Injection Molding Services

With over 20 years of manufacturing experience, we are committed to reducing mold making and injection molding costs during production. That’s why we’ve developed proprietary technology to optimize lead times, producing affordable molded parts that can be delivered to you in as little as 8 days. We offer hard and soft molds for production or prototype injection molding, as well as world-class design optimization services. Elimold has delivered over 12 million molded parts to customers around the world through our services, and also offers mold ownership. Contact us now for a free instant quote.

Services for All Your Injection Molding Needs

Do you need a partner who can help you streamline your new product development process while controlling quality and costs? Elimold offers scalable, flexible, and expert-driven global plastic injection molding solutions to help you achieve your product launch and production goals. More than just a parts supplier, we are an extension of your team, providing technical guidance and operational excellence for your custom injection molding projects. Our full range of services can reduce your product development cycle by weeks (sometimes even months) and achieve mass production with molded parts in just days. Part injection molding orders can be shipped in as fast as 1 day. Elimold has a culture of excellence and provides consistent quality products and services to meet customer expectations.

Professional Injection Molding Manufacturer

With advanced manufacturing technology, a global partner network, and deep mold and molding expertise, we meet a wide range of customer needs from prototyping to high-volume production. Depending on your needs and budget, we can choose to produce in China, through international partners, or adopt a hybrid production method. Our manufacturing network is designed to quickly respond to supply chain disruptions, tariff policy changes, and other geopolitical changes, while helping you manage injection molding costs. We can also provide a variety of additive manufacturing solutions to solve prototype parts problems for your injection molding projects. Do you need help deciding whether injection molding or 3D printing is right for your project? Our project analysis report may be able to help you.

Efficient Injection Molding Service Provider

Elimold’s experienced and skilled technical team can guide you through every step of the injection molding process to ensure that your product meets all of your expectations. From small batches to orders of millions of pieces, our expertise in design, engineering, mold making, and production processes ensure that all projects are completed in the most efficient manner. With our extensive injection mold manufacturing capabilities, we are fully capable of meeting any design requirements of our customers. Our in-house mold manufacturing workshop is fully equipped with tools and equipment to meet our customers’ needs. Once we receive your design and confirm it, the actual production process can begin. Our streamlined manufacturing process can replicate millions of products based on your mold. With these key advantages, we ensure that your next custom injection molding project will be completed perfectly and meet precise specifications.

Online Injection Moulding for Custom Parts

If you work with Elimold, we guarantee that you will get the highest quality plastic injection molding products. We take every step of the plastic injection molding process very seriously. Before we start the actual injection molding, we carefully check that the material is of the highest quality. We also ensure that all customer specifications are met. As a precautionary measure, we always ask our customers if the mold dimensions meet their standards. We never start the actual plastic injection molding process before getting your full confirmation. This allows us to make necessary modifications before we start producing your product. We have extensive mold manufacturing capabilities and are able to meet any design needs of our customers. We are fully equipped with tools and equipment to meet the needs of our customers. Once we receive your design and confirm it, we can start the actual production. We have a streamlined process and are able to produce thousands of copies based on your mold. With these key advantages, you can have peace of mind when it comes to injection molding production.

One-Stop Service for Injection Molding

Our project managers and engineering teams work with a “one-stop service” philosophy to ensure your product is designed for the right process. Go from prototyping to on-demand manufacturing in just a few days for affordable, high-quality molded parts. Even better, once you move to on-demand manufacturing tools, prototyping tools are free to use. Working with a single supplier with free design consulting services also significantly speeds up the manufacturing process, improves supply chain flexibility, produces more consistent parts, and easily completes certification.

DFM (Design for Manufacturing)

Mold Design & Fabrication

Surface Treatment

Assembly Services

Quality Management

Packaging & Delivery

Ready To Get Started?

Contact us to turn your manufacturing vision into tangible results. Our team is ready to discuss your specifications and provide quality-focused solutions.

