Plastic Injection Molding Service

We are a full-service plastic injection molding partner that delivers exceptional solutions that redefine what successful outcomes mean. We have developed proprietary technologies to optimize lead times, producing affordable molded parts that can be delivered to you in as little as 8 days. We offer hard and soft molds for production or prototype injection molding, as well as world-class design optimization services. Elimold has delivered over 12 million molded parts to customers around the world through our services, and also offers mold ownership. Contact us now for a free instant quote.

Full-Service Plastic Injection Molding Partner

Engineers looking for a plastic part production partner look no further than Elimold. Our engineering team can convert your CAD data into actionable DFM (Design for Manufacturing) standards, setting the stage for your part’s success. Or, maybe you’re developing a product concept, but you’re not an engineer; don’t worry, we have a full team of engineers ready to help. Our complete manufacturing solutions span raw material validation, mold building, part machining, finishing, and final inspection. Our team of experts is dedicated to providing you with the highest level of professional support for your plastic injection molding service needs of all sizes and complexities.

Professional Plastic Parts Manufacturer

Our business strategy and operational plans are built on people, process control, and technology. We believe that by combining the best people with the right technology to control the injection molding process, we can produce consistently high-quality parts for our customers. We also believe that culture is a strategic advantage, and when we can create an environment where employees care about each other, they will take better care of the equipment, resins, customers, and company. Elimold is committed to being the best partner for custom plastic injection molding manufacturing services that adhere to the highest ethical standards in the markets we serve.

Comprehensive Plastic Solutions

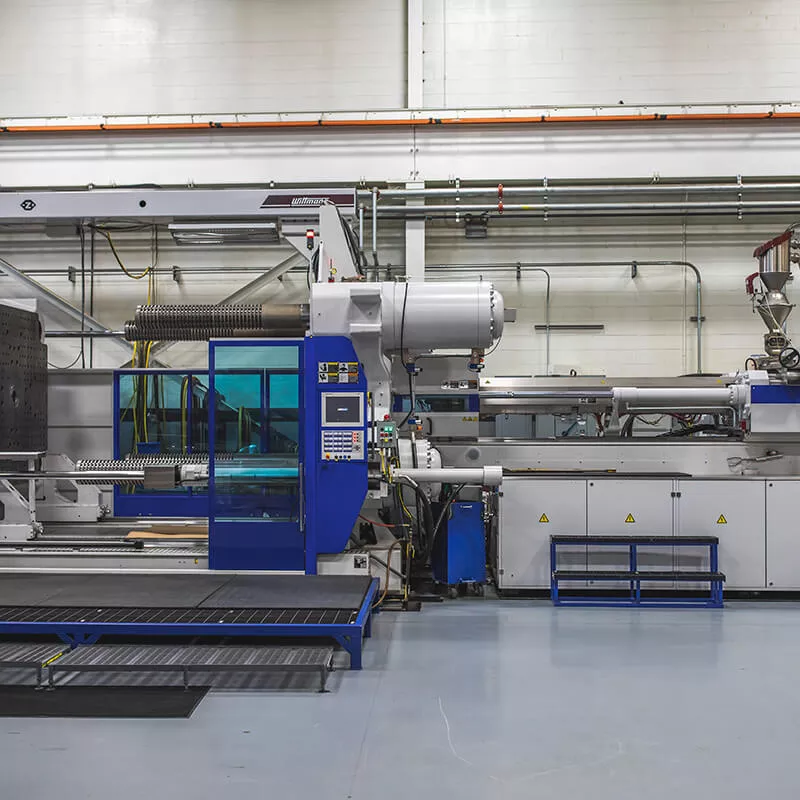

From mold making to final assembly, Elimold provides you with comprehensive plastic solutions. We offer a wide range of molding, tooling and assembly services to meet your specific needs. Since our founding, we have a modern, integrated injection molding and mold making facility in Shenzhen, China, covering over 36,000 square feet. Our technicians, engineers and mold makers have over 20 years of combined experience in the plastics industry, and we are committed to meeting your plastic needs with unparalleled innovation, quality and service. We have high-tech molding equipment to serve industries with tight tolerances and strict regulations. We have modern Class 10,000, ISO/Class 7 clean rooms, as well as Class 100,000 portable clean rooms. We combine traditional experience with modern scientific molding principles to provide you with high-quality molded parts. Elimold’s in-house facility has multiple quality certifications and strictly adheres to Good Manufacturing Practices (GMP) and complies with all applicable FAA and MIL SPEC regulations. We firmly believe in developing the right solution for your plastic part needs. We rely on our years of experience to ensure that your job is done smoothly. With our modern production and mold making methods, your ideas will become reality.

24/7 Plastic Parts Manufacturing Services

We work around the clock to meet your needs. With over 300 employees operating around the clock, we have strong plastic injection molding capabilities and management experience to ensure your project is completed smoothly. We are an integrated factory that integrates production, assembly, packaging, warehousing, drop shipping and other services. We can produce parts from 50 to 1,000,000 pieces or even more. We can use our in-house injection molding machines with a capacity of up to 3200 tons and a shot volume of 132 ounces. We are able to operate around the clock to meet your delivery needs, with delivery as fast as two weeks. If you need parts faster, we offer a convenient stocking program. Call our experts today to find out how working with a first-class custom plastic injection molding service company can make your life easier and save you time and money! Elimold is proud to provide turnkey, worry-free services to customers around the world.

