Overmolding Services

Looking for overmolding solutions or wondering about overmolding costs? Our team offers high-quality overmolding technology and cost-effective overmolding services to meet your needs. No matter what type of overmolding process you need, our expertise can meet all your needs, contact us today for a free quote.

Professional Overmolding Service Provider

Need a truly custom overmolded part? You’ve come to the right place. Elimold provides high-quality, on-demand injection molding for prototypes and production parts. We have a “do what you want” philosophy for all types of injection molding, regardless of your experience level. We specialize in complex projects, including those that require lateral motion or manual insertion of inserts. Our goal is to provide long-term overmolding solutions that go beyond rapid prototyping, with dedicated overmolding project managers and engineering experts to communicate through all project phases, from design to production. We provide end-to-end molding solutions for a wide range of industries to ensure your project is a success. From design to final manufacturing and packaging, our team of experts will work with you every step of the way to create the ideal solution for your specific needs. With our extensive material resources and superb equipment and facilities, Elimold is able to provide highly custom overmolding services to meet all of your project needs.

Complete Turnkey Overmolding Solutions

If you have a fully vetted design, our build-to-print services are ideal for you. We start production as soon as we receive drawings, specifications and purchase orders. If your project still needs improvement, don’t worry. We are ready to assist you in achieving a simpler, easier-to-manufacture design to achieve your goals. Our custom services can quickly and cost-effectively transform your concept into a finished product. Our company is built on a custom philosophy to meet your specific needs. We only produce prototypes when necessary for testing and proof of concept. We always strive to customize projects to your unique needs.