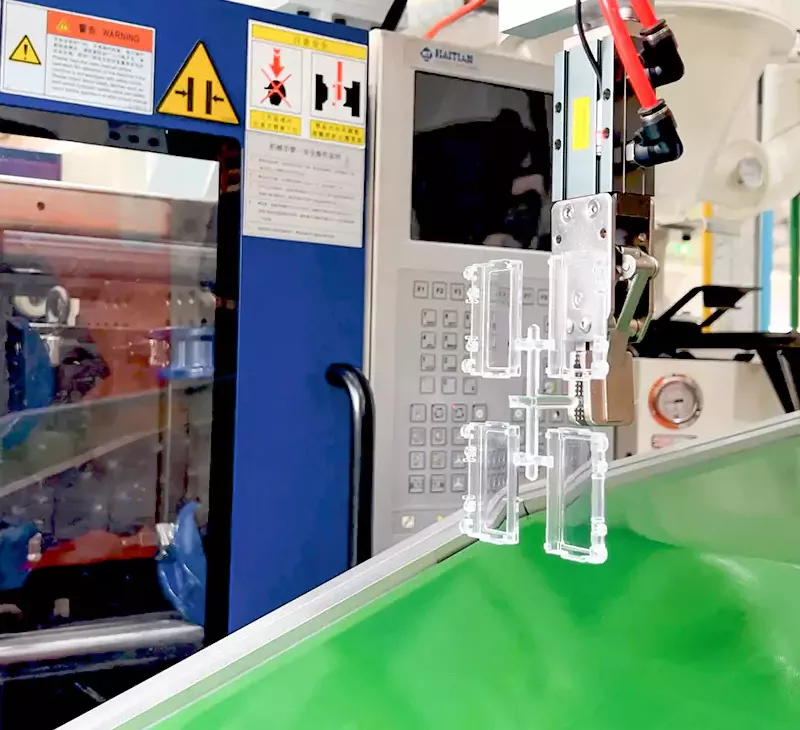

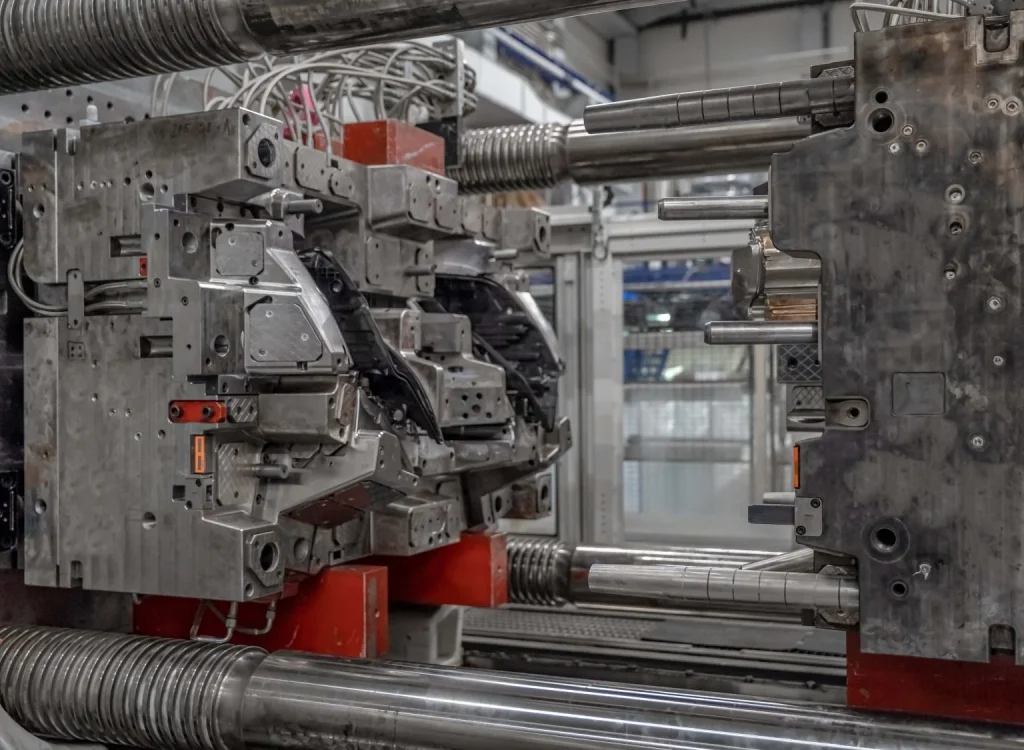

Elimold In-House Injection Molding Facility and Capabilities

Our in-house facility provides a full range of injection molding services including CAD design, mold making, tool repair and maintenance, prototyping, injection molding, testing, secondary operations (assembly, printing, painting and sterilization), logistics and shipping, and in-house tool development. Located in Shenzhen, China, Elimold’s in-house injection molding facility covers an area of 16,600 square meters (approximately 168,000 square feet) and has 135 injection molding machines ranging from 20 tons to 3,000 tons, a Class 7 clean room, a clean room and a dry room. The facility provides a controlled, particle-free production environment. A wide range of complex parts can be produced with sizes ranging from 3 mm (0.12 inches) to 2 meters (79 inches). Delivery times are as fast as 10 days, depending on part size, complexity and production volume. We can provide products that meet DIN 16901-130 standards and tighter tolerances upon request.

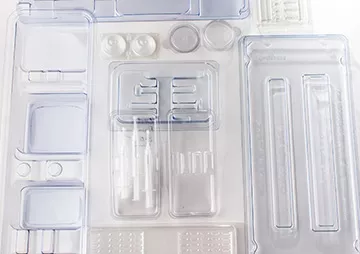

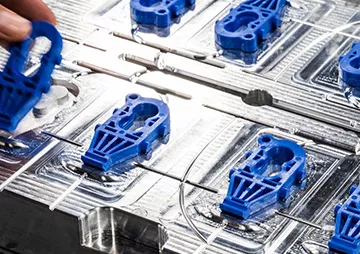

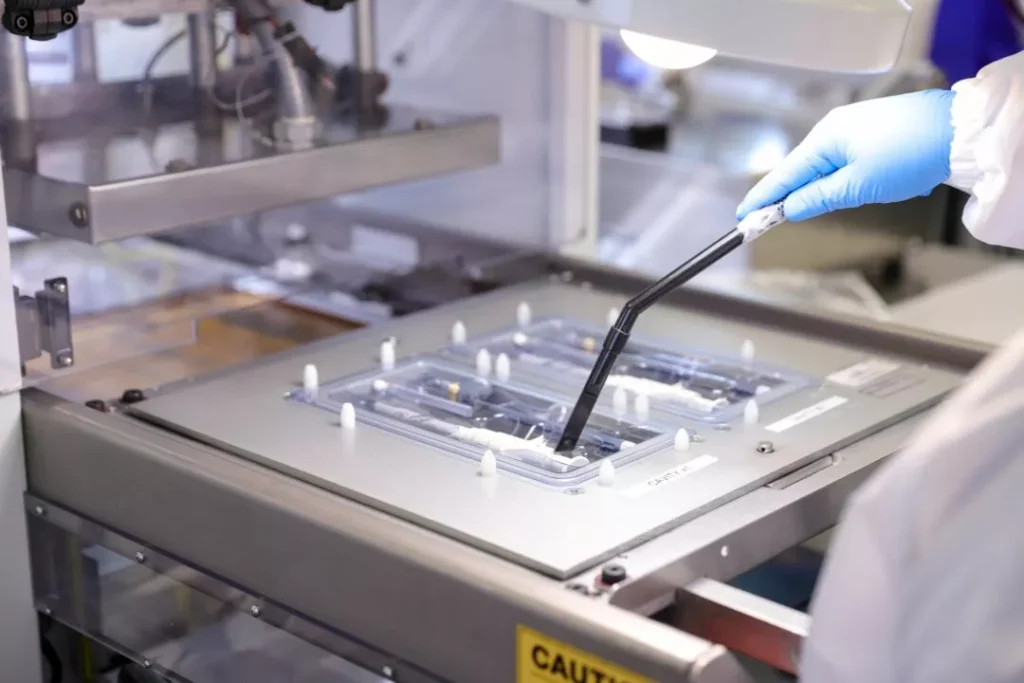

Cleanroom Injection Molding Shop

We have high-tech injection molding equipment to serve industries with tight tolerances and strict regulations. We have modern Class 10,000, ISO Class 7 cleanrooms as well as Class 100,000 portable cleanrooms. We combine traditional experience with modern scientific molding principles to provide you with high-quality injection molded parts. Therefore, Elimold has established an ISO-compliant, FDA-certified Class 7 cleanroom for the production of ultra-clean, contamination-free plastic parts that meet industry regulations. With our team of experienced employees, our cleanrooms allow us to safely produce injection molded products for you that meet strict industry requirements and provide clean and sterile custom assembly services. Our cleanrooms are also certified for assembly. This allows us to assemble the precision plastic parts we produce for you on-site in a strictly controlled environment. As a result, original equipment manufacturers (OEM) around the world trust us to bring their ideas from the concept stage to the market. Engineering support, design assistance, quality tooling, and excellent service before and after the cleanroom production of parts are all part of our commitment to you.

Custom Plastic Molding Company

When you choose Elimold, your satisfaction is our top priority. We work around the clock to meet your needs. With over 300 employees, we operate around the clock and have strong plastic injection molding capabilities and management experience to ensure your project is completed smoothly. We are a factory that integrates production, assembly, packaging, warehousing and other services. We are proud to provide turnkey, worry-free custom injection molding services to customers around the world. Whether you need plastic parts produced for your business or want to create a prototype for a brand new product, we can help you every step of the way. This is why we are considered a leader in custom plastic molding companies.

Injection Molding Service Types

Elimold offers a wide range of custom injection molding services, from on-demand prototypes to mass production molding, capable of producing high-quality custom plastic parts of various sizes and complexities. With fast delivery cycles and a focus on customer satisfaction, we will ensure your project is completed on time and within budget. Get expert quotes and solution guidance now to achieve a seamless transition from design to production.

Overmolding

2K (two-shot) Molding

Insert Molding

Gas Assist Molding

Micro-Molding

Compression Molding

Liquid Silicone Rubber (LSR) Molding

Multi-Component (Multi-Shot) Molding (3K Molding)

Custom Thermoforming

Custom Plastic Injection Molding

Injection Stretch Blow Molding (ISBM)

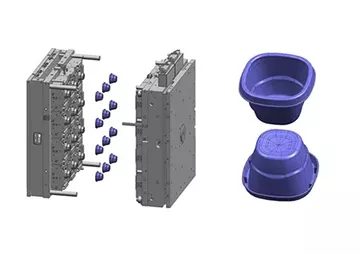

Multi-cavity Molding

Injection Molding Tolerances

All plastic materials expand and contract under the influence of heat and moisture. Our tolerance guides will provide more comprehensive information covering the behavior of common resin types under typical part features. We will work closely with you to optimize your design to make it more production-friendly. We will point out any areas where poor design may cause thermal stress, shrinkage, warping and other problems. Please refer to our design guides for more information on common defects and how to avoid them. Unless otherwise stated, we adhere to DIN 16742 standard tolerances for plastic injection molded parts. Learn about our cosmetic quality standards for injection molded parts.

Design Support From Parts To Mold

We are an end-to-end partner in the production of injection-molded plastic components, providing expert support part design and mold design. Our design support services leverage a number of specialized technologies, including design for manufacturing (DFM), design for assembly (DFA), design for disassembly (DFD), as well as a range of computer-aided design tools.