Cleanroom Plastic Injection Molding Services & Capabilities

At Elimold, we pride ourselves on our advanced manufacturing capabilities, including a stand-alone cleanroom molding unit. Our cleanroom and ISO13485 certifications provide medical customers with the component cleanliness their industry requires and meet stringent regulatory requirements. The controlled environment minimizes the presence of particulate matter, ensuring a high-quality product that is critical to pharmaceutical and medical device manufacturing companies. Our commitment to precision and quality runs through every aspect of our production process, and our cleanroom molding shop is no exception. This shop is specifically designed to produce healthcare components that require more stringent environmental controls than a standard production shop. In addition, our combination of cleanroom and two-shot injection molding technologies reduces the cost of secondary services and opens the door to product innovation.

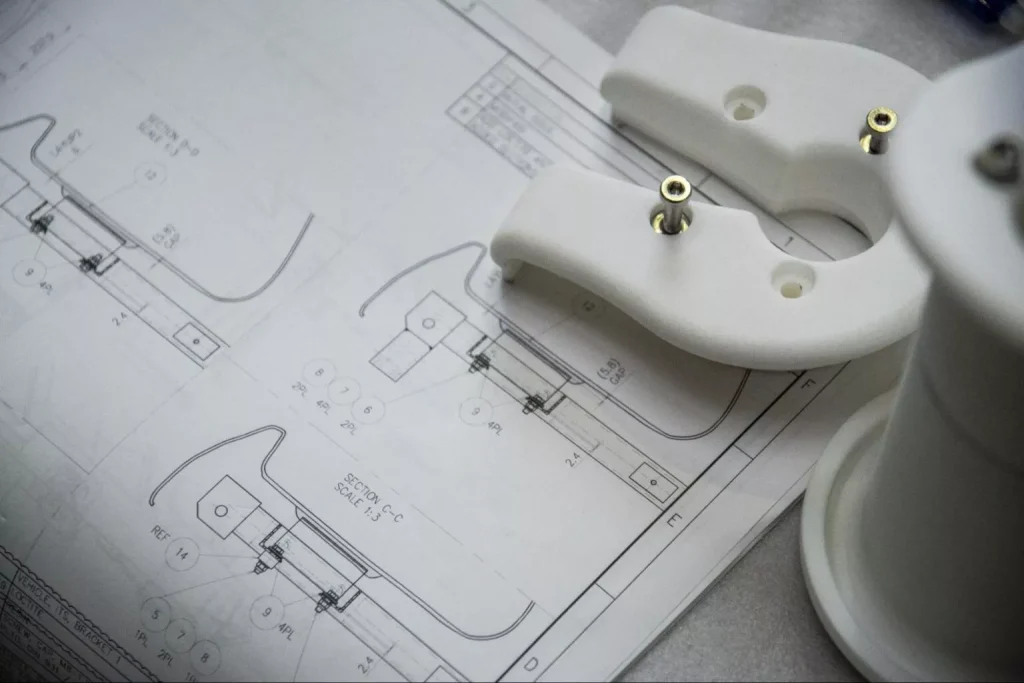

Solid Engineering Design Foundation

Early in your injection molding project, we work with engineers to develop highly customized designs to ensure that every step of production can proceed smoothly and efficiently. Careful design is essential to creating a finished product that meets your expectations and is affordable. Elimold has been a leader in the plastic molding industry for more than 20 years. Leverage our extensive expertise to save you time and money. Our experienced engineers will guide you through the logistics of design, development, production, and answer any injection molding questions you have, for an efficient and streamlined production experience.

Types of Custom Plastic Injection Molding Services We Provide

Elimold has the capability to handle a wide range of plastic injection molding projects, from prototyping to mass production. We support low-volume injection molding (with no minimum order quantity) as well as mass production and ongoing batch orders to meet your needs. We are able to seamlessly handle challenging and demanding projects, whether it is complex part geometries, exotic materials, extremely tight tolerance requirements, or specialized surface finishes. We use the latest plastic injection molding technology to deliver quality products quickly.

Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Service Process

1. Start A Free Quote

Send us 3D/2D drawings or physical samples and specify demands in details: resin, finish, demand quantity etc, we provide quotation in 24 hours.

2. DFM/Mold Design

DFM(design for manufacturing)available in one or 2 days to go through all the details regarding part design optimization and mold construction.

