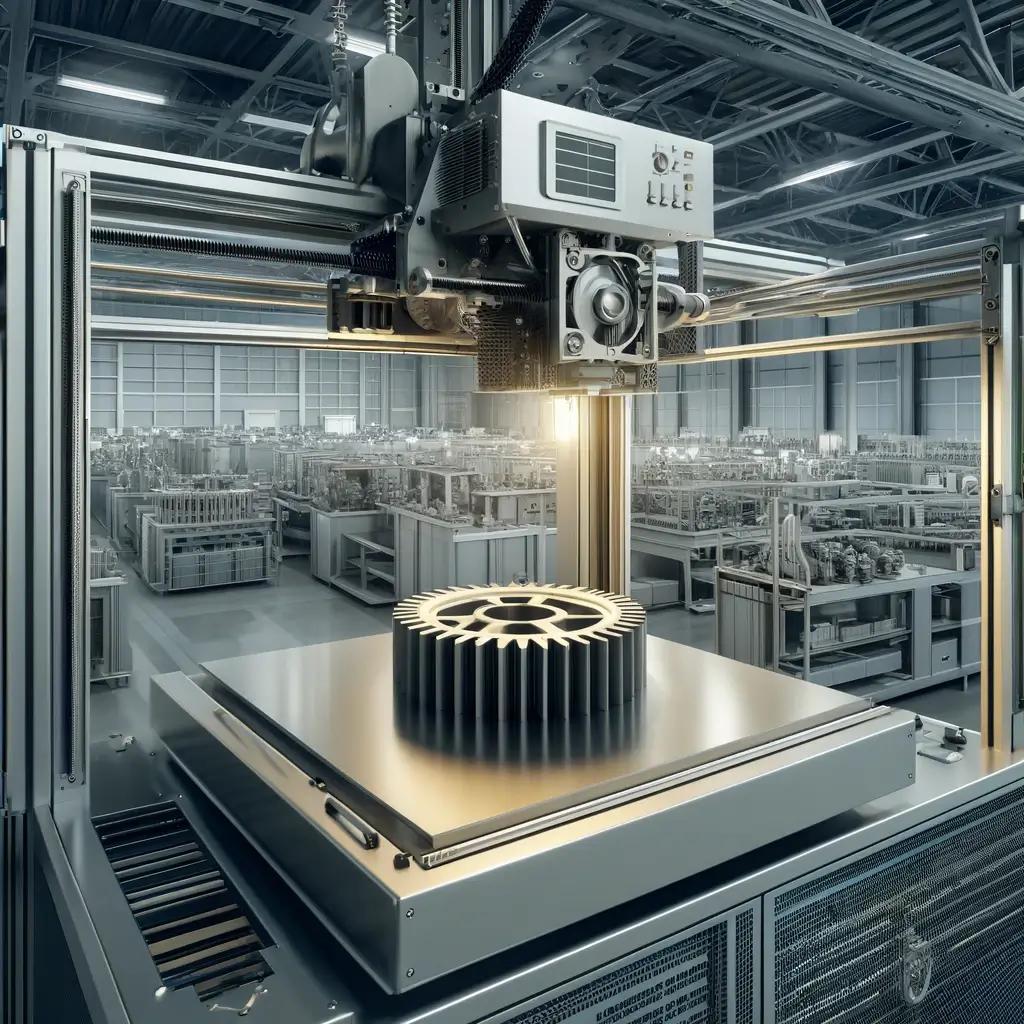

Industrial 3D Printing

Whether your product is one-of-a-kind or the first of many, you can count on Elimold. Our industrial 3D printing services provide rapid product development and innovative digital manufacturing, from concept to execution. Leverage our industry-leading industrial Additive Manufacturing (AM) facilities and unparalleled experience to accelerate your industrial AM projects today.

