High Volume Machining

If you need large-scale production, Elimold is ready to help you complete your project smoothly. We provide medium and high-volume processing services. We will select the most suitable machine for you to ensure that your project is completed on time and on budget. Our professional team and advanced manufacturing capabilities are ready to support your project, covering all aspects from prototyping to mass production. Contact us now to start your project journey!

High Volume Machining Manufacturer

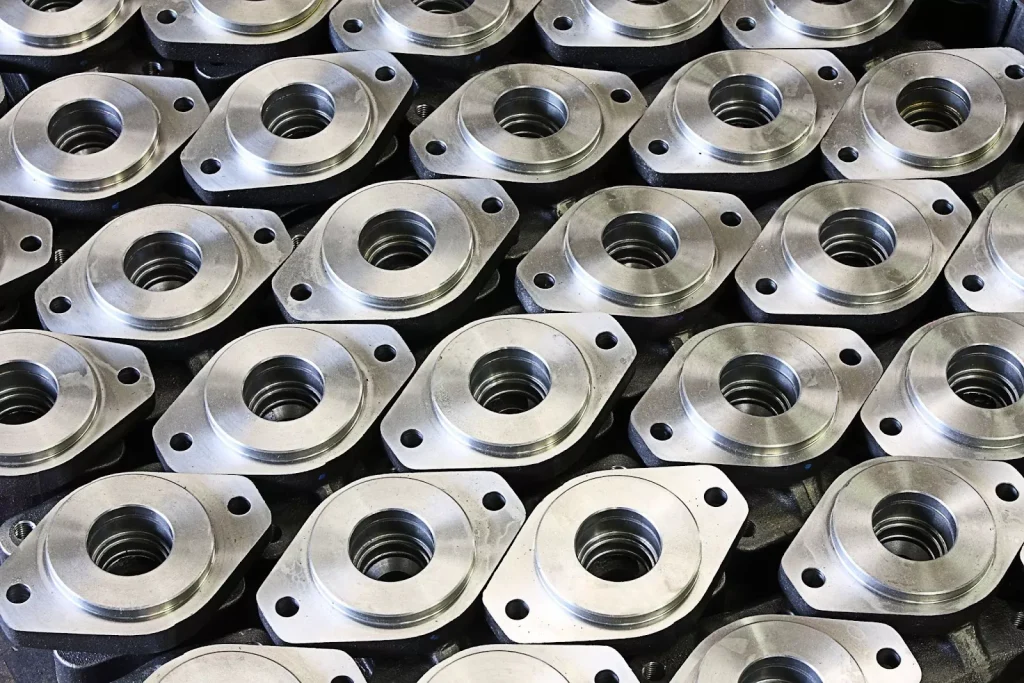

Elimold offers an in-house precision parts machining shop designed for high volume production without sacrificing quality. With 8 state-of-the-art production facilities and over 380 machines of all types, we offer custom machining capabilities tailored to meet the needs of mass custom parts machining. As a Tier 1 or Tier 2 supplier, we work closely with your team to develop smooth high volume production processes and provide support at any stage of the product lifecycle. Whether you are looking for outsourced high volume machining services or a complete high volume turnkey solution, Elimold can meet your quality, quantity and lead time needs with unparalleled customer service!

Full range of high-volume precision machining capabilities

Our in-house, high-volume machine shop features multi-axis CNC machining centers and wire EDM equipment that provide efficient and accurate custom machining, drilling, milling, boring, contouring, and surface finishing for both simple and complex shapes. These machines offer exceptional repeatability, enable fine tolerances, ensure your finished product meets your desired specifications, and are ideal for batch production runs of over 1,000 pieces per run. With our high quality standards in machining and finishing, we will ensure that every product exceeds standards. Our automated CNC machining and wire EDM equipment is integrated with laser cutting, punching, forming, rolling, welding, hardware mounting, and finishing equipment to provide a complete machining and manufacturing service.

High-Volume CNC Machining Service Provider

High-Volume CNC Machining meets the needs of a wide range of industries for high-volume production of precision parts. Elimold’s advanced machining processes, meticulous inspection plans, and automated systems help reduce overall production costs while ensuring accuracy and consistency throughout the production process. From estimation to final inspection and shipment, we always communicate with you and your team to ensure that your expectations are not only met, but exceeded. We specialize in high-volume production of complex parts. We can complete difficult tasks immediately, but impossible tasks take longer.

