Horizontal Boring

Elimold is the industry’s leading provider of CNC horizontal boring services for large parts. We are committed to providing unparalleled customer service, ensuring the highest part quality, and achieving exceptional precision in the machining process. Our superior horizontal boring technology ensures timely, accurate, high-quality part delivery for every order. Contact us now for a free instant quote.

Precision CNC Horizontal Boring Parts Manufacturer

Welcome to Elimold, your trusted source for quality horizontal boring manufacturers. Explore our selection of advanced horizontal boring manufacturing solutions that guarantee precision, efficiency, and quality in your finished product. And we have the resources to handle large machining needs independently. With a wide range of advanced machinery and skilled machinists, we are able to provide you with excellent CNC horizontal boring services and precision parts. And services can be customized to easily process even the largest parts, providing versatility and flexibility to meet your machining needs. Our technical service team has extensive experience in improving operations for all types of horizontal boring projects. If you are facing a problem in your production process and think that one of our CNC horizontal boring operations may be the perfect solution, we are always happy to help you.

Large Part CNC Horizontal Boring Service Provider

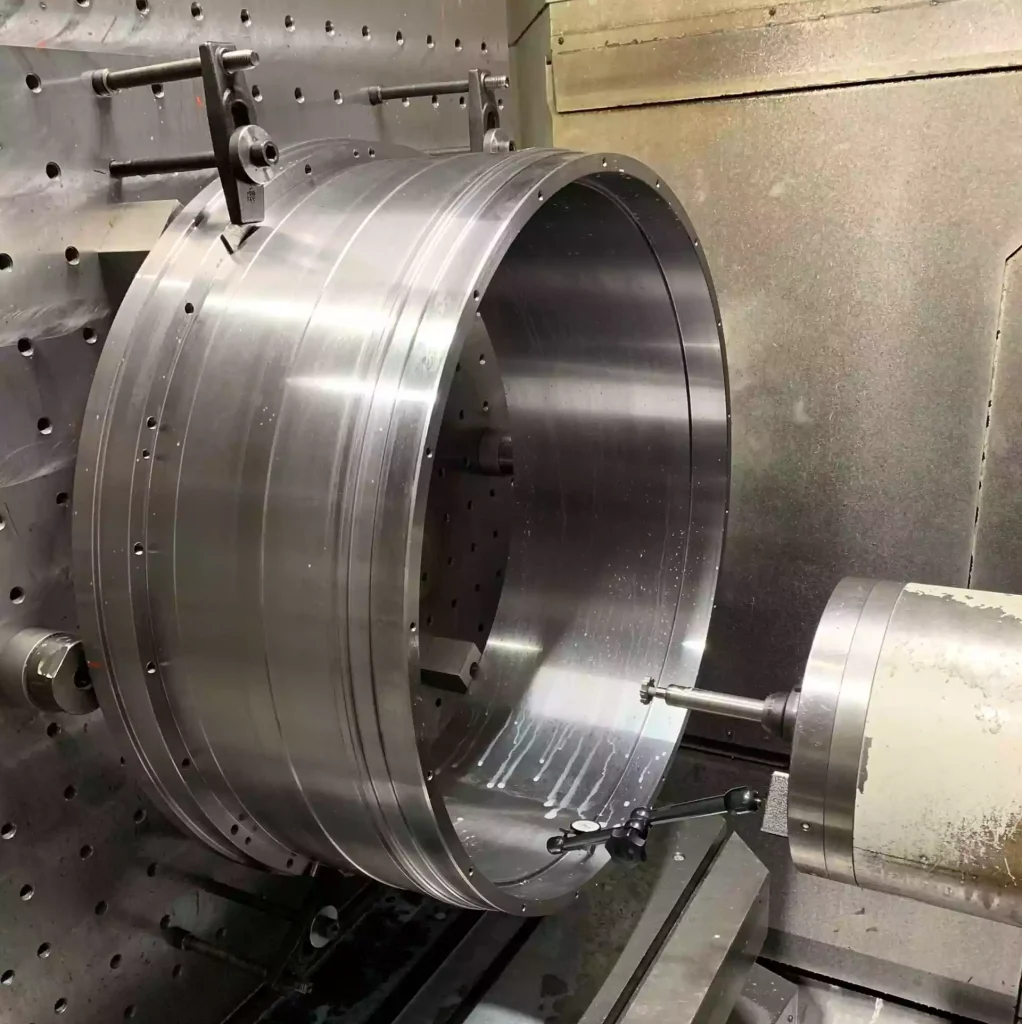

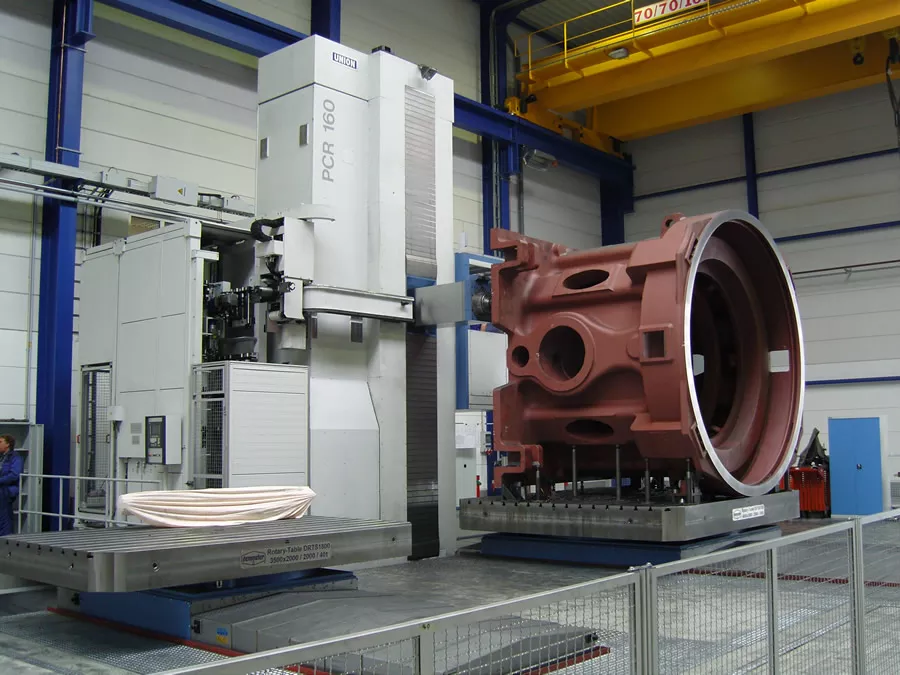

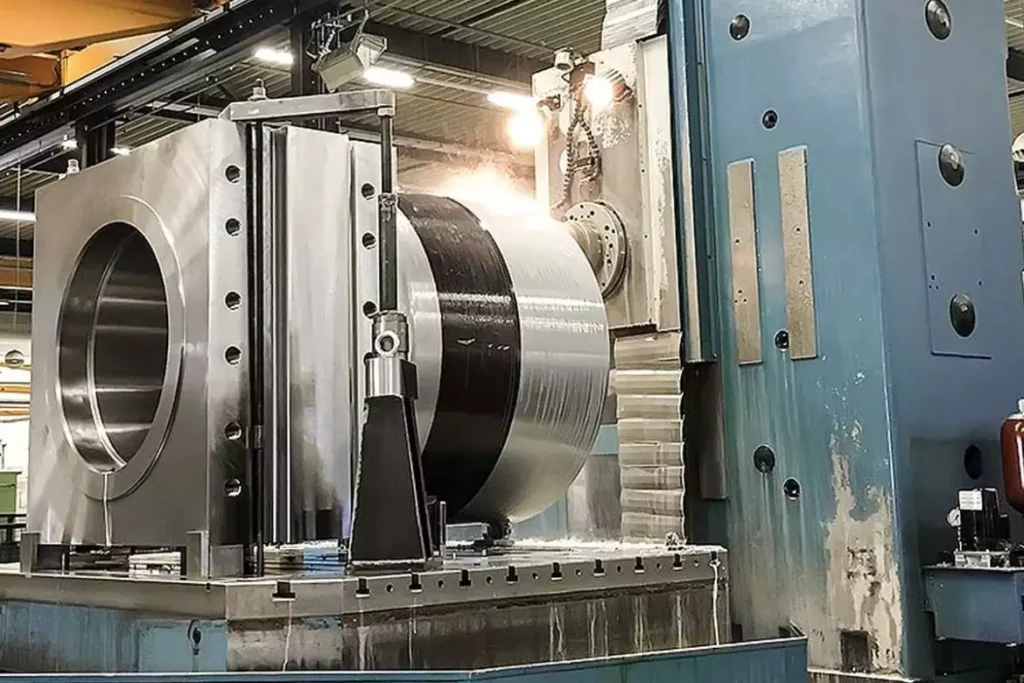

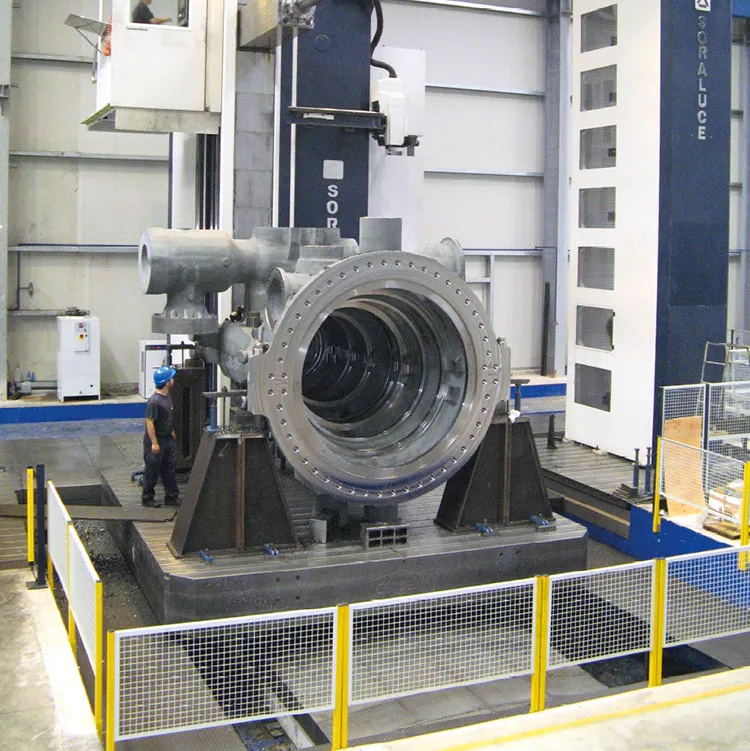

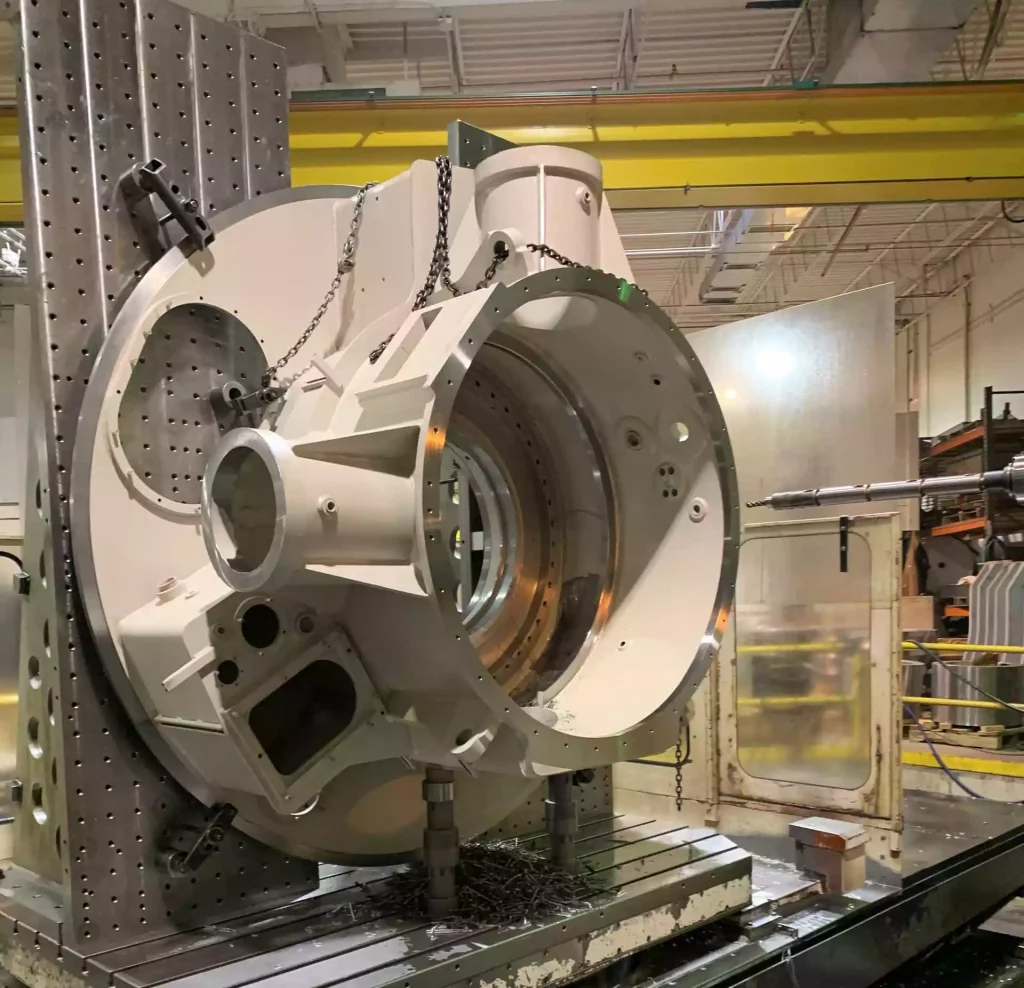

Elimold provides horizontal machining, boring, horizontal milling, large manual lathe machining and CNC machining services to manufacturing companies in various industries around the world. We are a reasonably priced and reliable large part CNC horizontal boring service provider. Our in-house factory can machine, mill and bore customer parts. And Elimold is known for its expertise in machining large parts using large horizontal boring mills. And we can also use small bridge port horizontal machining and boring small manufacturing equipment parts.

