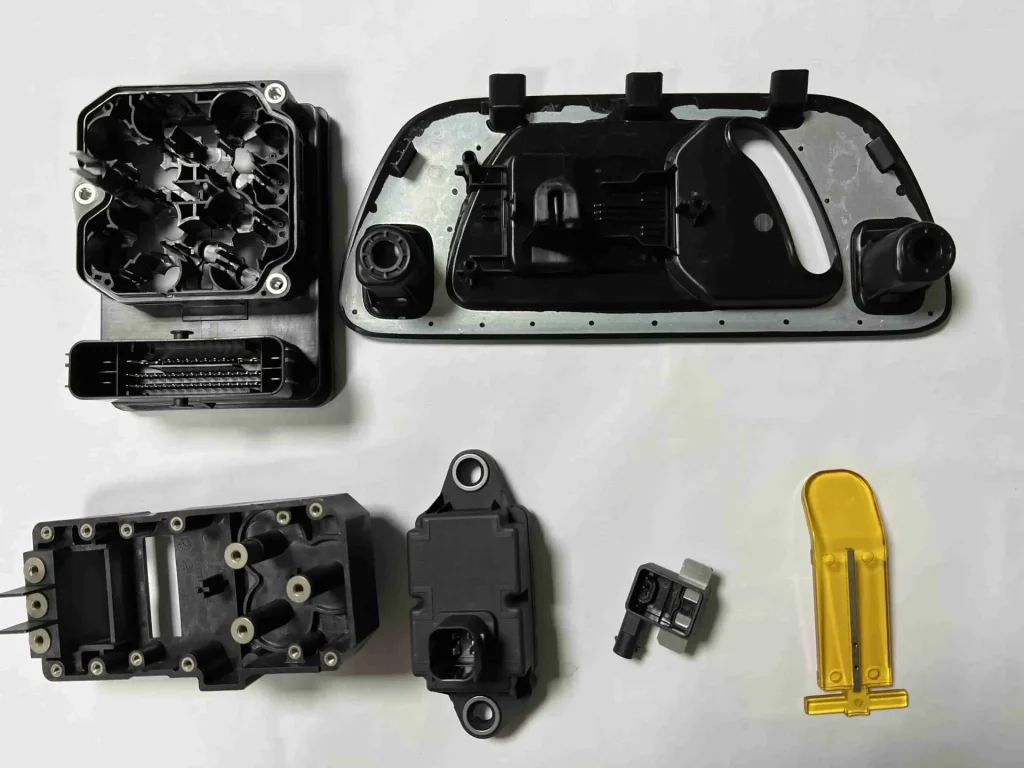

Insert Molding Services

Explore Elimold’s insert molding services, by combining different materials or integrating components directly into plastic parts. We provide innovative solutions to enhance product functionality, insert molding is suitable for high-quality prototypes and on-demand parts. Get a quote online, competitive prices and short lead times. Rapid mold production, as fast as 2 weeks.

Professional Insert Molding Manufacturer

Are you thinking of a project that requires customization? Do you need to improve the reliability and durability of your parts, or reduce their weight? Do they need to withstand a variety of environmental or application-related challenges? With insert molding, you can get components that are perfectly suited to your concept manufacturing needs. Elimold provides custom insert molding services to help you turn your final product into reality. Our comprehensive injection molding capabilities allow us to deliver high-quality insert molded plastic parts in as little as 10 business days. Our professional team can help you design and manufacture a variety of tools and molds, ranging from rapid prototyping to advanced mass production mold manufacturing, and high-volume production of various plastic applications.

Full-process Service Capabilities

At Elimold, we provide comprehensive one-stop molding services, covering everything from design and mold production to assembly and packaging. Our experts will work hand in hand with you to deliver high-quality results in a short period of time.

DFM (Design for Manufacturing)

Mold Design & Manufacturing

Surface Treatment

Assembly Services

Quality Management

Packaging & Delivery

Full Range of Insert Molding Services

Our full-service philosophy ensures that we can assist you from concept to production. We provide a full range of engineering services, including consulting, product design assistance, design for manufacturability (DFM) assistance, mold flow analysis and mold design. Our technical service department provides in-house mold manufacturing capabilities, as well as local and overseas precision injection mold parts procurement services. Our molding department can efficiently process almost all engineering-grade and commercial resins, and has extensive experience in two-color injection molding, overmolding, hot runner and valve gate. As a professional plastic parts molder, we can also provide value-added services such as ultrasonic welding, pad printing, hot stamping and assembly.

Professional Insert Molding Factory

Our modern 44,000 square foot facility in Shenzhen, China was custom designed after years of careful design and research. As the fourth building the company has moved into, we have put a lot of experience into the design and layout. Our injection molding and tooling departments are second to none, and the factory layout also facilitates material handling and the flow of finished products. All of this makes it easier for us to ensure “on-time quality” products for our customers. As a unique contract plastic parts manufacturer, we focus on “technical injection molding services” and can also provide services including multi-color injection molding, IMD (in-mold decoration), IMA (in-mold assembly), vertical insert molding and medical device injection molding. Typically we provide standard horizontal injection molding, with capacities ranging from 28 tons/1 ounce to 500 tons/68 ounces. And Elimold is also committed to using robotics and automation technology to provide “value-added” services and reduce “total cost of part”.