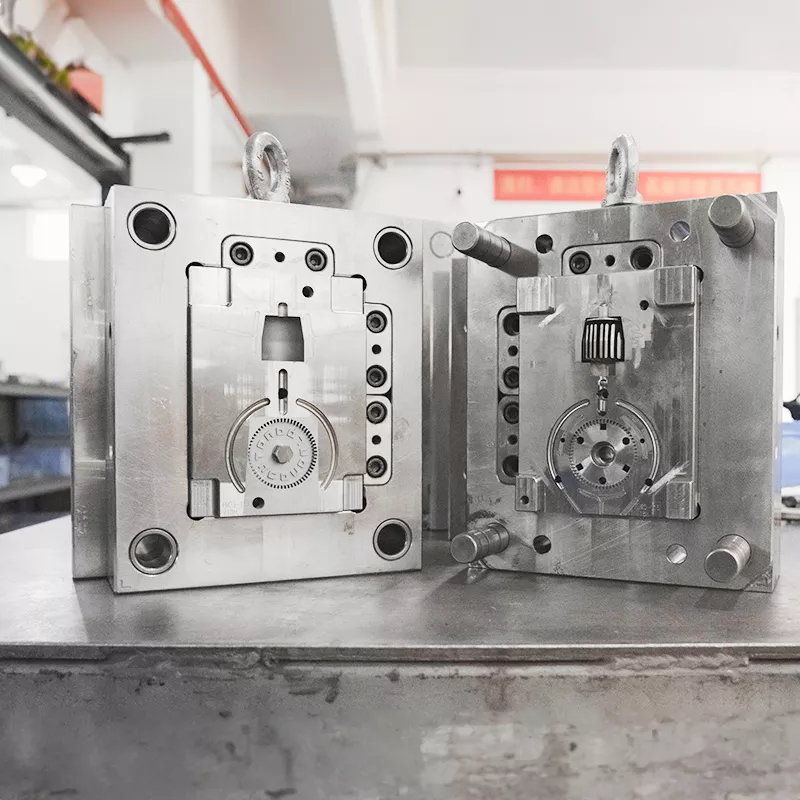

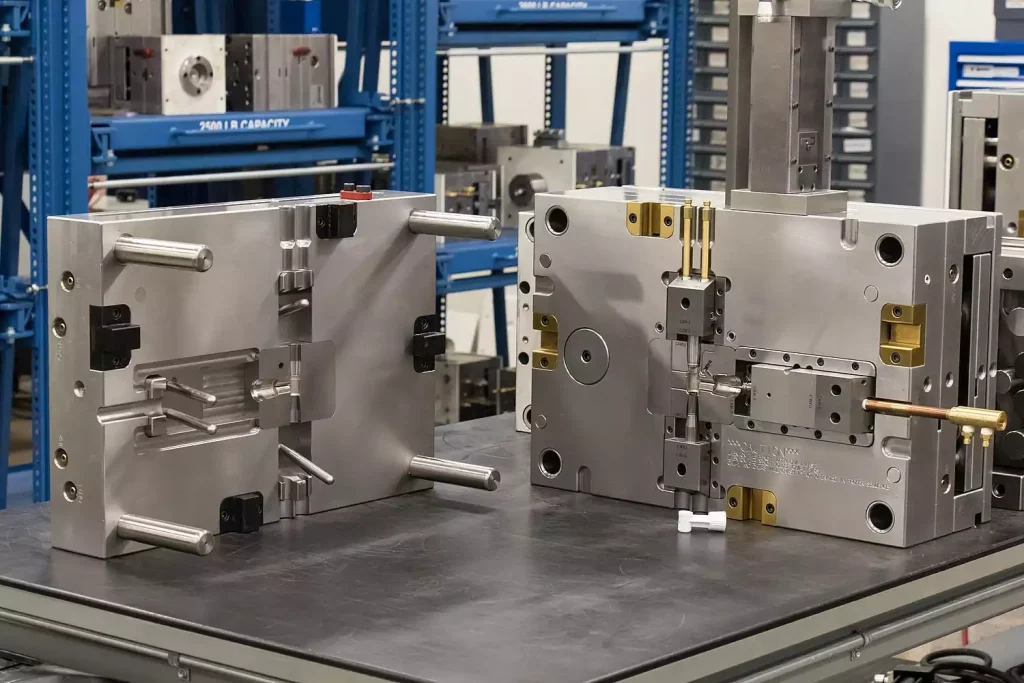

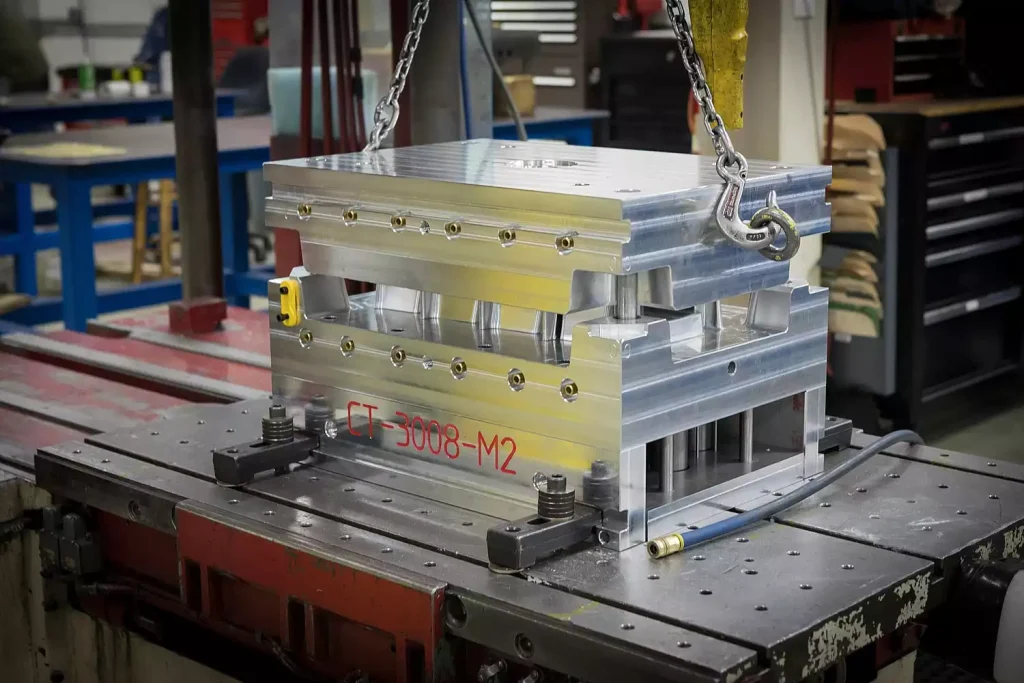

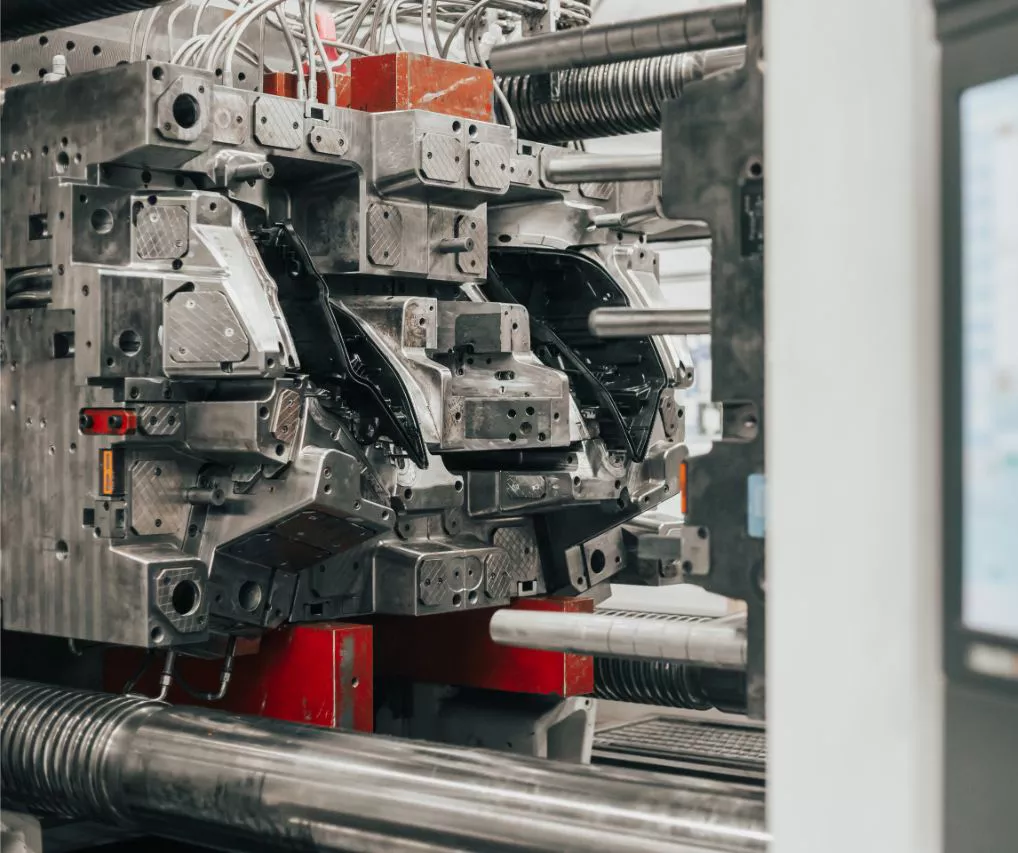

In-House Plastic Overmolding Manufacturing Facility

Elimold’s team has over 20 years of experience in the overmolding process. With advanced tooling and design capabilities, our team will work with you to develop the right mold design and select the best materials. Coupled with over 150,000 square feet of on-site manufacturing, warehouse, and office space in Shenzhen, China, the in-house facility features 100 state-of-the-art plastic injection molding machines ranging from 25 tons to 3200 tons, and advanced hot runner systems to meet the tightest tolerances, provide design flexibility, and reduce production cycles. This allows us to precisely customize high-quality molded parts to your project specifications.

Full-process Service Capabilities

At Elimold, we provide comprehensive one-stop molding services, covering all services from design and mold production to assembly and packaging.

DFM (Design for Manufacturing)