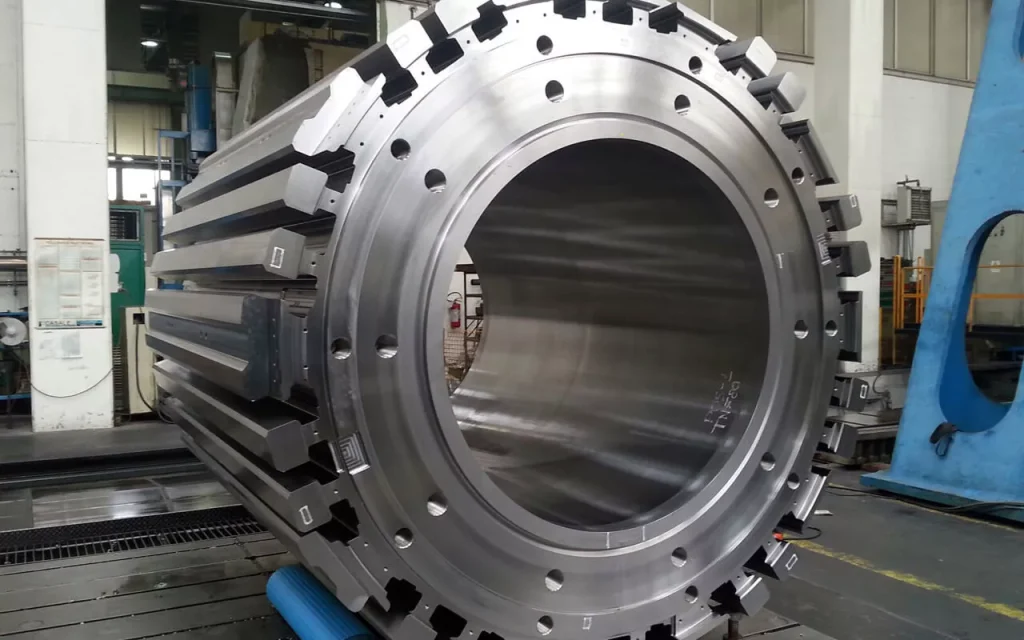

In addition, our strong boring and milling equipment capabilities and experienced technical team can handle designs of all sizes. With CNC machining capabilities, we are able to provide the most efficient process to save cost and time for your project. Our large horizontal boring mills can complete a variety of processes such as precision boring, large plate processing, large CNC machining, face milling, beveling and deep hole drilling. Elimold specializes in large part horizontal boring and custom precision part manufacturing, so we can also manufacture a variety of custom components using a variety of CNC machining centers.

