- Elimold Slogan: Make One, Made More

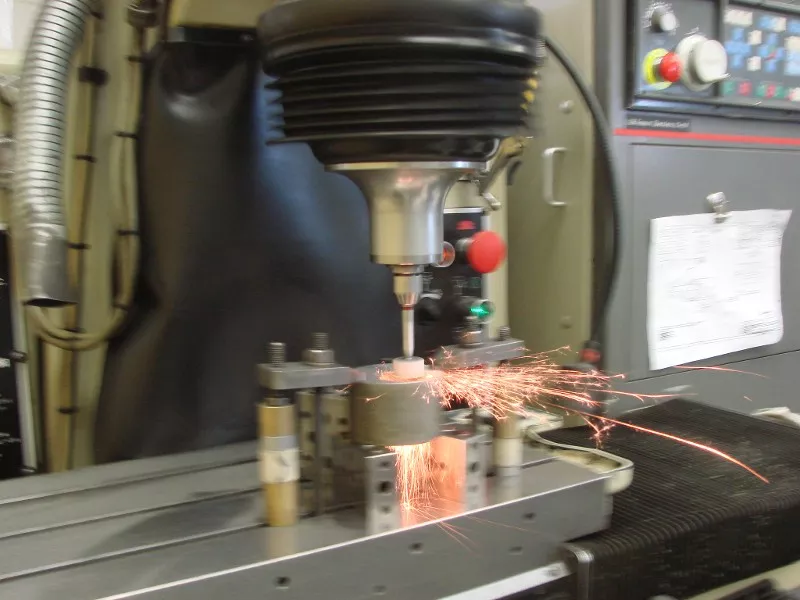

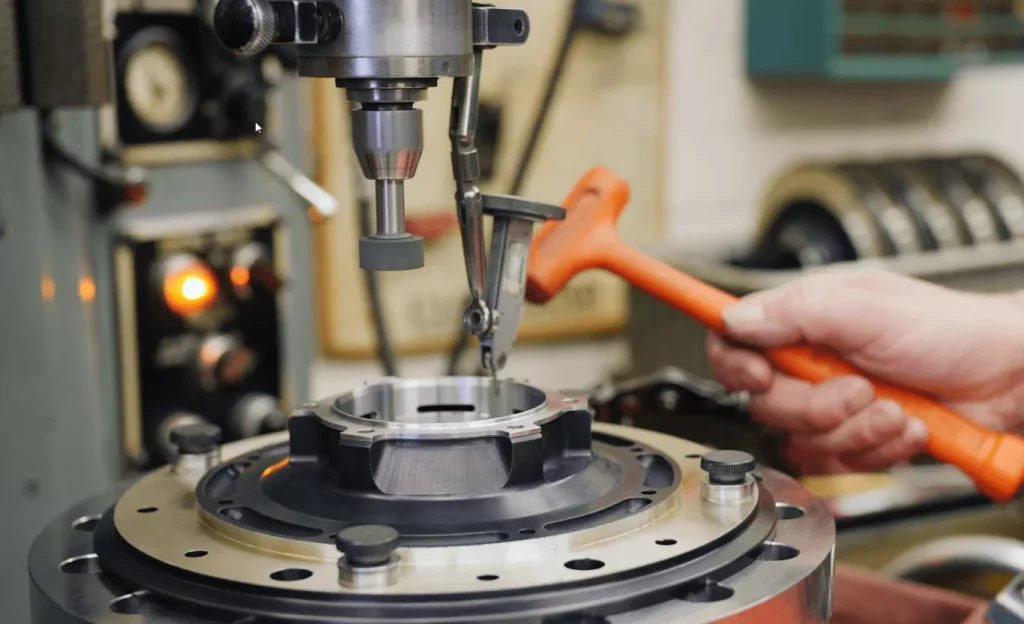

Jig Grinding

Elimold is proud to offer precision Jig Grinding services and is your reliable partner for achieving superior quality and precision in all your projects. We are also proficient in a wide range of precision grinding processes. With a strong team of professional equipment, we offer a comprehensive solution to meet even the most demanding requirements. Contact us now for a free instant quote.