As a leader in large-scale production, we can produce 10,000,000 precision parts per month. We have more than 300 advanced machines and more than 1,000 materials that can be processed. Elimold is committed to quality and holds ISO 9001, ISO 16949 and ISO 13485 certifications to ensure the highest standards and processing services in large-volume production. With unparalleled capabilities to provide efficient, accurate and diverse products, we are a reliable choice for industries that require large-scale production without sacrificing quality.

Our High Volume Production Capabilities

Our in-house facility produces over 400,000 parts per week! Elimold’s high volume production area is designed with our customers in mind. The 65,000 square foot facility operates 24 hours a day, producing 400,000 high quality parts per week. Our ring manufacturing capabilities set us apart in the machining industry. Our processes vary depending on your needs, such as volume, part complexity, or material yield. Currently, part sizes range from 1” to 9” in diameter, and our production runs range from 500 to 40,000 parts per week.

The state-of-the-art equipment and advanced manufacturing methods in our in-house facility allow us to manufacture a wide variety of tight tolerance parts at an incredible rate. To meet the needs of our customers, our in-house facility’s machinery uses machine automation as well as robotics and cutting-edge measurement solutions to eliminate variables and ensure the highest quality products are produced at the desired production rates.

Lead Times

Lead times for our high-volume services vary by project. In many cases, orders over 5,000 parts can be delivered within our standard 5-8 week lead time for initial delivery. Once production begins, we can ship on a weekly, monthly, or on-demand basis. We accept volume orders and stocking agreements, where we will produce and stock parts for future delivery on a scheduled or on-demand basis. Depending on the complexity of the part and expedited options, we can shorten or lengthen a specific lead time to keep it consistent with our standard lead time. Whatever the lead time, we will let you know at the time of quote so you know when the part will arrive at your dock.

Your partner for high-volume machining projects

By choosing Elimold for your next high-volume machining project, you will benefit from our strong capabilities, expertise, and focus on customer service. Together, we will advance your business with precision and efficiency. Contact us now for a free instant quote.

Types of our high-volume CNC machining services

Elimold offers a comprehensive range of high-volume CNC machining services to meet diverse production needs. High-volume machining covers a range of processes including precision milling, turning, drilling, grinding, etc. These processes involve removing workpiece material to achieve the desired shape, size and surface finish. These high-volume machining processes combined with advanced CNC technology can produce high-volume parts efficiently and accurately.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

High Volume Machining Turnkey Solutions

Our high volume machining services cover a wide range of capabilities to meet your precision manufacturing needs. At the heart of our high volume machining services lies our advanced machining technologies and resources. Our facility is equipped with advanced equipment and an experienced technical team to handle high volume machining jobs with exceptional precision and efficiency. In addition to CNC machines, we also have a fully equipped department for other manufacturing processes, providing flexible solutions for specialized or low volume needs. Our centerless grinding capabilities allow us to achieve extremely tight tolerances, while our dedicated finishing department with cleaning equipment ensures that each component leaves the factory in pristine condition, ready for immediate use or further processing.

Our large network of strong and trusted material suppliers and partners enables us to source a wide range of materials, ensuring that we can provide tailored end-to-end solutions based on your specific project needs. Therefore, our diverse machining technologies, coupled with a strong supplier network, allow us to flexibly use a wide range of materials and provide comprehensive turnkey solutions to meet the most demanding specifications and production volumes.

Tolerance and Dimensional Manufacturing Capabilities

Our team of engineers and designers embrace the challenge of machining complex, precise, and tight tolerance parts. We work on projects involving a wide range of metals, including those that are unusual and difficult to machine. We also machine a wide range of different types and grades of plastics. We can machine parts from 0.125″ to 20.0″ in diameter and 0.125″ to 24.0″ in length, including small parts and parts up to 50.0″ long x 24.0″ wide x 16.0″ high. Our mill-turn machines can machine parts up to 8.0″ in diameter. We develop intelligent workholding solutions for easy setup, precise machining, and fast cycle times. Our ID/OD tolerances approach ±0.0005″ and our straightness and concentricity tolerances approach ±0.001″.

