High Volume Production Services

Need to manufacture a large number of parts quickly? Elimold has a range of cost-effective engineered solutions to help our customers meet production quantities and deadlines. Our precision production line processes are geared towards high-volume production, and our large custom production shop is designed to manufacture quality parts for manufacturers in a variety of industries. Contact us to discuss the solution that best suits your needs and budget.

Contract High Volume Machining

We take you through the entire product evolution, from powerful designs through to prototypes and low-volume manufacturing. Based on your requirement, we also help you transition smoothly to high volume manufacturing, helping you get your product to market in record-time.For high volume manufacturing requirements, we have the expertise and the right network of trusted channels that you can rely on. Our team will help you to find the right manufacturing option, so you can make the most profit by leveraging production in mass quantities.

In preparation for high volume or mass manufacturing, we will prepare and share compatible manufacturing files (including the Bill Of Materials – BOM) for maximum production efficiency. Our rapid prototyping and low volume manufacturing processes will ensure our designs are validated and ready for high volume manufacturing saving you time, money, and effort. Along with this, we will make sure that all industry standards are respected by supporting you through all the necessary testing and certification procedures prior to production.

High Volume Manufacturers

Elimold’ high volume production service has manufactured tens of millions of parts in our 10 years. Our state-of-the-art production facility employs 40+ manufacturing experts working in over 50,000 sq. feet of manufacturing space. Advanced machining processes, detailed inspection plans, and automation help lower the overall cost of production while ensuring precision and consistency across the entire production run. From estimating thru final inspection and shipping, we are in constant communication with you and your team to make sure every expectation isn’t just met but exceeded. We specialize in manufacturing complex parts in high volume production quantities – The difficult we do right away, the impossible will take a little longer.

Our Capabilities

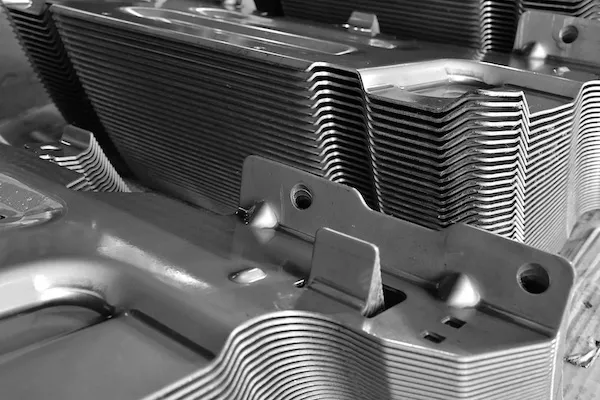

Elimold is a production giant with facilities that have the capacity to prepare us for orders of any size, from a single part to millions of parts, including CNC machining, die casting, metal stamping, plastic injection molding, and additive manufacturing (3D printing).

- Full service custom manufacturing

- 100k – 1 Million+ Parts

- Automation, 2nd Ops, Inspection & more!

- Class 7 Clean Room

- Precision Manufacturing with tolerances as +/- 0.0002 in

- High Quality (ISO 9001:2015, AS9100OD, ITAR, CWB, AWS)

- Quick Quotation Response (24 to 48 Hours)

High-Volume Production Processes Variety

Low, medium, or high volumes of parts with a single design or multiple part designs. Our engineers can advise our clients on which processes and materials will perform best in the final product.

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Die Casting

Urethane Casting

Lead Times and Capabilities

The lead times for our high production services vary by project. In many cases, initial delivery on orders over 5,000 parts can be accomplished within our standard 5-8 week lead time. Once production begins, we can ship weekly, monthly, or as needed. We accept consolidated orders and inventory agreements where we will manufacture and stock parts for future delivery as scheduled or as needed. Depending on the complexity of the part and expedited options, we can shorten or lengthen a specific lead time. Whatever the lead time is, you will be informed of it at the time of quote, so you will know when the part will arrive at your dock.

Dedicated To The Full Product Lifecycle

Our clients rely on our engineering commitment that stretches beyond design and follows the product lifecycle through production and shipment. Whether clients need help electing the right contract manufacture or increasing confidence in the set-up of the assembly, testing, and qualification processes needed for manufacturing, we are here to help.