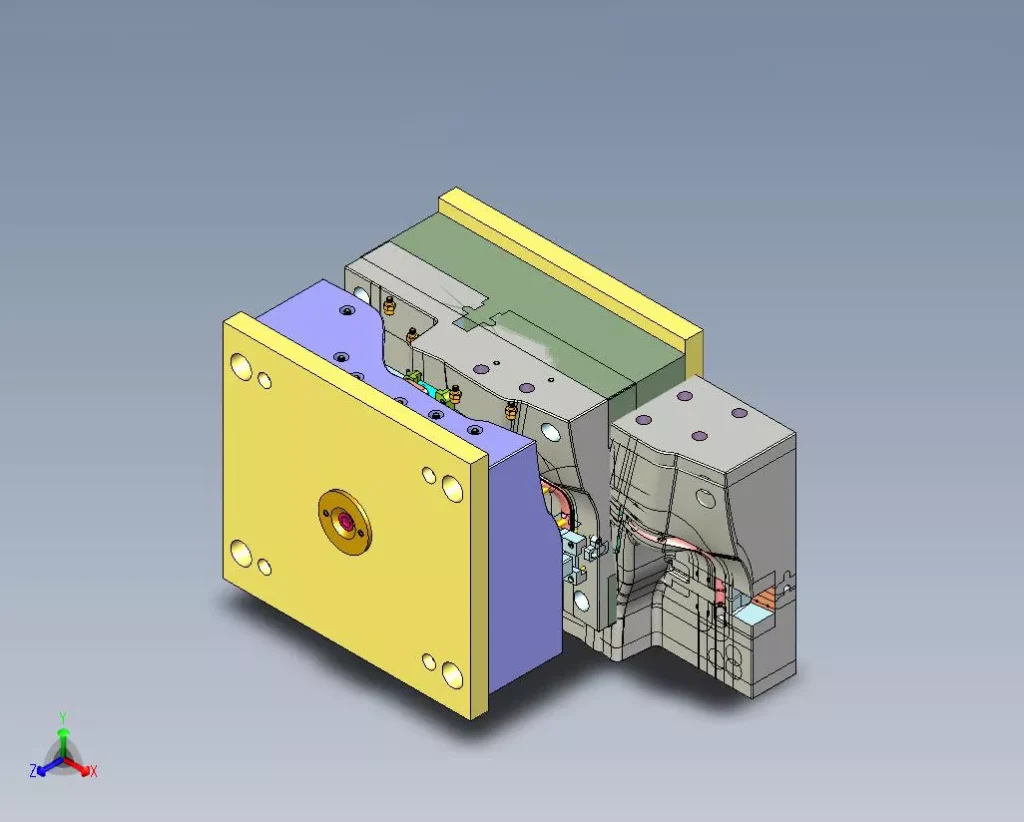

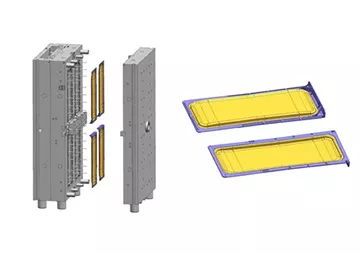

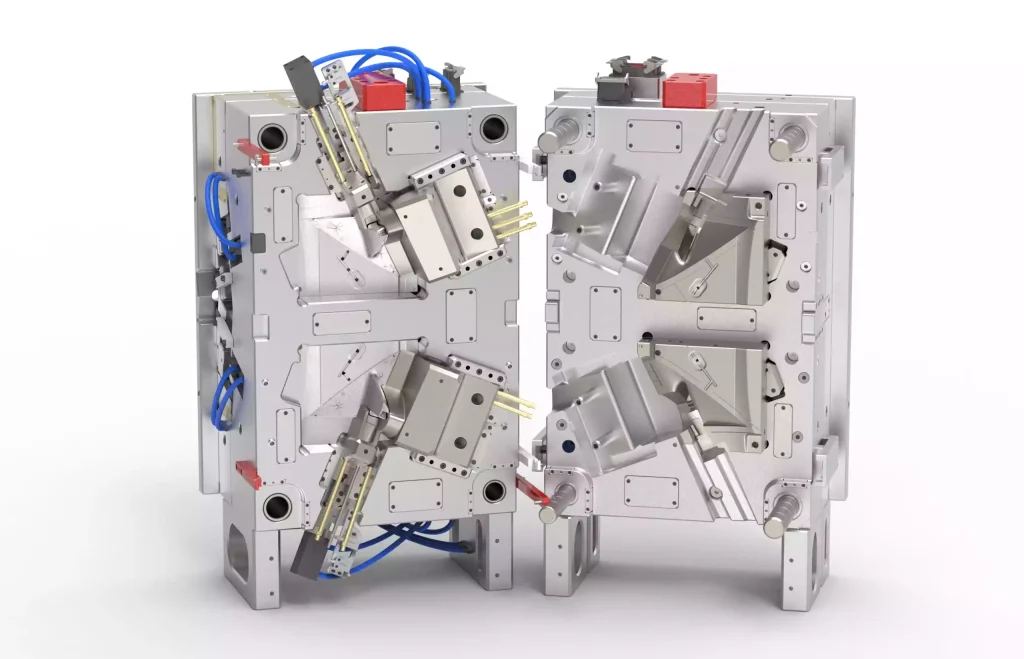

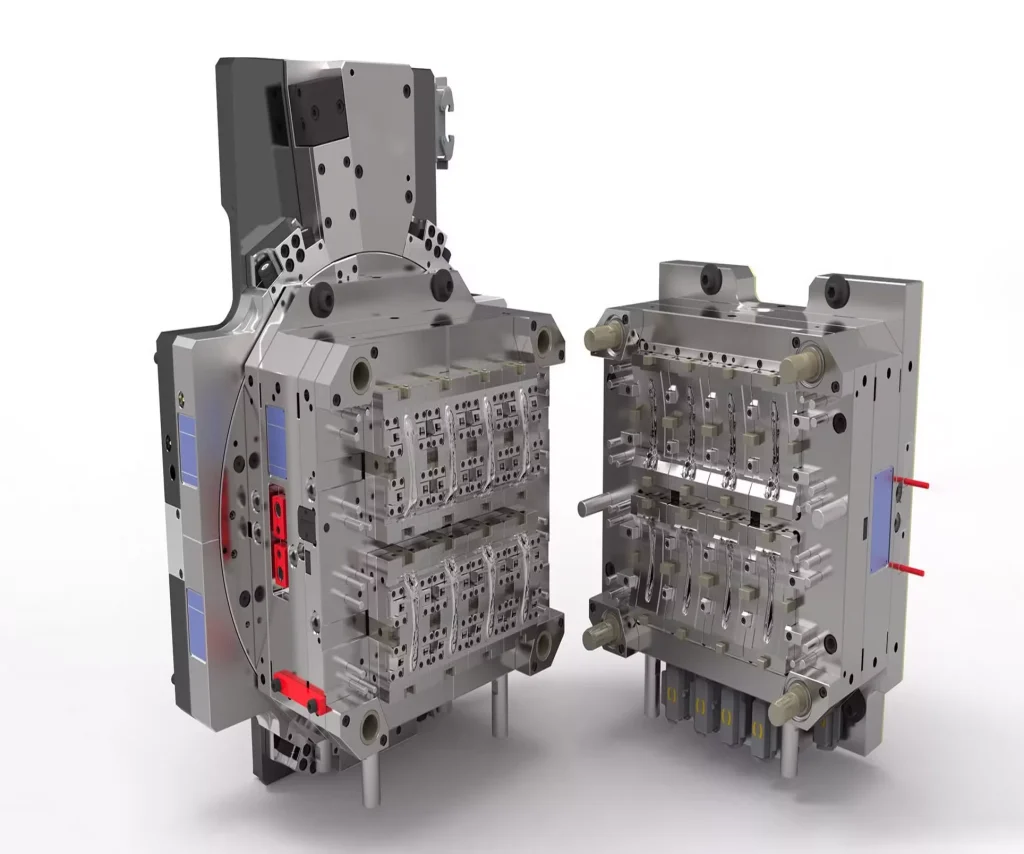

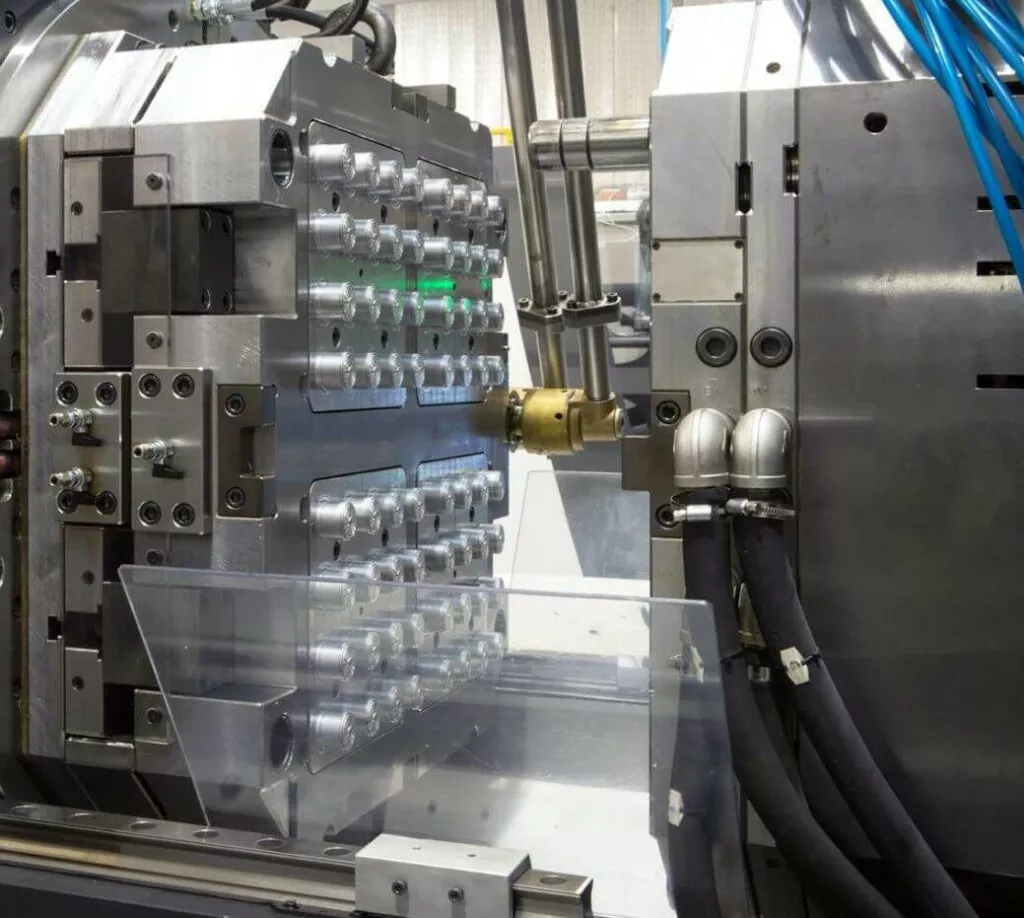

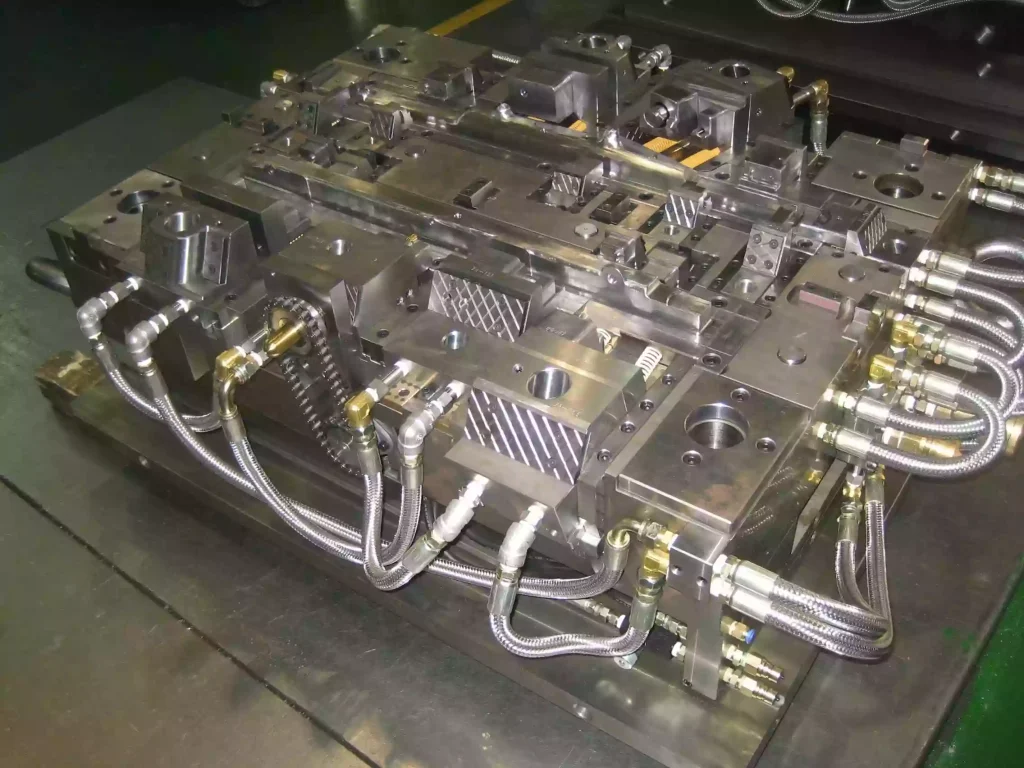

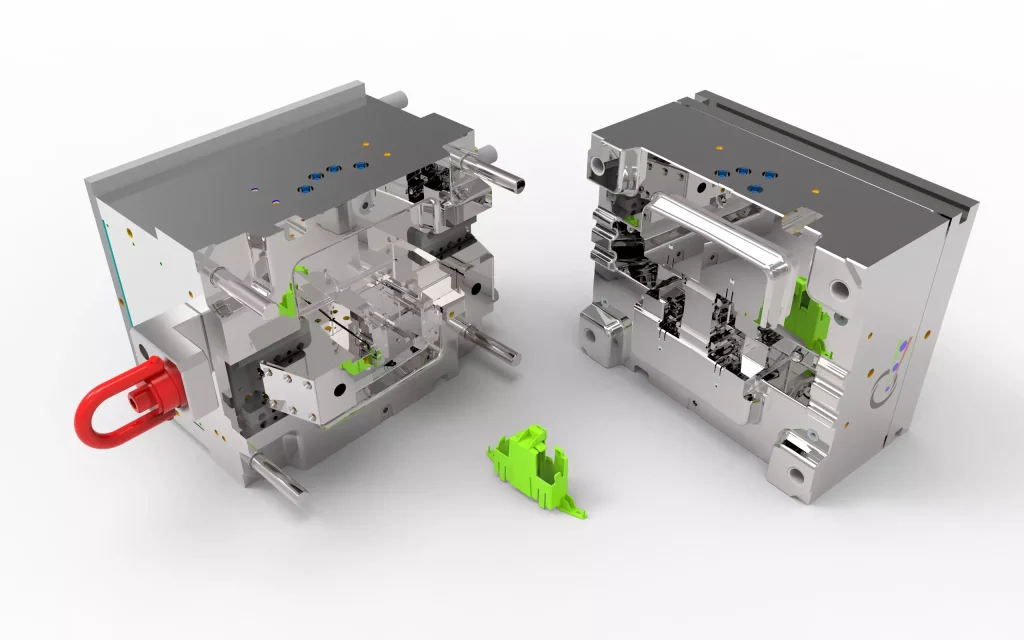

