, making them ideal for functional parts and tooling that need to withstand stress. Customization is another big benefit of FDM 3D printing services. Whether you require complex geometries, unique shapes, or specific surface finishes, we can tailor our process to your needs. This flexibility makes FDM ideal for printing everything from small, intricate designs to large, functional components.

FDM Rapid Prototyping Services

Use the design freedom of 3D printing to generate models directly from CAD designs and create any shape you can imagine. Combine beauty and function to create a stunning model that can be held in your hands and displayed much faster than traditional manufacturing processes. Fix errors and improve designs in the early stages of development. You can also use high-performance materials to check thermal, chemical and mechanical stresses to improve performance data for your products. Whether you need a concept model, a functional matching part or a functional prototype, our team can provide you with the best solution.

Expert Team of Engineering Design Services

As pioneers in FDM 3D printing technology, we excel at taking manufacturing projects to the next level. We have a large fleet of industrial-grade FDM printers and a team of engineering experts who are constantly pushing the boundaries of what’s possible with new materials and research. When you outsource to Elimold, you gain a partner with over 20 years of additive manufacturing expertise and a team ready to exceed your expectations. So whether your FDM project is in the early stages of development or the final production phase, choose a partner who is always committed to excellence, Elimold. Whether you need rapid prototyping or cost-effective mass production, we deliver reliable results with professional precision and efficient cost estimation based on your project needs.

Order High-quality FDM 3D Printed Parts Online

We are passionate about what we do. We combine the latest technology with years of experience to provide you with a fast, reliable, custom service that meets your needs. From choosing the right material to ensuring your part is printed with the highest precision, our experienced team of professionals will help you every step of the way. Our commitment to high-quality, no-wait results is what makes us stand out. We know that time is of the essence, so we work as quickly as possible to ensure that your part is delivered to you without changing our quality standards. In addition, we offer a range of customization options to ensure that your part is exactly what you expected. Most importantly, we are committed to ensuring that you have an excellent experience. Our customer support team is always available to answer questions or provide guidance. When you choose Elimold, you are not only getting a service, but also working with a team dedicated to turning your ideas into reality.

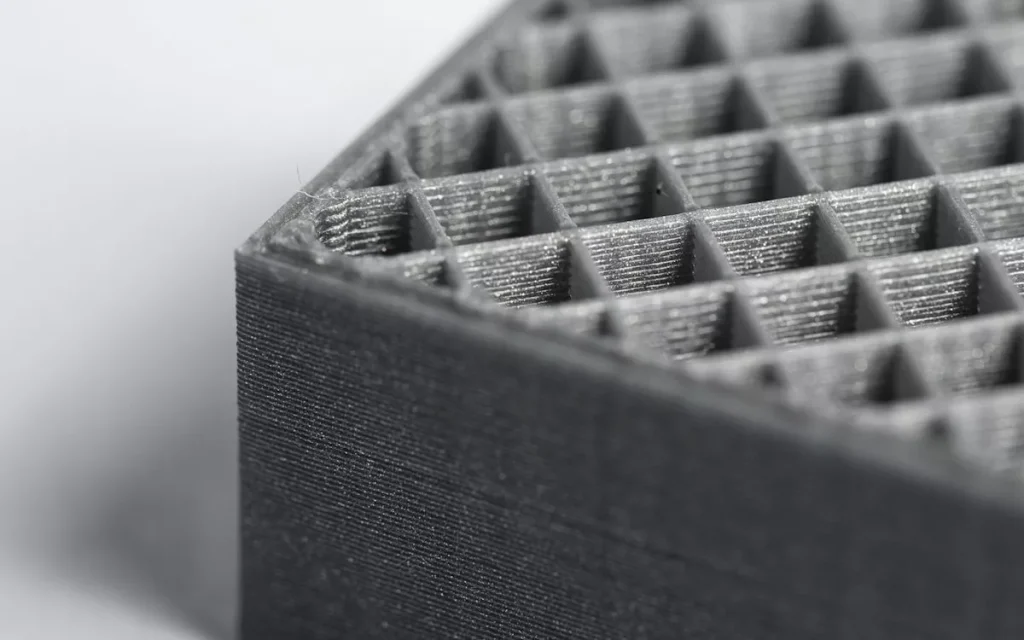

FDM Infill Options

Fused Deposition Modeling (FDM) is a 3D printing technology that builds a part layer by layer by depositing heated thermoplastic along an extrusion path. In this process, there are several different ways the interior areas of a part can be interpreted when the part is built. Infill describes how those interior areas of a part should be filled in.Elimold offers three types of infill options:

Ultralight FDM infill

Light FDM infill

Solid FDM infill

What is Infill?