Ready to start your next high-volume machined custom parts project?

Contact us today to discuss your project needs and get a custom quote. Let us help you succeed with precision parts and efficient mass production.

On-demand manufacturing services

Elimold can also ensure that production processes can be expanded or reduced according to changing needs. This requires flexible manufacturing systems, adaptable production lines and agile scheduling. Modular tools, standardized processes and flexible machine configurations enable fast switching, efficient use of resources, and the ability to adapt to different production volumes and product changes.

By implementing efficient customized parts production solutions, Elimiold is able to meet specific application needs, provide high-quality components, and maintain a competitive advantage in the market. We can provide you with professional high-volume processing services, including a variety of material options, manufacturing processes, and highly competitive cost and quality advantages. We also have a range of advanced machinery and experienced technicians to assist you with your important projects.

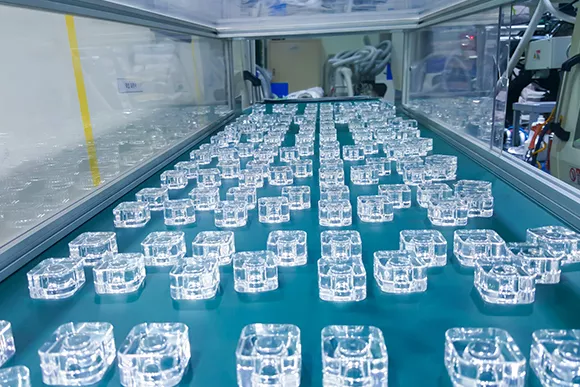

Prototyping and Rapid Manufacturing

Prototyping plays a vital role in custom part production solutions. It validates design concepts, performs functional testing, and identifies potential issues early in the process. Prototypes can be iterated, incorporating feedback and making necessary modifications to improve performance, manufacturability, and overall quality. Eimold offers rapid prototyping technologies such as 3D printing to help reduce turnaround time and enable cost-effective iterations.

If you need precision engineered components manufactured with the highest quality, competitive pricing, and fast delivery, then we can help. Our extensive custom machining capabilities enable you to design, develop, and prototype parts using our integrated modular multi-station machining systems, then quickly scale up production for high-volume production.