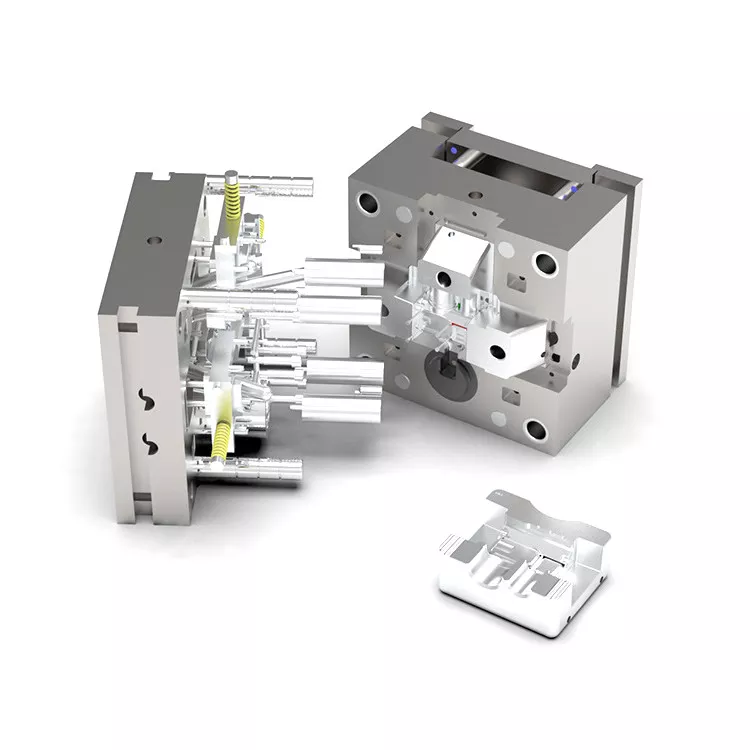

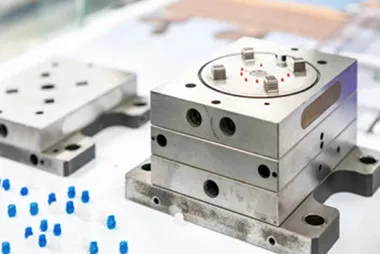

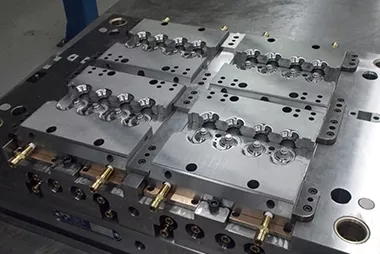

Mold Design & Manufacturing

Surface Treatment

Assembly Services

Quality Management

Packaging & Delivery

Engineering Design Services Capabilities

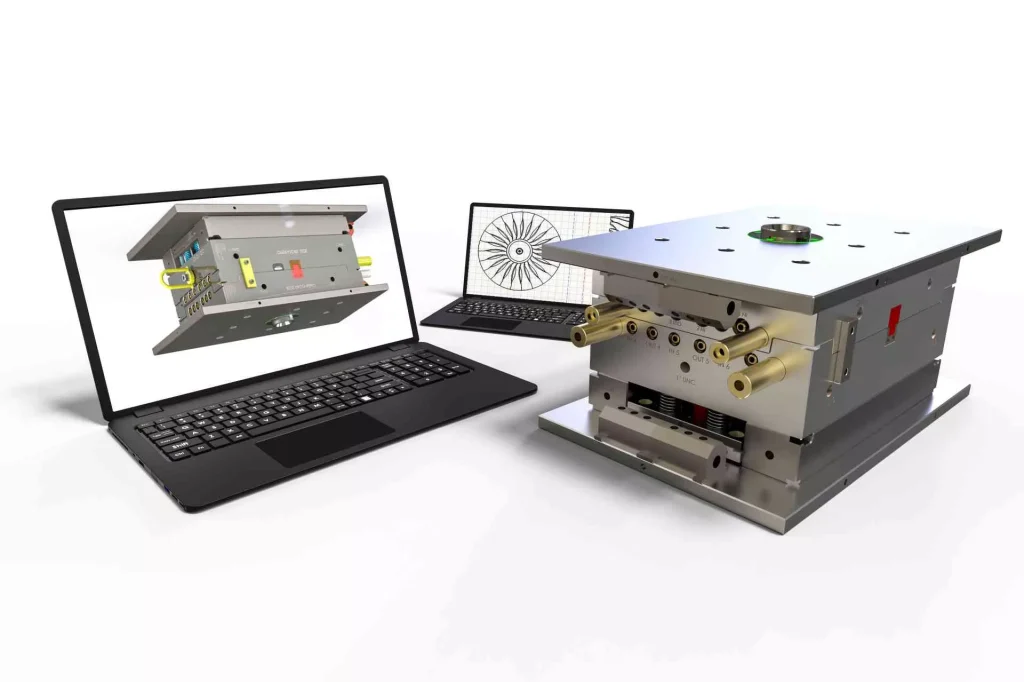

Elimold’s dedicated engineering team provides the services you need to successfully manufacture your products. From the initial contact, our team of product designers and engineers will provide you with full-service services. You can take advantage of our experience in plastic part design and design for manufacturing (DFM) audits, as well as injection mold design, mold flow analysis, material selection, prototyping, and even 3D printing support. In addition, by involving Elimold early in the product development process and communicating key information about project requirements in detail, we can maximize the benefits of design optimization and help you quickly bring your products to market with the highest quality and lowest cost.

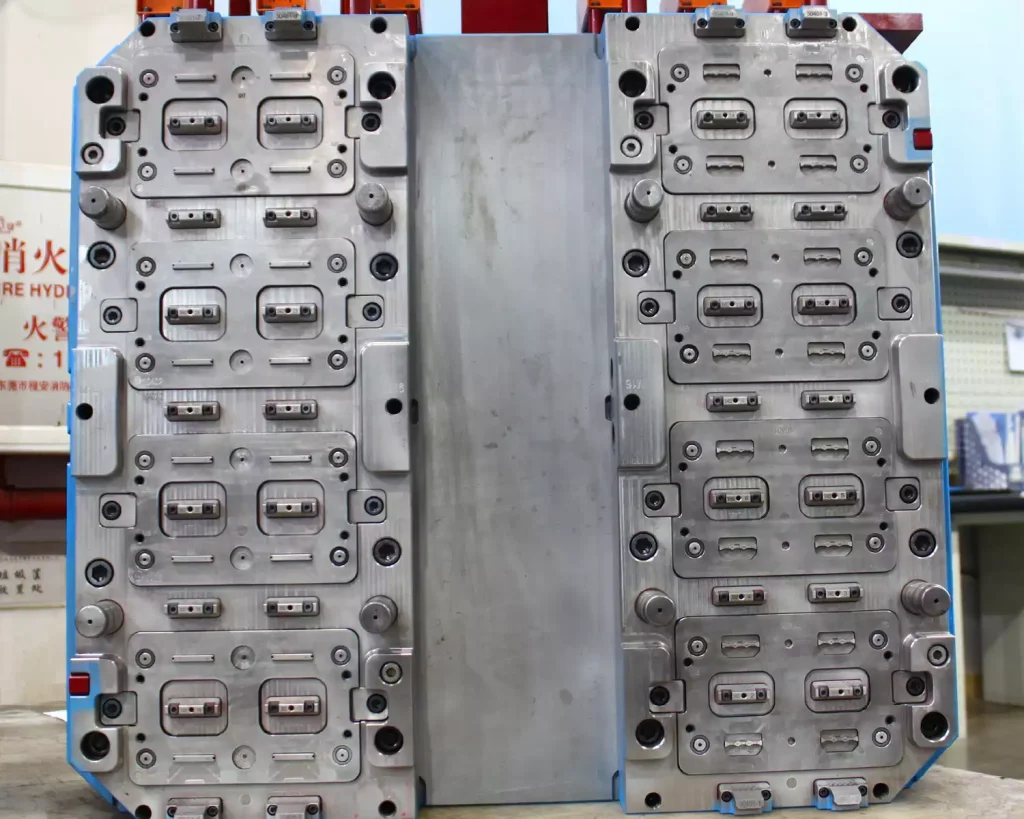

One-Stop Overmolding Mold Manufacturing Service

Injection overmolding mold manufacturing is highly specialized. Our team will develop solutions based on our customers’ plans. We provide a one-stop mold manufacturing service, allowing customers to understand the range of products we offer while working with us. Elimold provides services ranging from mold design, rapid prototyping to mass production. We provide custom mold manufacturing, prototype molds and production mold services. Our experienced team uses advanced CAD/CAM software and cutting-edge equipment to design, manufacture and maintain injection molds, ensuring molds have excellent precision and durability to produce high-quality custom molded parts.