Professional Custom Jig Grinding Company

Elimold is a company that specializes in precision jig grinding services. We specialize in providing high-quality jig grinding processing solutions to meet the specific needs of our customers. We have advanced technology, equipment and skilled personnel to ensure the accuracy and efficiency of the grinding process. Custom Jig Grinding serves a wide range of industries and provides services including the production of complex geometries and tight tolerances. Our commitment to precision and customer satisfaction makes us a reliable partner for companies seeking professional jig grinding capabilities. This allows Elimold to perform your custom metal grinding project with the quality and consistency to meet your precision product needs. Our full-service grinding department is equipped with a range of CNC equipment and inspection equipment to perform complex, tight tolerance grinding operations.

Is Your One-Stop Machine Shop for Precision Jig Grinding Services

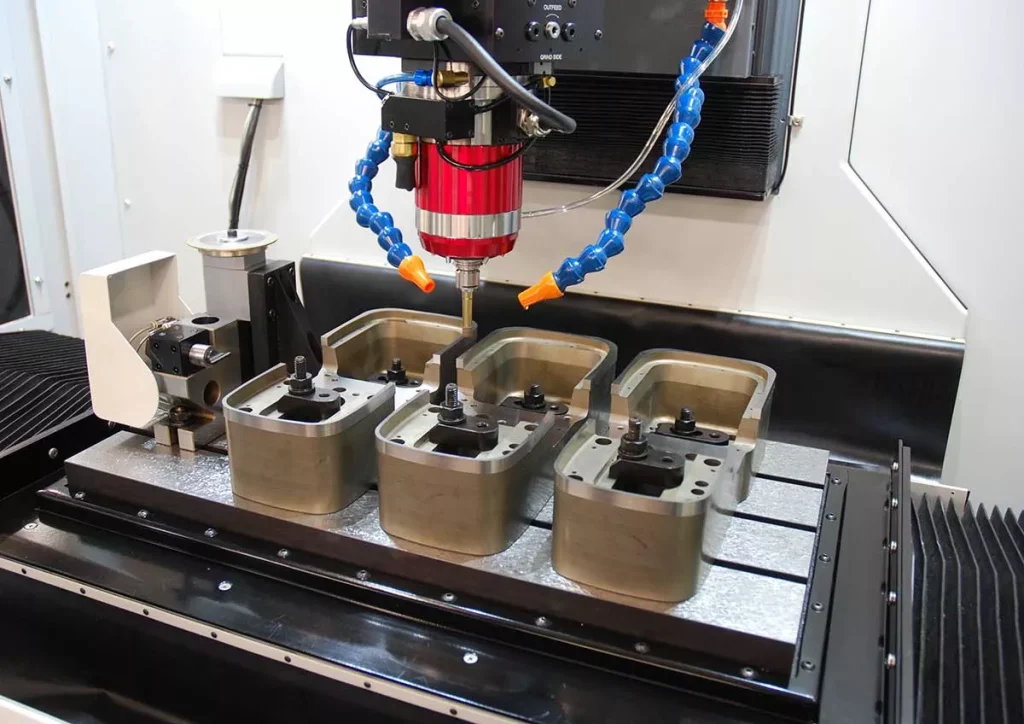

We are committed to providing quality service to our customers and welcome you to visit our advanced jig grinding production facility. Spanning 24,000 square feet, we have 18 CNC jig grinders and 14 conventional jig grinders that can easily achieve tight tolerances and complex shapes. We complete each precision jig grinding service with superb craftsmanship and a focus on precision. We are currently certified to AS 9100 Rev. D and ISO 9001:2015. We can undertake any production batch from 1 to 1,0000 pieces and can deliver quickly.

Precision jig grinding services are one of our specialties, and we excel in providing precise and complex components. Our grinding and conventional machining services are performed by experienced machinists who have many years of industry experience. This allows us to process a variety of materials with high precision parallelism, flatness, perpendicularity and perpendicularity, and provide a variety of surface finishes. To find out how our advanced surface grinding and conventional machining can help you with your next precision manufacturing project, please contact us or refer to the table below.

