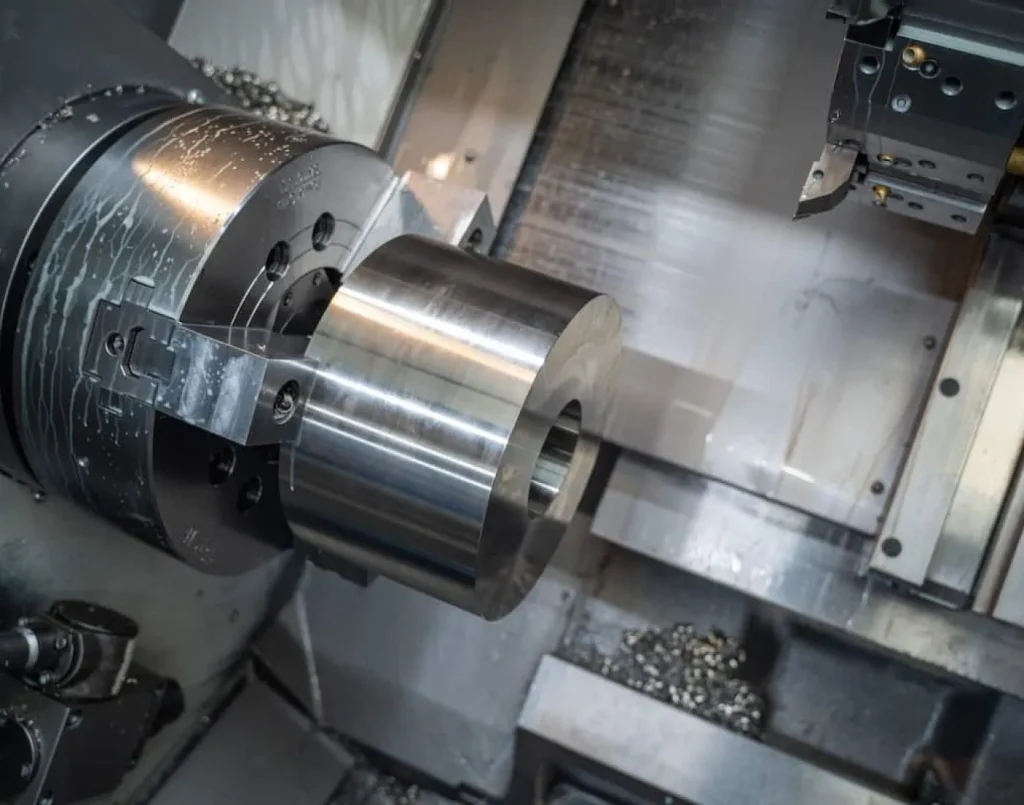

Inconel CNC Machining

Elimold offers precision Inconel CNC machining services for a wide range of applications. We help you achieve precision machining results that meet specifications and exceed your expectations. We can machine Inconel parts ranging in size from 2 inches to over 100 feet. Contact us today to learn how we can boost your production with CNC Inconel machining services.

Custom Inconel Parts to Your Specifications

Whether you need simple CNC Inconel prototype parts or parts with complex geometries and tight tolerances, Elimold can perfectly complete your project. In addition to our strong in-house Inconel manufacturing capabilities, we have a complete supply chain that provides special surface treatments, non-destructive testing, and virtually any service we don’t offer ourselves, all overseen by your dedicated project manager and adhering to Elimold’s consistently stringent quality standards.

Our Industry-Leading Inconel CNC Machining Capabilities

Elimold provides mission-critical Inconel CNC machining services with world-class quality and fast lead times. With over 136 state-of-the-art CNC machine tools, including some of the world’s largest, we offer consistent capacity, competitive pricing, and unparalleled Inconel CNC machining capabilities. Leveraging our comprehensive in-house machining capabilities and robust supply chain, we can perfectly reproduce the most complex Inconel prototypes and production parts using a wide range of alloys and surface treatments. Partner with Elimold today and experience the industry standard for Inconel CNC machining services.

What is Inconel?

Inconel is a nickel-based superalloy, primarily composed of nickel and chromium. It also contains significant amounts of iron, niobium, molybdenum, titanium, and aluminum, as well as trace amounts of cobalt, manganese, silicon, copper, and other elements. This composition gives Inconel its unique properties. While there are many types of Inconel alloys, each with similar yet unique properties, their shared nickel-based composition provides numerous advantages for machined parts. Inconel exhibits exceptional oxidation resistance, corrosion resistance, high-temperature resistance, and resistance to drastic pressure changes. These characteristics make Inconel components widely applicable and capable of stable operation even in the harshest industrial environments.

Inconel Grades For CNC Machining

We offer one of the most comprehensive ranges of Inconel CNC machining materials in the industry, including many materials that other companies cannot source or are unwilling to process. If you cannot find the material you need, we may be able to help you. Contact us today to speak with an Inconel CNC machining expert.

