Laser Cutting Services

Elimold’s precision laser cutting service for rapid prototyping and production. Free laser cutting quote and DFM review within 1 day. Delivery cycle as fast as 3-5 days. Whether you need a single part, rapid prototype parts or high-volume production, Elimold can provide a cost-effective cutting solution.

Professional Laser Cutting Manufacturer

If you are looking for a production technology that is affordable and superior to other options, then you should choose Elimold’s custom laser cutting services. It is ideal for manufacturing complex parts with tight tolerances, high-quality prototyping, and high-volume production. We have an in-house factory that can provide faster and more rapid production timelines. So, whether your part quantity is one or thousands, we can help you accelerate your sheet metal project with laser cutting in a cost-effective way. In addition, our engineering and production teams have decades of experience in laser cutting technology and can provide you with advice on the best processes, materials, and design adjustments to improve the manufacturability of your parts. We can also answer any questions you may have about laser cutting and other cutting methods. Talk to us today about your laser cutting project and how to make your project take full advantage of its high quality and precision.

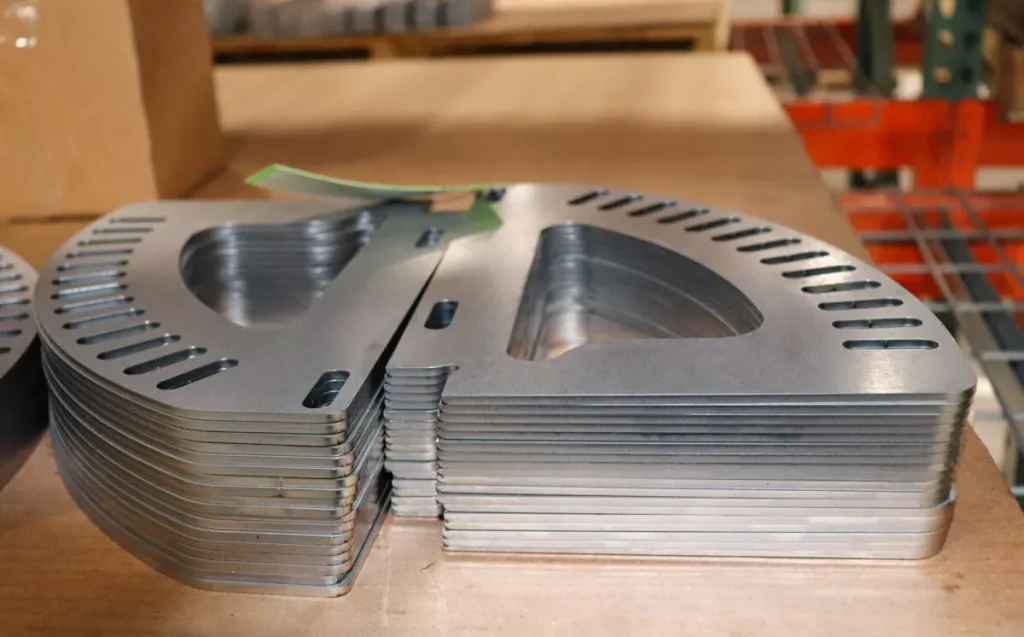

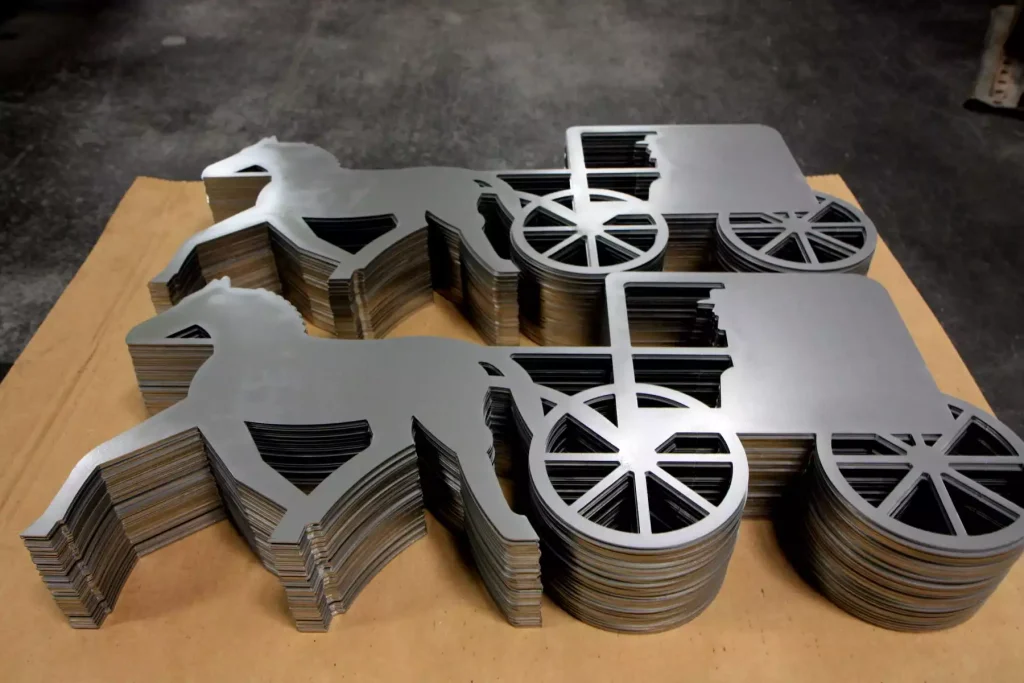

Custom Laser Cut Parts Supplier

Elimold has served over 33,000 customers and produced over 2 million parts. Our 99.7% part accuracy record is a testament to our reliable parts manufacturing capabilities, while our 365-day warranty ensures that all parts ordered meet all requirements. Whether it is a prototype or a mass-produced product that has been released to the market, every part we produce is treated the same and adheres to the same high-quality engineering standards. Therefore, no matter how big or small the order is, you can rely on our laser cutting services for all parts. Let us become an extension of your team’s hard work. Our metal processing and laser cutting capabilities are designed to provide you with the best service. Whether you are looking for a complete processing solution or just need a small amount of metal processing services, you have come to the right place.