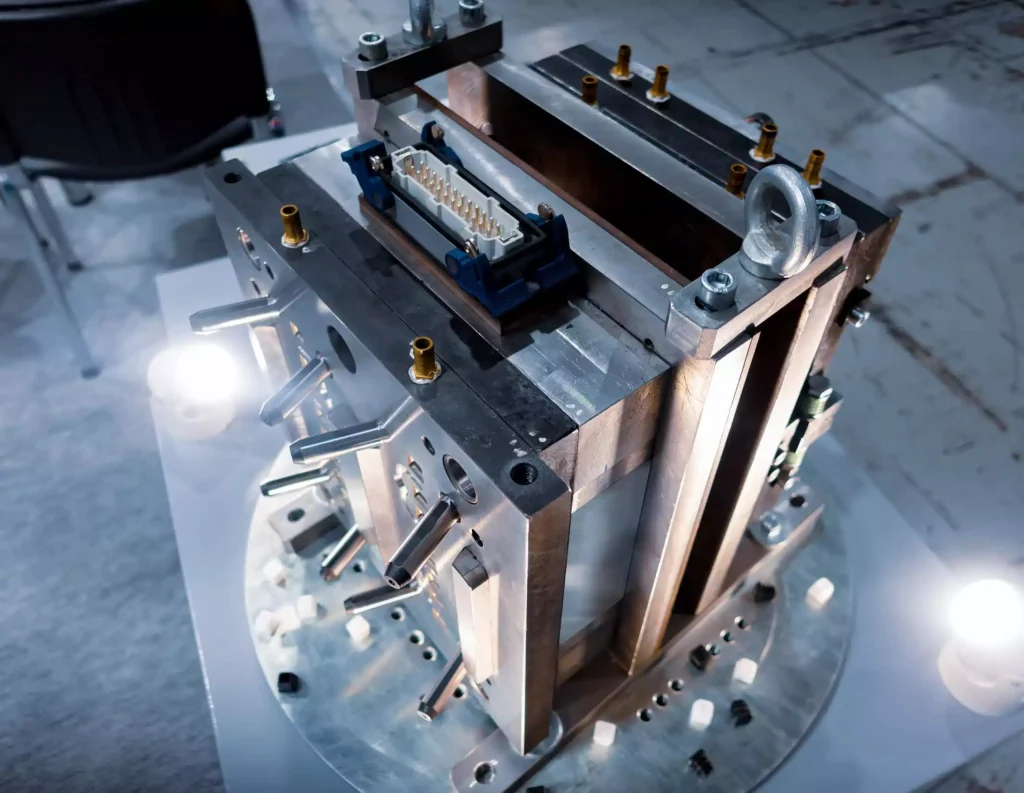

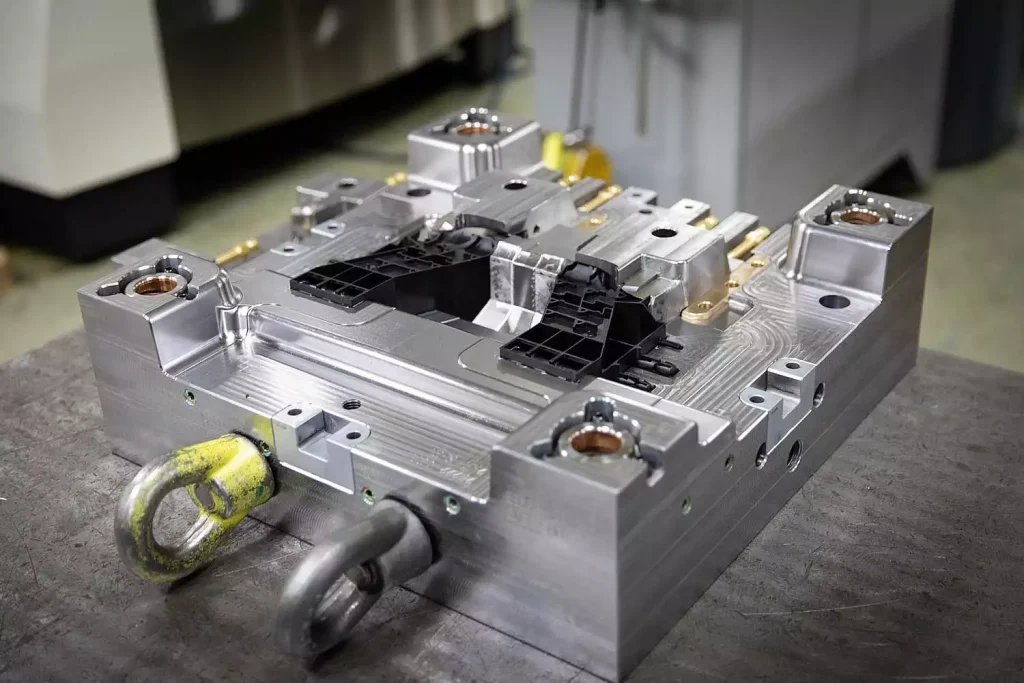

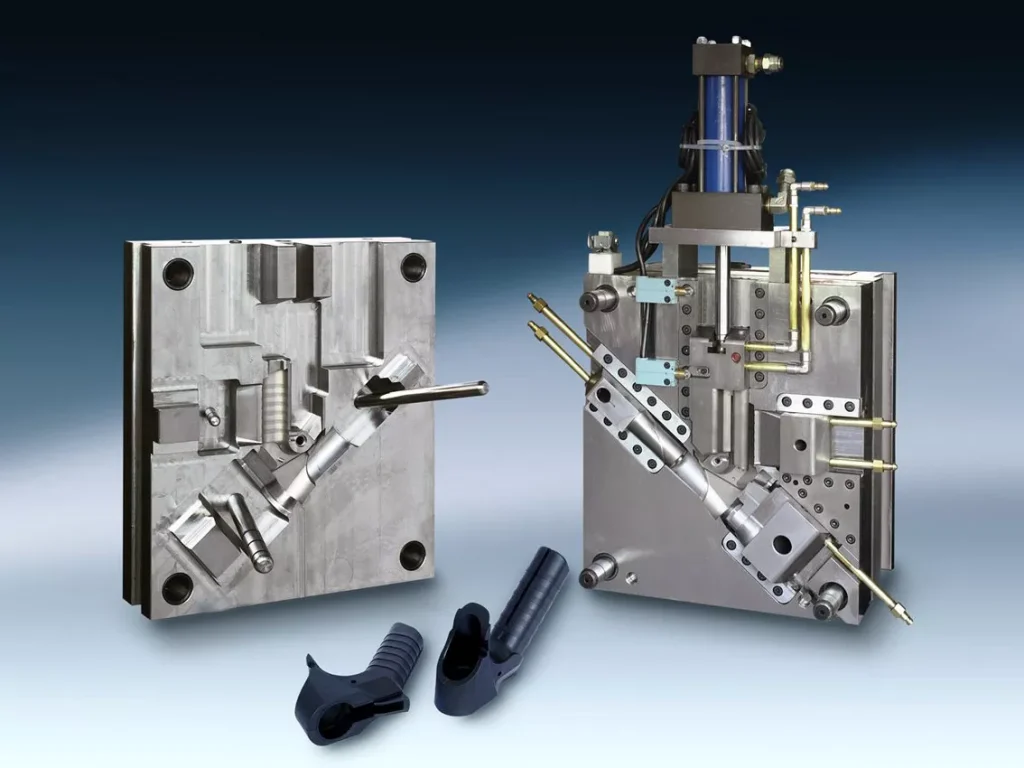

The productivity and service-life of a molded part has a direct correlation to the quality of the tools employed. Our high-quality, in-house mold-making capabilities boost production efficiency and ensure a seamless translation of design specs into molded parts. Our skilled engineers employ state-of-the-art mold making equipment to develop a range of high-quality tools, including multi-cavity molds, hot-runners, insert- and overmolding systems, improving part longevity while also reducing time-to-market.