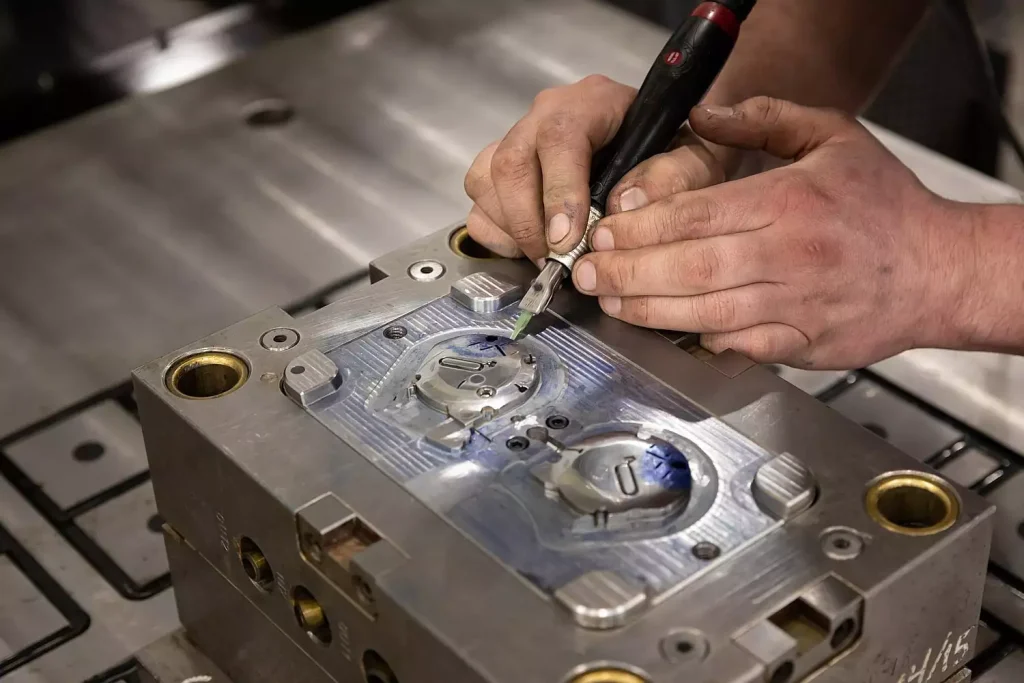

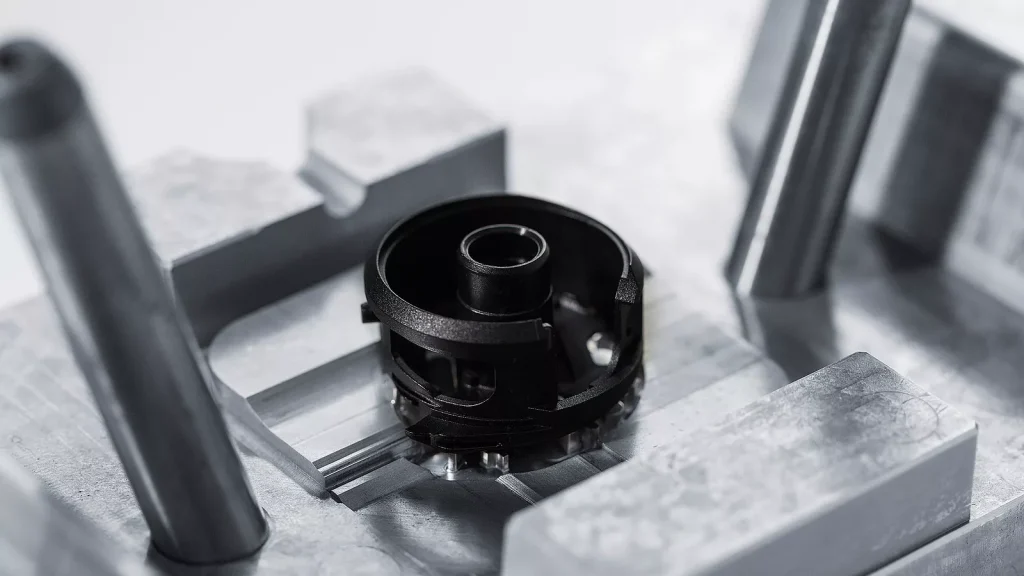

3. Mold Manufacturing

Order steel/mold base, machining process includes CNC, DME, wire-cut, milling, grinding, polishing, assembly and mold fitting.

4. Mold Trial

Setting up the mold to do injection molding test, verify the mold functionality and correctness of the molded part, keep all data in records.

5. Trouble Shooting

Resolve mold/molding issues revealed by mold trial, typically it takes 1-2 rounds mold trial and modification before the mold is ready for mass production.

6. Mass Production

Prepare resin and quality acceptance documents, setting up molds for mass production.

Plastic Injection Molding Tolerances

Plastic resins expand and contract due to temperature, mechanical stress, and humidity. Our Manufacturing Tolerance Guide provides you with general information about the shrinkage characteristics of the most common resin types to help you make design decisions. As part of the design analysis, we identify areas in the molded part that may cause thermal stress, shrinkage, warpage, or other avoidable defects. For more information, see our Design for Manufacturing Guide for common defects and how to avoid them. Unless otherwise stated, we adhere to DIN 16742 standard tolerances for injection molded parts. Ensuring the highest quality is an important part of our production process. Be sure to read our guide to visual quality standards for injection molded parts.