Advanced Equipment and Manufacturing Capabilities

We use advanced injection molding machines and equipment capable of processing a wide range of plastics from commodity grades to advanced engineering grades. This versatility allows us to accommodate projects of all sizes and complexities, from simple parts to complex multi-cavity molds. Our factory is equipped with more than 150 electric and hydraulic molding machines of various types, ranging from 50 tons to 500 tons, and equipped with a variety of barrel sizes for conventional and vertical injection molding. Each machine is equipped with a Yushin automation system to optimize part handling and a Plastrac color feeder to ensure color consistency. We also have a robot gate picker, automatic conveyor, coordinate measuring machine (CMM) and multiple vertical presses using rotary tables and engineering grade plastics. Our advanced equipment and more than 20 years of experience enable us to handle the most complex tasks reliably and accurately.

Expert Solutions for Your Insert Molding Needs

Our injection molding facility has been in operation for many years. This makes our molds and parts pricing very competitive. We have project managers, design engineers, quality specialists, and an excellent customer service team ready to meet your needs. We have more than 20 years of experience in manufacturing precision insert molding. And we know how to make molds and can assist your engineers in part processing to help you produce insert molded parts that meet your application and needs at the lowest total cost. We work with the most difficult engineering grade resins every day to help you achieve your goals for every application. In addition, we can usually provide 100% electrical or mechanical testing to confirm that our insert molded components meet our customers’ SPC requirements and drawing specifications.

Types of Insert Molding Processes

Our insert molding capabilities allow us to manufacture insert molded parts with flexible quantity options, from small batches to large production runs.

Multi-component molding

Multi-color injection molding

Ready to get started on your custom insert molding quote?

Whether your project requires engineering support, tool building assistance, or simply insert molding production, we have a full team ready to help you from start to finish. Contact us today for a free instant quote.

Cleanroom Insert Molding Shop

To produce ultra-clean, contamination-free medical parts that meet industry regulations, we have established an ISO-compliant, FDA-certified Class 7 cleanroom. With our team of experienced employees, our cleanroom allows us to safely produce injection molded products for medical OEM that meet the stringent industry requirements and patient safety. Providing perfect medical custom plastic injection molding and assembly services. Our cleanroom is also certified for assembly. This allows us to assemble your manufactured medical devices and complex medical parts on-site in a strictly controlled environment. Medical original equipment manufacturers (OEM) trust us to take their ideas from the conception stage to the operating room. Engineering support, design assistance, quality tooling, and excellent service before and after the parts are produced in the cleanroom are all part of our commitment to you.