In-House Mold Making Shop

All Elimold customer molds are made in-house at our manufacturing facility in Shenzhen, China. Our mold making department is staffed by experienced designers and machinists using state-of-the-art software and CNC machines. Once the customer part design is finalized and approved for production, our team will design and build a durable, trouble-free plastic injection mold for your production needs.

If your company needs to source new molds for an injection molding project, you should want a single source for the quality of your injection molds and production parts. If your injection molding supplier does not produce their own molds, you could face significant quality issues, delivery delays, and unforeseen costs in your budget. If you are an engineer or buyer tasked with finding a plastic injection molding supplier, let us provide you with high-quality parts and tooling.

In-house Mold Design And Production

To ensure maximum productivity and minimize wasted time, we are able to complete end-to-end production of molds in-house, from design, mold filling analysis, CAM, CNC machining, EDM, bench machining, assembly to trial molds. We call this Engineered Mold Manufacturing.

- High-precision mold production equipment operates 24 hours a day, further reducing lead times

- Molds are cut according to customer CAD data and specified materials (including manufacturer specified shrinkage). Mold tolerances are typically +/- 0.005″. If a customer requires a molded part with

- tighter tolerances or specific tolerances, we will review the request on a case-by-case basis. Tighter tolerances will increase lead times and production costs.

- Elimold offers a “Lifetime Injection Mold Guarantee” – this service means that we will store the customer’s molds indefinitely for future production if there is a follow-up order or a nominal storage fee.

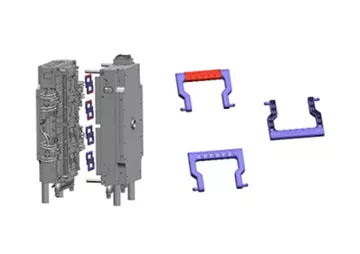

Injection Mold Types

Single Cavity Molds

Multi-Cavity Molds

Family Molds

Rapid Tooling

Production Tooling

Tandem Molds

Mold Cavity Tolerances

We are able to maintain mold cavity tolerances within +/- 0.05 mm (or +/- 0.002 inches), ensuring that every product we produce is accurate. These extremely tight tolerances are critical in industries where even the slightest deviation can affect the function of the product. We hold each component to such a stringent standard that it will fit precisely into your assembly without any adjustments, ensuring consistency during large-scale production. You can request tighter tolerances, but doing so may increase tooling costs due to the need for more sampling and trimming.

Elimold Injection Molding Mold Classes

Standard injection mold tooling is defined by classes from Class 105 (prototype) to Class 101 (high volume production). These mold classes help manage expectations for both customers and suppliers on the overall tool requirements and scope.

What is a Class 105 Mold?

Under 500 cycles. Prototype only. This mold will be constructed in the least expensive manner possible to produce a minimal quantity of prototype parts. Class 105 molds are also known as Class V tools.

What is a Class 104 Mold?

Under 100,000 cycles. Low production mold. Use only for limited production, preferably with non-abrasive materials. Low to moderate price range. Class 104 molds are also known as Class IV tools.

What is a Class 103 Mold?

Under 500,000 cycles. Medium production mold. This is a very popular mold for low to medium-production needs. Most common price range. Also known as a Class III tool.

What is a Class 102 Mold?

Medium to high production tooling, suitable for abrasive materials or parts requiring close tolerance. This is a high-quality, reasonably high-priced mold. Class 102 Molds are also known as Class II tools.

What is a Class 101 Mold?

Over 1,000,000 cycles. They are engineered for extremely high production. This is the highest-priced mold and is made with only the highest-quality materials. Class 101 molds are also known as Class I tools.

Ready To Start Your Injection Molding Project?

Elimold’s IM services deliver customized, high-quality parts that meet customer requirements quickly and accurately. Each IM project is supported by a dedicated global team to ensure that every customer understands the entire process and ensures that the project moves smoothly from DFM to mass production and final delivery.

Comprehensive Capabilities From Prototype To Production

Elimold provides high-quality, scalable injection molding solutions to a wide range of industries around the world. Whether you are developing a single prototype or need large-scale batch production, we can provide the precision, speed and reliability you need to help you bring products to market faster and smarter. We focus on providing a full range of injection molding services to meet your unique part needs and production goals. From material selection to final assembly, our engineering-oriented approach ensures excellent quality at every stage. With advanced facilities, automated production lines and high-tonnage injection molding machines, we are fully capable of handling large-volume orders with precision and efficiency. With a scalable infrastructure, in-house mold manufacturing capabilities and strict quality control systems, we can deliver consistent results on time and at scale, regardless of complexity or quantity.

Professional Injection Molding One-Stop Service Company

From design to delivery, Elimold helps you realize your next great idea. Our professional team of technical designers and engineers can provide you with design, prototype parts supply, mold manufacturing and production services. And we can also use your existing molds to start producing parts immediately, or we can turn your concept into a real product. We provide batch delivery and single order fulfillment services. We have three warehouses in the United States to ship your products efficiently and economically. Elimold offers a variety of molds, from small single-cavity prototypes to 64-cavity high-production molds. We are experienced and can manufacture molds for a variety of materials used by our customers. Please contact us for a quote to find out how we can help you realize your vision.

Injection Molding Solutions

Get custom plastic prototypes and production parts with flexible solutions from Elimold.

Rapid Prototyping

Low Volume Injection Molding

Mass Production

Custom Plastic Parts

Elimold has the best and brightest professionals in the plastic molding industry. You can count on us to work with you to find creative design solutions that maximize the quality and efficiency of your plastic parts and maximize your cost savings. When we meet with you, we first take a deep dive into your plastic project. After that, we guide you through everything from product design to material selection. You’ll find that our extensive experience in plastic manufacturing will save you time, effort, and potentially even money.

Engineering Design Capabilities and Services

Our design team has over three decades of industry experience in creating and designing high-quality molds. Our in-house engineering team uses the latest CAD/CAM software to accurately design molds and products for you. They have received scientific molding training from the top experts in the United States and will carefully review your 3D drawings before mold manufacturing to identify and correct any factors that may affect product design. Advanced design software such as Solid Works allows us to quickly and easily modify and evaluate part designs to meet our customers’ precise specifications. With many years of experience in plastic processing, Elimold can assist you in developing application specifications and ensuring structural integrity to meet your pressure, service and time requirements. And we are also equipped with rapid thermoplastic prototyping equipment using the latest 3D printing technology (fused deposition modeling). This technology allows us to produce thermoplastic prototypes in a few days; you can quickly and cost-effectively evaluate, adjust and test your design and adjust the design as needed before the steel or aluminum mold is manufactured.

Design & Engineering Support

At Elimold, we provide design and engineering support with a people-first approach. Our quotes may start with an algorithm, but they go far beyond that. Each quote includes a basic Design for Manufacturability Model (DFM) that alerts you to any potential design issues that need to be addressed. When you entrust your project to us, we assign a project engineer to guide you through a deep analysis of part, tooling, process, and material selection to achieve the best results. A deep dive into your part design helps us get your part into production faster and avoid costly tooling changes later. Your project engineer will also manage the process from prototyping to mid-volume production, streamlining decisions and ensuring your project moves quickly and smoothly. This tailored, white-glove approach is key to your project’s success and the foundation for a long-term relationship with you.