Jig Grinding Capabilities

- Maximum work area width: 22 inches

- Maximum work length: 48 inches

- Maximum work height: 30 inches

- Bore depths to 4.00

- Extension limits: 120 inches (or more)

- Materials: All

- Coating and plating: All

- Tolerance: Up to +/–0.0001

- Concentricity to +/–0.0001

- Cylindricity to +/–0.0001

- Surface finish to 8 micro

Jig Grinding Service Provider

As part of Elimold’s integrated manufacturing capabilities, we are proficient in a variety of grinding methods. Our Jig Grinding department is staffed by experienced professionals and is an important part of our full-service manufacturing capabilities. With our high level of expertise, we are able to provide independent jig grinding services, giving customers the opportunity to fully benefit from this precision service. Our factory is equipped with a variety of manual and computer-controlled equipment as well as inspection equipment, allowing us to achieve high dimensional and geometric accuracy and high-precision surface finish. Our staff is well-versed in all the basics of precision grinding, and is able to select the best abrasive and grit size to complete each grinding task, and is able to grind parts of various sizes, shapes and geometric complexities. All of our grinding projects produce excellent results, and we have the flexibility to handle small or large batch production. We also provide many other value-added support services.

Prototype-to-Production Capabilities

Elimold’s diverse product offering enables us to produce parts from small to large batches. In addition, we offer rapid prototyping services to help customers turn their ideas into reality. In addition, we have the expertise to design and manufacture custom tools and fixtures that securely hold the workpiece during the grinding process. This not only ensures consistent and precise results, but also allows us to rely on the quality of our in-house produced tools. Our best-in-class solutions and responsive customer service deliver outstanding results for our customers.

From Design to Full Drawing to Production

As a full-service factory, we will work with you to determine your specifications and design the products you need and want. We can design your tooling, create full drawings, and manufacture them in our brand new facility.

Prototyping and Reverse Engineering

Elimold's expertise in rapid prototyping and reverse engineering has helped many customers breathe new life into their machines and helped them improve their business.

Short-Term/Long-Term Production

We have been providing short-term production services to help customers meet daily needs. Whether you are facing a tight delivery deadline or inventory shortage, we can produce the parts you need to help you succeed. We can provide long-term production services based on project requirements.