Horizontal Boring Capabilities

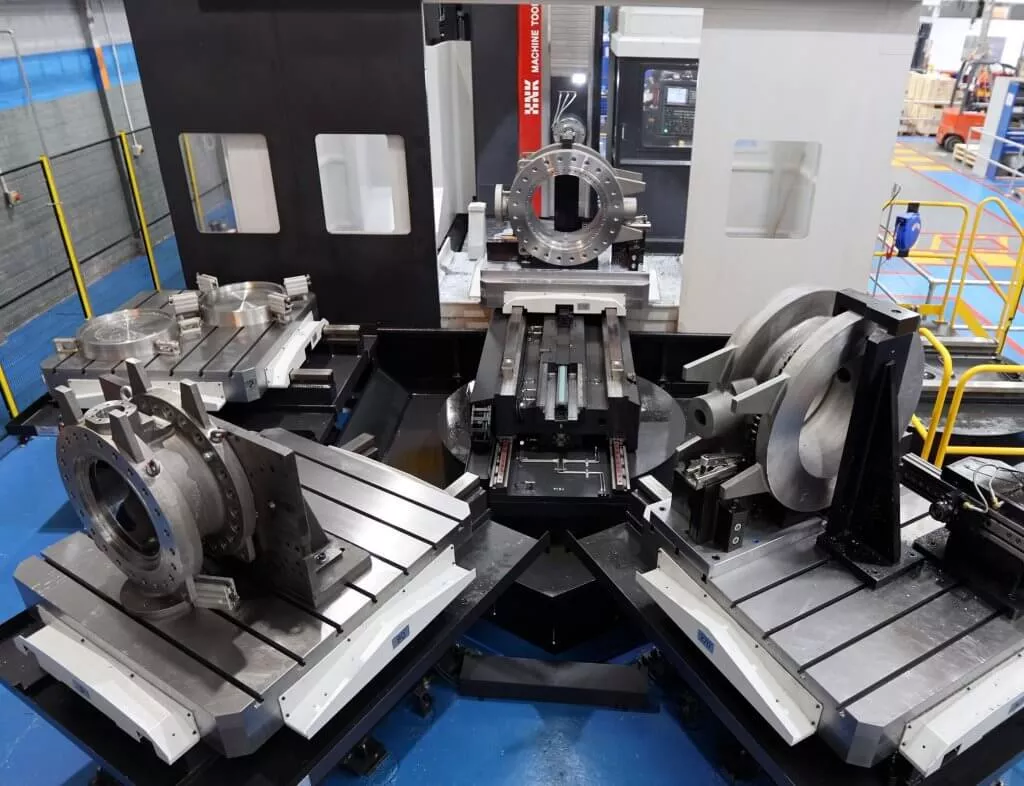

Elimold has a wide variety of horizontal boring and milling machines that can provide prototype and low-volume horizontal and vertical machining services for a variety of large components. We have strong production capabilities and can machine components weighing up to 70 tons. We manufacture components to tight tolerances, with milling accuracy of +/- 0.0005 inches and boring accuracy of +/- 0.0002 inches. Our reliable horizontal boring services ensure that part orders are accurate, high-quality, and delivered on time. We use state-of-the-art horizontal boring equipment, including machines with a maximum machining range of 120″ x 152″ x 70″, as well as five-axis machining capabilities. These capabilities allow us to machine some of the most complex parts at consistently fast speeds.

Our horizontal boring equipment capabilities

The CNC horizontal boring and milling machines owned by Elimold’s internal factory are suitable for the processing of large and medium-sized parts and box-type parts, rough and fine boring, milling and other processes. The worktable of our CNC boring equipment is equipped with a 4×90° optical positioning device, which can meet the turning processing requirements of large parts. It is usually suitable for hole processing, plane processing, cylindrical surface turning, cutting of annular grooves in holes, tapping of external threads and imperial threads for box-type parts with more processes. It also has the rectangular coordinate system, polar coordinate system, contour processing and other process functions of CNC machine tools. Moreover, the CNC horizontal boring and milling machine we use has strong rigidity and is equipped with a closed-loop detection system. It can meet the requirements of rough processing and fine processing. It is an efficient and precise general large-scale processing equipment.