Cleanroom Overmolding Services

We have two fully equipped Class 7 cleanroom manufacturing facilities with ample space and capacity to meet your project needs from development to mass production. Whether your project is a small batch prototype design or involves an ongoing mass production contract, we can meet your needs. Our in-house cleanroom is equipped with the necessary technology and capabilities to ensure that we always keep our quality commitment. In addition, we can provide a full set of assembly and packaging services, including finished or semi-finished products. All our processes are operated efficiently and follow the Lean Six Sigma methodology, with quality-centric multi-step release criteria, covering pass/fail gauges, integrated process verification and final testing stages.

Types of Overmolding Services

Insert Overmolding

Two-color Overmolding

Multi-material Overmolding

Overmolding Manufacturer with 24/7 Service

Elimold is proud to provide you with high-quality plastic overmolding parts and respond quickly to your needs. We can provide you with plastic overmolding project services 24/7. Once you send us the 3D file, we will quickly give you a quote within 2 hours. After the quotation is completed, our engineers will provide you with the most professional suggestions. Our sales engineer team will keep in touch with you. If you have any questions, we will answer you as soon as possible. If you are not sure about our quality issues, you can also send us your 3D file first. Then we will make samples according to your specifications for free. If you can, we sincerely invite you to visit our factory to learn about the plastic overmolding process.

Elimold's Early Supplier Involvement Process

Early Supplier Involvement (ESI) with your manufacturing partner is critical to the overall success of your project, especially in terms of cost and schedule. By involving our engineers as early as possible in the development process, we communicate critical information about your specific needs so that they can be incorporated into the design of your project. In this way, costly unplanned design changes or modifications can be avoided, ensuring that your project stays on schedule and on budget.

Design for Manufacturing Reviews

Through Design for Manufacturing reviews, Elimold’s plastics manufacturing engineers have the opportunity to understand your product requirements and guide improvements that will reduce tooling costs, produce stronger, more durable molds that last longer, and achieve optimal and repeatable part quality. Our experienced engineering team can help you optimize every element of your design and reduce your risk of developing a product that is too complex or too expensive to produce. Manufacturing optimization of overmolded products involves the strategic application of our broad range of tools to maximize the efficiency, productivity, and profitability of your products. As such, our team considers the entire lifecycle of your manufactured product requirements, from the early forecasting stages through planning, scheduling, dispatching, execution, and post-production analysis.

Your Partner for Overmolding Services

Discover the superior solutions Elimold offers in overmolding services. We have unparalleled expertise in combining multiple materials into a single, high-quality product. We leverage the benefits of overmolding to produce custom components with superior adhesion, compact design, lower production costs, and high durability to meet the needs of different industries. Our services are highly customizable to ensure that all specific needs are met. Our attention to detail, cutting-edge technology, and deep understanding of material combinations provide business owners with superior products that combine functionality, aesthetics, and performance. Our cost-effective processes ensure that time and resources are used to the maximum extent possible.

Types of Overmolding Process

Overmolding can be used to improve the strength, durability, and aesthetics of a plastic part. It can also be used to add functionality to a part, such as adding a grippy surface or creating a water-tight seal.

Plastic Over Plastic

Rubber Over Plastic

Plastic Over Metal

Rubber Over Metal

Prototype Overmolding Solutions

We prioritize personalized solutions to meet your unique needs. We provide rapid prototype overmolding solutions, providing engineering experts and project managers with seamless guidance from design to production. Our strategy combines cost-effective tooling with cutting-edge technology-driven overmolding services to ensure high-quality parts that exceed expectations. With certified in-house factories and a strong supply chain system, we accelerate product development schedules and efficiently connect to the production of your overmolded parts. Certified factories, rigorous process inspections, and post-dimensional verification ensure that custom molded parts maintain excellent quality and high precision regardless of complexity. Work with our experienced team of experts who have many years of experience in the field of injection molding. Our streamlined process can efficiently transition from prototyping to full production. Work with us to experience the power of tailor-made overmolding solutions to enhance the quality, functionality, and aesthetics of your products.

Overmolding Plastic Mold Supplier

Elimold has successfully created prototype molds for thousands of challenging overmolded parts. Allow us to review your part design with our extensive industry expertise. We will identify any opportunities for improvement to ensure your overmolded part meets functional requirements the first time. And we provide more than just an automated review of your part model. After a detailed review by our experienced engineers, we will meet with you online to review our observations, explain why adjustments are needed, and answer any questions you may have. Our personalized approach to customer service is unique among prototype molding service providers. This service is critical because it better ensures the success of every prototype mold we create.

Quality Control

At Elimold, quality is our top priority. We implement stringent quality control measures throughout the overmolding process to ensure that each component meets the highest standards of precision and reliability. Our comprehensive quality assurance system includes advanced inspection tools and techniques to ensure product consistency and excellence.