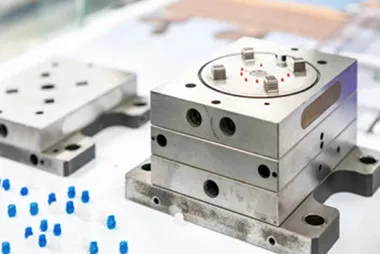

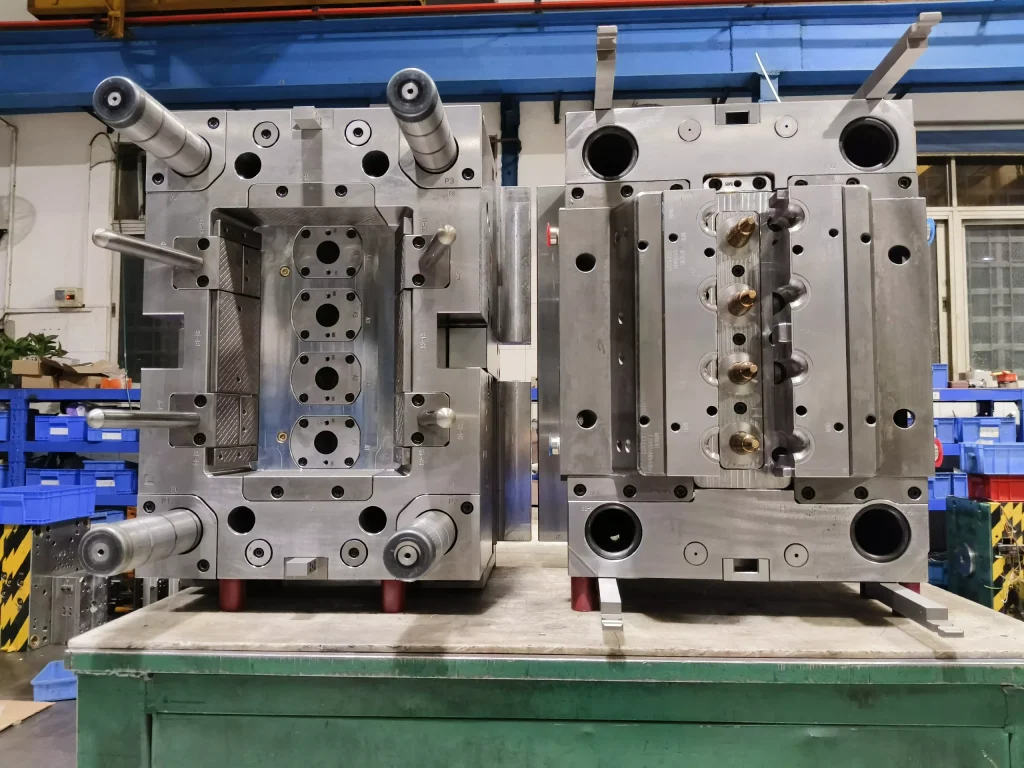

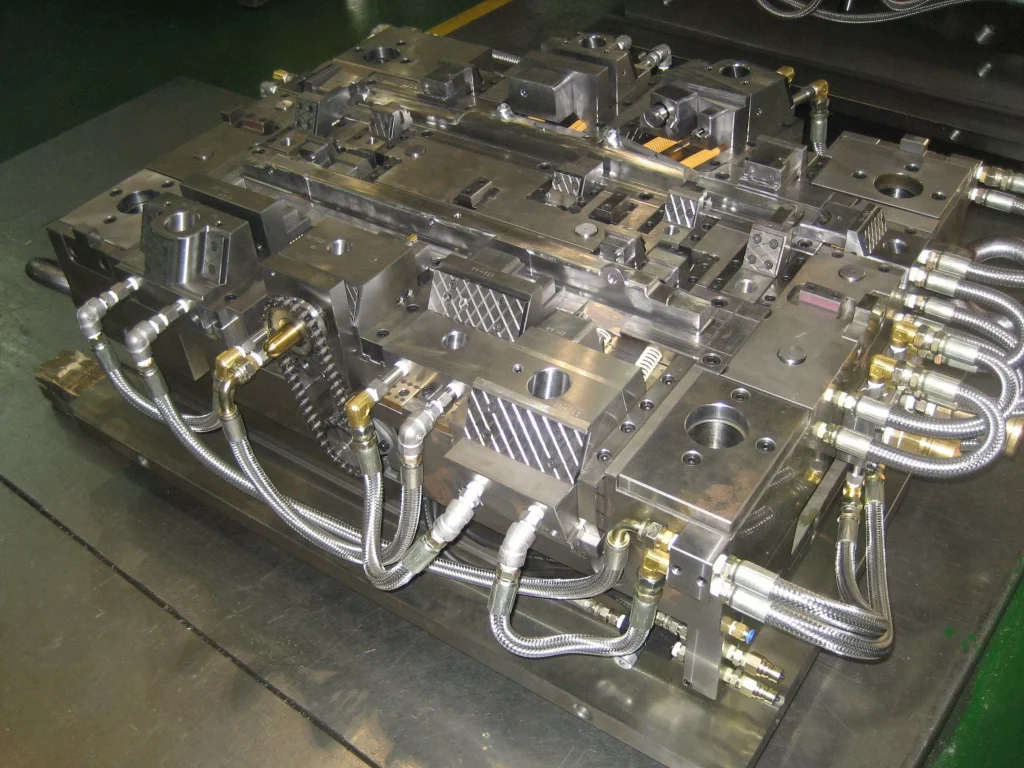

Full-Service Plastic Mold Making Department

As part of our custom mold making capabilities, we offer in-house design, mold making, and engineering support. All mold design and fabrication is performed by our team to provide complete custom applications. Our engineering and mechanical technicians are experienced in general purpose and engineered materials as well as specialty resins to help you develop molds that are best suited to the materials of your project. Our mold making services begin with in-house design, mold building, and quick turnaround tooling to get your project to market quickly. We offer quick turnaround soft tooling as well as high production hardened tool steel tooling in a variety of material options including aluminum, stainless steel, and various grades of tool steel. Wondering which mold category is right for your manufacturing needs? Contact us today.