In-House Laser Cutting Factory

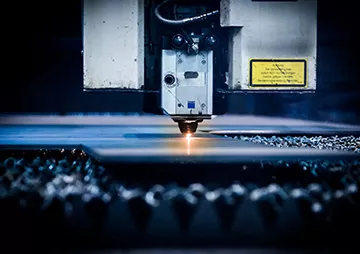

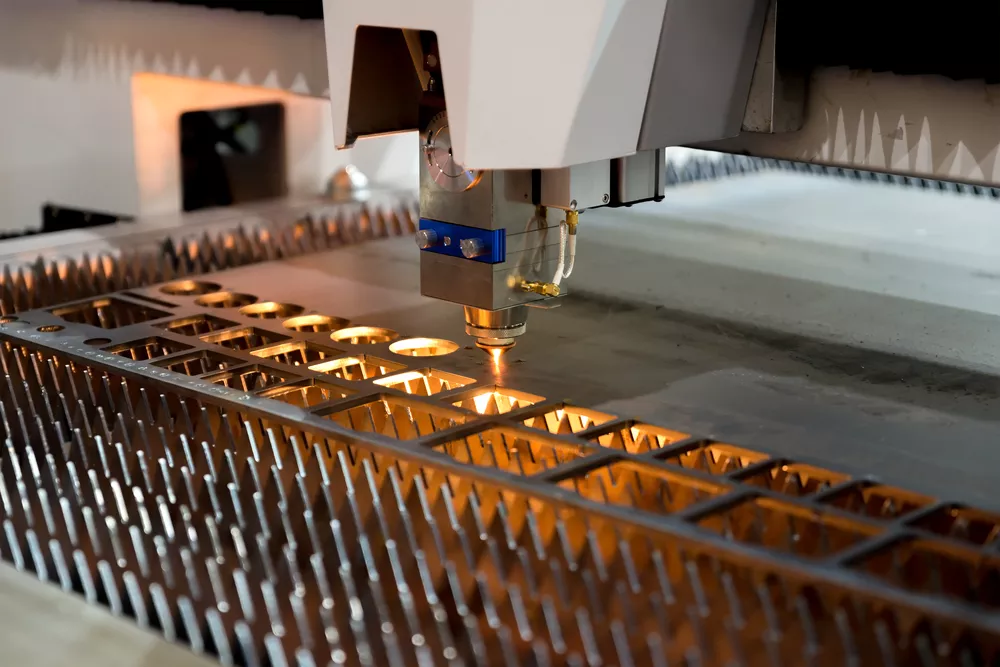

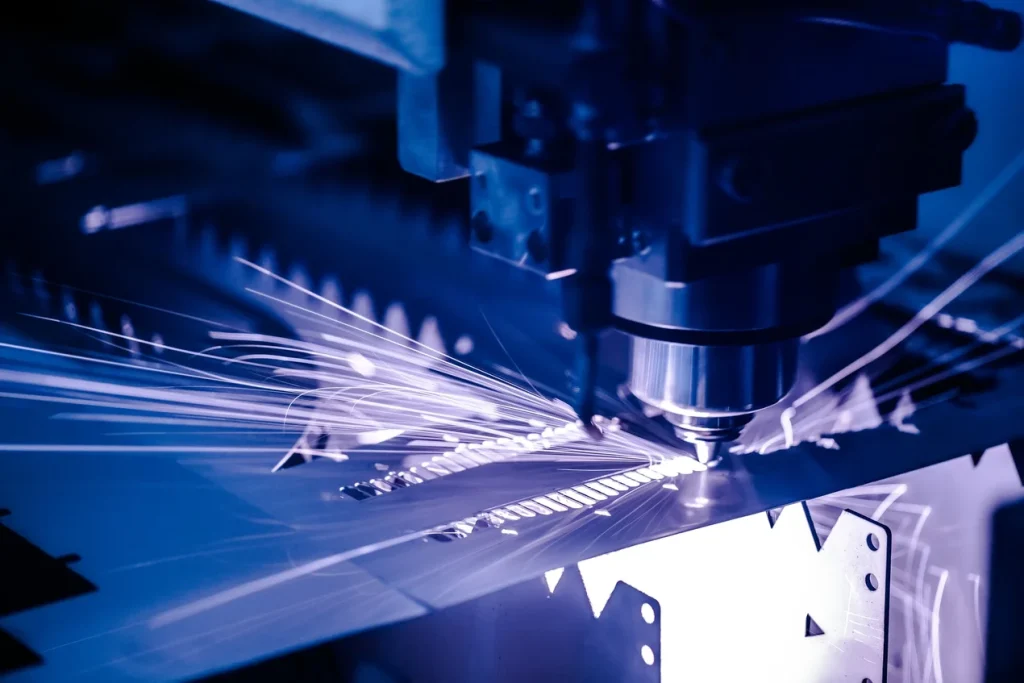

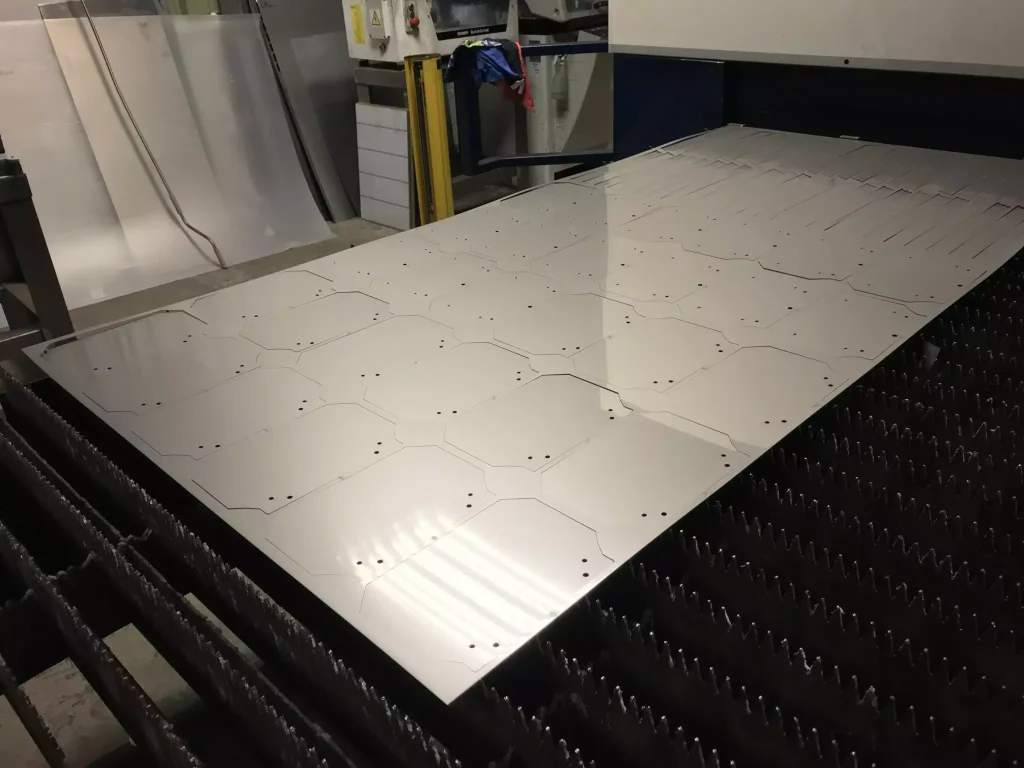

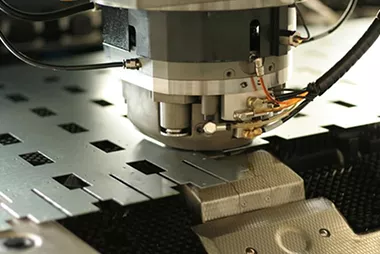

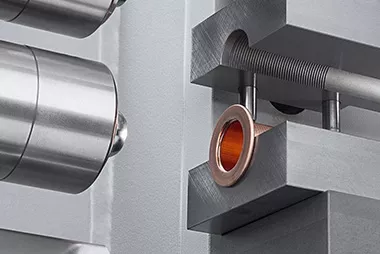

With our in-house manufacturing capabilities, you are always in control of your production. At Elimold, we have our own production facility, which is 25,000 square feet and surrounded by paved parking for easy loading and unloading of materials. This gives us full control over manufacturing, quality control, and delivery times. The in-house facility features over 36 low-, medium-, and high-power CO2, YAG, and diode and fiber lasers, operated by our skilled and experienced laser processing professionals to optimize the performance of each machine. In addition, the laser cutting equipment in our facility is a “lights-out” machine. 24-hour laser cutting resources increase production efficiency and reduce downtime. Fully automated metal cutting equipment provides our customers with fast turnaround and reduced project costs. Partnering with Elimold, whether you need contract services, manufacturing services, or prototyping services, our fast laser cutting machines allow us to provide high-quality parts with short delivery times.

Advanced Laser Cutting Equipment and Capabilities

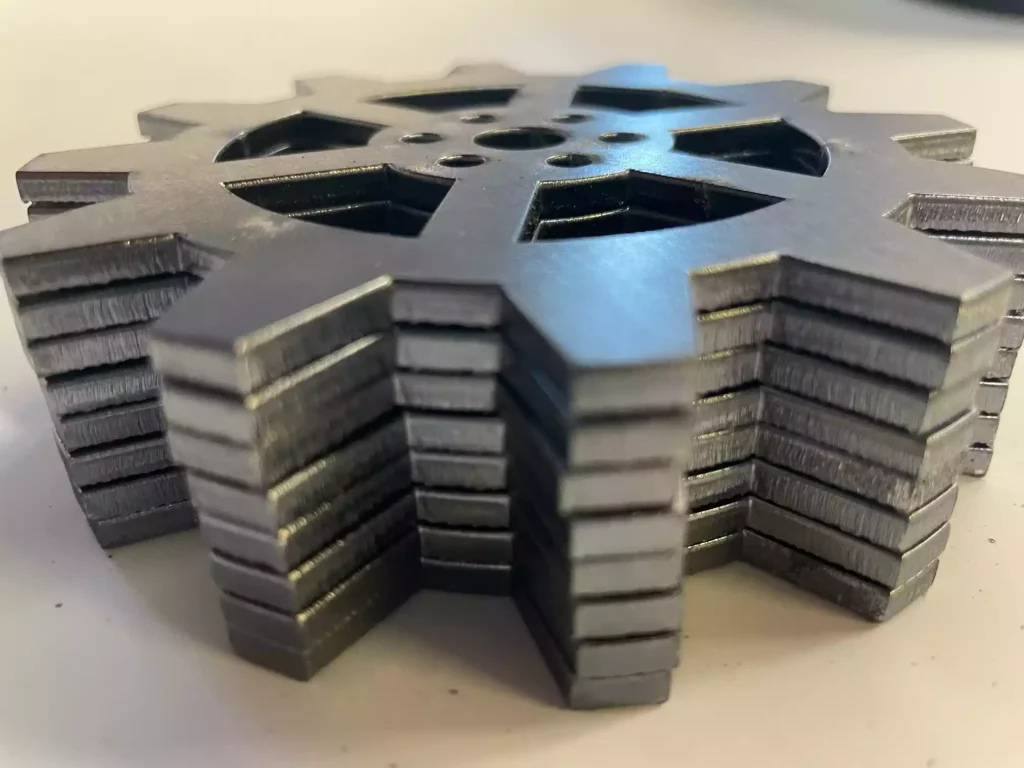

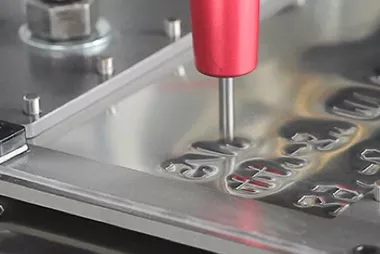