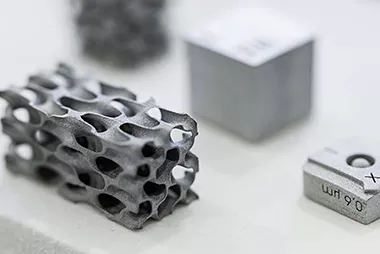

Infill is a characteristic unique to the FDM process. In FDM, an extruder nozzle deposits material along the toolpath, fusing it to previous layers to build a 3-dimensional body. The interior of the volume can be printed as “solid,” but it does not necessarily have to be. The pattern printed inside the contours is referred to as “infill.”Infill can reduce material consumption and weight and allow for the production of confined volumes.

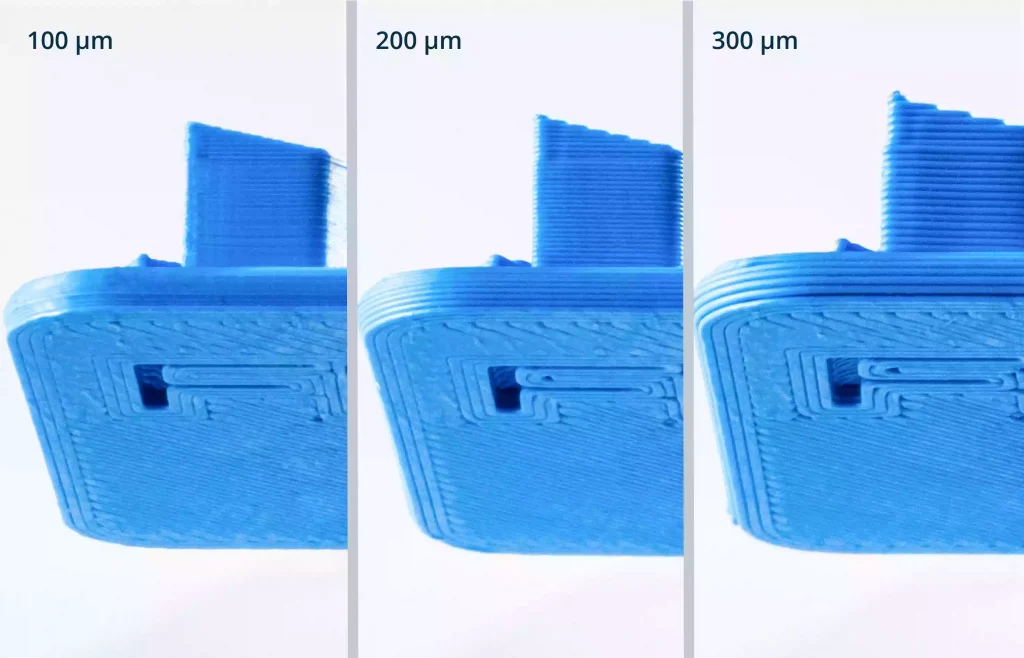

FDM Layer Thickness Options

Layer thickness refers to the height of each layer added during the additive manufacturing or 3D printing procedure, where multiple layers are stacked upon one another to create the final product. For FDM, choosing your layer thickness is a critical parameter that directly impacts a part’s visual appearance, properties and printing time.Elimold offers three layer thicknesses:

- 100 µm (Fine)

- 200 µm (Standard)

- 300 µm (Economy)

Manufacturing With FDM 3D Printing

Elimold sets the gold standard in Fused Deposition Modeling (FDM) 3D printing services. We have an excellent track record in high-performance FDM part manufacturing and have ISO9001, AS9100 and ITAR certifications, as well as quality audits and process controls to ensure we meet the highest demands and standards.

As a leader in FDM 3D printing technology, we excel at taking manufacturing projects to the next level. With our in-house fleet of industrial-grade FDM printers and dedicated team of engineering experts, we continually push the boundaries of what’s possible with new materials and research. When you outsource to Elimold, you gain a partner with additive manufacturing expertise and a team ready to exceed your expectations. So whether your FDM project is in the early development stages or final production, choose a partner that is committed to excellence.