Design for Manufacturing Feedback

Injection molding is a tricky process and we want to work with our customers. This means we evaluate your 3D CAD model and help you identify features that may create challenges during molding. So, not only do we provide in-platform draft, thickness and shrink analysis with every quote, but we also provide advanced DFM (Design for Manufacturability) such as parting line visualization, lateral motion analysis and mold flow analysis upon request.

Trusted Experts in Injection Molding Solutions

At Elimold, we take quality control throughout the injection molding process very seriously to ensure that every plastic part meets the highest standards of precision and reliability. The first stage of our quality control system begins with a comprehensive design review. Our team provides detailed DFM feedback to help you optimize your design, improve moldability, and reduce potential production issues. During production, we implement strict in-process quality control measures. From incoming raw material inspection to final product inspection, our experienced operators and technicians monitor and improve each step to maintain consistency and accuracy. We use advanced inspection tools such as coordinate measuring machines (CMM), XRF analyzers, and micrometers to ensure precision. To guarantee the quality of the final product, we perform first article inspection (FAI), dimensional inspection, and functional testing. Each part undergoes a comprehensive final inspection by professional technicians who are well-trained to detect even the slightest differences. With our ISO 9001:2015 certification and commitment to excellence, we ensure that every part that leaves our facility meets the highest standards of quality and reliability.

Quality Reporting

We integrate quality assurance throughout the product lifecycle from design and validation to production and post-market surveillance. Our quality engineers work cross-functionally to ensure compliance every step of the way. Customized protocols include installation qualification (IQ), operation qualification (OQ), performance qualification (PQ), and process validation in accordance with ISO. We also provide full traceability and change control for transparent record keeping. Our metrology lab uses advanced measuring equipment for dimensional inspection and functional testing. We use optical comparators, vision systems, and coordinate measuring machines to conduct comprehensive evaluations of molded parts and finished device assemblies. We adhere to strict procedures and documentation specifications, combining robust quality processes with continuous training. Our obsession with quality and process control helps improve product quality.

In-House Value-Added Services

We are committed to making your job easier. That’s why we offer a wide range of molding options, as well as in-house value-added services to make your project even better. We proudly offer processes such as spin welding, ultrasonic welding, hot plate welding, vibration welding, pad printing, hot stamping, as well as kitting and assembly services. We also have a fully equipped tool shop to ensure that your tooling investment is fully protected and maintained. We work hand in hand with our customers to create customized project management solutions. This covers everything from engineering support to assembly, kitting, warehousing and order fulfillment. We call it end-to-end manufacturing solutions. When choosing a business partner, you have many choices, but when you choose Elimold, you will not only get high-quality parts, but also peace of mind.

Assembly and Sub-Assembly Services

Elimold offers custom and turnkey assembly and sub-assembly services. We use bonding, ultrasonic welding, inserts, post-molding processing, modification, decoration, custom packaging, warehousing, distribution, mechanical and electromechanical assembly processes. We do more than just make your mold parts. We can provide you with mold parts, source other required components, and complete the complete processing of your product. If the finished product does not meet your requirements, we can provide a complete sub-assembly to simplify your assembly process, saving you time and money.

Project Management Expertise

Our inventory controls help prevent you from carrying unnecessary product, which can unnecessarily increase your overhead costs. With Elimold, you can produce the exact quantities you need without having to rely on unreliable forecasts or worry about over or understocking. With our fast turnaround times and exceptional customer service, we work closely with you to ensure every project is a success. With our Just-in-Time (JIT) inventory strategy, you get exactly the quantities you need, when you need them, reducing work-in-process inventory and warehousing costs and further increasing your return on investment. Contact us to learn more about how Elimold’s project management services can improve the way your business operates.

Logistics Management Services

Elimold can also provide customers with services beyond manufacturing. We also provide comprehensive logistics services covering all aspects of our customers’ production process, from injection molding of new products, custom injection molds, to the final delivery of products to customers, we will do everything we can to help you. Our logistics services include order fulfillment and managed transportation. Our service does not stop after your product is removed from the injection mold, but will accompany you until the goods are delivered. In addition, we also provide on-site warehousing and container loading and unloading services, as well as distribution center coordination services to speed up your product’s time to market and save you money.

Injection Molded Parts Suppliers

Looking for a partner to take your company’s design, manufacturing and distribution to the next level? Elimold is a full-service custom plastic injection molding factory. Our goal is to be your partner. We are able to design, manufacture, mass produce and stock products at internationally competitive prices. Therefore, our in-house injection molding factory and distribution center in China are able to bring your concept from sketch to reality and finally to your customers. Whether your product is still just a concept, an improvement of an existing product or part, or it is currently in production but you are working with multiple suppliers from design to distribution, we will simplify the process for you.

Ready to Get a Custom Injection Molding Quote?

Upload your design files to get instant quotes and delivery times. Our team is ready to help you turn your parts into reality. Our on-demand injection molding services help you quickly capture the market.

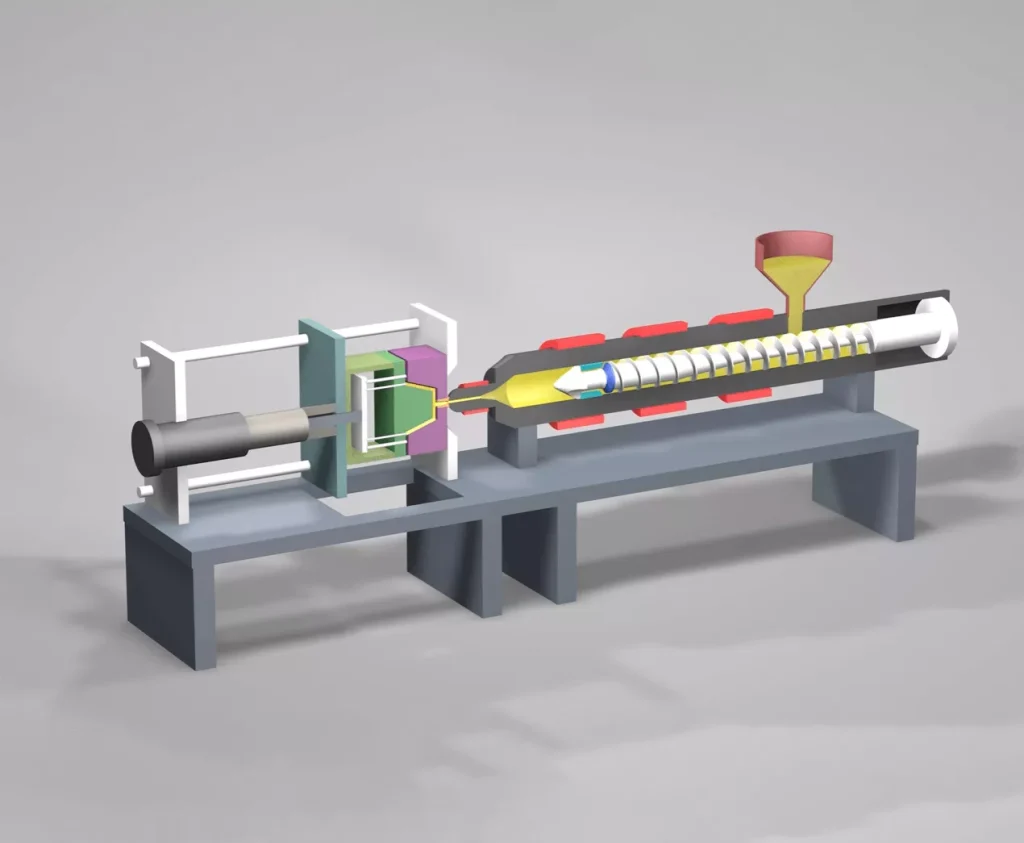

What is Injection Molding?