Custom Plastic Injection Mold Manufacturing Services

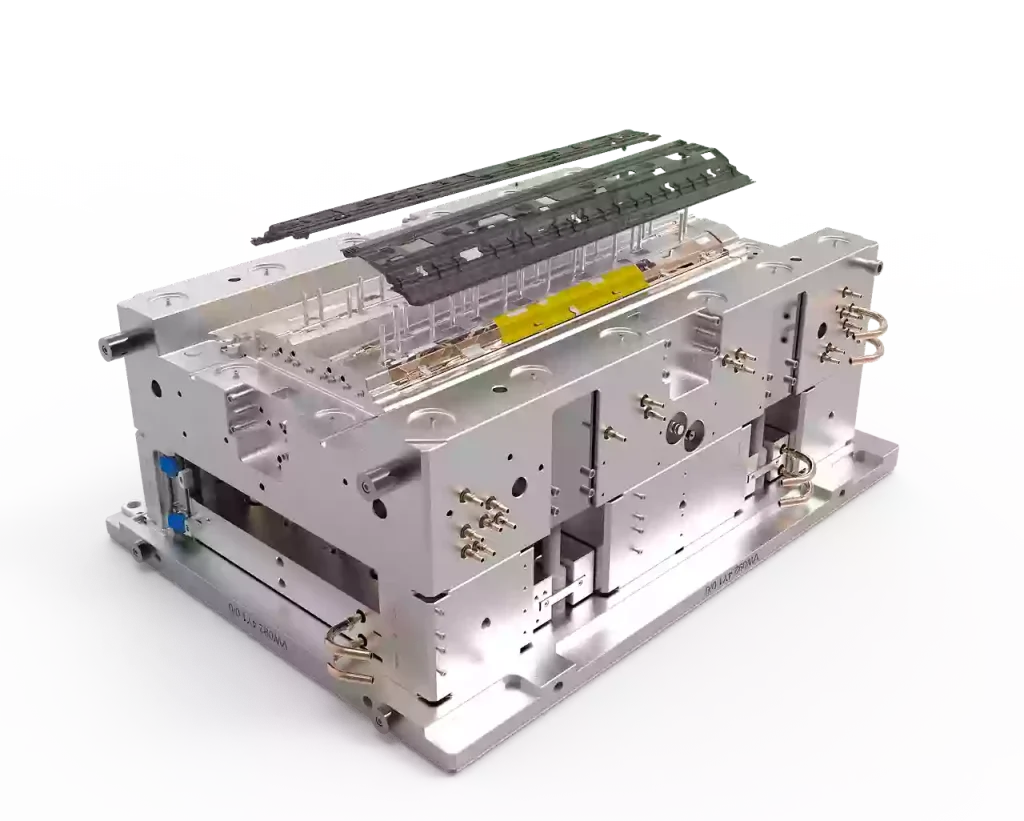

Elimold can provide complete custom injection mold manufacturing services and accept transfers from existing molds, all managed by our professional engineering team. Our staff is committed to achieving optimal mold performance and cost-effectiveness. As a custom mold manufacturer, we provide in-house design and long-term mold maintenance services, and provide improvements based on new product needs. Our custom injection mold manufacturing capabilities begin with a comprehensive design review of the product and the pending mold layout to ensure product quality and mold functionality are met. We provide high-precision traditional molds as well as modular molds (MUD units) through CNC 3D machining, EDM electrical discharge machining, polishing and texturing to meet your mold manufacturing and surface treatment needs. We consistently provide molds that achieve high-quality custom plastic injection molding, which is evident from our excellent cooperation record with many international top brands around the world.

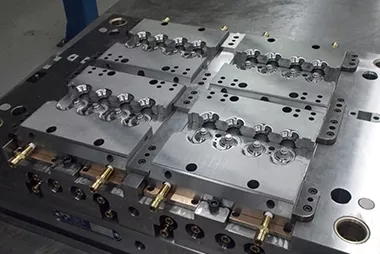

Mold Testing And Training

We deliver production-ready products and as a technology leader we test and optimize our molds on injection molding machines of all sizes in order to provide you with production-ready tools. In our test center, all molds are tested and adjusted to production conditions. For this purpose, the center is equipped with the latest injection molding machines with a clamping force of up to 3,200 tons. During the test phase, we offer our customers a comprehensive training program on site. In addition, our service technicians ensure a smooth and trouble-free start of production at the customer’s site.