End-to-End Industrial 3D Printing Solutions

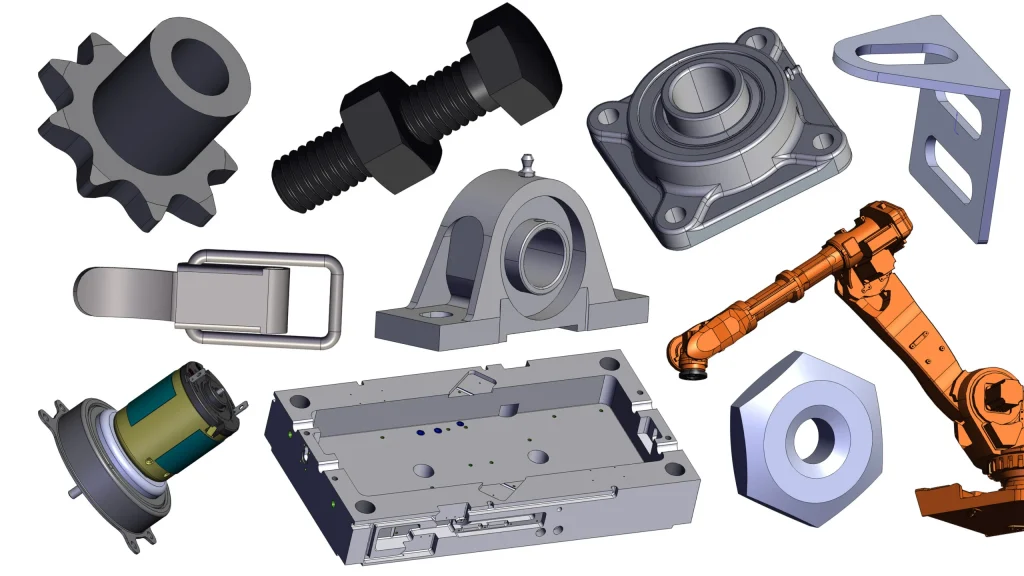

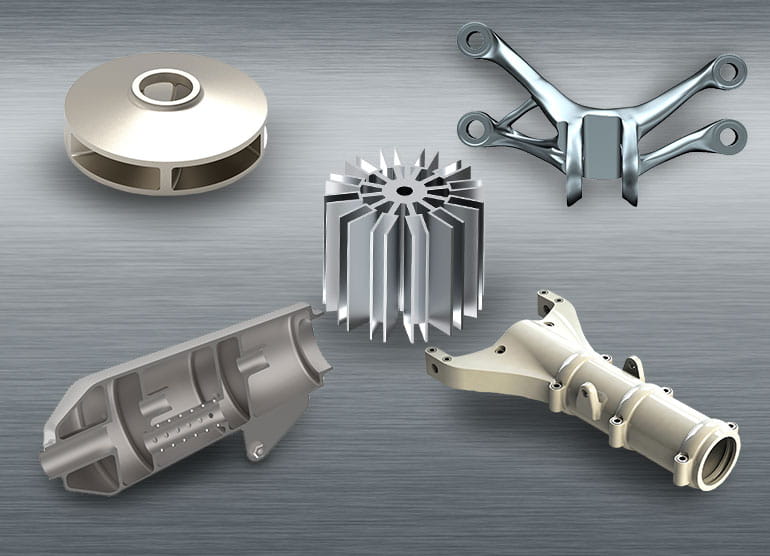

Industrial 3D printing is an additive manufacturing method that builds parts layer by layer using materials such as plastics, resins, powders, metals, etc. to achieve components of the desired shape. The process is suitable for prototyping and low-volume production, and can produce parts with complex configurations that are difficult to manufacture using traditional manufacturing methods. Industrial 3D printing allows for rapid design iterations, allowing you to reduce time to market without sacrificing quality. It also helps reduce material waste and tooling costs.

Elimold’s professional industrial 3D printing services ensure an effective turnkey solution for precision products and detailed designs. Our team is experienced in working with a wide range of materials and multiple industrial 3D printing technologies, working closely with customers to select the best combination of materials and production methods to provide high-quality results and optimal versatility while helping you reduce turnaround time. Whether it is an initial prototype or an end-use part, we leverage cost-effective industrial 3D printing to transform the way new products are brought to market.