Our Shenzhen, China facility is equipped with the latest laser cutting technology, offering both 2D and 3D laser cutting services, with machines equipped with special features such as flying optics that can cut along 2, 3, and 5 axes. We can cut workpieces up to 96″ x 240″. We can process both very thin sheets and thicker sheets up to 4″ thick, with positional tolerances of 0.00039″ and repeatability tolerances of 0.00019″. Depending on your needs, we can laser cut pre-punched and stamped parts, or work with you to design a custom project. And all of our equipment is carefully calibrated to achieve the best tolerances even on extremely precise projects. We can configure virtually any frequency, power, and speed, enabling us to cut highly complex components.But cutting metal is just one of many uses for this technology; others include: engraving, welding, cleaning and drilling.

Types Of Laser Cutters Available From Elimold

Our in-house laser cutting shop features a wide range of advanced equipment capable of processing a wide range of materials with high precision and efficiency.

Fiber Laser Cutting

CO2 Laser Cutting

Nd:Yag Laser Cutting

Leaders in Precision Laser Cutting Services

Elimold is more than a machine shop; we are your partner in manufacturing and innovation. We serve a wide range of markets around the world and understand the unique dynamics and needs of our customers. Whether your project is large or small, standard or complex, we have you covered. With a wide range of services, an experienced team and cutting-edge technology, we are committed to providing more than just a service, but a solution that can move your project forward. For developers looking for a reliable laser cutting shop in any region, Elimold is your only choice. Consider us for your next project and let us show you how we are at the forefront of laser cutting technology and service quality.