Quality Management Standards

We not only meet the high standards for FDM 3D printing, we set them. Our commitment to excellence is reflected in every step of the manufacturing process, from materials to the final delivery of the FDM part. Our strict process controls, comprehensive quality audits, and multiple certification standards demonstrate our determination to produce excellent FDM parts. We never stop until we exceed expectations. We produce your custom parts according to strict manufacturing standards, ensuring that all parts and processes meet wheel standards. We send an inspection report with each order, which contains a comprehensive review of these requirements. Choose Elimold for FDM 3D printing and ensure reliability and performance.

Optimize Product Development with DFMA

Design for Manufacturing and Assembly (DFMA) provides a proven framework to streamline product development, reduce costs, and improve quality. By incorporating manufacturing and assembly considerations from the earliest design stages, DFMA enables teams to simplify product architecture, reduce development time, and improve manufacturability.

We start or revisit your design with DFMA at its core, supported by modern tools like Elimold’s Digital Manufacturing Platform. With DFMA as a core design strategy, your team can bring better products to market faster and more cost-effectively than ever before. Ready to optimize your product designs for manufacturing and assembly efficiency? Contact us for a free quote.

3D Scanning

We offer a comprehensive range of scanning services, including inspection scans for First Article Inspection Reports (FAIR). We provide thermal map models with basic dimensioning. Our team specializes in capturing accurate, high-quality 3D data. We can capture raw scan data for printed models or provide enhanced reverse engineering services to help you produce a usable CAD model. Our team uses a variety of software packages and can provide parametric models with a full design tree, giving your team full control over CAD design parameters if modifications are required. We can accurately replicate parts up to 0.035 mm.

Get Your Printed Parts Into Production Runs Today

From design to prototype and production, our team of engineers is ready to help bring your idea to life with 3D printing.Send your CAD files, Receive your customized custom Fused Deposition Modeling (FDM) printing quote. Choose from a variety of process materials to suit your needs.

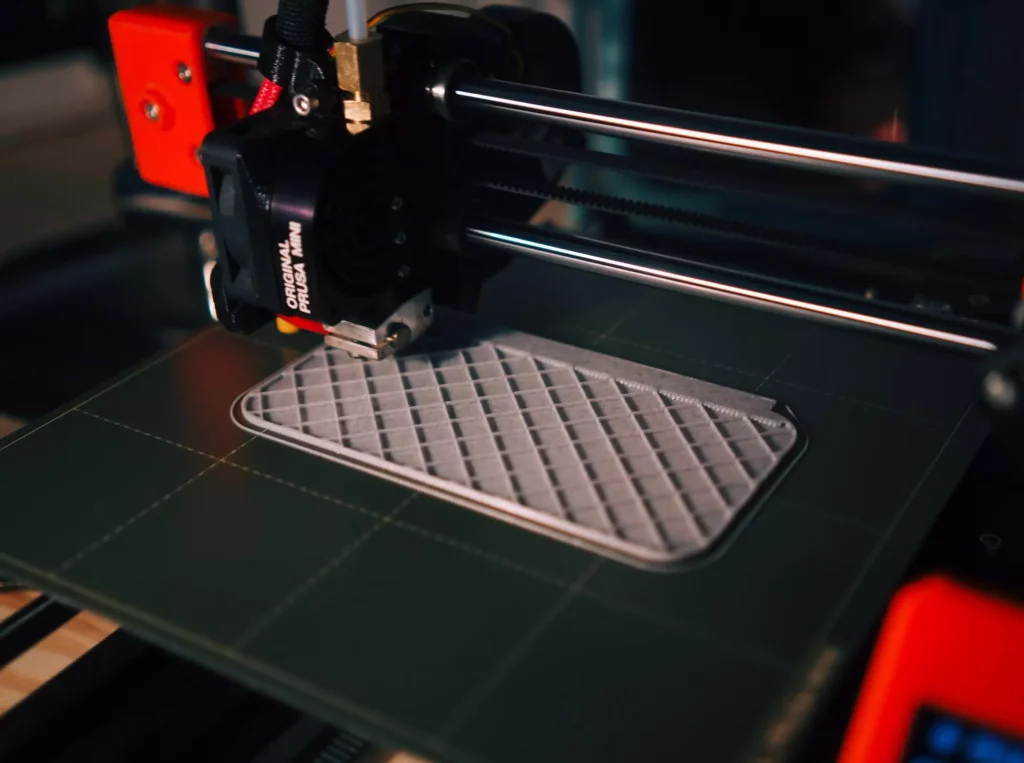

What is FDM 3D printing technology?