Industrial 3D Printing is Our Business

Headquartered in Shenzhen, China, Elimold has worked over the years to build a reputation for excellence and become a trusted partner for customers around the world. We specialize in prototyping and low-volume production services for mission-critical applications in industries around the world. At Elimold, supporting product development is more than just a service, it’s part of our corporate culture. Our dedicated team is at the heart of our success, passionate about driving growth and ensuring 100% customer satisfaction. We are committed to quality and safety, and are an ITAR-registered company with ISO 9001 and ISO 27001 certifications. Our goal is to provide the highest quality in-house industrial 3D printing services to provide customers with high-quality components that enhance their competitive advantage. Our advanced industrial 3D printing technology ensures precision, enabling finer details in the final product. From real prototypes and 3D printed models for proof-of-concept applications to high-resolution printed final products, we are committed to meeting your budget and project time needs. Elimold emphasizes the affordability and efficiency of our industrial 3D printing services, with lead times as short as 72 hours for prototypes and production.

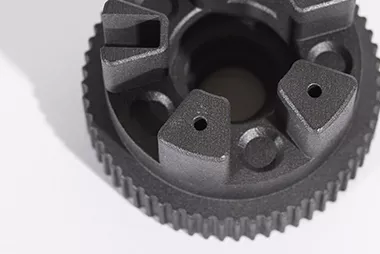

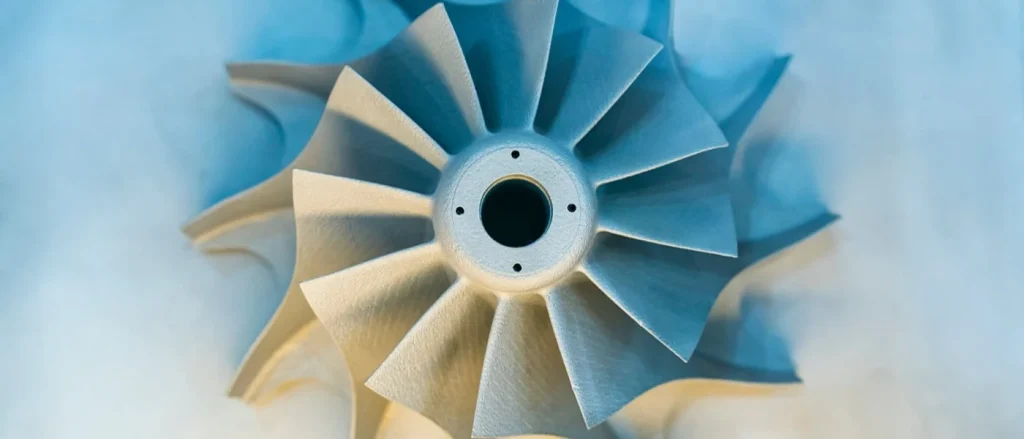

Industrial Metal 3D Printing

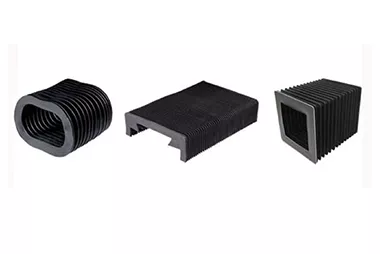

Industrial Plastic 3D Printing

Available industrial 3D printing technologies

Elimold believes that every designer should be able to create products without limitations. Our industrial 3D printing capabilities include the most comprehensive range of technologies, materials and finishing levels in the world, giving you unbiased access to the best solution for your project.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused Deposition Modeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Micro 3D Printing

Wire Arc Additive Manufacturing (WAAM)

Metal Binder Jetting

Rapid Prototyping

An iterative design process that uses 3D printing to quickly create scale models of real parts or product components. This prototyping method facilitates agile product development, is cost-effective, and significantly reduces the time required for the design and engineering phases. Rapid prototyping services are the application of 3D printing technology to the manufacturing process, and are a cost-effective solution for producing prototypes, small batches, and testing end-use parts. With rapid prototyping services, you can gain unparalleled design freedom, shorter lead times, and a streamlined supply chain. You can accelerate production and gain a competitive advantage in the market.