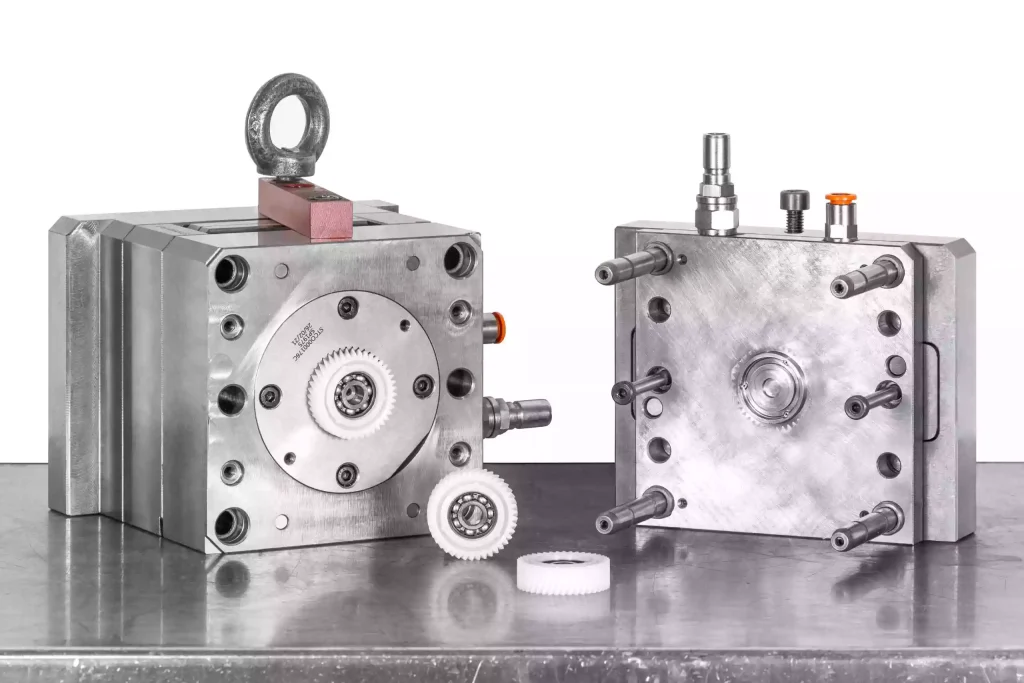

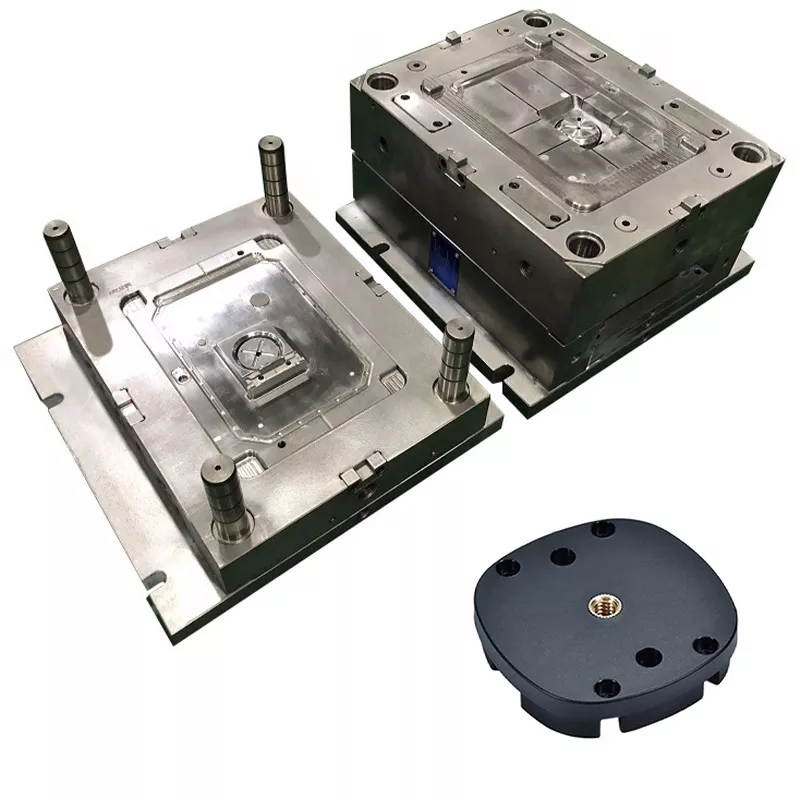

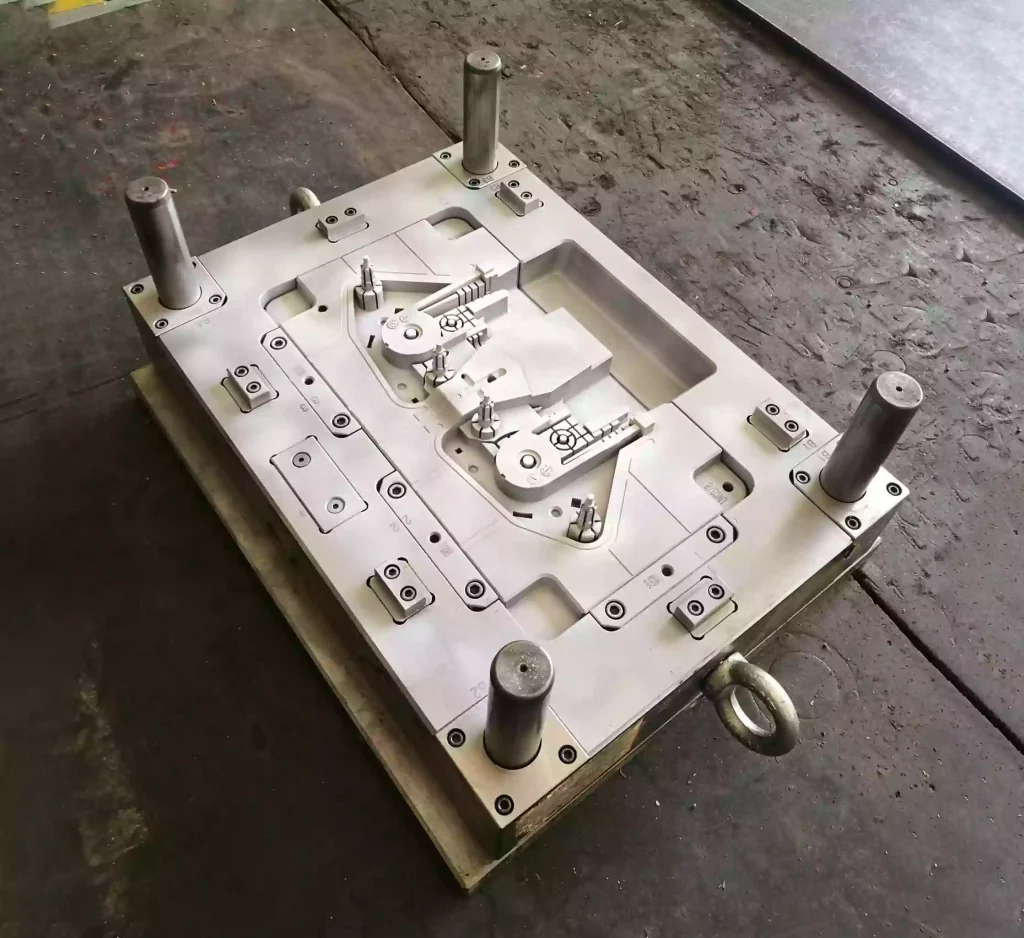

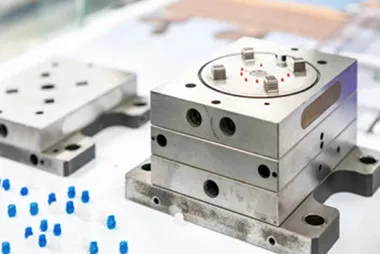

In-house Mold Making Shop

We have a fully equipped in-house mold making shop. Our master mold makers can build a variety of custom equipment, including insert injection molds, prototype molds, and production fixtures. Whether the size of your project is large or small, we have a dedicated shop to meet your unique needs. We are also happy to be as flexible as possible throughout the process. We are able to build your design based on your own CAD model/drawing, or we can work with you to develop a CAD model or drawing of a concept design from scratch. Our team of engineers has unparalleled knowledge to ultimately meet the design in your mind. Our in-house machining experience and use of advanced equipment can help reduce the total lead time and cost in the product development process, thereby creating value for customers and helping you bring products to market more efficiently and cost-effectively. At Elimold, we strive for excellence with advanced methods and high standards. As a result, our employees in the fully equipped in-house engineering tool room can produce top-notch, safe products.

Insert Mold Manufacturing Capabilities

We can quickly transform your 3D part data into high-quality insert molding molds. We provide mold, die and prototype services from design to manufacturing, as well as production molds. The production molds for our insert molding projects are typically high-cavity SPI 101 and 102 grade molds made of hardened steel. Both cold runner, hot gate and hot runner molds can be designed with up to 128 cavities. We can also provide mold maintenance plans to ensure that each set of molds is regularly cleaned and inspected at pre-set intervals based on the number of setups and cycles. Mold inspections, routine mold maintenance, major mold maintenance and preventive maintenance are all standard operating procedures.

Insert Rapid Prototype Tooling

For rapid tooling design, customers receive T1 samples of steel molds in as little as 10 business days. Customers own core and cavity inserts, and we use our own interchangeable base inserts. We offer aluminum, S50C, P20 and NAK80 mold inserts, as well as a master mold (MUD) quick-change system. Side motion is achieved by hand-picking inserts. For production tooling, we produce individual molds that are ultimately owned by the customer. We offer P20, H13, S7, NAK80 and SS420 blade steels, as well as serial and multi-cavity molds. We polish the molds to make the molded parts smooth enough with no visible machining marks.

You can easily get design feedback and validation with high-quality prototype tooling. Easily produce small batches of plastic molded parts with superior injection molded prototypes. We excel at making prototype tooling in a few days, allowing you to perform functional testing and validate market demand. We can also provide affordable aluminum tooling to help you reduce financial risk before full-scale production.

Engineering Design Capabilities

Each development project requiring insert molding services is managed by a project engineer who monitors deliverables and provides regular status updates. Our full suite of engineering services includes insert molding services and is supported by MoldFlow analysis, viscosity profiles, cavity balance studies, pressure window characterization, gate seal time studies, and cooling time studies. Our team of engineers is well versed in insert configuration and can design single-cavity R&D molds with steel insert areas. Interchangeable plates, inserts, and sub-inserts enable faster design iterations at lower costs without the need to create a new mold for each feature change.