In-Process Inspection

Our quality control begins with in-process inspection, where each component is checked at various stages of production to ensure that it meets the design specifications. This proactive approach helps to identify and correct any problems early in the manufacturing process.

Final Inspection

Before any component leaves the factory, it undergoes a comprehensive final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each component meets the required specifications and standards.

Precision Measuring Tools

We use a variety of precision measuring tools, including coordinate measuring machines, (CMM) and specialized gages to ensure that insert placement and bonding meet precise specifications. These tools allow us to maintain tight tolerances and high precision to produce reliable insert molded components.

Certifications

We demonstrate our commitment to quality by being certified to ISO 9001, ISO 14001, IATF 16949 and AS9100D. These international standards ensure that our quality management system is effective and continually improving, providing our customers with a consistently high quality product.

Continuous Improvement

We embrace a philosophy of continuous improvement and regularly review our processes and practices to identify areas for improvement. We work hard to maintain our reputation for quality and innovation by investing in the latest technology and employee training.

Ready to start your project?

Are you looking for an overmolding project? Perhaps you need a small run for market testing? Contact us today and we will be your trusted plastic injection molding partner for fast response and professional overmolding services.

What is overmolding?

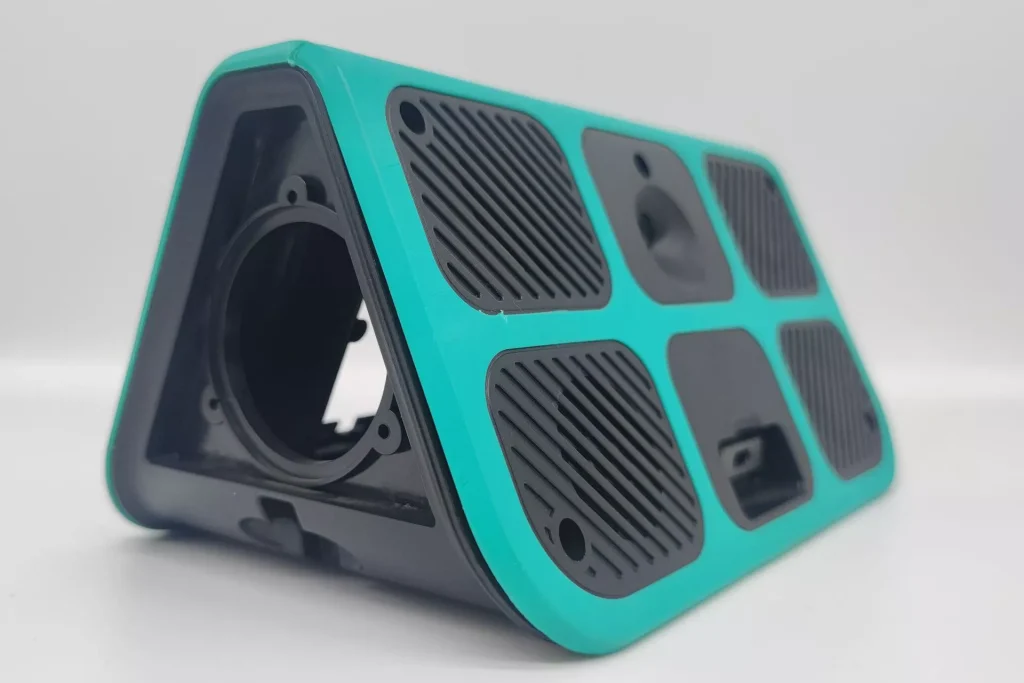

Overmolding is an injection molding process in which multiple injections of thermoplastics are made to form individual parts. The thermoplastic is first injected into a mold or cavity to form the substrate, and then the overmolding material is injected into, on or around the substrate. The thermoplastic layers bond during cooling to form a uniform and highly durable end product. The bonding between the substrates depends on the properties of the overmolding material in question. Overmolding has a huge impact on reducing the cost of manufacturing parts. It is not always possible to combine materials with different parameters, especially in the case of plastics. Therefore, when looking for such new solutions, it is necessary to rely on the extensive experience of engineers, technicians and material scientists who are able to correctly select the type and form of the raw materials to be used. In addition, the overmolding process is not only suitable for the most advanced materials, but also combines innovation with robustness.

Rich Material Selection

Whether you are a designer, engineer or inventor, our materials can help you turn your ideas into reality accurately and easily. In addition, our materials are affordable, so you can iterate and improve your designs without spending too much.