Inconel 600

A nickel-chromium alloy known for its excellent resistance to high-temperature corrosion and oxidation, along with good carburization resistance in a variety of environments.

Inconel 601

An alloy with exceptional resistance to high-temperature oxidation and good resistance to aqueous corrosion, with added metallurgical stability for prolonged exposure at high temperatures.

Inconel 617

A nickel-chromium-cobalt-molybdenum alloy offering a combination of high-temperature strength and oxidation resistance, particularly suitable for applications that demand both elevated temperature and corrosion resistance.

Inconel 625

A versatile nickel-chromium-molybdenum alloy recognized for its exceptional corrosion resistance in a wide range of corrosive and high-temperature environments, including seawater and chemical processing.

Inconel 690

A high-chromium nickel alloy with excellent resistance to many corrosive aqueous media and high-temperature environments, particularly suitable for applications where exposure to aggressive chemicals and high temperatures is anticipated.

Inconel 718

A precipitation-hardening nickel-chromium alloy known for its outstanding tensile, fatigue, creep, and rupture strength at high temperatures, making it suitable for various high-stress applications.

Inconel 725

A nickel-chromium-molybdenum-titanium alloy with exceptional mechanical properties at elevated temperatures, offering high strength and corrosion resistance in various harsh environments, including sour gas and oil wells.

Inconel C-276

A nickel-molybdenum-chromium alloy known for its exceptional corrosion resistance in a wide range of aggressive media, particularly in reducing and oxidizing environments, making it suitable for various chemical processing applications.

Inconel X750

A precipitation-hardenable nickel-chromium alloy recognized for its high creep-rupture strength at high temperatures, along with excellent relaxation resistance, making it ideal for high-temperature applications in various industries.

Precision CNC Machining Services for Complex Inconel Alloy Components

Elimold is a trusted brand for providing advanced Inconel alloy machining services. With CNC technology and state-of-the-art equipment, we are capable of performing complex machining operations on a variety of CNC materials, including Inconel alloys. Our advanced machining capabilities encompass four-axis and five-axis milling, Swiss-type lathe machining, and even micro-machining. This allows us to manufacture parts with the highest precision and smallest tolerances. We can achieve tolerances as small as 0.0005 inches.

Advantages of Choosing Inconel Alloys

Inconel alloys are the material of choice for components that need to operate in extremely harsh environments. They are renowned for their superior corrosion resistance and oxidation resistance, maintaining strength and structural integrity even at extremely high temperatures. Their chemical inertness also makes them ideal for components exposed to corrosive substances. Therefore, Inconel alloys are the preferred material in industries with extremely high requirements for reliability and service life, such as aerospace, energy, and chemical engineering.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order, we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

Start Your Inconel Machining Project Today

Partner with Elimold to get expert advice, fast turnaround, and premium results for the parts you need. Request a Quote Today.

Inconel Machining

Inconel machining is a challenging task, but Elimold boasts over a decade of experience and expertise. We will apply this experience to your custom Inconel machining projects. Our in-house facility is ISO 9001:2008 and AS9100 certified and complies with ISO 13485 standards. We have a Class 100 cleanroom and offer turnkey solutions to streamline your supply chain, shorten delivery times, and reduce overall costs. Elimold provides a one-stop service for Inconel machining, ultra-high purity welding, CNC bending, and more. In addition, we offer surface treatments including electropolishing, anodizing and passivation, heat treatment, cleaning, leak testing, and vacuum testing, as well as assembly and packaging in a Class 100 cleanroom.

Surface Finishing

We can provide various surface finishing processes for Inconel alloy CNC parts. If the process you need is not listed below, please contact us.

Bead Blast

Black Oxide

Heat Treat

Electroless Nickel Plating

Polishing

Gold Plating

Silver Plating

Powder Coating

Brushing

Applications and Industries of Inconel Machining

Due to the superior properties of Inconel alloys, their machining plays a crucial role in a wide range of high-performance applications. Below are the main industries and applications that benefit from Inconel components.

Applications Suitable for Inconel

Inconel is often encountered in extreme environments. Common applications include:

- Gas turbine blades

- Seals

- Combustors

- Turbocharger rotors and seals

- Electric submersible well pump motor shafts

- High temperature fasteners

- Chemical processing and pressure vessels

- Heat exchanger tubing

- Steam generators

- Core components in nuclear pressurized water reactors

- Natural gas processing

How do we handle your rush orders?

Yes, we can shorten the production time for rush orders. If you require faster delivery, please inform us when placing your order. Rush orders incur an additional charge, the specific cost of which depends on the current production schedule and the complexity of the parts. Prioritizing your order, we can typically shorten the delivery time to 1-7 days. Our team is dedicated to meeting your delivery deadlines and ensuring you receive the parts you need on time, even for urgent projects. Please contact us directly to discuss your specific needs and rush options.