DFM and Flow Analysis Simulation

With our DFM services, you can avoid potential manufacturability issues in advance, saving time and cost in the project design and development process. Therefore, design for manufacturability is an essential tool for anyone designing plastic injection molding products. Therefore, we provide design for manufacturing (DFM) and flow analysis simulation, and perform manufacturing readiness reviews (MRR) based on the customer’s final design. We help you optimize product production cycle and obtain high-volume production by providing design for manufacturing (DFM) and flow analysis simulation. In addition, we encourage early design consultation to optimize your design, save you money and find ways to bring competitive advantages to your products.

Custom Insert Molding Parts Supplier

Elimold has successfully created prototype molds for thousands of challenging insert molded parts. Allow us to review your part design with our extensive industry expertise. We will identify any opportunities for improvement to ensure your insert molded parts meet functional requirements the first time. At Elimold, we provide more than just an automated review of your part model. After a detailed review by our experienced engineers, we will meet with you online to review our observations, explain why adjustments are needed, and answer any questions you may have. Our personalized approach to customer service is unique among injection molding service providers. This service is critical because it better ensures the success of every insert mold we create.

Quality Management and Testing Capabilities

Elimold is an ISO 9001:2015, ISO 13485:2016 and ISO 14001:2015 certified manufacturer of injection molded parts and assemblies for demanding applications. No matter how complex the design, we deliver products that meet the expected size, shape and function on time and within budget. Elimold’s quality management system requires all molded parts to undergo rigorous inspection and testing procedures, including first article inspection, dimensional consistency inspection, material quality testing and sampling. Our advanced integrated quality system includes key process monitoring and has invested in a highly sophisticated MRP software package for proactive monitoring and upfront part quality assessment. We are a Beta testing site for the latest 8.0 software version, providing customers with the best system available today. Our computer controlled process includes bar coding of each job and all related documents.

We Save Time and Reduce Costs

At every stage of the project, we use Advanced Product Quality Planning (APQP) to ensure maximum efficiency in high-volume production. Complete production capabilities enable seamless transition from our production floor to yours. In-house tool maintenance ensures maximum production efficiency and tool life. And through our extensive production capabilities, we can more effectively meet your requirements for tight tolerances and provide beautiful, durable and dimensionally stable insert molded products. When you work with Elimold on your insert molding project, you get a precise, repeatable process and reduce the number of parts. Flexible and reliable designs reduce assembly and labor costs, ultimately saving money for our customers.