Low-volume and high-volume production

We have introduced revolutionary industrial 3D printing technology, the perfect solution for both low-volume and high-volume production needs. With our cutting-edge capabilities, we are transforming traditional manufacturing processes, unlocking new levels of efficiency, precision, and cost-effectiveness. Whether you require a limited-run custom product or need to quickly scale up production volumes, our industrial 3D printing services can revolutionize your business.

Low-volume production has never been easier. Our advanced industrial 3D printing technology allows you to easily create highly detailed, complex designs without the need for expensive and time-consuming tooling. By leveraging the ability to quickly generate complex geometries and prototypes, you can significantly reduce your time to market and secure a distinct competitive advantage. We enable you to quickly iterate and improve your designs, ensuring the highest quality products reach your customers in record time.

Industrial 3D Printing Can Transform Your Business

- Decades of experience in custom Parts and supply chain management lower your purchasing costs, and produce significant cost savings so you can concentrate on your core business.

- Engineering expertise during the design phase, saving you time and money with more efficient fastening solutions.

- Reducing component count and increasing installation efficiency adds to your bottom line.

- Qualified sourcing team to take your printed part, verify dimensions, and provide that to our suppliers. A model inhand, with exact dimensions, means efficiency is increased and down time risk is lessened.

- Knowledgeable sales team ready to discuss the different materials and printing capabilities available.

- Printing resources from value-oriented to the highest specification available, we can accommodate your needs.

Reverse Engineering

Reverse engineering is the process of creating a 3D CAD model from an existing physical object. Our service team can quickly perform 3D scans, both on-site and off-site, from small parts to large objects, to create CAD models for prototypes and legacy parts. Even if you don’t have 3D CAD files, you can get to market faster with Elimold’s professional design and engineering CADaaS (CAD as a Service) team.

Contact our Industrial 3D Printing experts today!

Our expert engineers will personally answer any questions you may have and help you determine the best materials and industrial 3D printing technology for your application. Even if the product design you require is very complex, we will help you choose the right solution for your business.

Experts in industrial 3D printing produce parts on demand

Elimold also offers additive manufacturing services worldwide. From the fast and high-quality production of models and prototypes to series production based on plastic materials or small batches of sand molds for metal casting. In our expert center for industrial 3D printing, we personalize your industrial 3D projects based on CAD data sets with high quality and favorable terms. Short-term outsourcing of production peaks is also attractive from an economic point of view.