Machining Processes

Our facilities and tooling capabilities ensure that we can perform a number of machining processes, including:

- Boring

- Milling

- Drilling

- Tapping

- Threading

- Counterboring

- Countersinking

- Knurling

- Broaching

- Pocketing

- Profiling

- Reaming

- Parting/cutting

- Facing

- Gear Hobbing

Ready to get started on your next large CNC horizontal boring part machining project?

The name Elimold stands for quality craftsmanship and pride in a job well done. At Elimold, our mission is to provide you with consistent quality and exceptional service at competitive prices you can afford. Contact us now for a free instant quote.

Your Partner for Premium CNC Horizontal Boring

Our in-house shop can handle boring operations for parts of almost any shape, size and material. They are able to provide accurate positioning, precise round holes and high-quality surface finish according to customer requirements. Elimold is capable of many types of boring operations, such as straight holes, tapered holes, conical holes, eccentric holes, and more. In addition, our engineers specialize in deep hole boring, providing maximum cutting and efficiency in our ISO 9001:2015 certified in-house CNC machining shop, and have a variety of grades and sizes of boring equipment, which can machine steel up to 45 Rc hardness and reserve 0.050 inches of honing allowance to meet all standard, metric or oversized finishing requirements. Our team has many years of experience in horizontal boring machining and can meet your various needs. We keep up with the ever-changing technological advancements and diverse customer needs to ensure that your greatest needs are always met.

Quality Management and Inspection Equipment

We are committed to providing the highest standards of product quality and have a large number of measuring equipment and a complete quality system to ensure that customer expectations are met. We have an advanced MRP system and are committed to providing a seamless customer experience.

For inspection equipment, Elimold has coordinate measuring machine (CMM) equipment that can ensure the dimensional accuracy of precision manufactured products. Our equipment is almost the size of a room. This coordinate measuring machine (CMM) can measure very large parts and achieve micron-level resolution within a measurement range of 1-5 meters. Therefore, we are able to measure parts up to 5 meters long. Large, high-precision parts must be fully acclimated to the temperature in the coordinate measuring machine (CMM) room before being mounted on the measuring equipment. While most manufacturers and metrology service providers are able to measure small and medium-sized parts, few companies have the CMM capability to measure large parts.

Materials

From standard metals to high-performance alloys and engineering plastics, our skills and equipment allow us to work with an expansive portfolio of materials, such as:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

- Bronze

- Nickel

- Cast iron

- Inconel

- Hastelloy

- Plastics

What is CNC Horizontal Boring?

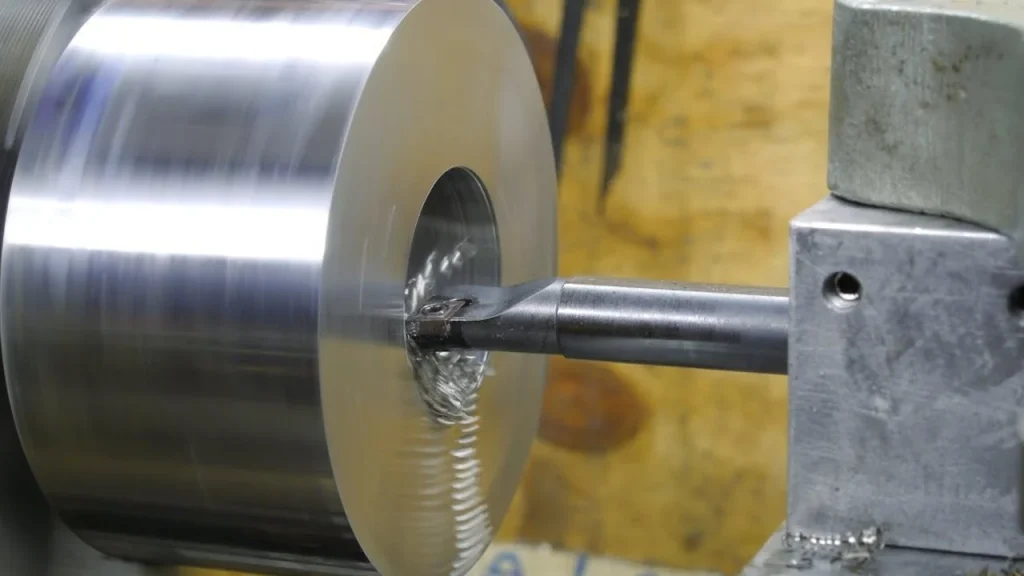

Horizontal boring is a drilling process that allows for more accurate holes. Horizontal boring is primarily used to drill holes in larger parts and components or to further enlarge existing holes in a workpiece to improve their dimensional accuracy.