Custom Product Assembly Services

Elimold offers a variety of custom product assembly services, including RF thermoforming processes (such as lamination and welding), pad printing, and eyeleting, all performed in our clean, regulated whiteroom environment. Our whiteroom environment ensures that our customers receive trusted components that are never exposed to harmful environments. Our work environment not only allows employees to produce components in a safe environment, but also enables more functions, such as complete product assembly, resulting in a higher quality product.

A range of tests are performed using our advanced testing equipment. All components are thoroughly inspected to ensure that the quality of the products delivered to all customers is up to standard. All finished components are packaged in non-sterile bulk and are processed under a laminar flow hood with deionized air for particle control. The Elimold team is truly dedicated to ensuring that your project is completed successfully. There is nothing more gratifying than seeing our customers succeed and grow with the assistance of our professional engineers. We are always happy to work with small businesses, small batch orders, and organizations that require large batch orders. Regardless of the size of your project, Elimold always puts quality first, and we have key ISO certifications that you can trust to back it up.

Ready to get a quote for your new project?

Contact us to turn your manufacturing vision into tangible results. Our team is ready to discuss your specifications and provide quality-focused solutions.

What is Insert Molding?

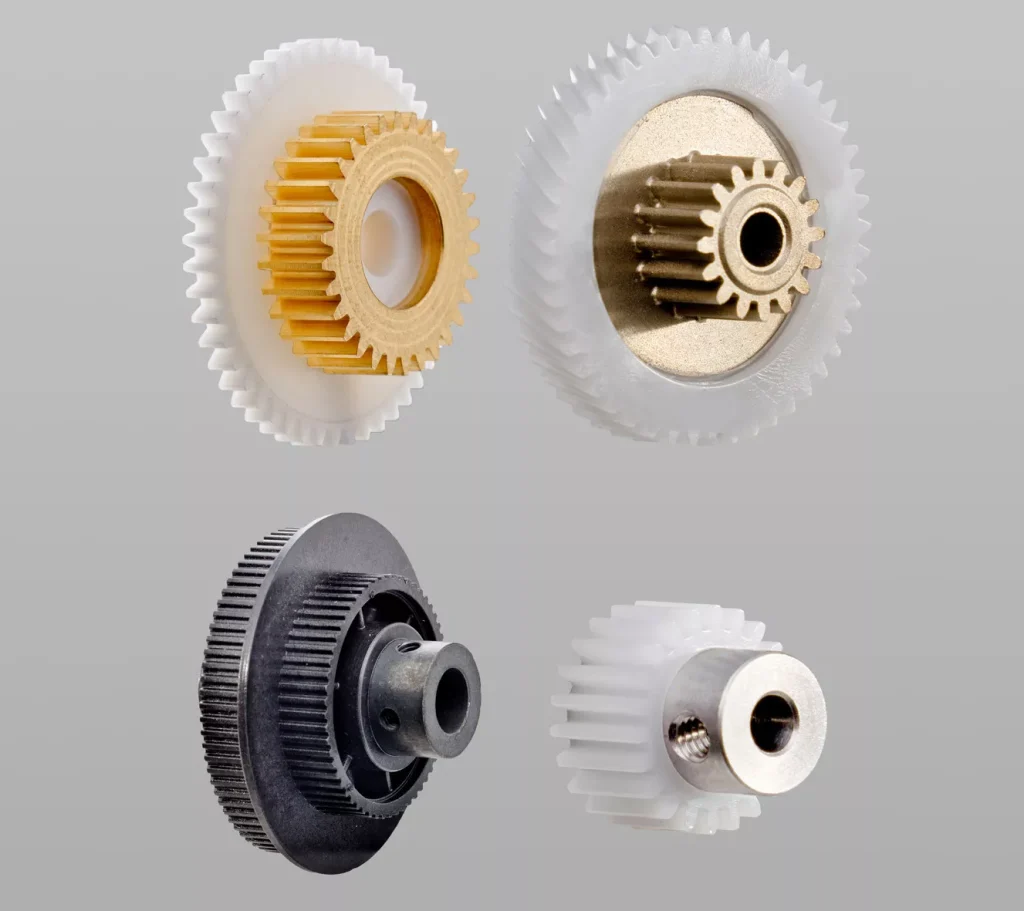

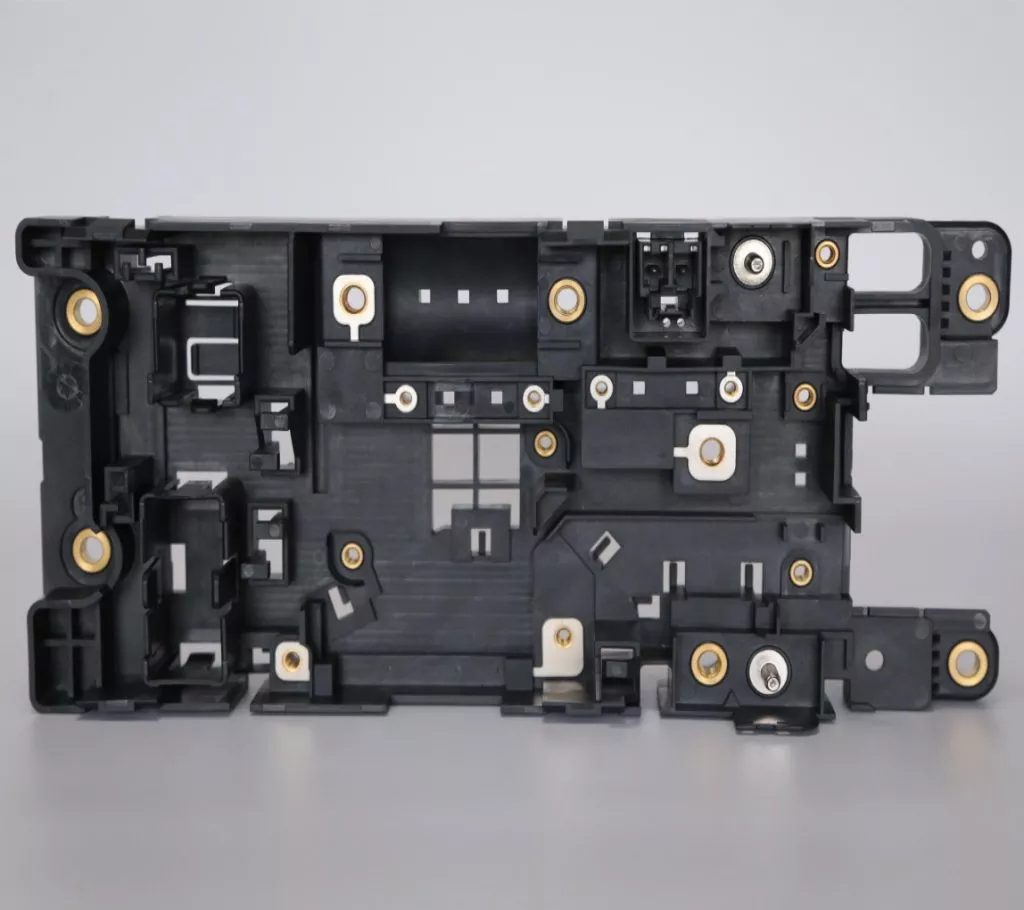

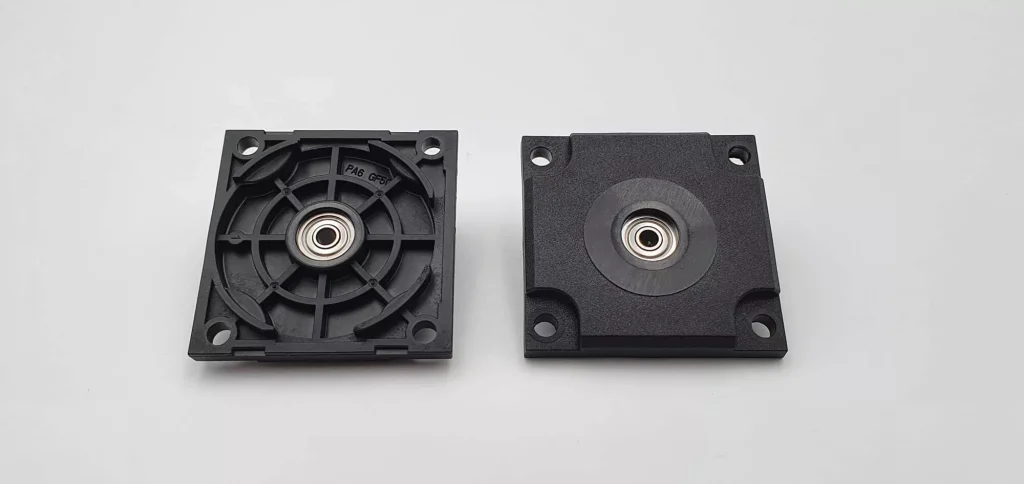

Insert molding is a branch of injection molding technology that involves inserting metal parts into the mold cavity before the actual injection molding. This insertion process can be done manually or in an automated process with a robot. Once the insert is completed, the mold is closed and the plastic covers the insert, combining the different parts into a single integrated component.

The typical feature of insert molding is that these components (called “inserts”) are molded directly into the part. Insert molding is an injection molding process used to embed metal parts into plastic to form the final plastic part. The process consists of two basic steps: first, the molded insert is prepared before molding and loaded into the mold. Second, the molten plastic is injected into the mold cavity and the final plastic part is removed after cooling. The range of applications for insert molding is very wide. Since the insert can be almost any material, from alloy threads to electrical contacts, its application possibilities seem endless. It is essential to understand the insert molding process and then correctly design the part to optimize the production process. Its advantages include: no secondary processing in the secondary processing department, thus reducing costs; and obtaining a component with stronger performance than pure plastic parts. Even when a product requires replacing metal, insert molding can maintain performance strength on key design features.