Injection molding is the process of injecting molten plastic into a mold cavity, rapidly cooling it, and then ejecting a solidified plastic part. It is the most widely used manufacturing process for plastic parts and the most economical way to mass produce them. Once a metal mold or tool is made, hundreds, thousands, or millions of plastic copies can be made in a short period of time, and each additional mold reduces the actual cost of each part as the mold cost is amortized. Injection molding is compatible with a wide range of materials: including thermoplastics, thermosets, and even metals, and these materials can be easily mixed with color pigments and other additives to adjust the function and appearance of the molded product. Therefore, the injection molding process provides excellent consistency from unit to unit because the tooling always remains unchanged.Injection molding also has the most variety in materials, colors, finishes, finishes, and surface textures compared to CNC machining or even 3D printing.

Advantages of Injection Molding

Injection molding is the preferred manufacturing process for industries that need to produce high-quality, complex and scalable parts. Its main advantages are as follows:

- Capable of complex designs

- Wide material compatibility

- Strong and durable parts

- Suitable for mass production with short production cycles

- Lower cost per part as production scales up

- Efficient use of materials and reduced scrap

- Consistent quality and tight tolerances

- Wide selection of colors and textures

Differences between injection molding and 3D printing

In the molding process, plastic or metal parts are formed inside a mold. They are then removed from the mold as fully formed parts. 3D printing is an additive manufacturing process, which means that the parts are built layer by layer using processes such as deposition or sintering. Injection molding is well suited for high-volume production with consistent quality, while 3D printing is better suited for prototyping and small batch production. Injection molding can produce more durable parts. The cumulative cost of 3D printing can be staggering. Once part production reaches a certain level, the unit price of injection molding will be much lower than 3D printing. With the injection molding process minimizing capital investment, the smart move from 3D printing to injection molding will come faster.

Injection Molding Material Options

Elimold commonly uses more than 200 kinds of injection molding materials, including general-purpose plastics, engineering plastics, high-performance materials, etc. Modified materials are formed by optimizing the basic materials by adding fibers, flame retardants or adjusting the molecular structure. We currently have experience in manufacturing various products using more than 18,000 commercial modified materials to meet the performance requirements of different applications.

Plastics

- ABS

- HDPE

- PA

- PTFE

- PP

- PC

- PE

- PS

- PA6

- UHMWPE

- POM

- PMMA

- LDPE

- PVC

- PU

Rubbers and Elastomers

- NR

- Silicone

- NBR

- NBR

- PU

- CR

- EPDM

- VMQ

- FKM

- IIR

- TPE

- TPU

- TPV

Additive & Fibers

If the standard materials can’t meet your custom injection molding parts requirements, the additives and fibers can improve the material properties.

- UV absorbers

- Flame retardants

- Plasticizers

- Colorants

- Carbon fibers

- Glass fibers

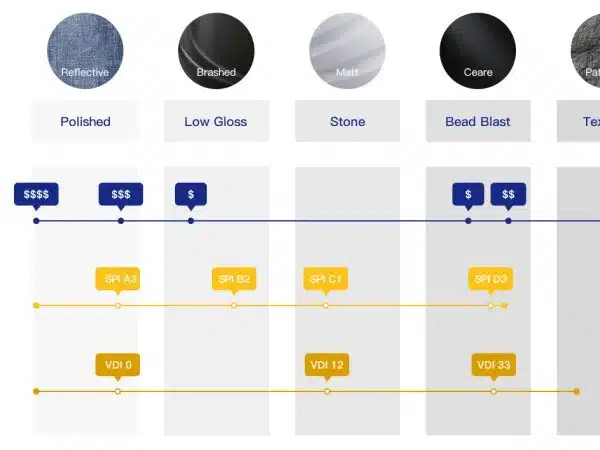

Custom Surface Finish Options for Injection Molded Parts

Beyond functional performance, the right surface finish enhances the aesthetics and durability of your product. Elimold combines in-house standard surface finish expertise with a network of over 15 years of expertise to provide textures, colors, and coatings that match your brand vision.

Standard Finish

Moldmaker’s choice of finish. Typically SPI B-2, depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

SPI Finishes

Range of Society of Plastics Industry (SPI) finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3

MoldTech Finishes (Mold Texturing)

Range of finishes including matte, swirls, lines, and patterns. Our most common texture finishes include: MoldTech MT11010, MoldTech MT11020, and MoldTech MT11030. Other textured finishes can be added by request.

Other Textures - VDI

VDI 3400 Surface Finish (commonly known as VDI surface finish) refers to the mold texture standard set by Verein Deutscher Ingenieure (VDI), the Society of German Engineers. This is mainly processed by EDM machining, producing fine to coarse matte finishes.

As Molded

No secondary polishing or grinding. Part will show tooling marks.

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Pad Printing

Transfer a 2D image onto a 3D part. All images are subject to review.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

Assembly

Elimold has the ability to assemble and label injection molded parts. Discuss your needs with your salesperson.

Functional Coatings And Aesthetic Treatments

- EMI/RFI Shielding: Conductive nickel coatings for electronics enclosures.

- Anti-Fingerprint (AF) & UV-Resistant Layers: Protects consumer device surfaces.

- Electroplating: Chrome, nickel, or gold finishes for automotive trims.

- Anodizing (Metal Inserts): Color-stable aluminum components.

Can My Metal Parts Be Made With Plastic?

The top question on most business owners’ minds is, can my metal part be made with plastics? Yes, in many cases, plastics are an effective alternative. High-quality plastic injection molding makes many custom parts that were previously metal fabricated from CNC machining.

Elimold is happy to discuss if moving production from metal to plastic is a beneficial solution for your parts needs. We’ll provide you with different quotes to establish multiple possible solutions and the cost-effectiveness of each. Manufacturing thousands to millions of identical injection molded parts is the strength of plastic injection molding.

Full-Service Injection Molding Service Provider

With one-stop facilities, Elimold has been a leading manufacturer in the field of high-tonnage custom and large-part injection molding. We are committed to providing you with one-stop convenient injection molding services. With a wide range of plastic injection molding equipment, our company is able to meet all your plastic injection molding needs. We are proficient in developing a complete plastic manufacturing strategy, and our goal is far more than plastic manufacturing. We have first-class full-service project management, convenient assembly, product delivery and logistics services to streamline your production process and ensure your company stays on track. Our comprehensive plastic injection molding services help customers save costs, reduce operating costs, shorten time to market and improve overall product quality. This is why we have become the preferred injection mold manufacturer for companies around the world.

Transfer Tooling Solutions

We pride ourselves on providing seamless mold transfer services, which directly translates into saving valuable resources and time for businesses. Our expertise in handling complex transitions ensures that businesses can smoothly transfer molds even when business relationships have broken down. Our streamlined processes minimize transition periods, allowing for rapid integration and resumption of production operations. We understand the importance of maintaining product quality and specifications throughout the transfer process. Elimold offers a full-service in-house tool room that can quickly meet expected or unexpected mold adjustment needs. We are committed not only to bridging the gap caused by strained partnerships, but also to providing a path to increase efficiency and refocus on core business goals. In addition, our injection molding experts inspect, test and adjust the transferred mold to ensure it works seamlessly with our equipment and processes. Our strategic approach to tooling ensures that every mold we produce has long-term value, providing high precision, tight tolerances and efficient performance throughout the product life cycle.

Helping You Deliver On Your Promises

Our team of experienced mechanical engineers has helped our customers bring nearly 20,000 projects to production. We work with thousands of businesses from around the world to provide them with quality plastic parts. Even though they have their own supplier choices, they continue to choose us because we do our best to help them meet their business obligations and deliver high-quality plastic parts on time and within budget. We strongly encourage you to take advantage of our expertise, and we are happy to provide you with a wealth of resources to help you understand the materials and processes required to manufacture your parts. Tell us your questions and we will be sure to answer them. We are here to help you complete your project with confidence!

Request Your Free Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom mold and Injection Molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.