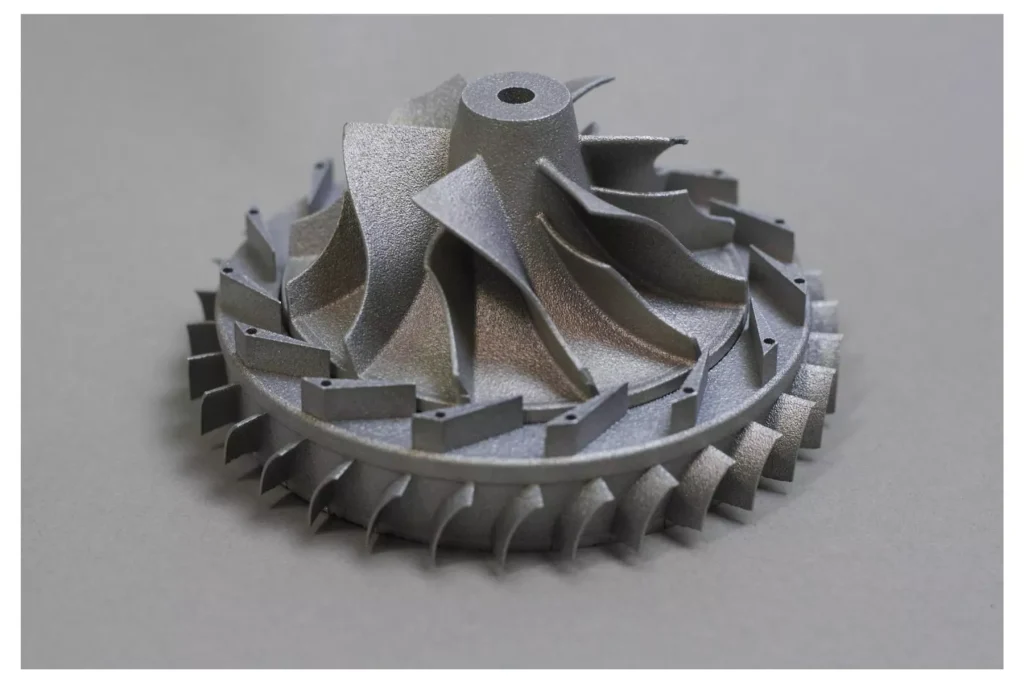

Industrial 3D Printed Replacement Parts

Elimold’s industrial 3D printing facility has the ability to scan, reverse engineer, optimize, print and post-process parts in-house. By industrially 3D printing spare parts, the useful life of assets can be effectively extended. In some cases, part costs and lead times can also be reduced. We manufacture many parts, such as impellers, which are in operation in our customers’ assets. We are developing a digital passport database to track and confirm the fitness of our customers’ industrial 3D printed spare part designs. This will enable customers to have technically guaranteed, certified spare parts printed on demand, furthering the goal of reducing inventory and waste in the supply chain.

Advantages of our industrial 3D printing manufacturing

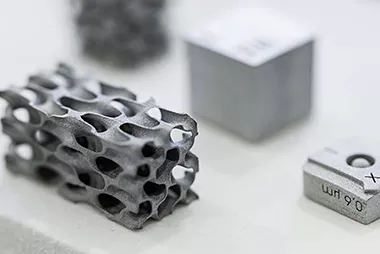

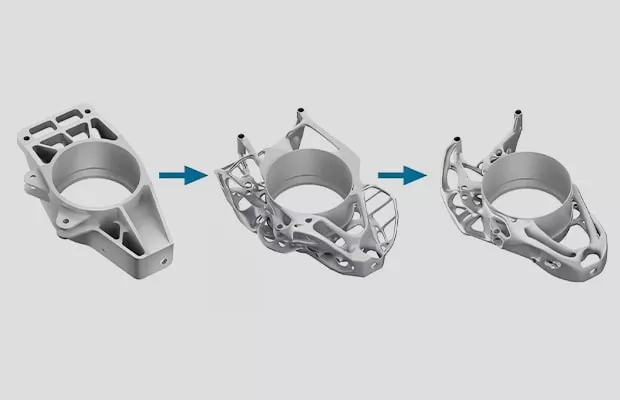

Most complex geometries

Based on the latest technology, Elimold’s industrial 3D printing services enable the production of the most complex geometries and customized components with the finest details in a single production step.

Optimize costs

Complex geometries and increasingly diverse and smaller batches. When conventional processes reach their economic limits due to high tooling costs or long changeover times, voxeljet’s large-scale additive 3D printing services offer important economic advantages and complement existing production lines.

Production at any scale

Elimold offers large-scale industrial 3D printing services for printing large objects or for serial production of small parts. We are known for our efficiency, reliability and attention to detail in prototyping and small-batch production. We offer unrivaled services worldwide for high-performance, high-volume and/or large-scale builds.

Accelerate time to market

Additive production processes reduce component manufacturing time by up to 75% by eliminating the need for tool and mold manufacturing. This is true for product development for model and prototype manufacturing, small and medium-sized batch production or the manufacture of components for multiple models.

Certifications and Inspection Reports

Elimold can provide various certificates (conformity to order types 2.1 and 2.2, metal and plastic raw material certificates, heat treatment protocols, RoHS certificates, etc.) and inspection reports (CMM, First Article Inspection Report – FAIR, measurement reports, etc.).

Quality Assurance

Elimold is ISO 9001:2015 certified. Our in-house industrial 3D printing facility with in-house application engineering team and quality assurance lab ensures that every part we deliver is of top quality.

Our Value-Added Services

Elimold combines high-tech, innovative manufacturing methods with a dedicated team to achieve complete customer satisfaction even on the most challenging projects. Our service capabilities support customers throughout the product development process, eliminating the need to work with multiple service providers. In addition to industrial 3D printing and prototyping, we also offer design and engineering, CNC machining, casting, finishing, assembly and more to provide customers with comprehensive product and production solutions.