However, horizontal drilling can also be used on workpieces of various shapes and sizes. To produce high-volume applications faster, we specialize in CNC horizontal drilling. We utilize advanced horizontal drilling centers and computer numerical control units to fully automate the control, movement and accuracy of our horizontal drilling methods.

Advantages of Horizontal Boring

Horizontal boring manufacturing offers many benefits, such as:

- The Ability to Produce Large-Format Elements: The right horizontal boring equipment works with large workpieces, enabling the production of large-format parts for various industries. This is especially useful for industrial and agricultural applications.

- The Ability to Produce Large Numbers of Parts: Due to their ability to make multiple cuts simultaneously and their high speed of cutting, horizontal boring machining can produce many parts for applications requiring a high volume of components quickly.

- Minimized Tool Deflection: If a tool faces more resistance than it can handle, deflection may occur. As a result, the tool may initiate an improper drilling angle due to the application of excessive force. However, horizontal boring machines help prevent this because they maintain a closer distance between the drill and the anchor point during drilling.

- The Ability to Apply CNC Boring Technology: Computer numerical control (CNC) is a type of technology that controls certain machining tools through software programming. This enables operators to enter specific commands that machines must follow, including horizontal boring machines. These CNC machines help maximize precision while minimizing the risk for human error during the boring process.

Industries & Applications

We provide precision Horizontal Boring services for many products, including:

- shafts

- large valves

- gear boxes

- mud pumps

- injector head skates

- flanges

- jig boring

- hydraulic manifolds

- machine repair work

- line boring

- robot bases

- motion products

- guide bushings

- cold chamber inserts

- platens

- die plates

- risers

- skids

Real-World Applications

Our CNC Horizontal Boring Service has been instrumental in various projects across different industries, examples include:

- Power Generation Industry: Machining critical components like turbine casings and valve bodies.

- Mining Industry: Creating robust and durable parts for mining equipment, such as gear housings and drill components.

- Industrial Equipment Industry: Crafting custom parts for heavy machinery, including frames and hydraulic components.

Alternative Services For Horizontal Boring

Our CNC machining shop offers more than just horizontal boring services. Here you can learn about the various types of CNC machining services we offer, select the process range that is right for your project, and meet our team with any questions you may have.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Key Differences Between Horizontal and Vertical Drilling

The main difference between horizontal and vertical boring is that the workpiece is stationary in a horizontal milling center. Whereas, the tool in a vertical milling machine is stationary and the workpiece is moving. Between the two, CNC horizontal boring mills offer more flexibility in tool capabilities and can also be equipped with special tools or options.

With horizontal drilling, operators have more freedom in approach and machining process. It also ensures efficient machining, especially for projects that require a lot of chip removal.

One-stop high-precision parts machining service

We provide one-stop services from raw materials to machined components and assemblies, covering processing equipment from light to heavy duty, which can perform basic operations such as turning, milling, boring, as well as complex contour milling and critical precision operations. Operated by professional and dedicated employees, achieving human-machine collaboration. Elimold’s in-house CNC machining plant has facilities for the production of prefabricated parts weighing up to 10 tons. It has extensive experience in the manufacture of prefabricated parts using modern welding technology. Products range from simple structures to key functional parts of complex assemblies. Our in-house factory in Shenzhen, China has a dedicated horizontal boring parts production center with a first-class infrastructure, covering an area of 4,000 square meters, divided into 2 units, equipped with various types of advanced CNC machine tools, and can provide heavy engineering parts manufacturing and processing services. Our skilled workforce manufactures precision parts for heavy engineering products such as forgings, precision machined parts and prefabricated parts. We are able to undertake and execute every task with result-oriented solutions.

Request Your Free CNC Horizontal Boring Quote Today

After receiving your drawings, our engineers will analyze your custom CNC Horizontal Boring parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.