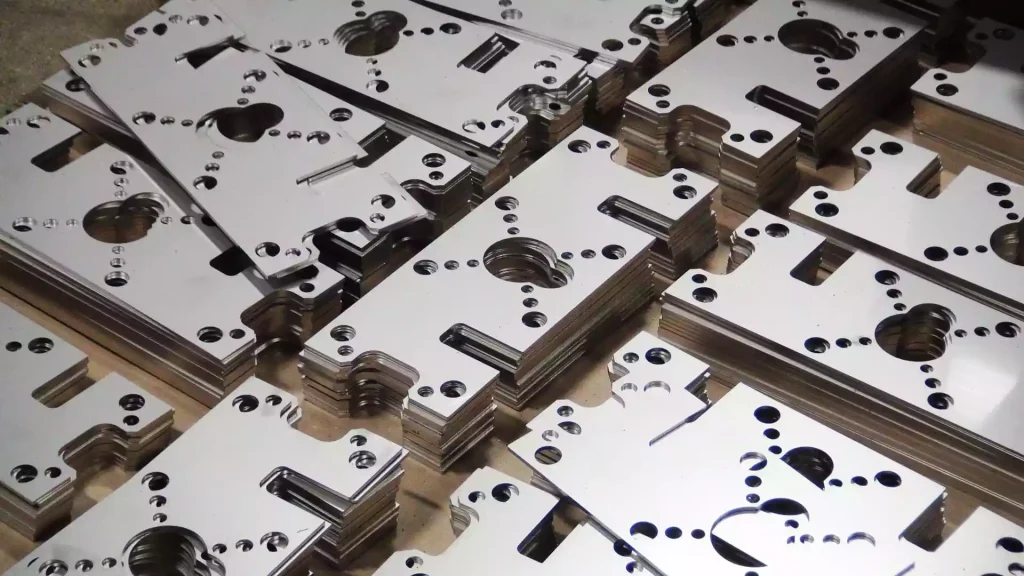

Laser Cutting Full Production Services

We understand the importance of time-sensitive projects. Our advanced technology and experienced team enable us to deliver quickly, helping you meet your project deadlines without sacrificing quality. Whether developing a custom prototype or executing large-scale production, our comprehensive services are designed to meet your unique needs. In addition to prototyping services, Elimold excels in full production. We are able to efficiently produce high-volume parts while maintaining strict quality standards. Our laser cutting process is optimized for consistency, ensuring that every component we produce meets precise specifications and minimizes waste.

Request a Precision Laser Cutting Service Quote

Elimold has the advanced equipment, strong facility capabilities, and professional manufacturing experience to quickly complete your laser cutting project. We are committed to providing high-quality products and look forward to working with you. Welcome to contact us to discuss your precision sheet metal cutting needs.

From Prototype to High-Volume Production

Not only is our facility capable of taking on high-volume industrial projects, we are also happy to collaborate on rapid prototyping projects, even if they may only be single projects. As such, Elimold serves our customers through both the prototype and high-volume production phases. While our average order volume is between 50 and 10,000 parts, we are also able to perform high-volume production with no part quantity restrictions. We consistently meet and exceed our customers’ expectations for value, quality, turnaround, and service to maximize customer profits and overall success. We meet our customers’ needs, so we’re confident we can meet yours, too. Let our experienced and skilled team work with you to find the best and most cost-effective solution for your pre-production and professional laser cutting production needs. Contact us today for a quote.