Quality Assurance and Inspection

We are renowned globally for our on-time delivery, budget control, and tolerance control. We understand that every project is unique, therefore we offer bespoke Inconel machining services to meet our clients’ specific needs. Our expertise in providing high-quality bespoke Inconel parts manufacturing and machining services is second to none. Elimold’s rigorous quality assurance and inspection processes ensure that every precision Inconel CNC machining service we provide meets the highest standards.

Comprehensive Inconel Material Sourcing Solutions

We can use various types of Inconel materials provided by our clients, or we can source them ourselves. Letting us handle the sourcing saves you time and money. We have established partnerships with numerous certified steel mills and distributors, enabling us to quickly and easily provide you with Inconel materials of the right size, length, thickness, and shape. We manufacture parts using a wide range of Inconel materials.

We are happy to use materials provided by our clients to produce products, or to source them ourselves, thus saving you time and effort. All materials are sourced from reputable suppliers and undergo compliance verification upon arrival.

Other High-Temperature Alloy Machining Capabilities

Elimold possesses extensive experience and strong capabilities not only in machining Inconel high-temperature alloys, but also in understanding the various challenges of high-temperature alloy machining. Utilizing advanced equipment and proven technology, we deliver high-quality custom high-temperature alloy components. Choosing Elimold means benefiting from working with experts capable of handling the complexities of high-temperature alloy machining, ensuring product reliability and precision. Our successful high-temperature alloy machining projects demonstrate our expertise and unwavering commitment to excellence. Contact the Elimold team for consultation and project discussions.

Why Choose Elimold for Precision Inconel Machining?

Choosing Elimold for custom inconel machining means choosing a high-quality CNC machining center provider. We are committed to providing superior products and services, consistently exceeding customer expectations. Using Elimold’s CNC machining centers to produce inconel parts means we will handle all the details for you, ensuring you receive the right product for your quote. We work hand-in-hand with you, guided by the philosophy of “Innovation and Precision,” to minimize costs through manufacturability design and process development.

FAQs

Inconel CNC machining is a precision manufacturing process that uses computer-controlled machine tools to remove material from Inconel workpieces, producing high-precision, complex Inconel parts. This process enables the production of complex parts with extremely small tolerances, ensuring consistent quality, precision, and repeatability in the final product.

The cost of CNC-machined Inconel parts varies depending on factors such as design complexity, the type of Inconel alloy selected, batch size, surface finish requirements, and more. For an accurate quote, please contact our team immediately; we will provide a customized quote based on your specific project needs.

Our CNC machine tools can produce a wide variety of parts, including high-precision, complex Inconel parts for demanding applications such as aerospace and defense, precise Inconel prototypes, traditional parts, and replacement parts. We can handle parts of various designs and sizes, from simple to highly complex, to meet specific customer needs.

We have the equipment and experience to produce CNC machined Inconel parts of all sizes, from small enough to fit in the palm of your hand to parts up to 100 feet long.

We specialize in small to medium batch Inconel alloy CNC machining services. Our typical batch size is under 1000 pieces. We can sometimes handle larger orders if there is spare capacity.

Yes, Inconel alloy is more difficult to machine than titanium alloy. Inconel alloy has a high work hardening rate, which leads to severe tool wear, a problem that titanium alloy does not have.

Inconel 625 alloy is suitable for chemical and marine applications due to its low work hardening rate and excellent corrosion resistance. Inconel 718 alloy is commonly used in aircraft turbines, exhibiting superior strength and durability at extremely high temperatures. Both alloys require specific CNC machining methods.

Due to its high hardness, tendency to work harden, and poor thermal conductivity, Inconel alloys are very difficult to machine. These properties lead to rapid tool wear, workpiece bending, and overheating, necessitating complex and specialized CNC machining techniques to ensure machining accuracy.

Industries such as chemical, power generation, shipbuilding, and aerospace use Inconel alloys extensively. Due to its superior strength, corrosion resistance, and heat resistance, Inconel alloys are ideal materials for manufacturing heat exchangers, exhaust systems, engine components, and turbine blades.

Monel is easier to machine than Inconel. Monel has a higher nickel content but lacks the same level of high-temperature strength and hardness found in Inconel. This makes Monel less demanding on tools and cutting speeds.

The main disadvantages of Inconel are its high cost, difficulty in machining, and rapid tool wear. Additionally, its low thermal conductivity leads to significant heat buildup during machining.

Yes, Inconel is hard to weld due to its tendency to crack and its high-temperature strength. Proper techniques and filler materials are essential to achieve good weld quality.

Yes, Inconel has a higher strength-to-weight ratio than most steel grades and retains its mechanical properties at much higher temperatures. This makes it ideal for aerospace and high-temperature environments, where tensile strength and heat resistance are critical.

Get An Accurate Quote For Your Next Projects

Have a part request or questions about Inconel machining? We encourage you to get in touch with our experts at Elimold. to learn more about Inconel machining and the many ways we can optimize your processes with superior component design.