Horizontal & Vertical CNC Turning

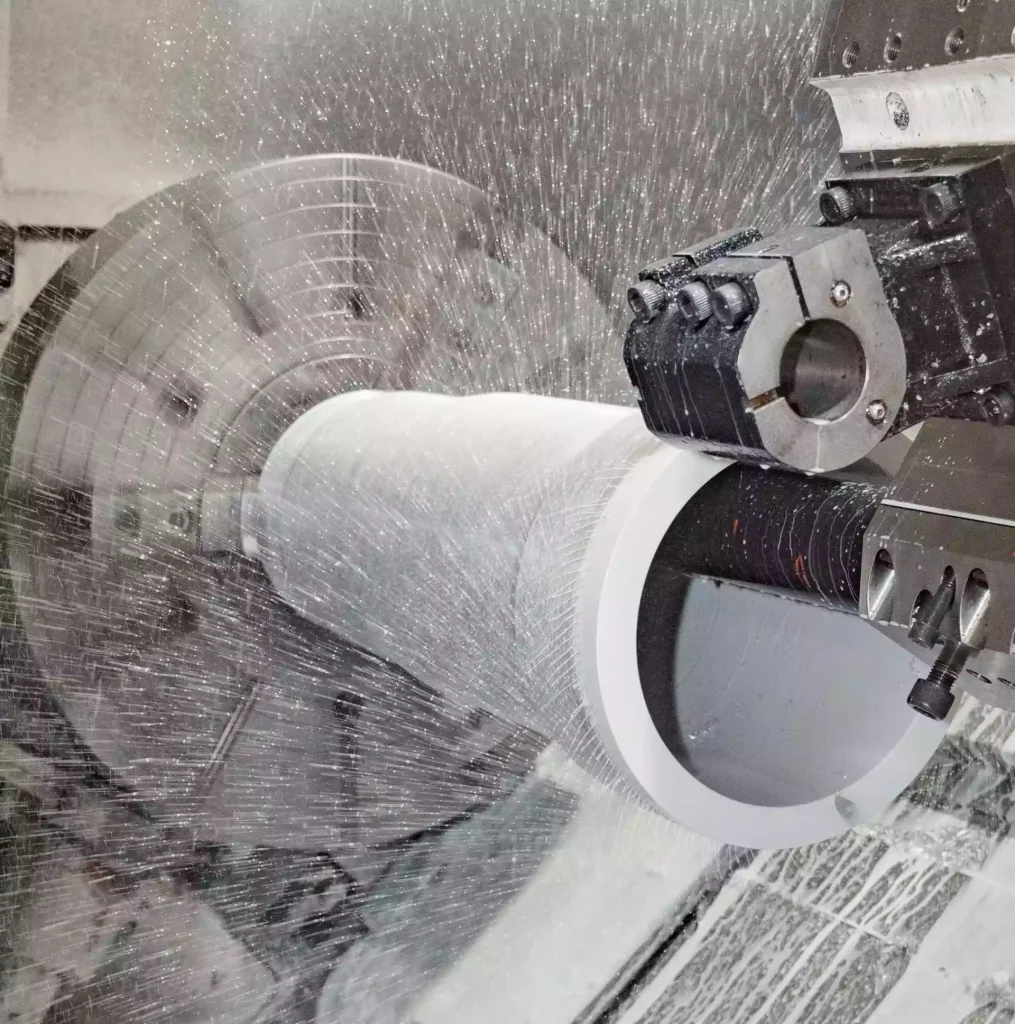

Our horizontal and vertical machining centers can handle precision machining, milling and turning that always maintain the highest quality. With our level of technology and expertise, we can handle all jobs, from small jobs for custom designed parts and prototypes to large jobs that require extensive horizontal and vertical cutting capabilities. And provide extremely fast turnaround times.

Vertical and Horizontal CNC Turning Shop

As a leading CNC lathe shop, Elimold offers a full range of vertical turning CNC machining and horizontal turning CNC machining services. Our experienced technicians use advanced CNC technology to tailor precise and reliable parts for your industry.

We are headquartered in Shenzhen, China and serve customers in a variety of industries around the world. At Elimold’s in-house factory, we have advanced equipment that enables us to produce parts with unparalleled accuracy. Whether you need precision CNC vertical turning parts or precision CNC horizontal turning parts, our team can meet the needs of a wide range of industries.

