HDPE Injection Molding Service

Elimold is a professional manufacturer of custom HDPE plastic products, providing reliable, high-quality HDPE injection molding services. We offer fast delivery, customized solutions, and highly competitive prices.

Precision High-Density Polyethylene Injection Molding

Looking for high-performance plastic parts? As a trusted supplier of high-density polyethylene (HDPE) injection molding, Elimold focuses on providing precision, high-performance HDPE plastic injection molding solutions for various industries. No matter what type of HDPE plastic parts you need, our experienced engineering team ensures optimal part design and mold quality, and helps you select the right material based on function and performance. With advanced in-house mold making capabilities and years of experience in HDPE injection molding, we can help you transform your ideas into scalable, manufacturable solutions.

Complete Production Support Team

We have a dedicated manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

What is High-Density Polyethylene (HDPE)?

High-density polyethylene (HDPE), or PEHD, is a thermoplastic polymer polymerized from ethylene, a petroleum byproduct. It is a low-cost thermoplastic with a linear structure and very low or almost no branching. It is produced at relatively low temperatures (70-300°C) and pressures (10-80 bar). Furthermore, HDPE has two sources: modified natural gas (a mixture of methane, ethane, and propane); or from crude oil catalytic cracking. Currently, most high-density polyethylene (HDPE) products are produced using slurry polymerization or gas-phase polymerization processes. These processes first polymerize ethylene monomers in a solution, followed by separation and drying.

Advantages of HDPE Materials

Superior Performance for Demanding Applications

Chemical Resistance

Excellent resistance to acids, alkalis, solvents, and corrosive chemicals, suitable for harsh environments.

Impact Strength

Excellent impact resistance even at low temperatures, ensuring durability under harsh conditions.

Moisture Resistance

Extremely low water absorption, maintaining dimensional stability even in humid environments.

Lightweight Design

Low-density material reduces product weight while maintaining structural integrity and strength.

Environmentally Friendly

100% recyclable material, supporting sustainable production and environmental protection.

Affordable

A cost-effective material with excellent performance-to-price ratio, suitable for high-volume production.

What is HDPE Molding?

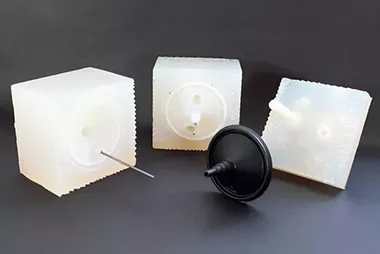

First, HDPE plastic is melted into a moldable molten state. Once the resin reaches a molten state in the injection molding machine, the molten HDPE material is injected into the mold. The plastic resin hardens almost immediately after injection. After the part cools and solidifies, the mold is opened, and the part is removed. The mold is then reinstalled, and the process is repeated. Elimold uses only high-strength steel in manufacturing HDPE injection molds. This high-strength steel ensures that the molds can withstand hundreds of thousands of cycles of wear.

High-density Polyethylene in Injection Molding

Leveraging our expertise in HDPE plastic molding, we provide scalable solutions for industries that require durability, chemical resistance, and cost-effectiveness.

HDPE 5000S

HDPE 5000S boasts excellent tensile strength of 30 MPa and high elongation at 600%, an impact strength of 30 J/m, a heat deflection temperature of 85°C, low shrinkage (1.5%), and shape retention during cooling, contributing to the precise and consistent production of precision parts.

HDPE 6000F

HDPE 6000F exhibits superior melt flowability, with a tensile strength of 27 MPa, a flexural strength of 45 MPa, an impact strength of 35 J/m, and a heat deflection temperature up to 90°C. Therefore, this material possesses excellent mechanical properties, strong impact and shock resistance, and is suitable for applications facing moderate thermal challenges. It is ideal for manufacturing precision parts with complex geometries.

HDPE 7000F

HDPE 7000F boasts a flexural modulus of up to 1300 MPa and an elongation at break of up to 500%. Its higher molecular weight further enhances its mechanical properties and durability. This material combines flexibility and strength, making it suitable for products requiring both, and it excels in applications demanding high rigidity and structural integrity.

HDPE 8000F

HDPE 8000F features an impact strength of up to 50 J/m, a heat distortion temperature of up to 100°C, and a shrinkage rate as low as 0.8%. This material stands out for its excellent resistance to stress cracking, making it a representative of high-performance grades. It also exhibits excellent impact resistance, seismic resistance, and high-temperature resistance.

