- Elimold Slogan: Make One, Made More

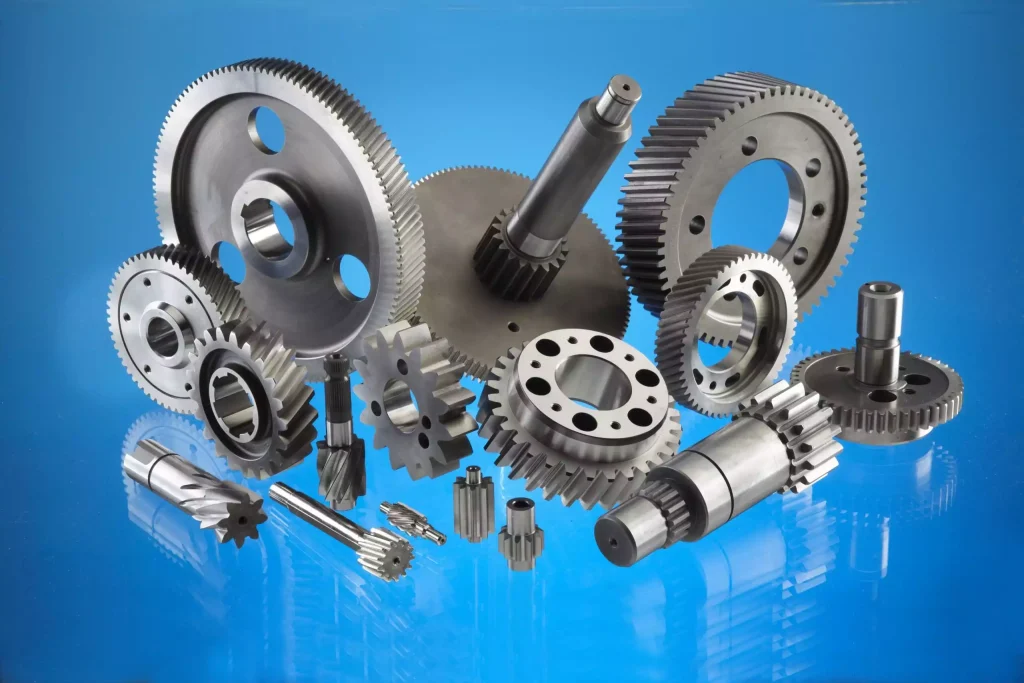

Gear CNC Machining

Custom CNC machining gears are gear parts that are specially manufactured to meet specific requirements or designs that cannot be met by standard off-the-shelf gears. Our customers rely on Elimold’s capabilities to meet the gear CNC machining contract manufacturing needs of a rapidly evolving industry. You can count on our talented team to provide expertise, technology, and the highest level of customer service. The reliability of our gear products is ensured by our in-house engineering team providing analysis, precision inspection, and quality control services. Elimold is the custom gear CNC machined parts supplier you need. Contact us today for a free instant quote.

Gear CNC Machining Manufacturer

At Elimold, we are experts in gear CNC machining. We use the latest technology and techniques to produce precision gear parts for a variety of industries. With our experience and expertise, we can perfectly meet your needs. Our in-house gear machining factory can provide a comprehensive gear part CNC machining solution. Including design, drawing, material selection, product costing, production processing and assembly, inspection, delivery, after-sales and other services. In addition, we also provide complete and complex CAD programming directly from the design drawing step file, which enables us to optimize the process and ensure that our parts are manufactured to the precise specifications of our customers. With our skilled technicians and strict quality control processes, we can provide gear parts that meet the highest standards of quality and reliability.

At Elimold, we are committed to providing the best results for our customers. Whether you need a single custom gear component or large-scale production, we have the expertise, equipment and capabilities to meet your needs. Contact us today to learn more about our gear CNC machining services and how we can help you achieve your goals.

Custom Gear Machining Production

Precision is the cornerstone of our CNC machined gear parts expertise. We use state-of-the-art machinery, cutting-edge software, and a team of skilled professionals to ensure that every gear and component we manufacture is manufactured with unparalleled precision. From complex gear profiles to intricate tooth shapes, we adhere to the highest industry standards and achieve seamless integration and optimal performance. We are at the forefront of gear CNC machining technology, providing innovative CNC machined gear part solutions to solve your most difficult challenges. Elimold is your ideal partner for CNC machined custom gear product needs in a variety of applications.