We are known for our quality workmanship and reasonable prices. We have an ISO 9001:2015 certified quality management system. We are committed to sound engineering, ethical business practices and innovative design. We specialize in small batch, low-volume production and provide expedited and emergency services with fast delivery.

Your trusted vertical and horizontal CNC turning company

Since its inception, Elimold has had the expertise and equipment to produce large parts from prototypes to mid-volume production. We have a dedicated team fully equipped to handle your bulk orders as well as prototype and rush orders. Whether you need parts made from standard metals, high-performance alloys or engineered plastics, we are able to meet your specifications, timelines and budget requirements.

We have a culture of quality and perform a variety of supervised and documented testing and inspection procedures at all critical stages of production. Customers can rest assured that parts will not leave our factory unless they meet the highest quality standards. We are ISO 9001 certified and are committed to implementing this commitment in our policies/procedures, complying with NCA-3800 standards and modeled after AS9100 with more stringent processes to ensure that our facilities meet the stringent quality standards that our customers deserve. In addition, whether you need 5 parts to meet an unexpected emergency customer demand or 10,000 parts to meet a project supply, our facility can deliver the right parts on time and within your desired delivery deadlines.

Our Facility Capabilities

Elimold has the right equipment and technical experience to meet your most demanding turning needs. We have a large fleet of horizontal, vertical and CNC lathes capable of turning parts up to 152 inches in diameter and 240 inches in length while maintaining tight tolerances of ±.001 inches. Our smaller machines swing up to 16.5 inches and range from 40-inch centers to chucks capable of running parts as small as needle valves, while our turret lathes can process 5-inch bar stock. An in-house facility crane with a 15-ton lifting capacity makes it easy to transport large, heavy parts throughout the facility. Whether you need a part made from standard metals, high-performance alloys or engineered plastics, we can meet your specifications, timelines and budget requirements.

Vertical vs. Horizontal Lathes

Machining operations can take place on either a vertical or a horizontal lathe, which refers to the orientation of the spindle.

Vertical Lathes

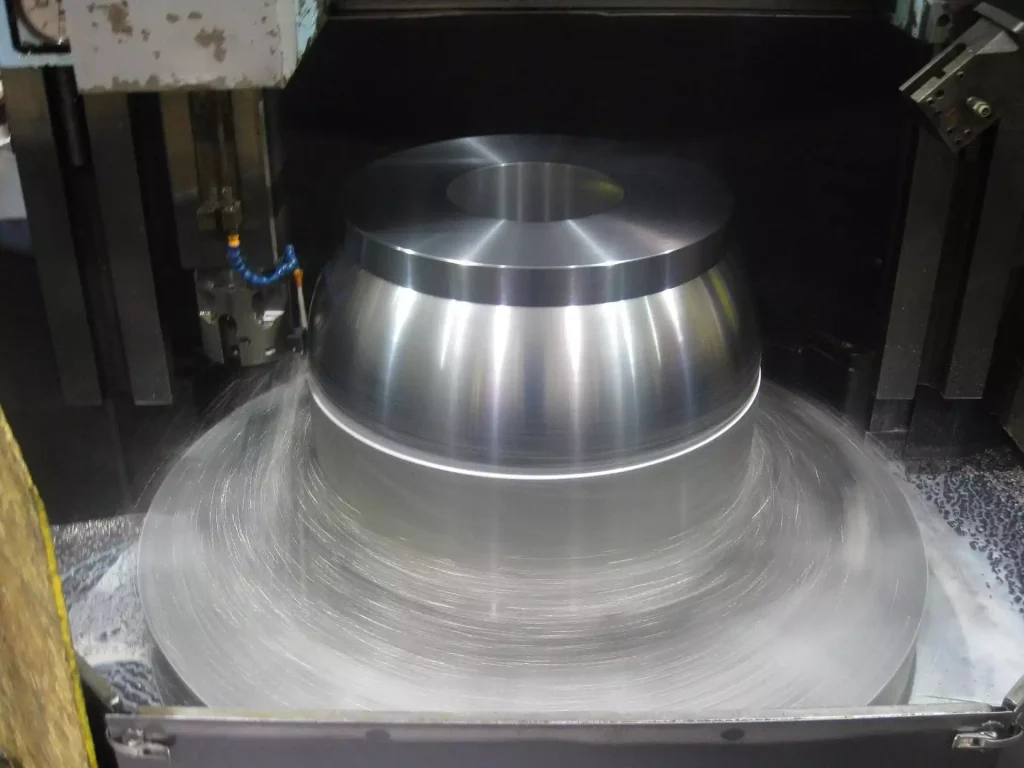

Vertical lathes orient the spindle in a fixed position in the vertical plane. The workpiece moves up or down to place it in line with the appropriate tool necessary for the desired operation.