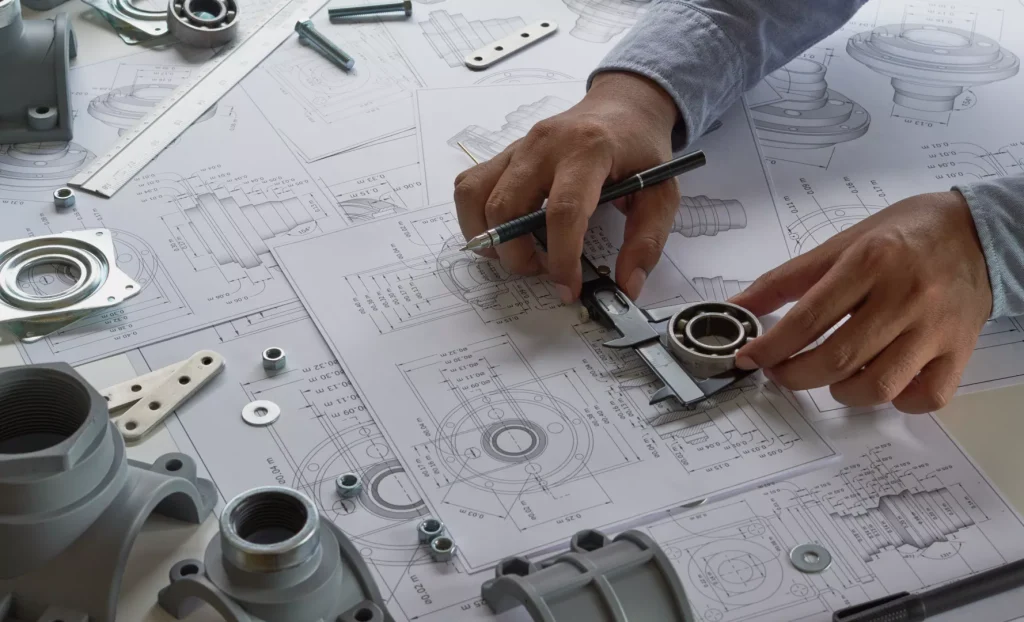

Design for Manufacturability (DFM) Services

Design for Manufacturability (DFM) principles are essential for custom part production. DFM involves considering manufacturing processes, capabilities, and constraints when designing a part. DFM considerations include material selection, design simplification, tolerance optimization, and assembly feasibility. Elimold’s design and manufacturing teams can provide DFM analysis for your project, and their collaboration ensures that parts are optimized for efficient production, minimizing manufacturing challenges, and reducing costs.

In-house Engineering, Tooling and Automation

To ensure that your needs are met in a timely manner, Elimold has a team of engineers responsible for designing our own tooling, including custom molds, tool grinding and wire cutting technology, as well as custom equipment automation and inspection automation. Our strong team of manufacturing and automation engineers is committed to ensuring that all high-volume custom machined parts have the tightest tolerances, best surface finishes, detailed dimensions and high consistency. Our skilled technicians will perform quality assurance verification throughout the manufacturing process to ensure that the final machined parts are of the best quality.

Quality Control for High Volume CNC Machined Parts

At Elimold, our commitment to quality assurance sets us apart. We are a certified IATF 16949 prototype manufacturer, recognized as one of the top Chinese suppliers, and an ISO 9001 certified rapid prototype manufacturer. Our factory operates 24/7 and is committed to meeting your needs in a timely and efficient manner.

Every part that leaves our factory comes with a Zeiss CMM inspection report that verifies accuracy up to 0.001 mm. Your satisfaction and confidence in our products is our top priority.

Our quality control process is very comprehensive and covers every stage from material procurement to processing. Each step is precisely controlled, tested and thoroughly inspected to ensure that high standards are maintained. Final shipment inspection ensures the highest quality before delivery.

Materials Machined in High Volume Machining

High-volume CNC machining meets the needs of a wide range of industries and applications. To efficiently and accurately produce parts, we use a wide range of high-performance metals and plastics, as well as a variety of composite materials. We also integrate automation and multi-axis machining technologies to increase productivity and flexibility in your production processes.

Metals

- Alloy Steel

- Aluminum

- Beryllium

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Iron

- Lead

- Stainless Steel

Plastics

- Titanium

- ABS (Acrylonitrile

- Acetal

- Acrylic

- Fiberglass

- Reinforced Plastics

- Nylon

- Phenolic

- Polyamide-Imide

- Polycarbonate

- PEEK

- PET

High Volume Machining Secondary Services

In addition to our machining services, we offer a variety of value-added operations that allows the ability to complete most component part applications. The result is outstanding service, exceptional quality, shorter lead times, and lower costs! Our services include:

- Engineering

- Inventory Management

- Assembly

- Part Washing

- Packaging

- Plating

- Heat Treating

- Grinding

- Thread Lock

- Broaching

- Slotting

- Piercing

- Notching

- Much More

Surface Finishing Options

Usually, after parts are processed, most parts need to be surface treated. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. Elimold can provide the following surface finishing process options.

Metals

- Anodizing

- Bead Blasting

- Powder Coating

- Electroplating

- Polishing

- Brushing

- Passivation

- Black Oxide Coating

- Chromate Conversion Coating

- Painting

- E-coating

- Laser Etching/Marking

- Heat Treatment

Plastics

- Vapor Smoothing

- Flame Polishing

- Painting

- UV Coating

- Clear Coating

- Texturing

- Laser Etching/Marking

- Ultrasonic Cleaning

- Plasma Treatment

- Sanding

- Polishing

- Deburring

- Tumbling (Vibratory Finishing)

Composites

- Painting

- UV Coating

- Clear Coating

- Laser Etching/Marking

- Sanding

- Polishing

- Deburring

- Tumbling (Vibratory Finishing)

- Plasma Treatment

- Ultrasonic Cleaning

- Texturing

Ready to get started on your High Volume CNC quote?

Have a question? Reach out to our team to learn more about our high volume machining services and get a quote for your next project.