- ABS(Acrylonitrile Butadiene Styrene)

- ABS+PC(ABS + Polycarbonate Alloy)

- HDPE(High Density Polyethylene)

- HIPS(High Impact Polyethylene)

- LCP (Liquid Crystal Polymer)

- Nylon 6(Polyamide 6)

- Nylon 11(Polyamide 11)

- Nylon 66(Polyamide 66)

- PBT(Polybutylene Terepthalate)

- PC(Polycarbonate)

- PE(Polyethylene)

- PEI(Polyetherimid)

- PET (Polyethylene Terepthalate)

- PMMA(Acrylic)

- POM(Acetal)

- PP(Polypropylene)

- PPA (Polyphthalamide)

- PPS(Polyphenylene Sulfide)

- PS(Polystyrene Crystal)

- SAN(Styrene Acrylonitrile)

- LDPE(Low Density Polyethylene)

- PVC(Polyvinylchloride)

- TPR(Thermo Plastic Rubber)

- TPU(Thermoplastic Polyurethane Elastomer)

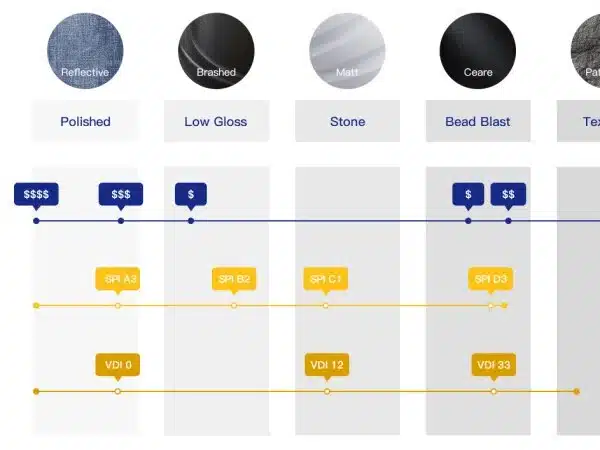

Surface Finishing Options

We offer multiple finishing options to complete the products made with the overmolding process. You can choose from any of the following depending upon your application’s requirements:

Standard Finish

Interior, non-cosmetic finish according to the geometry of the mold.

SPI Finishes

Range of SPI finishes from Grade 3 diamond / high polish to 320 stone low polish. These Finishing options include SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

Threaded Inserts

We can install the most commonly used and popular standard inserts in UNF and metric sizes.

As Molded

As the name suggests, the mold will remain ‘as it is’ – without any secondary texturing or polishing.

Mold Texturing

Creating textures on the molds so that it shows on the final product. This finishing option includes matte, swirls, patterns, and lines.

Laser Engraving

Engrave part numbers, designs, logos, or any other specified printing onto your parts.

Pad Printing

Application of an ink-based design to the surface.

Painting

Painting the surface with standard colors or Pantone matching, including Primer and topcoat. Masking available; EMI (copper) paint.

Benefits of Elimold’s Overmolding Process

- High part precision achieved by leading edge molding equipment, capable tooling, and robust validation procedures

- Shot-to-shot consistency guaranteed by instrumented molds

- Improved part functionality (i.e. creating a water-resistant seal)

- Cost-effective high volume production achieved through robotics and automation

- Ultra-precise positioning of overmolding tool inserts enabled by in-line camera systems

- Avoidance of foreign materials such as glues and adhesives into the final medical device

- Significant reduction or elimination of costly and cumbersome assembly operations that can lead to failure modes and high fall-out rates

Overmolding Design Tips

- Wall thicknesses between 0.060″ to 0.120″ (1.5 mm-3 mm) generally provide the best bonding.

- Keeping radii between 0.020″ or 0.5mm minimum in corners reduces localized stresses.

- If the part requires thick TPE sections, they should be cored out to minimize shrinkage problems, reduce the part weight, and lower cycle time.

- Avoid deep or un-veritable blind pockets or ribs in your design.

- Use gradual transitions between wall thicknesses to reduce or avoid problems with the flow (backfills, gas traps, etc.)

- The TPE/TPV should be less thick than the substrate to prevent warpage, especially if the part is flat, long, or both.

- Overmolding needs mechanical or chemical bonding to the substrate, so your material choices should enable this.

Get a quote for your overmolding project now

If you are interested in using overmolding for your next project, trust Elimold’s expertise and experience to deliver high-quality results that meet your specifications and requirements.