In addition, we understand that every industry and application has unique requirements. Our CNC gear services can be tailored to your specific needs. Whether you need low-noise gears or lightweight, high-strength gear assemblies, we have the ability to provide custom gear CNC solutions. Our expert engineers work closely with you to understand your project goals and ensure that the final product exceeds your expectations. With years of experience in gear CNC machining, we have accumulated a wealth of industry expertise. Our team of engineers and technicians have a deep understanding and understanding of the unique needs of industrial, robotics, aerospace, and medical applications. We closely monitor industry trends, regulations, and best practices to ensure our solutions always meet the latest standards.

Gear Types

Elimold can process gear parts of any specifications, and can process any gear product with a diameter not exceeding 20 feet through CNC machining.

- Spur gears

- Helical gears

- Bevel gears

- Worm gears

- Rack and pinion

- Spline

- Helical gears

- Double helical gears

- Herringbone gears

- Split herringbone gears

- Spiral bevel gears

- Bevel gears

- Ring gears

- Worm gears

- Double enveloping worm gears

- Hypoid gears

- Spiral gears

Our CNC Gear Machining Capabilities

Elimold is pleased to offer precision gear CNC machining capabilities to a variety of industries, including but not limited to industrial equipment, mining, oil and gas, and heavy construction. These capabilities include state-of-the-art CNC gear hobbing, shaping, and grooving machine equipment. The gear hobbing machines can accommodate parts up to 78.7 inches (2000 mm) in diameter or up to 46 inches (1168 mm) in maximum axial face width, and gear teeth up to 1.6 DP (15.88 module). Elimold also has heavy-duty manual and CNC routers that can accommodate parts up to 69 inches in diameter and 60 inches in height, and cut gear teeth up to 1 DP (25.4 module), with stroke lengths up to 17 inches. Finally, the 2400 size gear grooving machine enables Elimold to perform external hobbing or grooving (roughing or finishing applications) on spur and helical gears up to 78.7 inches in diameter with an axial travel length of approximately 69 inches (1760 mm). The machine can also cut internal teeth on parts up to 94.5 inches (2400 mm) in diameter. We can work with a variety of materials to suit our customers’ needs, from prototype to production. Our state-of-the-art gear inspection equipment can perform comprehensive analytical gear inspections to verify the quality of the parts produced, ensuring they meet the specifications required by our customers.

Gear CNC Machining Factory

Elimold operates a 67,000 square foot state-of-the-art facility featuring a wide range of gear manufacturing equipment. Our fully equipped in-house gear machining facility provides CNC turning, milling, broaching, grinding and other services for your custom gears, parts and assemblies. Elimold is your trusted partner. Our commitment to providing precise, custom gear CNC machining solutions, unmatched quality, cutting-edge technology and industry expertise is what sets us apart. By choosing us, you gain a competitive advantage knowing that your gears and components are carefully crafted and built to perform in the most demanding environments.

In today’s competitive environment, it’s critical to stay ahead of the curve. We pride ourselves on employing the latest advancements in CNC gear hobbing and carbide re-hobbing technology. Our in-house manufacturing facility is equipped with state-of-the-art CNC machines, robotic automation and advanced simulation software. By utilizing these cutting-edge tools, we can optimize production processes, increase efficiency and provide exceptional results for our customers.

Gear CNC Machining Technology Types

The choice of gear CNC machining process depends on the application, accuracy requirements and other practical circumstances. Our advanced technologies in gear cutting, gear grinding and custom gear CNC machining result in longer life of gear parts and the highest quality components worldwide. Coupled with the fastest response and delivery time, Elimold is the right choice for you, no matter where on the planet and in which industry you are.

Gear Forming

In gear forming, the cutting edge of the cutting tool has the same shape as the space between the gear teeth. Two machining operations, milling and broaching, can be used to form cut gear teeth.

Forming Milling

In forming milling, a milling cutter called a forming mill is advanced axially along the length of the gear tooth at the appropriate depth to produce the gear teeth. After each tooth is cut, the cutter is withdrawn, the gear blank rotates, and the cutter continues to cut another tooth. This process continues until all teeth are cut.

Broaching

Broaching can also be used to produce gear teeth, especially internal gears. The process is fast and produces a fine surface finish with high dimensional accuracy. However, because broaches are expensive and a separate broach is required for each size of gear, this method is mainly suitable for high-quality production.

Hobbing

Hobbing is a machining process that uses a spiral cutting tool to gradually form gear teeth through a series of cuts. All movement in hobbing is rotational, and the hob and gear blank rotate continuously like two meshing gears until all teeth are cut.

Gear Generation

During the gear generation process, the tooth flank is obtained as a profile for the subsequent position of the tool, which is similar in shape to the mating gear in the gear pair. There are two machining processes, forming and milling. These processes have various modifications for different cutting tools.