Exceptional Machining Capabilities

Our high-volume machining systems offer exceptional speed, power, and flexibility. When it comes to machining parts for your application, we are able to:

- Seamlessly cut complex shapes

- Reduce or eliminate secondary operations

- Minimize manual labor for technicians

- Apply to both tubular and flat materials

- Maintain tight tolerances

- And more

Customers have come to associate our contract manufacturing production systems with quality and accuracy. We work hard for our customers and are committed to their success. That success comes in improving their processes so they can enjoy new levels of quality and cost-efficiency.

Industries Served

- Agricultural

- Aerospace CNC Machining

- Architectural

- Commercial

- Dental

- Electronics

- Firearms

- Food

- Law Enforcement

- Precision Medical Machining

- Military Machining

- Oil Field

- Prototype CNC Machining

- Optical Components Manufacturer

- Packaging/Converting

- Pharmaceutical

- Marine

What is High Volume CNC Machining?

High Volume CNC Machining is the cornerstone of industries that demand precision in mass production. It is the ultimate solution that seamlessly transforms raw materials into components that are flawless and of unmatched consistency. By automating processes, we ensure consistently fast production, minimizing the need for constant human intervention. This operational efficiency not only drives businesses to meet market demands, but also ensures that they remain at the forefront of an ever-evolving industry.

At Elimold, High Volume CNC Machining reigns supreme, offering unparalleled efficiency and adaptability. With a wide range of materials and cutting-edge technology, we excel in mass production while upholding the stringent quality standards that are essential in today’s competitive environment. Utilizing our expertise in CNC machining along with advanced automation and multi-axis capabilities, we are committed to providing superior components to a diverse range of industries, ensuring the success and satisfaction of our customers.

Benefits of Automation in High Volume Production

Due to the rigorous nature of high volume production machining, automation plays a vital role in the entire process. Since we utilize CNC machines, we’re confident that we can deliver the results our clients want within a short timeframe. Besides the speedy production, below are more benefits of automation in high volume machining:

- Low operating costs: Minimal material waste due to streamlined processes that increase part accuracy.

- Better worker safety: Manual tasks and operations are eliminated, improving our workers’ safety.

- Faster ROI: The faster production turnarounds mean quicker delivery, leading to the rapid growth of your ROI.

- Improved output: Automated machines can work 24/7 without stopping at a constant speed, increasing production output.

Alternatives to High-Volume CNC Machining Services

Customers seeking alternatives to high-volume machining services can consider a variety of manufacturing processes, each with its own advantages and application scenarios. The following are alternatives that Elimold can provide:

Injection Molding

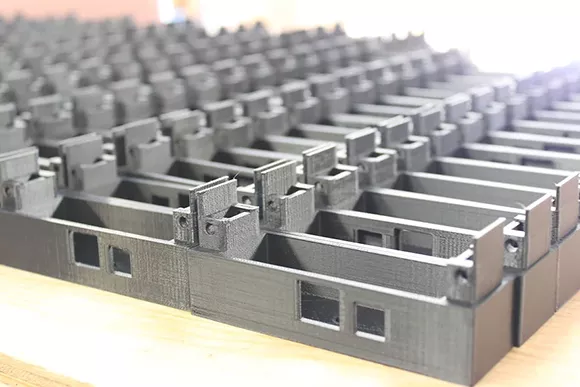

3D Printing

Stamping

Casting

High Volume Production

With our state-of-the-art equipment, highly skilled operators, and efficient processes, our team is able to complete high-volume work quickly. We have the ability to handle any size project with the highest quality and precision. Located in Shenzhen, China, Elimold specializes in providing high-volume custom machined parts services and is committed to being known for high production volumes. Our experienced engineers are committed to providing the highest standards of precision and quality. Our team works diligently to ensure your project is completed quickly and efficiently while meeting all of your precise specifications. We have a wide range of advanced equipment, tools, and materials to provide the best quality and precision for your project. We understand that your time is valuable, so we prioritize efficiency and precision to ensure your project is completed on time. Our technicians are highly skilled and always stay up to date on the latest technology and processes. We are committed to providing you with the highest quality products and are always here to answer any questions or concerns you may have.

Request Your Free Custom Parts High Volume Machining Quote Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.