FDM printers work by the addition of layers using FDM filaments. It is one of the most used additive manufacturing technologies, appearing as a natural alternative to traditional manufacturing processes.During the FDM 3D printing process, the filament is extruded through a nozzle which melts while being gradually deposited in a structured way on the build platform until the object is finished. The extruder of the 3D printer is attached to a system with three axes: X, Y, and Z directions. When the material is melted and extruded, it is deposited in predetermined locations on the 3D printing bed, where it cools and solidifies. The bed lowers for each new layer, and this process repeats until the object is completed.There is also particular importance of support structures in filament 3D printing technologies. While 3D printing with FDM technology, support structures are often required. Indeed, some geometries, such as overhangs, can’t be printed without supports.

Benefits of Fused Deposition Modeling (FDM)

The advantages of industrial-grade FDM include durability, large printing volumes, material selection, high reliability, and high production efficiency.

- Durability: Industrial-grade FDM uses production-grade thermoplastic materials to produce durable, high-strength, and high-toughness parts suitable for high-load and high-durability applications.

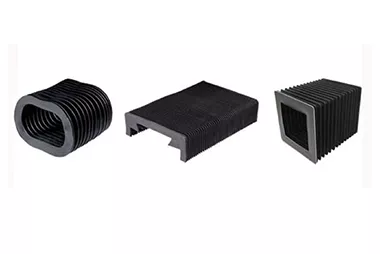

- Large printing volume: Many industrial-grade FDM printers have large printing volumes, which can produce large or batch parts.

- Material selection: Industrial-grade FDM can use a variety of production-grade thermoplastic materials, such as ABS, PC, PPSU, ULTEM, to meet the requirements of various applications.

- High reliability: Industrial-grade FDM printers have high precision and stability and can produce consistent and reliable parts.

- High production efficiency: Industrial-grade FDM can achieve automated production, reduce labor and time costs, and improve production efficiency.

FDM 3D Printing Material Options

One of the great benefits of FDM technology is the number of available materials. They include durable engineering-grade thermoplastics for high-use, general-purpose printing, strong carbon fiber materials, and high-performance polymers that can handle the most demanding applications. Here are the materials we offer.

Standard materials

- ABS

- ABS+

- ABS ECO

- ABS FLEX

- ABS PRO

- PETG (COPET)

- PCTG

- PLA

- PLA+

- PLA-HT

- PLA-LW

- T-PLA

- HIPS

- SAN

- SLICE SUPPORT

Engineering Plastics

- ELASTAN

- TPU

- PET

- PC

- NYLON

- PA

- ASA

- PBT

- ABS/PC

- PP

- WAX-FILAMENT

Composite materials

- ABS/PC

- ABS PRO CCF (CARBON FIBER)

- ABS PRO CGF (GLASS FIBER)

- PETG (COPET)-CG GRAPHITE

- PETG (COPET)-CCF (CARBON FIBER)

- PLA-COFFEE

- PLA-CCU COPPER

- PLA-CNI NICKEL

- PLA-СG+ GRAPHITE

- PLA-CCF (CARBON FIBER)

- ELASTAN D70 CCF (CARBON FIBER)

- TPU CONDUCTIVE

- NYLON-CCF (CARBON FIBER)

- PA12 ССF (CARBON FIBER)

Finishing Options for FDM Parts

Discover the versatility of Fused Deposition Modeling (FDM), with finishing capabilities that go beyond printing. Our expert finishing and assembly services can transform your designs with a variety of post-processing options, finishing operations can change the appearance and performance of your components, allowing you to achieve outstanding aesthetics without compromising performance. Whether you are looking for a smooth polished surface, or enhanced durability and performance, Elimold has finishing options to take your FDM components to the next level.