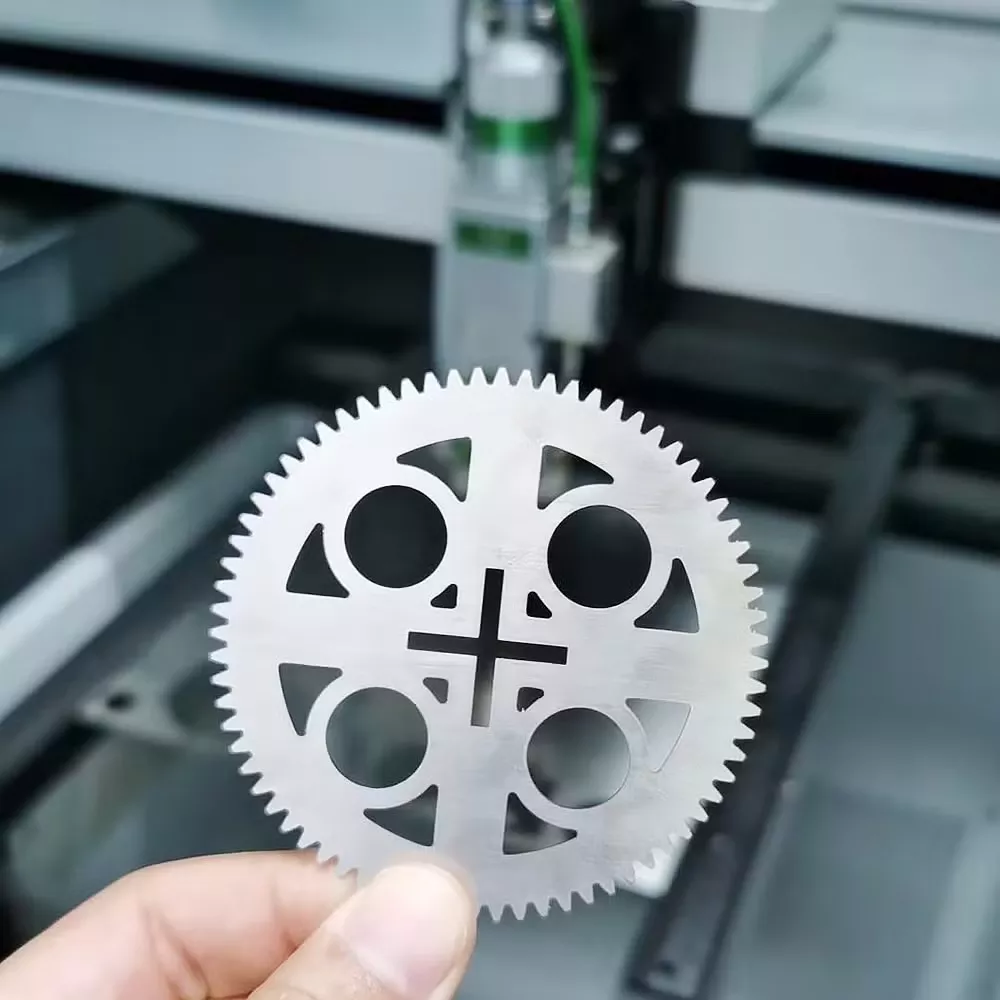

Laser Cutting Rapid Prototyping Services

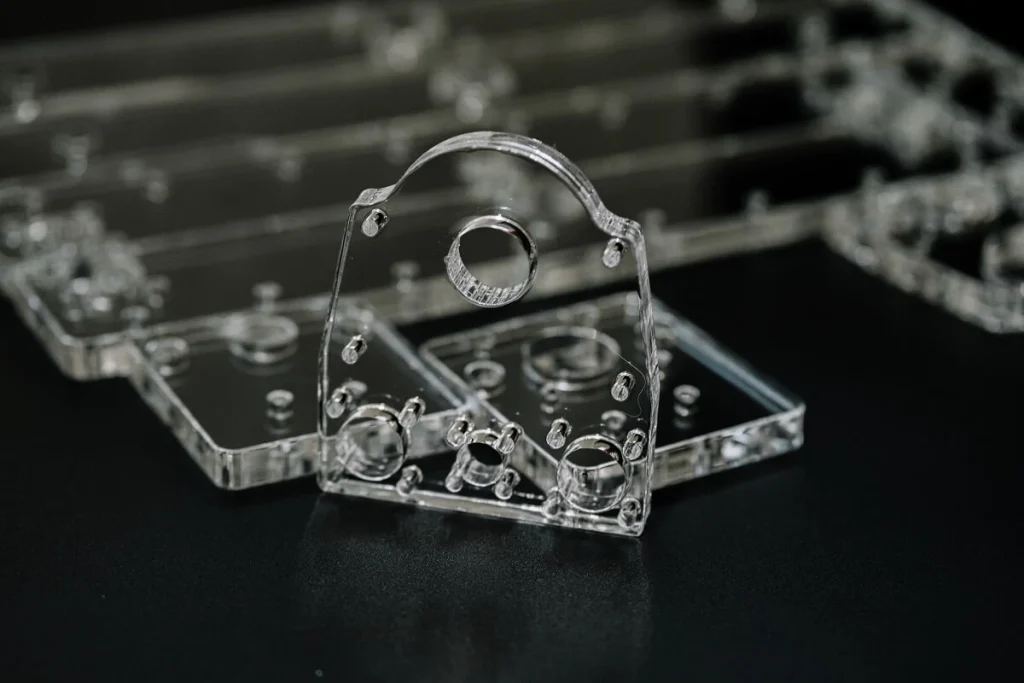

We’ll leverage our in-house laser cutting technology and manufacturing expertise to quickly provide you with prototype parts for early validation. Elimold’s custom prototyping services are the cornerstone of our business. We understand the importance of producing prototypes accurately and quickly. Our engineers and designers can help you quickly iterate on part designs and create more detailed prototypes to evaluate fit, finish, and functionality. Using advanced laser technology, we help innovators develop, test, and refine their designs before moving to larger production runs. This attention to detail ensures a seamless transition from prototype to full production. We can even help you transition your product into bridge production for field testing and evaluation.

One-Stop Laser Cutting Manufacturing Services

Our laser cutting technology also provides ultra-precision cutting for any shape or design. From determining the best solution for your project to providing a worry-free production experience, our dedicated team will guide you every step of the way and streamline your production process, ensuring that even the most complex projects can be completed efficiently and cost-effectively. Elimold can meet all your laser cutting needs. From prototypes to large and complex projects. Our experienced team of professionals always puts quality and accuracy first and works hand in hand with you to ensure that your project is completed within tight deadlines. We go the extra mile to deliver excellent results and help you achieve success. Contact us today for a quote and let us help you create a product that exceeds your expectations.

Engineering Design Services Capabilities

When you work with an outside company to manufacture your parts, first-rate engineering is essential. There are many factors involved in producing affordable and consistently high-quality parts, including part design, manufacturing methods, material selection, manufacturability, advanced prototyping, and efficient production process design. If you are proficient in CAD/CNC design, feel free to provide full vector graphics drawings. If you need help refining your ideas, we are also happy to provide design and production services. Whether you need additional metal processing services or just need laser cut parts, we can produce according to your design. Elimold can easily transform your design into the metal part you need, no matter the format. We provide our customers with more services.

Instant DFM Feedback

Our team of engineers analyzes your custom sheet metal parts and provides instant Design for Manufacturability (DFM) feedback for both flat and curved metal parts, letting you know if there are any issues that could affect the finished part. They anticipate what challenges you’ll face based on the geometry of your part. They are intimately familiar with the pros and cons of laser cutting manufacturing methods. They can help you achieve the perfect balance between design, material, manufacturing method, and finishing options to produce a part that meets all of your requirements and helps you avoid the headaches that less structured methods can bring.

Our Commitment to Quality

Our team is fully dedicated to ensuring customers receive the highest quality fabricated components for their needs. Elimold Company is proudly ISO 9001:2015 certified, meaning our quality management system meets all ISO requirements. We work hard to maintain this certification so our customers have peace of mind, knowing they will receive the highest quality products and services from our company. In addition, Elimold Company can provide the following services:

- PPAP (Production Part Approval Process) – All Levels

- FAIR (First Article Inspection Report)

- Capability Studies (Statistical Process Control)

- CMRT (Conflict Minerals Reporting Template)