Looking for Reliable HDPE Injection Molding?

Get high-density polyethylene injection molding solutions with exceptional durability and chemical resistance. Request a Quote Today!

Cost-Effectiveness and Scalability of HDPE Injection Molding Services

Elimold specializes in providing cost-effective and scalable high-density polyethylene (HDPE) injection molding services. Our efficient production processes reduce operating costs, ensuring competitive pricing while maintaining quality. As an experienced HDPE injection molding supplier, we offer flexible solutions for everything from small batches to large-scale production. Whether for custom orders or mass production, our efficient operational scaling capabilities make us the preferred partner for businesses seeking high-quality, low-cost HDPE plastic injection molding services.

State-of-the-art Equipment and Materials

We utilize state-of-the-art equipment and premium materials in high-density polyethylene (HDPE) injection molding to ensure that every product meets stringent quality standards. Elimold’s advanced injection molding equipment is optimized for a wide range of applications, including the injection molding of both thin-walled and thick-walled HDPE parts. We use premium HDPE injection molding resins, enabling us to manufacture durable, chemically resistant parts with high precision. Through continuous technological upgrades, we offer the latest HDPE plastic injection molding solutions, giving our customers a competitive edge in manufacturing.

HDPE Injection Molding Plant Capabilities

Located in Shenzhen, China, we have a state-of-the-art factory equipped with over 100 modern machines, ranging in tonnage from 180 to 2200 tons. From product conception to final assembly, we handle every step in a one-stop shop, helping you eliminate the need for additional suppliers, streamlining the manufacturing experience, and ensuring consistent quality at every stage. Furthermore, our in-house mold-making workshop boasts over 30 dedicated CNC machine tools, as well as EDM equipment and wire cutting tools, enabling high-precision mold manufacturing. We produce over 130 million plastic parts annually.

Custom Options for HDPE Injection Molding

You can customize materials, colors, and surface finishes to achieve precise part machining results based on your project requirements.

Material Customization

We can help you select the right materials based on factors such as strength, chemical resistance, or FDA compliance. We ensure your parts are made with the correct HDPE material to meet performance requirements.

Color Customization

The colors of HDPE parts can be customized to your needs. We use pigments and dyes for precise color matching to ensure parts align with your brand image or specific functional coding.

Surface Finish Customization

You can choose from smooth, matte, glossy, or specific textured surface finishes. Elimold can create molds to meet your requirements, achieving the look and feel you desire.

No Geometric Limitations

We can precisely manufacture parts with complex shapes and features. Elimold translates your detailed designs into high-quality physical parts that meet stringent tolerance requirements.

High-Density Polyethylene Injection Molding Experts

No matter the order size or design complexity, our team is dedicated to meeting your needs. We excel at producing parts according to your drawings, specifications, or purchase order requirements, and can also help you turn your brilliant ideas into finished products. If you haven’t yet received approval for your design, we’d love to collaborate with you to develop a prototype for testing and validation. Once the design is accepted, full-scale production can begin. Obtaining HDPE injection molded parts that meet your requirements may involve multiple processes. If your supplier cannot complete these processes, it may be necessary to transfer semi-finished products between different factories. This can extend lead times and reduce profit margins. Therefore, Elimold provides a variety of value-added services to its customers. You can rest assured that we will provide you with turnkey parts ready to use.

HDPE Injection Molding Quality Control

Elimold boasts an ISO 9001 certified workflow, with rigorous material testing as the first step in our quality control process. Our quality checks span the entire production process, beginning with First Article Inspection (FAI), hourly dimensional checks using calipers and gauges, and a 100% visual inspection of the final parts. Coordinate Measuring Machine (CMM) measurements verify critical dimensions against your drawings. Comprehensive documentation ensures traceability; each batch has a unique ID containing complete processing parameters, inspection results, and material certifications, eliminating concerns about consistency between different production batches.

Alternatives to HDPE Injection Molding

Vacuum Forming

Plastic CNC Machining

Plastic Extrusion

Ready to Make Custom HDPE Injection Molded Parts?

Contact us to start your project. Elimold will be your next-generation HDPE injection molding partner, from prototyping to mass production.