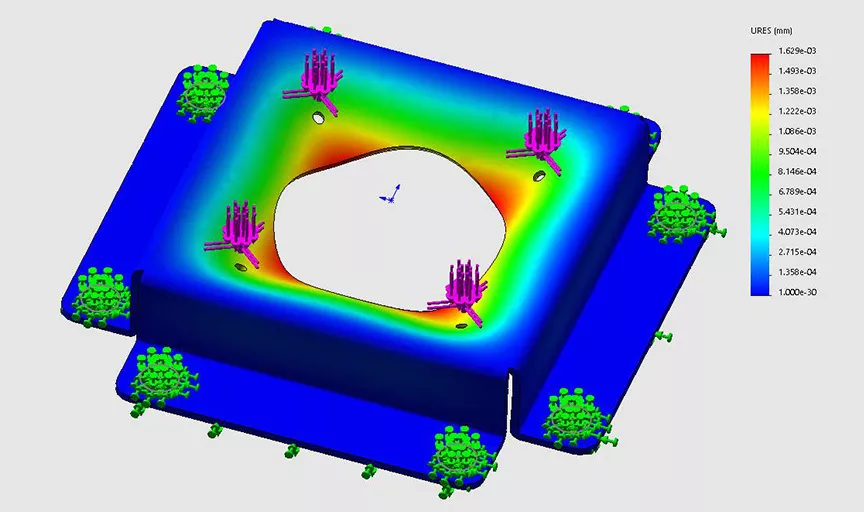

Clients regularly ask us to confirm that the processes used during manufacturing will achieve quality requirements. Analyzing production process metrics, such as Cp and Cpk data, that are critical to monitor and understand during production ramp-up, gives clients confidence in manufacturing quality. Dedication to the full product lifecycle and working closely with the contract manufacturer helps ensure that Client’s goals of minimizing cost while still having high part quality are met when the finished product reaches the hands of the end customers.

This includes cut-no-corners quality measures to ensure optimal end products: acceptable material substitutions, localization considerations, resource development, and other ways to improve overall product quality for your manufacturing engineering process.

In addition, clients regularly rely on our Quality Engineering team to design in-line test tools to provide built-in quality controls to minimize product failure or suboptimal performance as an integral part of the quality verification processes.

World Class Facilities Delivering Guaranteed Quality

With a relatively large production space and ongoing efforts to expand our footprint, we have the capacity to handle high-volume manufacturing requirements. Our dedicated manufacturing cells are tailored to specific production needs, allowing for efficient and streamlined processes. Whether it’s optimising workflow, implementing quality controls, or maintaining consistent production output, our expertise in volume production is unmatched.

Custom Manufacturing You Can Trust

Elimold is AS9100 and ISO certified, ensuring you get the same quality control and repeatability as traditional manufacturing. Our high volume production methods ensure that you have a fully custom approach, with the ability to change details large and small if necessary during the production cycle.

With our approach, you can rest assured that your products are perfect every time, keeping your costs low, your time free, and your customers happier than ever with the end result that ends up in their hands.

One-Stop Solution

As a leader in precision manufacturing, we offer a wide range of services that cater to both one-off prototyping and high-volume production needs. We specialize in delivering parts with complex geometries and beautiful appearance, ensuring the highest quality standards. Elimold is proud to be the manufacturer of choice for all your high-volume production needs, and we are committed to providing reliable and efficient one-stop solutions.

Engineering Capabilities

Fast Production

Surface Treatment

Quality Control

Precision Assembly

Packaging and Shipping

Scalable Manufacturing Solutions for Massive Demands

Elimold is a leader in high-volume production services, providing scalable solutions to meet the needs of industries that require large quantities of precision components. With advanced technology, a skilled workforce, and a commitment to quality, we can meet your production needs, whether you need thousands or millions of parts. At the heart of our high-volume production services lies our modern production facilities, equipped with the latest CNC machines and automation systems. These technologies allow us to produce large quantities of parts with exceptional speed, precision, and consistency, ensuring that each part meets your precise specifications. And our facilities are optimized for a fast, streamlined workflow. From material handling to processing, assembly, and packaging, every step we take is designed to minimize waste, reduce lead times, and deliver products quickly and efficiently.

Come To Us For Your High Volume Production

As you can see, there are many great reasons to check out our services if you are looking for some high-volume production services. We have many happy clients to testify for what we do, and we are proud of the quality of the work we produce.When you are ready to find out more about our high volume production, then please get in touch.

What is High Volume Production?