Reliable Metal Laser Cutting Service Provider

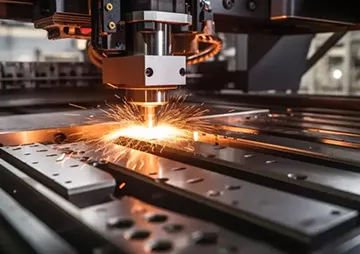

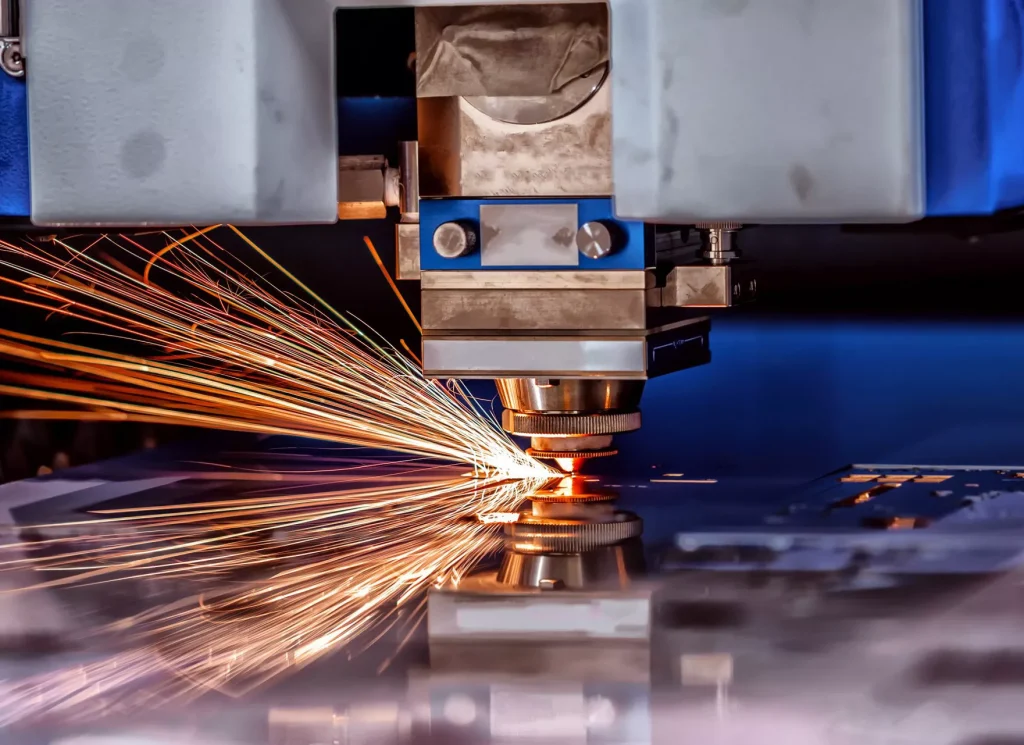

Not only do we use this breakthrough technology to produce high-quality metal products with unique shapes and intricate details, we also have state-of-the-art machines to meet almost any customer need. We know you’re racing against time to complete your project. That’s why we offer the superior benefits of laser cutting to help you stay on schedule and increase your profitability.

At Elimold, we’re committed to combining speed with quality to cut metal parts to perfection. Our process requires little to no human intervention, which significantly reduces human error. Our experienced experts are proficient in operating laser cutting machines, and can cut your custom products flawlessly, right down to the finest detail. In addition, our company is committed to reducing costs for our customers. One of the reasons we invested in this advanced technology is to minimize production costs and pass the savings on to you. Producing high-quality metal products at a lower cost than traditional methods is how we help your business grow. Elimold’s superior laser cutting solutions are at your service. Contact us today and we’ll learn more about your needs.

Fast Turnaround and Emergency Production Services

Our team embraces a spirit of continuous improvement, ensuring we stay on top of all the latest technologies, methods, and industry best practices. Our facilities adhere to the principles of lean manufacturing, helping us reduce project costs by minimizing waste and keeping inventory under tight control. We are AS9100 and ISO 9001:2015 certified, demonstrating our commitment to quality. We have incorporated automation into our production processes, ensuring our facility operates “lights out.” These capabilities allow us to offer 1-6 day lead times, and provide expedited and emergency production services when necessary, while ensuring precision and accuracy.

Ready to get started on your laser cutting quote?

Whatever your application needs, Elimold’s team of engineers ensures you receive a fast, accurate project quote and a realistic timeline. We understand the importance of planning and budgeting, and ensure you get all the information you need right away.

Special Projects

We also take on special projects with unique or special requirements. Whether it requires non-standard materials or the development of unique accessories, it can be difficult to find manufacturers willing to work around these issues without severely impacting the project. As a laser cutting company, we pride ourselves on being able to take on any project. Whether our clients are startups, small businesses, or large enterprises, our experienced team of engineers and machine operators can provide expert consultation on the design and manufacturing process. With over 20 years of experience in the laser cutting industry, we have taken on many unique projects. No matter how complex or special the project, our experienced team is ready to design a solution to meet those specific needs without compromising quality or efficiency.

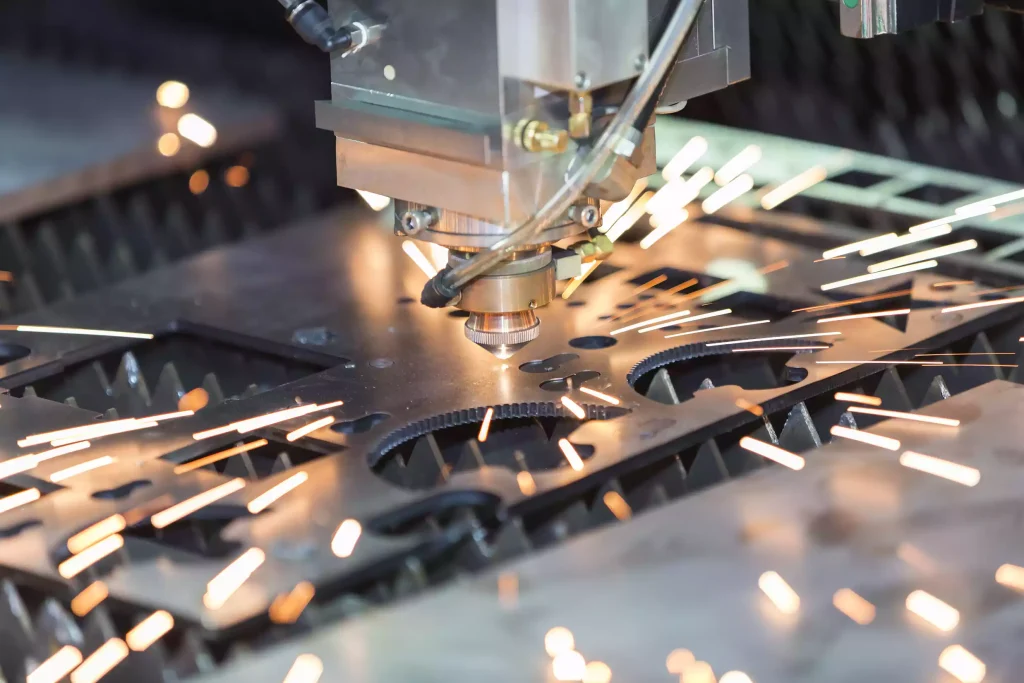

What is laser cutting?