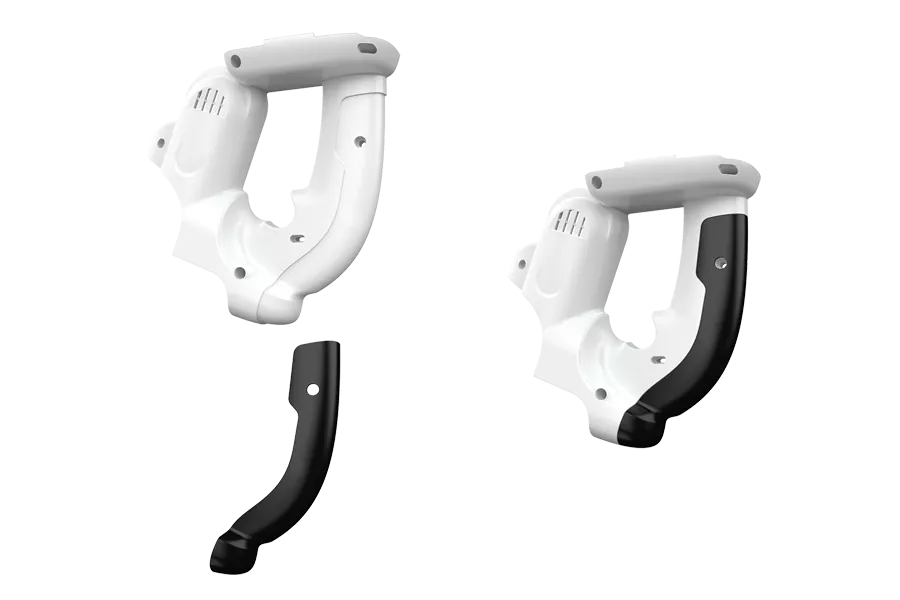

Professional Overmolding Plastic Parts Producer

Are you looking for a unique way to make your product stand out by incorporating multiple materials and colors? Do you need new ideas to enhance the ergonomics and functionality of your product? Elimold’s overmolding services can help you achieve these goals. We understand that every injection molding project is unique and may require a different injection molding approach. Therefore, we have invested in top-of-the-line injection molding equipment and assembled a team of professionals who are fully trained in injection molding technology. Our team consists of designers, mold engineers, and production engineers who work together in harmony. This ensures that each plastic part and mold design is optimized to enable overmolding and that the selected resin material is ideal.

Does Your Part Require Overmolding or Inserts?

Overmolding and insert molding are both subsets of injection molding. While both processes involve injecting plastic into a mold cavity, there are some key differences to understand when deciding whether overmold or insert molding is best for your application. Overmolding takes a part and then lays down an outer layer of plastic, while insert molding embeds small parts during the injection molding process. Of course, there are exceptions to any rule. If you have additional questions, Elimold’s experts can help you find the injection molding process, design, and product that meets your specifications.

Choose overmolding when:

- The completed object is made of thermoplastics or rubber

- The design calls for multiple layers, materials, or colors

- You are manufacturing both the substrate and secondary layer

- The finished object does not need to be disassembled

Consider insert molding when:

- Your substrate is prefabricated

- Your substrate is made of metal, wires, or computerized parts

- The finished part is one solid and complete piece

Overmolding vs. Two-color Molding

Two-color injection molding (or 2K injection molding) is a type of overmolding technology. They are similar in nature. However, we must note that two-color injection molding is usually used for large-volume production rather than small-volume production. At Elimold, we help you choose between the two types. Finding the solution that best meets your needs is always our top priority. We make sure to rigorously evaluate every step of the manufacturing process and your product needs.

Difference between Insert Molding and Overmolding

Insert molding and overmolding are two distinct processes in the manufacture of plastic parts. While both processes involve molding multiple materials together, they differ in many ways. The key difference between insert molding and overmolding is the location and purpose of the preformed component. In insert molding, the preformed component is typically rigid and used to add strength or functionality to the final product or to reduce manufacturing and assembly operations after molding. In overmolding, the substrate component is the functional component, while the overmolding material is used to add comfort or aesthetics. Furthermore, insert molding typically involves a preformed component placed in a specific location and orientation, while overmolding involves placing the substrate component in a mold and molding the overmolding material around it.

Parts and Applications

- Toothbrush handles

- Power tool grips

- Medical device housings

- Automotive gear shift knobs

- Smartphone cases

- Electrical connectors

- Sealed switches

- Goggles frames

- Laptop touchpads

- Syringe plungers

- Handheld scanner housings

- Surgical instrument handles

- Cable strain reliefs

- Earbuds housings

- Remote control housings

- Key fob covers

- Protective covers for sensors

- Camera grips

- Fitness tracker bands

- Wearable device housings

- Computer mouse shells

- Portable speaker enclosures

- Game controller grips

- Automotive dashboard buttons

- Flashlight housings

- Waterproof camera enclosures

- Industrial control panel buttons

- Insulated hand tools

- Razor handles

- Bicycle handlebar grips

- Plumbing valve handles

- Dental tool grips

- Safety helmet liners

- Child toy parts

- Fuel injector housings

- Appliance control knobs

- Electric toothbrush heads

- Prosthetic limb components

- Sports equipment handles

- Sealed battery packs

Comprehensive Overmolding Service Capabilities

We focus on providing high-quality overmolding services that complement our injection molding capabilities to provide you with a comprehensive range of options. Our experienced team of professionals is committed to providing excellent results that meet or even exceed your expectations, with comprehensive one-stop molding services covering all services from design and mold production to assembly and packaging. Our vertical integration ensures excellent control over parts and project delivery cycles, streamlines manufacturing processes, minimizes delays, and improves customer satisfaction. In addition, our experienced team of engineers uses the latest tools to provide tailored innovative solutions based on your unique needs. We ensure seamless integration of the entire industrialization process from project handover to DFM (design for manufacturability), samples, prototyping, mold design to mass production.

Other Plastic Injection Molding Service Types

Elimold is a trusted name in the manufacturing industry. With decades of experience and a commitment to excellence, we have unparalleled expertise in plastic injection molding and a variety of manufacturing techniques. Our state-of-the-art facilities and experienced team ensure that customers receive top-quality products that meet their needs. Below are the various plastic part manufacturing services we can provide.

Injection Molding

LSR Injection Molding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Request Your Free Overmolding Quote Today

After receiving your drawings, our engineers will analyze your custom Overmolding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.