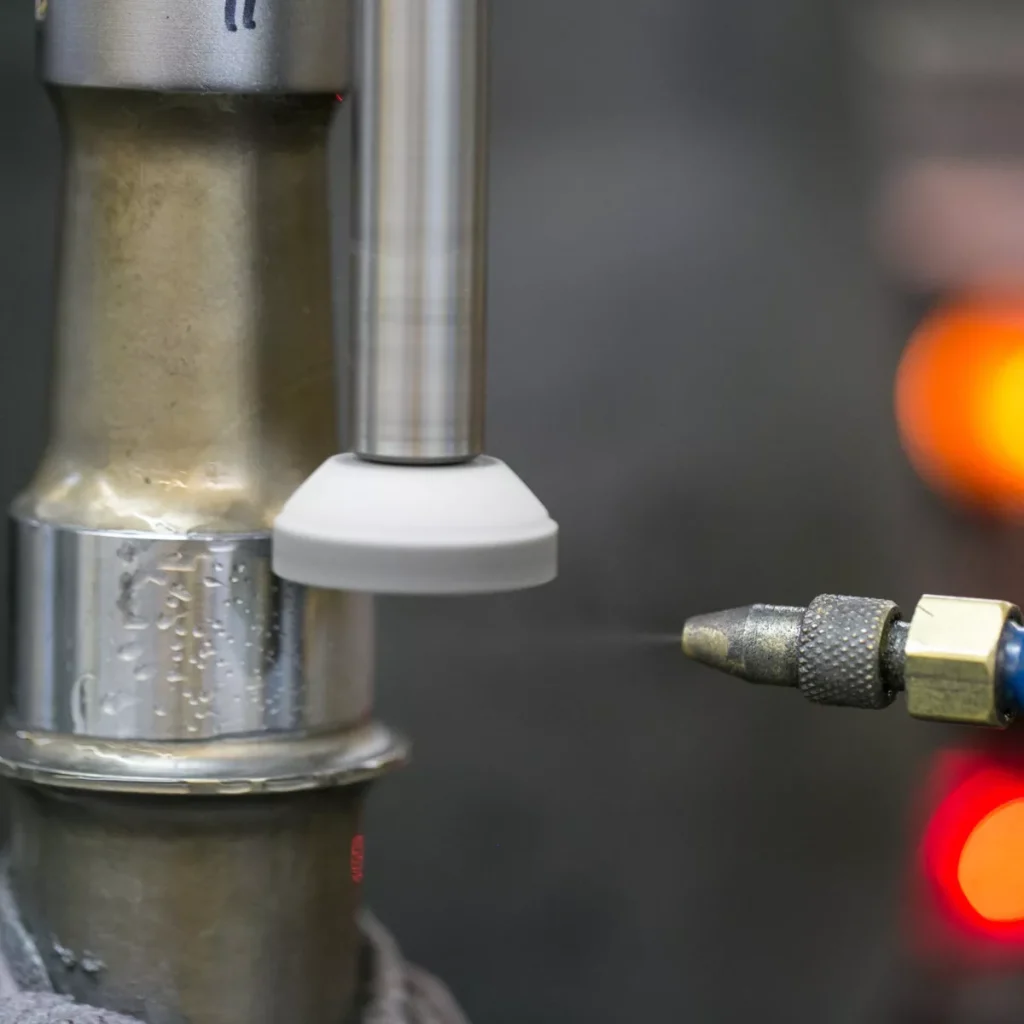

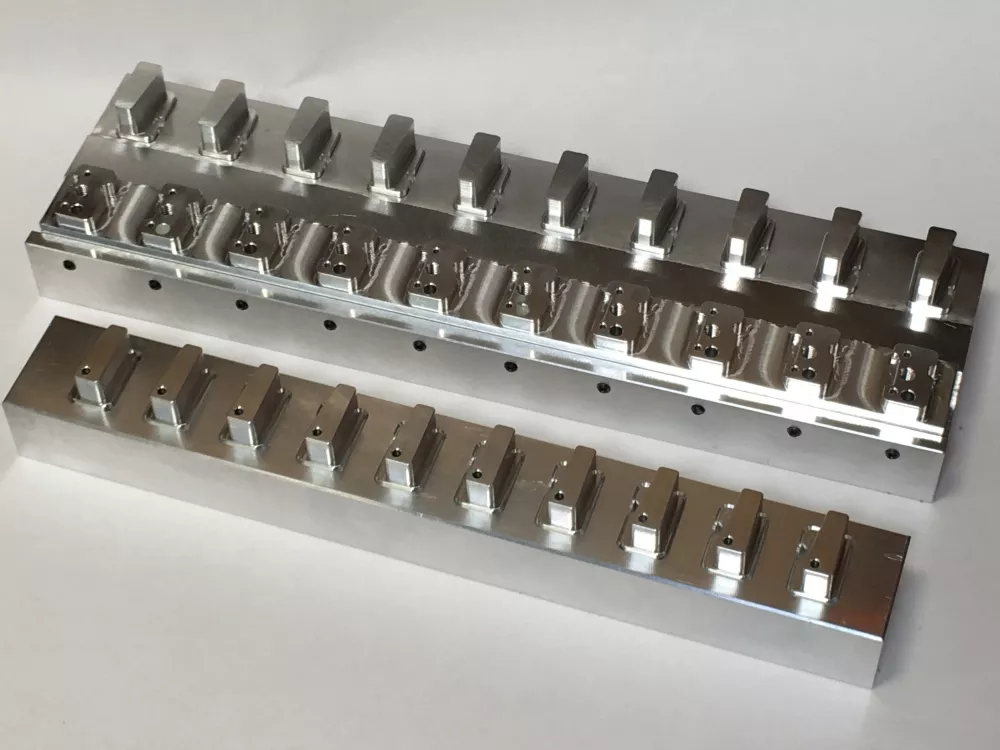

Maintaining Tight Tolerances

Our precision grinding process is able to create extremely accurate profiles (accuracy within one thousandth – 0.0001 inch) and excellent surface finish (8 – 16 RMS) using advanced grinding technology and grinding lubricants. The accuracy of the jig grinder is unmatched by any other machine tool, and the tolerances are consistently held to 0.0002 inches or better. High-precision bearing bore grinding can consistently maintain manufacturing specifications with little or no deviation.

In addition, one of the functions of fixture grinding is the finishing of holes, but not limited to this. This allows us to maintain tight tolerances, even the size of a hair, to achieve a polished finish. These holes and tolerances are key to the smooth operation of the mold. Ensure a tight fit and alignment of all mold components. We manufacture pins to ensure that the finished product remains aligned and accurate from the first punch to the last punch.