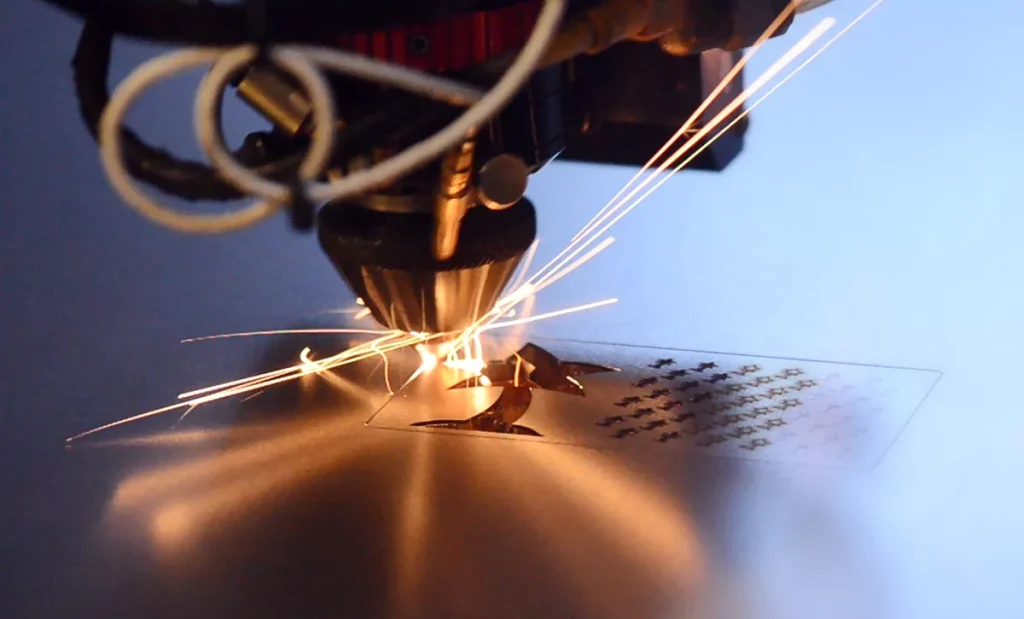

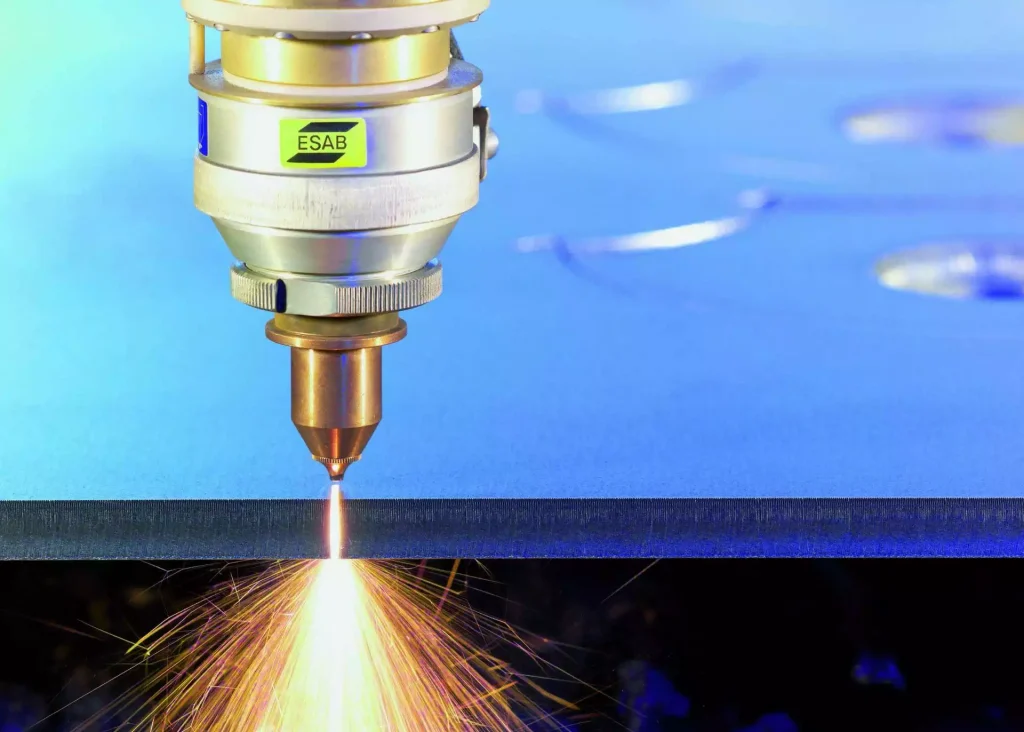

Laser cutting is a subtractive manufacturing process that uses a laser beam to cut parts from a sheet. However, the laser beam does not cut or melt, but rather vaporizes the material using its intense laser energy, which prevents the material from catching fire or degrading. Laser cutters are numerically controlled by computers (hence the name CNC), which allows them to produce any 2D part (changing the command will change the shape) and also allows them to provide high precision for thousands of parts.

Advantages of the Laser Cutting Process

Laser metal cutting uses a focused, high-powered beam of light to cut or engrave materials with extreme precision. Unlike traditional methods, custom laser cutting ensures precise, clean edges, ideal for creating complex shapes without sacrificing quality. This technology reduces manual intervention, which reduces production time, reduces errors, and provides customers with high-quality results they can trust.

- Laser cutting is more precise and energy-efficient than plasma cutting, but has an upper limit on the thickness of the material it can cut.

- Laser sheet metal cutting is one of the most precise forms of sheet metal processing, capable of easily creating complex shapes of any size and shape.

- Laser cutting can eliminate the need for machining, allowing customers to save money.

- The laser does not need to come into contact with the metal it is working on, which helps minimize wear and tear on the part.

- In the metal fabrication process, laser cutting services are used in conjunction with sheet metal bending and forming.

Material Options

Our advanced technology and experienced team ensures superior quality across a wide range of materials including metals, plastics, composites and polymers. We are committed to excellence and innovation, striving to deliver superior results that exceed our clients’ expectations and ensure projects are completed on time. If your project requires a material that is not on the list, please let us know! We can accommodate other material needs, but quotes may take more time while we source the materials.