Lifetime Injection Mold Guarantee

Our dedicated team has incorporated their passion for mold making into our systems and methods, resulting in one of the most efficient mold production concepts in the industry. To ensure the highest productivity and the lowest wasted man-hours, we are able to complete end-to-end mold production in-house, from design, mold filling analysis, CAM, CNC machining, EDM, bench testing, assembly to trial molds. And our high-precision mold production equipment operates 24/7 to further reduce delivery time, cutting molds based on customer CAD data and specified materials (including manufacturer-specified shrinkage). Mold tolerances are typically +/- 0.005 inches. If a customer requires tighter tolerances or specific molded part tolerances, we will review them on a case-by-case basis. Tighter tolerances increase delivery time and production costs. Elimold offers a “Lifetime Injection Mold Guarantee”, a service that means we will store the customer’s molds for future production indefinitely if there is a follow-up order, or only charge a nominal storage fee.

Full Range of Custom Plastic Injection Molding Services

We provide more than just mold making and molding services. Our complete service covers all the manufacturing processes you need to provide a comprehensive product development solution to meet your specific needs:

Horizontal Injection Molding

Vertical Injection Molding

Multi-material Injection Molding

Need assembly? No problem!

Even if we have completed the manufacturing of your specific part, that doesn’t mean everything is done. We pay attention to your product needs and focus on the assembly of plastic parts as needed. Our assembly professionals have years of experience and are proficient in using a variety of machines and tools to ensure that each part is assembled correctly and functions properly. We are equipped with the necessary assembly tools, and if the finished product does not meet your requirements, we can provide complete sub-assemblies to simplify your assembly process, saving you time and money. . Adhering to the philosophy of “quality first, step by step”, we guarantee that you will deliver a plastic product that meets your design specifications, is accurate in size, and is perfectly assembled. For our skilled assemblers, “small quantity assembly” is no problem at all.

Precision Quality Assurance

We use innovative methods to streamline manufacturing processes and solve problems, resulting in cost-effective production of high-quality complex parts and assemblies. Our quality management system is based on ISO-9001:2015 standards, with a comprehensive system of plans and processes in place for daily work and every production run. Every new project at Elimold begins with a comprehensive project review, which includes an in-depth study of the inspection requirements for specific parts to ensure that we understand your product quality needs from the beginning. Our quality assurance department also provides other services, including complete product verification, process capability studies and PPAP investigations. We use cutting-edge plastic molding technology to strive to create the highest quality products. We use rigorous quality inspections to ensure consistent products and superb workmanship.

Quality Control for Custom Plastic Injection Molding

Our in-house facility features advanced quality control technology, including Brown and Sharpe coordinate measuring machines (CMM) for precise verification of molded plastic part dimensions. We implement statistical process control (SPC) monitoring throughout the plastic molding production process to ensure consistently high quality results. From incoming material to final inspection, our quality system ensures that each molded plastic part meets precise specifications, resulting in the delivery of superior custom plastic injection molding products. As a plastic injection molding company with over 20 years of plastic molding experience, we offer a wide range of services and exceptional customer service for all injection molding projects across a variety of industries around the world.

Our Certifications

We don’t just talk about quality, we’re certified for it. Quality has been the foundation of Elimold since its inception and will continue to be for decades to come. But don’t take our word for it, our certifications speak for themselves:

ISO 9001 Certified

The quality management systems we’ve put in place along with our demonstrated commitment to continual improvement has fulfilled the requirements of the ISO 9001 standards.

ISO 13485 Certified

Our implementation of quality system standards and requirements for medical devices sold in the United States has allowed us to earn and maintain the ISO 13485 certification.

IATF 16949 Certified

Thanks to automobile-related quality management systems for continual improvement in defect prevention, minimizing variation, and reducing waste, we’re ISO/TS/IATF 16949 certified.

SQF Certified

Our adoption of Good Manufacturing Practices (GMPs) has earned us the SQF certification for manufacture of food sector packaging materials and plastic molded food closures.

High-Quality Customer Service

If you’ve ever worked with a plastic injection molding company that didn’t offer a full range of services, including product development and design, in-house tooling, or a robust array of secondary operations, you’re probably all too familiar with miscommunication, project delays, cost overruns, and other frustrations that come with working with a supplier that can’t meet all of your needs. That’s not the way we do things at Elimold. Our project management expertise, collaborative approach, constant communication, and relentless focus on quality, combined with state-of-the-art technology and equipment, is how we achieve successful outcomes for our valued customers time and again.

Ready to get started? Request a quote now

Contact us today to discuss your project or request a quote. Our experienced engineers will guide you from initial concept to final production. With fast delivery cycles, strict quality control, and support every step of the way, we are committed to being an extension of your team for all your plastic molding needs.