Shaping

Gear shaping is frequently used to manufacture spur gears, herringbone gears and ratchets. This method is also considered a generative process of gear hobbing, as the gear is shaped according to the tool mounted on the tool spindle. The blank to be shaped is placed on a fixture or mandrel on the work spindle. The workpiece is rotated 360 degrees at a set feed depth until the required tolerance and shape are achieved.

Precision Gear Machining Services

Elimold offers exceptional gear CNC machining services, specializing in the production of precision gears and splines to tight tolerances. Utilizing advanced gear CNC machining capabilities, we ensure that every gear component manufactured meets stringent quality standards. Our process begins with design, where we translate customer specifications into tangible, workable 3D models. Utilizing state-of-the-art CAD/CAM systems, we ensure that every minute detail is captured and transformed into the final product. Once the design phase is complete, we use high-precision CNC equipment to produce your gears and splines. These automated systems provide unparalleled accuracy, with impeccable dimensional consistency even in high-volume production. The versatility of CNC machining allows us to process a wide range of materials, providing our customers with a wide range of options to meet their specific needs. As a result, we can meet the stringent requirements of various industries. With a deep understanding of industry-specific standards and regulations, we ensure that our products not only perform their functional role, but also meet all necessary guidelines. At Elimold, we pride ourselves on providing not only products, but also comprehensive solutions. Through timely delivery, stringent quality checks and unparalleled customer support, we ensure our customers receive a seamless, hassle-free experience from start to finish.

Elimold's Gear Order Processing Advantages

We encourage customers to place consolidated purchase orders for 12 months to meet annual needs. This allows us to reserve material specifically for the customer and can typically ship within one business day.

- Bulk orders for custom CNC gear parts save lead time.

- Single gear purchase orders are much more economical than multiple purchase orders.

- Our customers can avoid costs associated with shelf space or storage space.

- We want to help you determine your costs because product prices remain the same throughout the term.

Ready to get started on your next gear CNC machining project?

Whether you need a single custom gear or high-volume production, we have the expertise, equipment, and capabilities to meet your needs. Contact us today for a free, instant quote.

Materials commonly used in gear CNC machining

Modern gear CNC machining involves materials that provide strength, wear resistance and durability. The choice of material depends on the load capacity, operating environment and expected life. . The following are the most commonly used materials by Elimold:

Metals

- Steel (Carbon Steel, Alloy Steel, Stainless Steel)

- Aluminum (6061, 7075, 2024)

- Brass

- Bronze

- Copper

- Titanium

- Cast Iron

Plastics

- Nylon (PA)

- Acetal (POM, Delrin)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polypropylene (PP)

- PTFE (Teflon)

- PEEK (Polyether Ether Ketone)

- UHMW (Ultra-High Molecular Weight Polyethylene)

Quality Management and Customer Service

Our in-house engineering analysis team performs quality control and precision inspections to ensure your parts meet the precise tolerances required for your project. At Elimold, we are committed to providing a great environment for our employees to thrive. Our employees are experts in gear CNC machining, passionate and committed to providing the highest level of quality and customer service. Together, we form a team you can trust. Our years of experience coupled with cutting-edge equipment provide the highest-end gear products possible. We will work with you every step of the way to ensure a fast, efficient turnaround. Whether dealing with a one-off part or a large-volume production order, consistency and accuracy in gear CNC parts are our founding principles. All of our gears go through a rigorous inspection process to ensure they meet our customers’ requirements. Take the time to work with us to see if your needs are perfectly met. Remember, our experienced and skilled team is ready to work with you to meet your needs. Simply tell us your requirements and we’ll do the rest for you!

Inspection Equipment

- Gleason 475 Gear Checker (2 Machines)

- Keyence IM Optical Comparitor

- Jenoptik Opticline Shaft Scanner

- Zeiss o-Inspect 543 CMM

- Parkson

- Hardness tester

- optical comparators

- profilometers

- surface plates

- gage blocks

- micrometer sets

- dial bore gages

- plug gages and thread gages

Surface Finishing and Post-Processing for CNC Machining Gears

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Anodizing

- Electroplating (Nickel, Zinc, Chrome, etc.)

- Powder Coating

- Sandblasting

- Polishing

- Black Oxide Coating

- Passivation

- Phosphating

- Grinding

- Honing

- Lapping

- Heat Treatment (Case Hardening, Nitriding, Carburizing, Induction Hardening, etc.)

- Deburring (Manual, Vibratory, Thermal, Electrochemical, etc.)