- Aluminum

- Steel

- Stainless steel

- Mild steel

- Copper

- Brass

- Inconel

- Invar

- Kovar

- Nitronik 60

- Titanium

- Tool steel

Surface Finishing Options

We understand that the surface treatment of your parts is always a critical step in the manufacturing process. Whether your part’s end use is functional or aesthetic, we pay attention to the small details that matter to ensure that each part has a perfect surface finish. Below are the various surface finishes we offer for laser cut parts.

- Linear deburring

- Media blasting

- Brushing (cosmetic)

- Orbital deburring

- Tumble deburring

- Polishing

- Anodizing type II

- Anodizing type III

- Black oxide plating

- Chromate conversion coating

- Digital printing

- Electroless nickel plating

- Nickel plating

- Zinc plating

- Powder coating

- Silkscreen

Comprehensive Laser Cutting Solutions

In addition to our metal laser cutting services, you can add other services to your parts. We offer everything you need to go from concept to reality, all from one source. That’s why we have a range of in-house secondary and finishing services to complement our core metal fabrication capabilities, such as bending, forming and welding. As a one-stop shop manufacturer, we save our customers the hassle of managing multiple suppliers for different tasks, while reducing delivery time and costs. We want our customers to know that their projects are in the hands of an experienced team from start to finish. Need a laser cutting partner that can deliver results quickly and to your specifications? Start a conversation with Elimold today.

Sheet Metal Laser Cutting from Drawing to Delivery

We have an impressive portfolio of cutting technologies that allow us to tailor our metal profile cutting services to your needs. Whatever the size or complexity of your project, our sheet metal laser cutting services are designed to meet your needs. For customers operating in supply chains and requiring strict part tracking, all materials we cut are available with certification and full traceability in line with our ISO9001 and BSEN 1090 Execution Level 4 certification (CE and UKCA certified). From drawing to delivery, we streamline the manufacturing process and improve quality. Our customers benefit from cost savings and efficient downstream production processes.

More Value-Added Manufacturing Services

We have a complete facility to handle your project from design to delivery, with product lengths up to 48 feet (about 14 meters), and we can produce laser cut parts and products to your specifications with different manufacturing processes. For parts that need to be formed, we have press brakes with a maximum capacity of 360 tons and a bed length of 14 feet; and punch presses with a maximum capacity of 1,000 tons and a bed size of up to 60 inches x 144 inches. Our welding capabilities include MIG, TIG, spot welding, stud welding, and spin welding. We also provide metal forming, metal rolling, and metal tube bending. Our team is composed of skilled metalworking craftsmen with years of experience and a diverse skill set. Submit the contact form now and one of our friendly team members will contact you as soon as possible to learn more about your project.

Secondary Processing Services for Laser Cut Parts

Many CAD model designers use secondary processing techniques such as metal bending, tapping, and surface treatment in conjunction with laser cutting. For metal bending, the CAD model designer can specify the location of the bend and the desired angle or tapping instructions in the laser cut part design file. Once the custom part is produced, it is sent to a hydraulic press brake for bending or tapping. Most materials commonly used for CNC laser cutting can also be surface treated. This allows custom laser cut parts to have a uniform appearance, additional functionality, corrosion protection, or simply a more attractive appearance. Using these secondary processing services in conjunction with laser cutting can help CAD designers get custom parts into production more efficiently.

Take advantage of our state-of-the-art equipment and services

We invest in the latest laser cutting technology so you don’t have to worry about it. Our advanced laser cutting machines achieve the highest part quality possible. This superior quality ensures that our laser cutting process is efficient, which means we always offer our customers highly competitive sheet metal laser cutting prices. Waste is significantly reduced, which reduces material costs for our customers. Elimold’s goal is to provide our customers with everything they need to succeed, and our team is ready to assist you every step of the way. Our company’s reputation for excellence stems from our ability to provide our valued customers with the most efficient manufacturing solutions for their most demanding applications. Elimold is committed to consistently providing high-quality, precision laser cut products that meet all of your blueprint and tolerance specifications. Contact us today to learn more about our metal laser cutting services.

Cutting-Edge Laser Cut Parts Factory at Your Fingertips

We offer prototyping, manufacturing, and contract laser cutting services. We are able to handle prototype orders, small batch production, and low, medium, and high production volumes. With the fastest laser cutters on the market, we offer fast lead times of 3 to 5 weeks, and for projects that need immediate attention, we have 10 precision laser cutters ready to go. Our factory is located in Shenzhen, China, but our professional laser cutting services are mainly served by customers all over the world. Please feel free to contact us. Our laser cutting experts are ready to serve you. If you are not currently satisfied with laser cutting needs, why not take a look at our other excellent services. We also provide cnc machining, plastic injection molding, 3D printing and other services.

Other Sheet Metal Fabrication Services

With years of experience in sheet metal fabrication, we know that precision and efficiency are critical. Therefore, we use state-of-the-art equipment to handle a variety of custom sheet metal parts projects, from small customizations to large-scale production. Our goal is to help all industries get the exact sheet metal parts they need quickly, accurately, and with high quality.

Plasma Cutting

Punching

Stamping

Die Cutting

Bending

Welding

Extrusion

Embossing

Forming

Riveting

Waterjet Cutting

Laser Cutting vs. Waterjet Cutting

While laser cutting is one of the most effective methods for manufacturing complex, precision, two-dimensional parts, the process has some limitations, and certain design specifications are better suited to waterjet cutting. When choosing between laser cutting or waterjet cutting, it is important to consider the size of the part to be processed and, most importantly, the thickness of the material. For thicker metal cutting, waterjet cutting is the standard alternative to laser cutting due to its industrial-grade strength, precision, and power. Another major difference between laser cutting and waterjet cutting is cost. Laser cutting services tend to be more cost-effective for smaller parts and projects, while waterjet cutting services are more cost-effective for larger parts and projects.

Excellent Laser Cutting Service

We value working closely with our customers to ensure that each custom service meets their precise needs. By working together, we are able to accurately capture your vision and provide custom results that exceed expectations. This personalized service is essential to achieving perfect results. Therefore, choosing the right laser cutting service partner means not only focusing on advanced equipment, but more importantly, expertise, good service attitude and commitment to quality. Elimold only uses the most advanced laser cutting technology to ensure that each project is handled with the highest precision and meticulousness. We not only meet your expectations, but also strive to exceed your expectations and become your trusted partner for all your laser cutting needs. Let’s work together to create extraordinary things. Contact us today to start your custom project.

Request Your Free Laser Cutting Quote Today

After receiving your drawings, our engineers will analyze your custom Laser Cutting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.