Quality Assurance

Precision is the cornerstone of our operations. Elimold adheres to strict quality control measures at every stage of the grinding process. We have established quality standards and strictly monitor all projects to ensure that every part we produce and every service we provide (including fixture grinding, precision grinding) meets the standards. Our “First-Class Quality Solutions” program includes mandatory first-article inspection, continuous in-production inspection, and final detailed inspection using standard batch processes. These inspections are all backed by our satisfaction guarantee: if the part does not meet your specifications, you will pay nothing and we will gladly replace it for you! We are committed to ensuring that your components meet the most stringent standards of accuracy, surface finish and dimensional integrity. Our commitment to quality assurance makes us your trusted partner in precision grinding.

Quality control inspection equipment

- Optical Profilometer

- Standard Metrology Instruments

- Micrometers

- Slide Calipers

- Height Gages

- Depth Gages Indicators

- Bore Gages

- Squares

- Angles

- Gage Blocks

- Granite Surface Plates

- Rotary Tables

Contact our team to see how we can work together

Choose Elimold as your precision machining partner and experience the excellence that comes with quality, innovation and commitment. Contact us today to discuss your precision machining needs and take the first step towards a successful partnership.

Material Options

Elimold specializes in jig grinding of all materials, as well as precision grinding of nearly all materials, including metals, plastics, and ceramics. With an average of 20 years of experience, our staff can meet all of your grinding needs.

- Aluminum

- Beryllium

- Brass

- Bronze

- Carbide

- Cast Iron

- Colbalt

- Copper

- Gold

- Inconel

- Lead

- Magnesium

- Molybdenum

- Nickel

- Platinum

- Silver

- Stainless Steel

- Steel

- Tantalum

- Tin

- Titanium

- Tungsten

- Zinc

- Zirconium

- Ceramic

- Composites

- Ferrite

- Granite

- Graphite

- Polyester

- Sapphire

- Wood

Surface Finishing Options

- Bead Blast

- Anodizing

- Chromate Coating

- Electroless Nickel Plating

- Part Marking

- Passivation

- Powder Coating

- Press Fit Hardware

- Silk Screening

- Brushing

- Polishing

- Black Oxide

- Brushed + Electropolishing

Service Industry

- Aerospace

- Agricultural

- Auto/Truck/Transportation

- Marine

- Medical

- Military

- Mining

- Pulp and Paper

- Spindle

- Wire

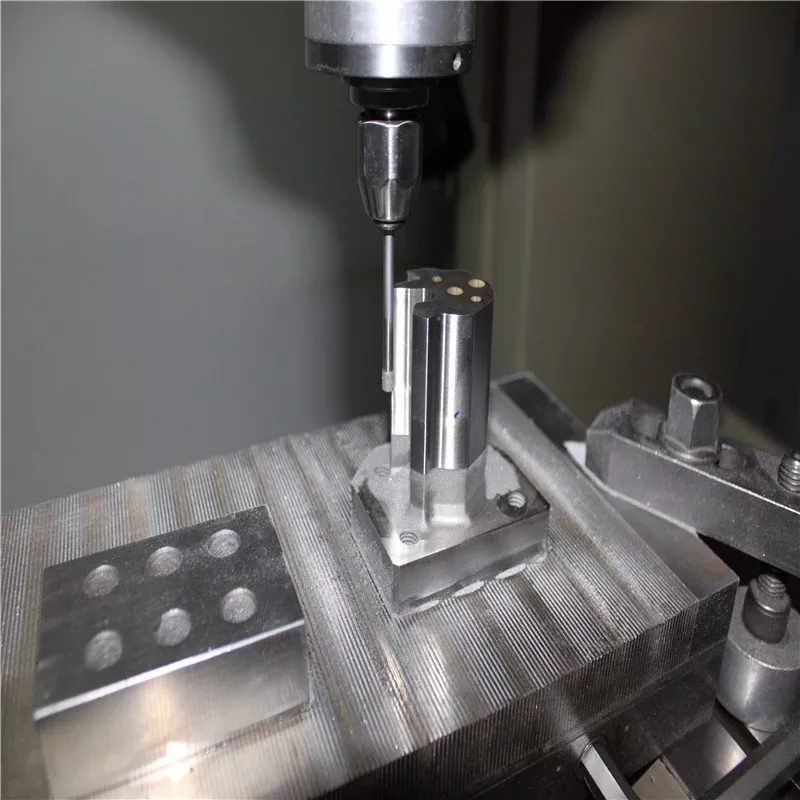

What is jig grinding?