Types of Equipment for Insert Molding

Vertical Insert Molding

Horizontal Insert Molding

Rotary Table Insert Molding

Material Options

We not only offer a wide range of insert molding materials, but also additives to meet special requirements. Our professional material experts can customize the most cost-effective materials to meet your specific needs. The following is a list of various injection molding materials and additives we offer for your reference.

Plastic Materials

The following is a list of common materials suitable for custom insert molded parts.

- ABS

- HDPE

- PA6/6

- PTFE

- PP

- PC

- PE

- PS

- PA6

- POM

- LDPE

- PVC

- PU

Elastomers and Rubber

Common rubber insert molding materials are as follows:

- EPDM

- PVC

- TPU

- Silicone

- TPE

- TPV

Metal Materials

The preformed and inserts metal materials are listed as below:

- Aluminum

- Brass

- Copper

- Stainless Steel

- Steel

- Titanium

- Nickel

- Other Special Materials

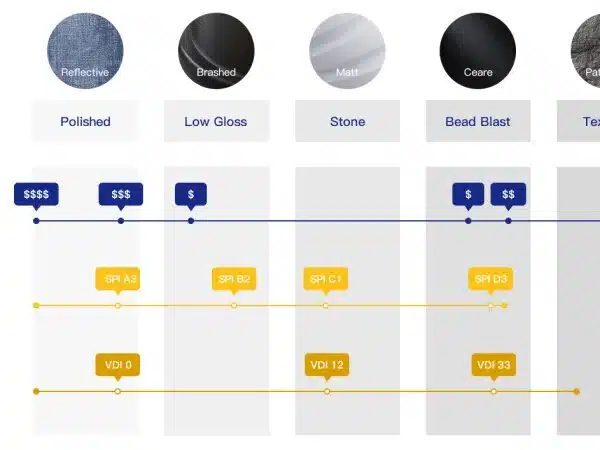

Finishing Options

We offer a variety of finishing options to complement products made with the insert molding process. You can choose any of the following based on the needs of your application:

Standard Finish

Internal, non-decorative finishing based on the geometry of the mold.

Mold Texture

Create textures on the mold to be reflected on the final product. This finishing option includes matte, swirls, patterns, and lines.

SPI Finishes

SPI finishes range from 3-grade diamond/high polish to 320 stone low polish. These finish options include SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

Laser Engraving

Engrave part numbers, designs, logos, or any other specified printing onto your parts.

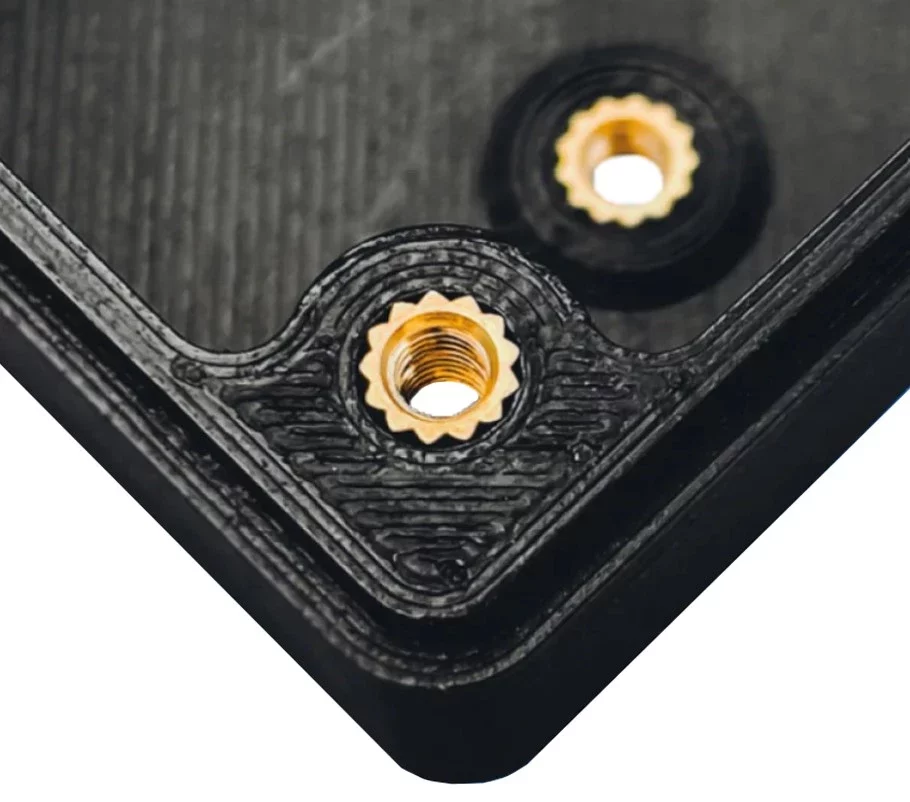

Threaded Inserts

We can install standard inserts in the most common and popular UNF and Metric sizes.

Pad Printing

Applies ink-based designs to surfaces.

Molding

As the name implies, the mold is left “as is” – without any secondary texturing or polishing.

Painting

Surfaces are painted with standard or Pantone colors, including primer and topcoat. Masking finish available; EMI (copper) paint.