High volume production is a manufacturing method that produces large quantities of identical parts or products at one time. For products with high market demand, such as electronics and automotive components, high volume production can produce large quantities of consistent products in a short period of time, thereby meeting market needs for large-scale supply.High volume production of composite materials refers to the ability to manufacture large quantities of parts while maintaining strict requirements and specifications. It is a complex task that requires well-developed processes, skilled personnel and a strong infrastructure.

At Elimold, we have invested years of expertise, resources and hard work to lay the foundation for efficient high volume production. With a dedicated team of commercial quality manufacturing engineers and well-trained employees, we have the ability to seamlessly scale up production. We have a proven track record in high volume production, which proves our ability to efficiently deliver hundreds or even thousands of composite parts per month.

Materials And Technologies For High-volume Production

High-volume production covers a range of advanced materials and technologies. To meet the demands of modern markets, it is necessary to integrate cutting-edge automation technologies such as robotics and artificial intelligence to increase productivity without compromising precision and quality. These technologies (for example, when integrated into CNC machining and injection molding) can significantly increase production while reducing the cost per part. The materials we commonly use in high-volume production processes include more than 160 different materials such as various plastics, metals and composites, covering hundreds of surface treatments, tolerances and marking combinations. We also provide material certification, inspection and measurement reports.

Streamlined and Cost-Effective High-Volume Manufacturing Capabilities

Our diverse range of equipment allows our engineers to compare many alternate manufacturing processes before deciding which is the most appropriate for the design and specifications of each custom part.

We have the capabilities and technology to deliver an optimized manufacturing solution for your unique products. Our versatile equipment and experience enable us to offer cost-effective results from prototyping to full-scale production. As an ISO 9001:2015 certified manufacturer, we ensure every custom-machined component is built to the print – whether a single prototype or one precision part amongst millions.

Mass-produce items faster

High-volume manufacturing is the fastest way to turn around large orders for parts or products. This means you can bring products to market faster, keeping your organization at the forefront of innovation. In a competitive economy where manufacturers constantly introduce new products, the time saved through high-volume manufacturing can make your organization successful.

High-volume production lowers your overall cost

Another benefit of mass production is economies of scale. While there are expenses associated with the initial tooling and prototyping stages, the low cost per unit can easily offset these expenses in high-volume production. Mass-produced molded parts also exhibit a high degree of consistency, which means less scrap due to quality issues.

Prototype Bulk Order

We often produce prototypes before mass production. This step ensures that the design meets your requirements and can be manufactured in large quantities. This is ideal if you are prototyping a product and are unsure if the design your team has created will be exactly what you want for the project. Purchase your first product at the regular 1-unit price for testing. Once you are ready to move on, we can produce your product in order quantities (5 units and up) and your demand schedule within 12 months based on your needs.

Standard Blanket Order

Standard Blanket Order is also known as JIT (Just in Time) production delivery method. If you have a custom design and want to produce small to large quantities regularly within 12 months, then a standard blanket order is the best choice. Quantities can be as low as 5 pieces for a single release and as high as 1000 pieces or more. If you know you will need multiple orders within 12 months, you can enjoy a lower unit price. You decide how long to produce and ship your products based on your needs. Whatever your needs, we will do our best to help. Please contact us for details on how we can help you with a single order, an OEM agreement, or any comprehensive order arrangement that best suits your requirements and application.

Our Production Capacity Grows With You

With our wide selection of equipment and the ability to optimize the process for each product, Elimold is able to meet all customer needs. We know that as your products succeed, your needs will grow with them. We continue to invest in new equipment and new capacity to optimize your product assembly, testing and packaging processes to consistently meet your expectations. Our factory has ample space to produce your products so that we can continue to meet and support your growing needs. Our current production plan steadily produces more than 100,000 parts per month, with plenty of room to expand capacity.

Industries We Serve

Elimold has been helping companies with both large and small volume production needs. We have completed thousands of projects and excel in matching the best technology and materials for each project. We have worked with the following industries for volume production work, including:

Your High-Volume Manufacturing Partner

At Elimold, we specialize in the high volume production service. Our goal is to work with our customers to maximize performance and minimize cost through our experience in selecting materials and processes for designs that will work for you. We’re committed to the quality and efficiency of our high volume production service and would love to be able to provide you with more information on our high volume production capabilities. Please feel free to contact us at any time.