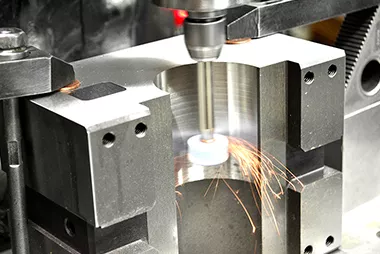

Jig grinding is a special form of precision grinding used to produce high-precision holes, contours and surfaces on a variety of workpieces. This machining process requires the use of a grinding machine called a jig grinder and is commonly used in molds and precision parts where sub-micron form and positioning accuracy is required.

The key benefit of jig grinding is its ability to achieve extremely tight tolerances and complex geometries that are difficult to achieve with other grinding methods. Jig grinding is commonly used to produce molds, dies and fixtures, as well as to finish parts with complex features such as holes, cavities and contoured surfaces.

With its ability to achieve exceptional accuracy and surface finish, jig grinding remains a vital technology in industries where the highest precision is critical to the performance and function of the end product.

Comprehensive Grinding Solutions

Elimold offers comprehensive grinding solutions for all your grinding needs. We have extensive grinding capabilities to process a wide range of materials, including metals, alloys, ceramics, and more. Whether you need surface finishing, complex CNC grinding, precision fixture grinding, or unique profile grinding, we have the experience, equipment, and expertise to provide you with excellent results.

CNC Machining Services We Provide

At Elimold, we offer more than just precision jig grinding. We have a wide range of in-house support processes, including all types of CNC machining processes, to meet our customers’ demands for fast delivery and excellent quality. Whether you require engineering specifications for a single product or batches of hundreds, our experienced team can provide you with precise results to meet all your needs.

CNC Milling

Our CNC machining services allow for the creation of complex milled parts at velocity. This expands the potential range of materials without minimising efficiency and standards. We can manufacture complex parts in a wide range of sizes, quantities, and with multiple angled features.

CNC Turning

Our team continues to refresh our fleet of machines, investing significantly in our Turning and Mill/Turn technology. This allows us to remain ahead of the game, providing a tailored service and solution to our customers that is hard to match within the industry.

3 Axis CNC Machining

The 3 axis CNC machining services offer the best value in the industry for small CNC machines. It packs a punch, an efficient smaller package that delivers big results and high standards of productivity. The best way to maintain productivity in a smaller space.

4 Axis CNC Machining

4 axis CNC machining is where the 4th axis rotates whilst the machine is not cutting, aiding precision. Our range of CNC machining services is designed to offer a wide range of precision to fit any manufacturing complexities and demand.

5 Axis CNC Machining

We continue to innovate, refining our 5 axis CNC machining services for maximum output at reduced time and cost. The 5 axis provides you with the power and precision for myriad uses, maintaining accuracy and delivering consistently.

CNC Prototypes

Creating a prototype is an important part of the manufacturing process. Our services allow our clients to see a product, part, or concept in action before making a decision on whether to continue production or make necessary changes.

Wire EDM Machining

Our advanced Wire EDM machines allow us to complete complex projects at quick turnarounds, and in tight tolerances up to +/_ 0.0001. We employ 4-axis machining to produce high-quality products. We use various advanced CAM software, which helps us import parts, files, and drawings easily.

CNC Threading and Tapping

Many components require threaded holes or tapped features for mounting screws, fasteners, or connectors. Our CNC machining service offers precise threading and tapping capabilities, ensuring that these essential features are accurately created to the required specifications.

CNC High-Speed Drilling

Custom parts manufacturing often involves drilling precise holes for components, connectors, and fasteners. Our High-speed dril with CNC machines guarantees accurate hole placement, diameter, and depth.

Swiss Machining Service

Swiss machining is an efficient way to produce complex, or slender component. By moving both live tooling and the workpiece, we can always cut the material which is close to the workpiece holder. To avoid deformation compared to traditional CNC lathe.

CNC Routing Service

Besides standard milling service for parts in engineering plastics or metals, we also offer CNC routing service for prototypes and parts in soft materials such as EPS foam, EVA, woods.

CNC Grinding Service

If you need a super flat surface part, or round part that needs OD and ID +/- 0.005mm in tolerances, our CNC grinding machining service will be the best match of your production needs for such type of parts.

Request Your Free Jig Grinding Quote Today

After receiving your drawings, our engineers will analyze your custom Jig Grinding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.