To work with a full-service product development team for affordable 3D printing services, we invite you to contact our team for more information or request a quote today.

Why use Industrial 3D Printing for novel designs?

Novel design research aims to create parts that perform better and function more efficiently. This practice is well established in industries such as aerospace, where aircraft parts are industrially 3D printed to be lighter while retaining the strength characteristics of traditionally manufactured parts. Industrial 3D printing can also be used to manufacture parts that cannot be made using traditional techniques such as die casting and forging combined with traditional machining techniques. Similarly, Elimold’s customers use industrial 3D printing to manufacture novel designs. We have printed a variety of novel designs to support various research projects.

Material Options

Our industrial 3D printing services offer metal, plastic, and composite options.

Plastic Materials

- Nylon (PA 11, PA 12, PA 6)

- Nylon with Glass Beads (PA-GF)

- Nylon with Carbon Fiber (PA-CF)

- TPU (Thermoplastic Polyurethane)

- TPE (Thermoplastic Elastomer)

- ABS

- PLA

- PETG

- PC (Polycarbonate)

- ULTEM (PEI)

- PPSU

- ASA

- PEEK

- PVDF

- Resin (Standard, Tough, Flexible, Castable, High-Temp)

Metal Materials

- Stainless Steel (316L, 17-4 PH)

- Aluminum (AlSi10Mg, 6061, 7075)

- Titanium (Ti6Al4V)

- Inconel (625, 718)

- Maraging Steel (MS1)

- Tool Steel (H13, A2, D2)

- Cobalt Chrome (CoCr)

- Copper

- Bronze

- Nickel Alloys

- Precious Metals (Gold, Silver, Platinum)

Characteristics of various types of industrial 3D printing technologies

Industrial 3D printing is a versatile solution for a wide range of applications, from high-resolution models to rapid prototyping, rapid tooling for traditional production processes, manufacturing aids, and even end-use parts in manufacturing.

Stereolithography

Stereolithography is one of the most widely used rapid prototyping technologies, ideal for high-quality visual models with impeccable surface quality, fine details, and fast turnaround.

Key Characteristics

- Vat photopolymerization technology that uses lasers to harden liquid resin

- Provides excellent surface quality and fine detail

- Parts require support structures, which need to be removed manually

- ldeal for visual models, prototypes, master patterns, and small series manufacturing

Selective laser sintering

Selective laser sintering is a popular and versatile 3D printing technology thanks to its wide range of high-performing materials and the absence of support structures which makes complex geometries possible.

Key Characteristics

- Powder bed fusion technology that binds powdered plastics using lasers

- Provides mechanical properties comparable to injection-molded parts

- No support structures needed, making highly complex designs and build optimization possible

- ldeal for all stages of the production lifecycle, from prototyping to small series or custom manufacturing

Multi Jet Fusion

Multi jet Fusion combines the design freedom of 3D printing with high-performance materials and a consistently fast build time to offer an attractive alternative to injection molding.

Key Characteristics

- Powder bed fusion technology that uses chemical agents and heat to fuse powdered plastics

- Provides mechanical properties comparable to injection-molded parts

- No support structures needed during printing, as powder is self-supporting

- ldeal for functional prototypes and small series of complex end-use parts

Fused deposition modeling

Fused deposition modeling couples 3D printing’s design freedom and fast lead times with production-grade thermoplastics to create durable parts that have excellent mechanical properties,

Key Characteristics

- Material extrusion technology that uses melted thermoplastic filament to build parts

- Uses production-grade thermoplastics to create durable parts with excellent mechanical properties

- Parts require support structures, which need to be removed manually

- ldeal for prototypes directly constructed in production materials and small series manufacturing

Metal 3D printing

Metal 3D printing, combines the design flexibility of 3D printing and the mechanical properties of metal tocreate unique, strong, and lightweight parts, even for the most complex applications.