Elimold offers these post-processing services for its FDM printing service:

Sanded

Tumbled

Media blasted

Vapor smoothed

Painted (EMI shield)

Painted (sand and paint, non-cosmetic)

Painted (sand and paint, cosmetic)

Painted (customer spec paint)

Specialty coated

Plated

Decals

Pad printed

Screen printed

Inserts

Post-machined

Assembly

FDM Design & Build Guideline

Each 3D printing technology is a little different, here are standard guidelines to consider when choosing FDM as your 3D printing process:

- FDM Build Layers

- 0.007” Build Layers = Best part finish, accuracy, detail, and strength but increases cost and build times (Ultem not available)

- 0.010” Build Layers = Best balance of finish, accuracy, detail, and strength with cost and build times

- 0.013” Build Layers = Best for quick low-cost parts but finish, accuracy, detail, and strength are reduced

- Minimum Wall Thickness & Features = .71-1.32mm (0.028”-0.052”) based on layers

- Standard Finish = Level 1 Support Removal Finish

- Standard Lead Time = 1-3 days

- Tolerances = +/- 0.005” for first inch then +/- 0.002” per inch thereafter

- Inserts = Preferred for threads, install in post-processing with heat stake or adhesives

- Holes = Drill, Ream, and Tap (Print threads then chase or ream in finishing)

Why Do Our Clients Prefer FDM Technology?

- FDM fused deposition modeling technology is easy to use.

- It reduces the production cost associated with 3D printing technology.

- The lead times for this manufacturing process are comparatively shorter.

- It is easy to deal with complicated cavities and geometries with FDM technology.

- There are several high-performance options that need element resistances.

- Our professionals can produce on-demand parts.

Traditional Technologies That Can Benefit from FDM

If you are currently using CNC machining, injection molding, or other traditional methods to produce prototype parts, FDM may be a faster, more flexible alternative. FDM manufacturing can be used to produce thermoplastic parts in small batches, making it ideal for bridge production or while you wait for traditional manufacturing tools to be completed.

Engineers and designers who plan to produce FDM parts will benefit from the design freedom the process offers. Unlike traditional manufacturing processes such as injection molding and CNC machining, the functional design of a part can be limited due to cost, setup, or tooling constraints. FDM 3D printing is an additive manufacturing process, so you are limited only by your imagination and a few basic guidelines.

FDM 3D Printing Parts Supplier

From prototyping to low-volume production, our network of certified in-house FDM 3D printing facilities will enable you to produce high-precision parts with quality and strength comparable to injection molding. Our expertise in additive manufacturing, high-end functional test prototypes, 24-hour service, competitive pricing, on-time delivery, and drop shipping to more than 150 countries can help you turn your ideas into projects, bring your innovative products to market faster, reduce your production costs, and save your R&D time. Upload your CAD file to receive an instant Fused Deposition Modeling 3D Printing quote and put your parts into production in less than 5 minutes.

Fusing Large Parts in FDM Printing

Need extra capacity or a larger build frame? Outsource to Elimold. Our extensive FDM printer resources provide extra capacity, a wide selection of materials, and fast lead times for your FDM projects. We offer a wide variety of engineering-grade thermoplastics that can be used to create parts for proof of concept, functional testing, manufacturing tools, and end-use production. Get high-quality parts quickly from Elimold, the original AM pioneer. If you are looking for industrial-grade 3D printing for plastic parts, we recommend trying our SLS (Selective Laser Sintering) or MJF (Multi Jet Fusion) 3D printing services. These printing technologies will provide higher precision, more advanced mechanical properties, and a wider selection of printing materials.

Other 3D Printing Services

If you have a complex part design, our 3D printing services can help you turn it into reality. With the right equipment, strong technical knowledge, and a focus on quality, Elimold ensures that every project is completed to a high standard and that your order is delivered on time, every time.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Direct metal laser sintering (DMLS)

Metal 3D Printing

Selective Laser Melting (SLM)

P3 technology (DLP)

Micro 3D Printing

Metal Binder Jetting

Ceramic 3D printing

Comparison of FDM Printing Services to Other 3D Printing Technologies

FDM vs. SLA

FDM vs. SLS

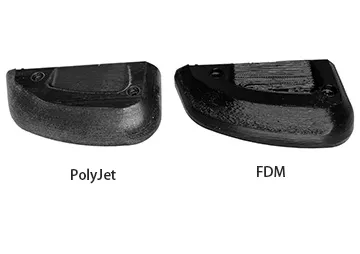

FDM vs. PolyJet

Ready to get started on your FDM 3D printing quote?

Our integrated approach to design, prototyping, and production allows you to bring your concept to market faster and more cost-effectively than virtually anyone else.