One-Stop Gear Machining Capabilities

With many years of experience in CNC precision machining,, Elimold has the expertise to produce custom gear products of all kinds. Our online CNC machining services feature a variety of gear machining processes and technologies. From gear design to production to shipping, we can meet your requirements at every stage. Our factory’s capabilities include gear processing (gear cutting, hobbing, milling, grinding) and gear forming (gear forging, gear extrusion, gear casting, gear injection molding), cutting-edge technology and advanced gear machining equipment, allowing us to make our customized gear products meet industry-leading standards or exceed customer expectations. Whether you are looking for a manufacturer of spur gears, helical gears, spiral bevel gears, or other types of CNC gears, we will provide high-quality products and fast turnaround. From hard metals to plastics, a variety of materials with excellent properties are available. We can also help you design and review nearly all types of gears to enhance their functionality and manufacturability.

Other Gear CNC Machining Process Types

Are you looking for a faster, more affordable, and more efficient solution to produce your precision gear components? Our full-service gear CNC machine shop is the best choice for high-volume production gear part needs, and we can handle complex geometries and angles quickly and accurately. With the expertise of our team, you can save on production costs, produce products faster and more reliably, and maintain a competitive advantage.

CNC Milling

Our CNC machining services allow for the creation of complex milled parts at velocity. This expands the potential range of materials without minimising efficiency and standards. We can manufacture complex parts in a wide range of sizes, quantities, and with multiple angled features.

CNC Turning

Our team continues to refresh our fleet of machines, investing significantly in our Turning and Mill/Turn technology. This allows us to remain ahead of the game, providing a tailored service and solution to our customers that is hard to match within the industry.

3 Axis CNC Machining

The 3 axis CNC machining services offer the best value in the industry for small CNC machines. It packs a punch, an efficient smaller package that delivers big results and high standards of productivity. The best way to maintain productivity in a smaller space.

4 Axis CNC Machining

4 axis CNC machining is where the 4th axis rotates whilst the machine is not cutting, aiding precision. Our range of CNC machining services is designed to offer a wide range of precision to fit any manufacturing complexities and demand.

5 Axis CNC Machining

We continue to innovate, refining our 5 axis CNC machining services for maximum output at reduced time and cost. The 5 axis provides you with the power and precision for myriad uses, maintaining accuracy and delivering consistently.

CNC Prototypes

Creating a prototype is an important part of the manufacturing process. Our services allow our clients to see a product, part, or concept in action before making a decision on whether to continue production or make necessary changes.

Wire EDM Machining

Our advanced Wire EDM machines allow us to complete complex projects at quick turnarounds, and in tight tolerances up to +/_ 0.0001. We employ 4-axis machining to produce high-quality products. We use various advanced CAM software, which helps us import parts, files, and drawings easily.

CNC Threading and Tapping

Many components require threaded holes or tapped features for mounting screws, fasteners, or connectors. Our CNC machining service offers precise threading and tapping capabilities, ensuring that these essential features are accurately created to the required specifications.

CNC High-Speed Drilling

Custom parts manufacturing often involves drilling precise holes for components, connectors, and fasteners. Our High-speed dril with CNC machines guarantees accurate hole placement, diameter, and depth.

Swiss Machining Service

Swiss machining is an efficient way to produce complex, or slender component. By moving both live tooling and the workpiece, we can always cut the material which is close to the workpiece holder. To avoid deformation compared to traditional CNC lathe.

CNC Routing Service

Besides standard milling service for parts in engineering plastics or metals, we also offer CNC routing service for prototypes and parts in soft materials such as EPS foam, EVA, woods.

CNC Grinding Service

If you need a super flat surface part, or round part that needs OD and ID +/- 0.005mm in tolerances, our CNC grinding machining service will be the best match of your production needs for such type of parts.

What is a gear?

A gear is a wheel with teeth that uses its meshing action to transfer the rotational motion of one shaft to another shaft and transfer motion or torsion between the two shafts. A gear is a mechanical element with teeth on the rim that can continuously mesh and transfer motion and power. Gears are mechanical parts with teeth that can mesh with each other. The application of gears in transmission has appeared very early. With the development of production, the smoothness of gear operation has been valued. Gears are used to change the direction of movement, increase or decrease the speed and output torque. Therefore, gear transmission can easily change the speed, torque and direction of the power source.

Industries that use gears

Gears are vital in many industries, including:

- Automotive: Vital to engines, transmissions, and drive systems.

- Aerospace: Used in aircraft engines and navigation systems.

- Industrial machinery: Pumps, conveyors, and mixers.

- Energy: Found in wind turbines and hydroelectric generators.

- Mining and construction: Used in excavators, cranes, and earth-moving machinery.

- Robotics and automation: Vital for the precise movement of robotic arms and actuators.

- Consumer electronics: Used in clocks, cameras, and toys for quiet operation.

Request Your Free Gear CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Gear CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.