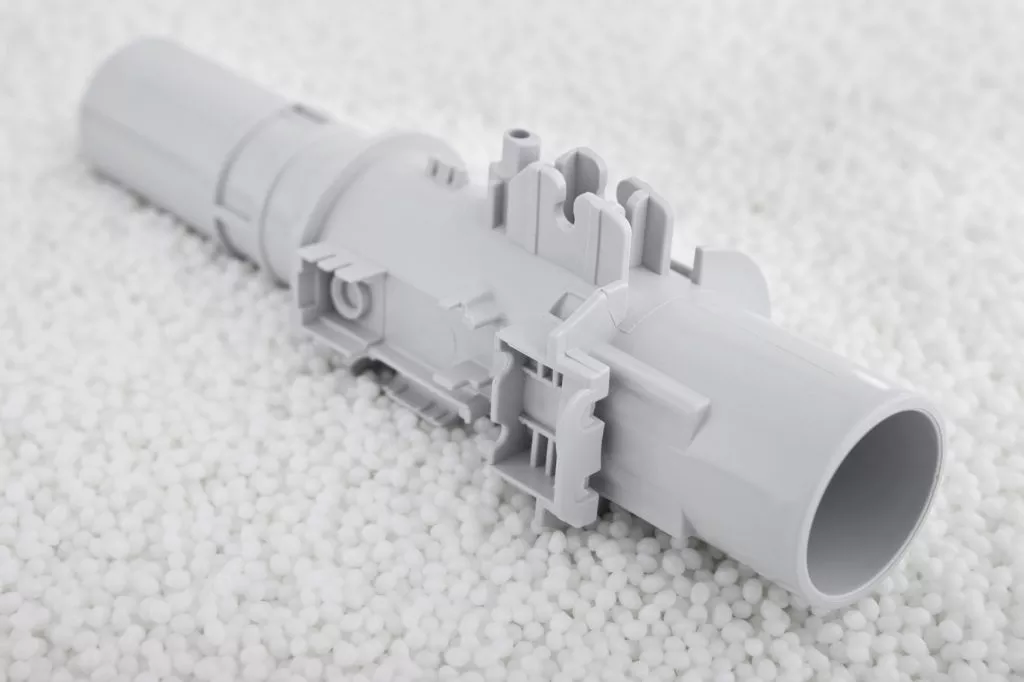

What is Injection Molding?

Plastic injection molding is a major molding process. With the help of an injection molding machine, granular plastic raw materials are melted and liquefied. The process takes place in a closed cylinder, in which a screw conveyor ensures plasticization of the plastic by friction and external heat. After the plastic is melted, it is injected into a mold (also called an injection mold) under high pressure. The shape and surface structure of the finished injection molded part are determined by the cavity in the injection mold (called the cavity). The plastic material injected into the tool cools in the cavity and returns to a solid state. The injection mold can then be opened and the finished injection molded part can be removed. Since the same mold is used for each part of the injection molding process, the quality of each part is consistent. Compared with CNC machining or even 3D printing, injection molding also has the most diverse materials, colors, surface treatments, finishes and surface textures.

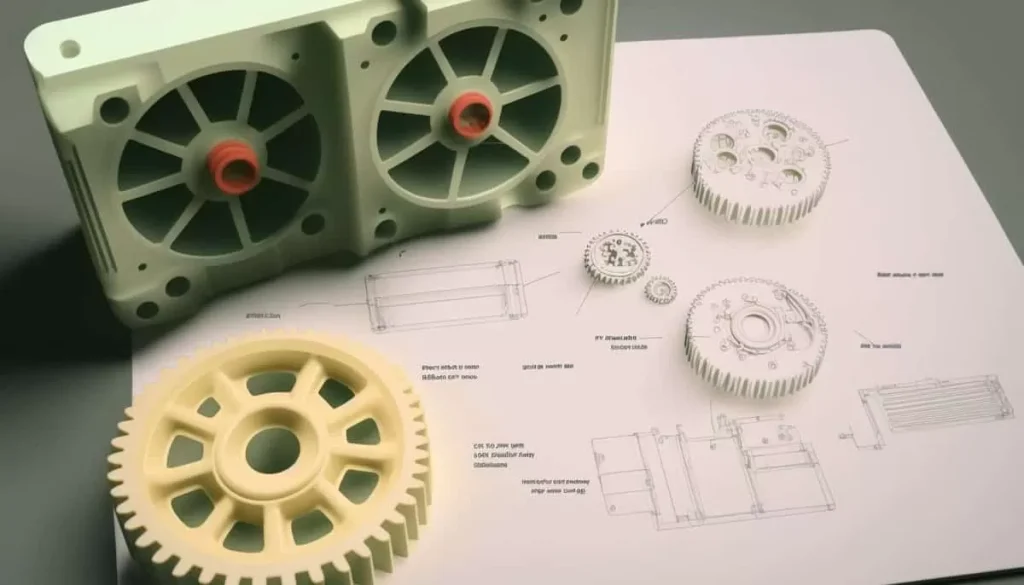

Engineering & 3D Printed Prototypes

At Elimold, we are often asked to assist clients with plastic part design development and new product prototyping. If you are focused on “fast time to market”, our in-house 3D printing service could be a solution for you, or you could consider developing rapid prototyping soft molds in our in-house tool room. As a full-service plastic injection molding company, we offer a range of product design and engineering services to help you develop the form, fit and function of your parts for successful plastic injection molding.

Material Options

Elimold offers injection molding for all types of plastics, including modified plastics and specialty plastics. We can provide material certifications, or purchase materials from your designated suppliers and provide proof of purchase.

- ABS

- ABS/PC

- Acetal

- Acetal Homopolymer/Delrin

- ETPU

- HDPE

- LCP

- LDPE

- LLDPE

- Nylon

- PBT

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- Polycarbonate

- Polypropylene

- PPA

- PPE/PS

- PS

- PSU

- TPU

- PMMA (Acrylic, Plexiglas)

Custom Injection Mold Finishes

Standard Finish

Moldmaker’s choice of finish. Typically SPI B-2, depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

SPI Finishes

Range of Society of Plastics Industry (SPI) finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

MoldTech Finishes (Mold Texturing)

Range of finishes including matte, swirls, lines, and patterns. Our most common texture finishes include: MoldTech MT11010, MoldTech MT11020, and MoldTech MT11030. Other textured finishes can be added by request.