Vertical lathes are less complex than horizontal machines. They provide the best option for projects that focus on a single side, like large metal plates and sinking dies. They hold an advantage over horizontal lathes in circumstances where workpiece sagging might be a factor.

Horizontal Lathes

Horizontal lathes do not have a fixed spindle but use a variety of heads mounted to a horizontal arbor. These machines accommodate a wider variety of shapes and sizes and gravity works to keeping the workpiece clean during machining. Most horizontal lathes have the capacity to incorporate automatic bar-stock feeders.

Lathe Machine Operations

Depending on the specific machine and its tooling, our horizontal and vertical CNC turning capabilities include:

- Drilling

- Milling

- Knurling

- Boring

- Tapering

- Threading

Horizontal and Vertical CNC Turned Parts Supplier

Elimold’s horizontal CNC turning capabilities allow us to produce high-quality turned parts with exceptional precision. This capability allows us to efficiently produce precision cylindrical parts, threads, and complex geometries, making it ideal for a wide range of applications. In addition, our vertical CNC turning capabilities are designed to process complex and large diameter parts with precision and efficiency. Our vertical turning equipment excels at machining large, heavy parts with the ability to hold tight tolerances and an exceptional surface finish.

Benefits of Partnering with Elimold

- Short Lead Times: We are committed to delivering your parts on schedule, and helping you keep your projects on track.

- Custom Machining Solutions: We tailor our services to your specific requirements, ensuring you receive the exact components you need.

- Expert Technicians: Our team brings years of experience and expertise to every project, ensuring precision and quality in every part.

Material Options

At Elimold, we utilize horizontal and vertical CNC turning centers to manufacture precision components made from a variety of metals, plastics, ceramics and composites; including:

Metals

- Aluminum

- Steel (mild, stainless, tool steel)

- Brass

- Copper

- Titanium

- Inconel

- Bronze

- Magnesium

- Nickel alloys

- Cast iron

Plastics

- ABS

- Nylon

- Polycarbonate

- Polyethylene (HDPE, LDPE)

- Polypropylene

- PVC

- PTFE (Teflon)

- PEEK

- Acetal (Delrin)

- UHMW

Composite Materials

- Carbon fiber reinforced polymers (CFRP)

- Glass fiber reinforced polymers (GFRP)

- Phenolic composites

- Bakelite

- Fiberglass laminates

- Thermoset composites

- Epoxy-based composites with fillers

- Metal matrix composites (MMC)

- Ceramic matrix composites (CMC)

- Kevlar composites

Surface Finishing Options

We can also offer a range of surface treatment services to suit all your production needs.

- Grinding

- Polishing

- Buffing

- Honing

- Lapping

- Sandblasting

- Shot Peening

- Tumbling

- Vibratory Finishing

- Electropolishing

- Anodizing

- Plating

- Powder Coating

- Painting

- Passivation

- Deburring

- Burnishing

- Laser Texturing

- Chemical Etching

- Ultrasonic Cleaning

Industries Served

We specialize in providing fast turnaround and unmatched quality to manufacturers across a wide range of industries.

- Medical

- Automotive

- Military

- Garage Access & Security

- Control & Automation

- Cable Connectors

- Marine

- Aerospace

- Alternative Energy

- Oil & Gas

Parts Application

Our horizontal and vertical lathes are suitable for high volume production of a wide variety of applications. Common parts applications include the following.

- Shafts

- Bushings

- Gears

- Housings

- Flanges

- Couplings

- Pins

- Valves

- Pistons

- Spacers

- Insulating bushings

- Seals

- Plastic gears

- Pulleys

- Threaded rods

- Spacers

- Covers

- Caps

- Washers

- Housings

- Aerospace brackets

- Tubes

- Bushings

- Structural reinforcements

- Insulating rings

- Flanges

- Rotor components

- Custom spacers

- Connectors

- End caps

Other CNC Machining Services

As a leading CNC machining shop, Elimold provides a variety of CNC machining services. Our experienced technicians use advanced CNC technology to tailor-make precise and reliable parts for your industry.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Request Your Free Horizontal & Vertical CNC Turning Quote Today

After receiving your drawings, our engineers will analyze your custom Horizontal & Vertical CNC Turning parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.