Key Characteristics

- Powder bed fusion technology that binds powdered metals using lasers

- Well suited to complex metal parts with intricate structures

- Parts require support structures, which need to be removed mechanically or manually

- ldeal for fully functional prototypes and small series manufacturing

Polylet

PolyJet offers the unique ability to print precision assemblies with multiple materials, colors, and levels of transparency, and with different mechanical or physical properties, all in a single build.

Key Characteristics

- Material extrusion technology that binds liquid photopolymer resins using UV light

- Polylet materials can be blended for specific properties, colors, and transparency

- Smooth surfaces right out of the machine, with a support structure that is washed away

- ldeal for complex visual models and prototypes,especially those that need multiple colors

Somos® TetraShell

DSM Somos TetraShell software converts solid 3D design files into lightweight, hollow models that can be printed using stereolithography to create high-quality patterns for casting.

Key Characteristics

- High-quality, 3D-printed patterns for investment casting or lost wax casting

- Increases design freedom and eliminates need for costly tool production

- Stereolithography ensures patterns with excellent surface finish

- Suitable for use in industries including aerospace and aeronautics, oil and gas, art and architecture,and more

Vacuum casting

Vacuum casting, using two-component polyurethanes and silicone molds, is a fast and effective way to produce high-quality prototypes or end-use parts comparable to injection-molded components.

Key Characteristics

- Copying technique that duplicates a 3D-printed master using polyurethanes and silicone molds

- Fast, cost-effective, and precise production method

- Offers high-quality surface comparable to injection molding

- ldeal for concept models, high-quality prototypes,or small series manufacturing

Surface Finishing Options

Elimold provides one-stop custom industrial 3D printing services, providing a variety of post-processing and surface treatment services after the customer’s plastic and metal 3D printed parts are manufactured.

Plastic Parts

- Support removal

- Sanding

- Bead blasting

- Vapor smoothing

- Chemical smoothing

- Polishing

- Dyeing

- Painting

- Coating

- UV coating

- Sealing

- Plating

- Heat treatment

- Ultrasonic cleaning

- Assembly

Metal Parts

- Support removal

- CNC machining

- Sandblasting

- Polishing

- Grinding

- Heat treatment

- Hot Isostatic Pressing

- Surface passivation

- Electrochemical polishing

- Electropolishing

- Anodizing

- Plating

- Powder coating

- Shot peening

- Ultrasonic cleaning

- Assembly

Industries Served

Elimold’s industrial 3D printing services are designed to help you differentiate yourself in your industry, bringing advanced on-demand custom manufacturing of complex components to your business at a fraction of the cost of a service bureau or traditional industrial 3D printer.

- Engineering

- Manufacturing

- Automotive

- Aerospace

- Dental

- Medical

- Education

- Entertainment

- Jewelry

- Audio

Why choose Elimold's industrial 3D printing services?

Planning to get started with industrial-grade plastic or metal 3D printing? Elimold has you covered. With years of digital manufacturing experience, we provide you with superior products and 100% product quality satisfaction. We are a leading industrial 3D printing center dedicated to providing you with excellent products because we have:

- Vivid experience: We have been in this industry for many years and we understand your business needs and all the necessary details.

- Fast expansion: We understand the importance of speed and quality in industrial 3D printing projects. To this end, Elimold has developed a streamlined production process to ensure rapid expansion.

- Wide range of materials: We offer more than 100 types of materials suitable for industrial 3D printing. You can easily choose the right material type according to your requirements and design specifications.

- Custom/On-demand services: Elimold is a reputable custom industrial 3D printing company dedicated to providing customers with cutting-edge 3D components and products. We have a reliable industrial 3D printing business to meet all your 3D prototyping needs and provide the world’s most competitive prices, best-in-class online industrial 3D printing services.

- Quality Assurance: We specialize in providing you with all the high-quality industrial 3D printing and other digital manufacturing services you may need. To guarantee the highest quality in every product we produce, we work with a dedicated team of quality control experts.

- Global Delivery: Our in-house workshops around the world are equipped with state-of-the-art machines, and we provide onsite and offsite custom manufacturing services. In addition, we provide digital manufacturing services such as 3D printing and CNC machining alternatives to customers around the world.

Request Your Free Industrial 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom Industrial 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.