Elimold's Insert Stock

Elimold stocks standard inserts in a variety of popular UNF and Metric sizes. If your part design requires an insert that we do not stock, we can produce quality inserts for your custom molded plastic part. Whether it is knurled on the outside or has a special shape, we can custom produce it. Elimold welcomes custom inserts (and is happy to quote you). We can produce insert molded parts regardless of the material you choose. Also, be sure to send us your CAD file as the part design and assembly drawings are required during the quote process.

Secondary Services

- Part Assembly

- Hot Stamping

- Machining

- Heat Staking

- Sonic Welding

- Flushing/Cleaning

- Hardness Testing

- Leak Testing

- Moisture Testing

- Force/Break Testing

- Destruct Testing

- Continuity Testing

- Part Decorating

Insert Molding Benefits

Recently, insert molding has changed certain industrial practices. Many industries are replacing metal parts with plastic ones because plastic is less expensive, resistant to corrosion, durable, and lightweight compared to most metals. Here are the benefits of insert molding:

- Durability: Insert molding offers high precision and enhanced product designs compared to other molding processes. Plastic parts with integrated components are more reliable and robust.

- Efficiency: Insert molding does not require separate assembly, reducing the risk of manufacturing errors. Because the insert is integrated into the molding step, it saves time and labor costs, increasing the efficiency of your entire operation.

- Cost-Efficiency: Insert molding is a cost-saving process since it allows the use of less expensive thermoplastic resins, which are more affordable than metals. It also minimizes labor costs and requirements for specialized assembly equipment.

- Lightweight: Plastic parts are generally 50% lighter than metal but are comparable in terms of strength. This has made many industries opt for plastics to replace metals. The lighter weight contributes to better fuel efficiency in automotive components and easier handling for surgical equipment.

- Size: Insert molding allows the production of smaller and thinner parts without sacrificing performance and durability.

- Material Variety: Insert molding uses a variety of common engineering thermoplastics including Nylon, PBT, PEI, PC etc. Many of these plastics are recyclable throughout their life cycle. They are also durable, versatile, and ideal for various consumer and industrial products.

- Design Variety: The process also allows different types of designs and shapes, expanding possibilities for engineering and design across many fields.

Insert Injection Molding vs Overmolding

Insert molding and overmolding are two distinctly different processes that produce their own unique types of products. The overmolding process takes place when one material is overmolded over a second material. The base layer is molded first and the additional plastic layer(s) are molded over and around the original part. This results in a single finished product. Overmolding creates a strong finished product with long service life and enhanced safety features.

Conversely, insert injection molding occurs when insert injection materials are injected into the mold cavity prior to plastic injection molding. The resulting product is a single piece with the insert encapsulated by the plastic. Plastic injection inserts provide a fast and cost-effective assembly process, producing parts with reduced size and weight.

Mold Transfers

Our team has developed a robust mold transfer program designed to support customers who wish to transfer molds to a new supplier due to cost, delivery or quality issues. We invest time in advance to obtain drawings, models, procurement specifications and mold data to prepare for the arrival of the mold. Relocating injection molds is a big decision. Elimold simplifies the process so you can move forward with peace of mind. Our transfer mold process ensures that your plastic injection molds are seamlessly transferred to our state-of-the-art injection molding facility in Shenzhen, China. In addition, with multiple production locations and continuous investment in equipment, automation, fixtures and finishing services, we can create the best production cell for your injection molded parts. Our expertise in plastic injection molding, mold design and tooling, as well as our comprehensive range of presses, enables us to maximize production efficiency while maintaining the highest quality standards.

Professional Customer Service Capabilities

Our organization is designed to provide comprehensive quality assurance and customer service. With more than 20 years of experience in the injection molding industry, we will help you optimize production and focus on lean manufacturing. We provide direct “from prototype to mass production work continuity” through a dedicated team to oversee every step of production. When you work with us:

- 1. Our business unit manager will lead, coordinate and continuously supervise the team involved in your project.

- 2. Our project engineers will guide your work from design concept to production start-up.

- 3. Our manufacturing engineers will improve production processes and increase efficiency.

- 4. Our logistics manager will be your exclusive contact person responsible for tracking production orders and ensuring on-time delivery.

- 5. Finally, our quality engineers will designate direct contacts responsible for the continuous improvement of your parts.

Your Trusted Insert Molding Service Provider

If you have a fully reviewed design, our build-to-print service is the ideal choice. We start production as soon as we receive drawings, specifications and purchase orders. If your project still needs improvement, don’t worry. We are ready to assist you in achieving a simpler, easier-to-manufacture design to achieve your goals. Our custom services can quickly and economically transform your concept into a finished product. Our company is built on a custom philosophy to meet your specific needs. We only make prototypes when necessary for testing and proof of concept. We are always committed to customizing projects to meet your unique needs.

Other Injection Molding Services

Elimold has extensive expertise in the field of injection molding and can provide excellent plastic molding solutions. Our team of experienced engineers and technicians work closely with customers to understand their needs and provide custom plastic part solutions based on their specific requirements. We ensure strict quality control throughout the production process to provide quality products that meet or even exceed industry standards.

Plastic Injection Molding

LSR Injection Molding

Gas Assist Injection Molding

Structural Foam Molding

Micro Molding

Rapid Tooling

Request Your Free Insert Molding Quote Today

After receiving your drawings, our engineers will analyze your custom insert molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.