Other Textures - VDI

VDI 3400 Surface Finish (commonly known as VDI surface finish) refers to the mold texture standard set by Verein Deutscher Ingenieure (VDI), the Society of German Engineers. This is mainly processed by EDM machining, producing fine to coarse matte finishes.

As Molded

No secondary polishing or grinding. Part will show tooling marks.

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Pad Printing

Transfer a 2D image onto a 3D part. All images are subject to review.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

Assembly

Elimold has the ability to assemble and label injection molded parts. Discuss your needs with your salesperson.

Benefits of Custom Plastic Injection Molding Services

There are numerous reasons to consider choosing injection molding for your project. Some of the most notable advantages include the following:

- Customizability. Your tooling/mold will be custom-built for injection molding. Additionally, parts created this way can be easily colored using additives, creating aesthetically pleasing products.

- Cost-effectiveness. The automation utilized in the injection molding process significantly reduces overhead costs, allowing a sole operator to oversee the molding process.

- Accuracy. With a properly designed mold, the injection molding process can ensure tight tolerance accuracy molding to meet customer demand to print specifications.

- Efficient use of materials. The injection molding process reduces unnecessary plastic waste, as the material is injected directly into the mold during production.

- Easy reclamation and recycling. Any unused material can easily be melted down for reuse.

- Enhanced strength. Plastics have an incredibly high resistance to wear and can be injected with fillers during the molding process to create additional strength.

What Makes Us Different?

People

A business is only as good as its people. Our people provide value to our customers through delivering creative ideas and innovative solutions. As such we seek to build our team with people that share our Core Values and have strong plastic engineering, technical and interpersonal skills.

Technology

Talented people and great systems can only deliver quality injection molded parts on-time with reliable technology. We are committed to maintain modern injection molding equipment, necessary auxiliary equipment, and supporting quality laboratory and injection mold maintenance and repair.

Process Control

Controlling the manufacturing process is critical to provide for the management and reliable growth of the operation. We will employ world class systems to control and support information management, manufacturing processes, quality systems, inventory, safety, environmental and other systems necessary to provide our customers defect free products to committed delivery dates.

Culture

The “Secret Sauce” or “magic in the bottle” that makes any company a great place to do business with and a great place to work is culture. We work very hard to wrap our strategy of People, Process and Technology with a culture where team members genuinely care for each other. When we care for each other, everything takes care of itself. We care for our customers, our equipment, our facilities and create an atmosphere that is an attractive and enjoyable place to work and do business.

Plastic Manufacturing & Logistics

Among injection molding manufacturing companies, Elimold goes beyond manufacturing. We also offer comprehensive logistics services that cover every step of our customers’ production process, from injection molding of new products, custom injection molds, to finally shipping the product to your customer. Our logistics services include order fulfillment and managed shipping. We don’t stop after your product is removed from the injection mold, but stay with you until the goods are delivered. We can also provide on-site warehousing and container loading and unloading services, as well as distribution center coordination services to speed up your product’s time to market and save you money.

Project & Inventory Management

Our inventory controls help prevent you from carrying unnecessary product, which can add unnecessary overhead to your overhead. With Elimold, you can produce the exact quantities you need without having to rely on unreliable forecasts or worry about over or understocking. With our fast turnaround times and exceptional customer service, we work closely with you to ensure the success of every project. With our Just-in-Time (JIT) inventory strategy, you get exactly the quantities you need when you need them, reducing work-in-process inventory and warehousing costs and further improving your return on investment. And our inventory levels can be monitored in real time to help assess future needs. We also use a Material Requirements Planning (MRP) system to efficiently monitor project progress from start to finish. Our extensive expertise in resin properties, part requirements, and cycle times ensures our 99.8% customer satisfaction rate.

Industries We Serve

Plastic injection molding technology enables the mass production of plastic parts in a cost-effective and fast manner. It is widely used in a wide range of industries to produce a variety of plastic products. Below are some of the major industries served by Elimold.

Applications of Plastic Injection Molding

- Bottle caps

- Electrical switch housings

- Automotive dashboards

- Medical syringes

- Toothbrush handles

- Mobile phone cases

- Laptop shells

- Remote control casings

- Printer parts

- Plastic gears

- Appliance knobs

- Game controller shells

- Camera housings

- Plastic cutlery

- Plastic containers

- Plumbing fittings

- Safety goggles

- Cosmetic packaging

- Cable connectors

- Battery holders

- Fan blades

- Chair glides

- Helmet shells

- Tool handles

- Storage bins

- Water filter housings

- Lighting fixture covers

- Medical device enclosures

- Baby bottle parts

- Pen bodies

- Food trays

- Electrical junction boxes

- Air conditioner vents

- Car light housings

- Soap dispensers

- Plastic fasteners

- Garden tool parts

- Toys and figurines

- Pill organizers

- Trash bin components

Plastic Injection Molding vs. 3D Printing

Plastic Injection Molding vs. Die Casting

Request Your Free Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom plastic injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.