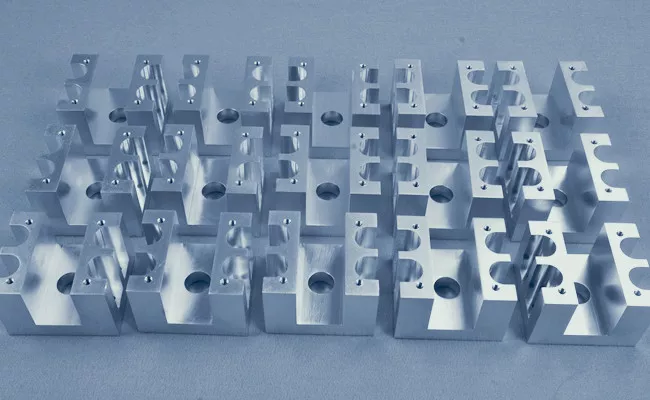

Low Volume CNC Machining

Elimold is a trusted industrial manufacturer that offers a wide range of CNC machining capabilities, with low-volume CNC machining being one of our specialty services. We offer a customer-centric, flexible approach designed to meet your unique project needs. Whether you require late-stage prototype production, short-run production, or a seamless transition to larger volumes, we prioritize craftsmanship, collaboration, and agility to ensure your specialized production goals are perfectly achieved. Contact us today for a free, instant quote.

Low Volume CNC Machining Manufacturer

Elimold introduces our latest Low Volume CNC machining solutions. With advanced equipment and a professional team, we are able to provide high-precision machining for small batch CNC part projects. Whether you need prototyping or small batch production, our Low Volume CNC machining services can meet your specific needs. With advanced technology and comprehensive quality control, we ensure that each product meets the highest standards. Our team is committed to providing efficient and economical solutions for small batch production, helping you save time and resources. At Elimold, we understand the unique needs of small batch custom parts production, so we are committed to providing tailor-made solutions for each customer. Believe that we are your trusted partner in the field of small batch CNC machining.

One-stop small batch CNC machining service

At Elimold, we can provide low-volume production services according to your requirements. With one-stop services from prototyping to low-volume production, we are able to realize the parts you want by transforming original designs into market products.

Our CNC machining services are ideal for low-volume custom parts production. Our advanced in-house factory has more than 30,000 square feet of production space and more than 200 CNC machines and experienced staff working 24/7, so we have strong production capacity and efficient CNC project support capabilities. Secondly, our CNC services cover milling, turning, EDM, lathe machining and surface finishing, all of which can handle complex low-volume parts. In addition, we can also provide a variety of metal and plastic materials. Even if you don’t need a large number of parts, you can reduce the overall cost. From estimation to final inspection, we always communicate with you and your team to ensure that your expectations are not only met, but also exceeded.

Rapid Prototyping

Elimold specializes in rapid turnaround prototyping and low-volume machining tasks, and continually improves component designs and specifications throughout the manufacturing process to achieve optimal precision. Our fully equipped machine shop, expert engineering knowledge, and extensive post-processing services enable us to complete prototyping and low-volume machining tasks for companies around the world faster and at more competitive prices than our competitors.

In addition, throughout the prototyping and low-volume machining process, our engineers and machinists, with their extensive industry backgrounds and decades of industry experience, provide in-depth hands-on support to improve prototypes and focus on the manufacturability of final component designs. This in-house expertise is critical to ensuring that initial designs exceed all customer specifications and guarantee an efficient and cost-effective full-scale production process. These experience-based recommendations have been proven to save our customers valuable time and avoid potential headaches in future production runs. Elimold is committed to integrating cost-saving measures at every stage of the manufacturing process and will make recommendations on designs immediately before final production runs based on feedback from early prototypes.

Prototype to Production

Once we have perfected your prototype, we can quickly turn these final designs into mass production, ranging from a few hundred to tens of thousands of pieces. To ensure consistent quality throughout the production process, our team can also design and manufacture any additional tooling that helps optimize the machining process. We follow strict quality control standards and procedures throughout the machining process from prototype to production, including documentation, inspection, and post-machining analysis. We continuously optimize machining centers and other precision instruments to ensure that all dimensions and tolerances meet customer specifications.

Similar to the prototyping process, we look for available opportunities during the final production process to further reduce the cost of future production while increasing production, turnaround time, and overall efficiency. With extensive experience in custom machined precision parts, we have the ability to machine precision parts for almost all industries. As a Chinese machining shop, we pride ourselves on quality products and are committed to reducing customer costs. From prototyping and low-volume machining to high-volume production, Elimold is the CNC machining shop of choice for manufacturers around the world.

Types of Small Batch CNC Machining

A number of CNC machining processes are compatible with small batch production. Certain capabilities are required to successfully achieve cost-effective, low-volume production. These include CNC milling, which allows for complex designs and tight tolerances, CNC turning for fast production speeds, subassembly for added value, and finishing processes that enhance product aesthetics.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Cost-Effective Low-Volume CNC Machining Solutions

We have the ability to meet our customers’ needs, no matter the quantity. Our experienced team is able to provide end-to-end custom CNC part solutions. We provide CNC machining services at the lowest cost. Our custom solutions drive production innovation, cost savings, supply chain optimization and reduced time to market. Whether you have one or a hundred thousand products, we will adjust the plan to meet or even exceed your delivery requirements the first time. We quickly set up and run your job using modular tooling concepts to ensure accuracy and repeatability in a cost-effective process. We create job packages with routing instructions and process inspection reports to control the quality of your parts.

Prototyping & Reverse Engineering Services

Customers trust us for reverse engineering designs because of our engineering expertise and reliable complementary services. We understand the tight timelines across industries and the cost savings that can be achieved by accelerating prototype production. That’s why, in many cases, we can produce prototypes from alternative materials to actual products within days of receiving the initial design or component to be reverse engineered.

If you already have a component design but need further assistance, such as optimizing dimensions, selecting the ideal material, or processing options, our team can work closely with you to finalize all the details. We may recommend alternative materials, modify the design to reduce processing time, or suggest different processing techniques to save costs and increase efficiency when the prototype enters final production. In addition to prototyping new designs, we can also reverse engineer existing components to achieve new features, experiment with new materials, or increase efficiency.

In addition, we understand the importance of confidentiality throughout the prototyping process. As part of our standard prototyping services, we regularly sign nondisclosure agreements (NDA) with our customers to build trust and protect their intellectual property.

Project Engineering Support Services

To help you optimize your design for lowest manufacturing cost and better component performance, Elimold offers comprehensive engineering support. This allows us to serve you from initial conception to final functional realization.

We perform Design for Manufacturing (DFM) analysis on your part design to ensure that the part is fit for purpose and economical after final production. Proper Design for Manufacturability (DFM) is essential to ensure an efficient production process. In low-volume CNC machining, incorporating DFM principles helps optimize the design. This can shorten lead times and reduce the need for adjustments during production. In addition, DFM ensures high-quality parts while minimizing waste.

Lead Times

Lead times for our low volume services vary by project. In most cases, batches of 50-5,000 parts can be completed or started within our standard 4-6 week lead time. Depending on the complexity of the part and expedited options, we can shorten or lengthen our standard lead time for a specific lead time. Whatever the lead time is, we will let you know at the time of your quote so you know when your parts will arrive.

Start Your Project Today

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations. Contact us for a competitive quote.

Different services to meet all your needs

Elimold stands out from many market competitors with the extremely wide range of processes it offers. Our skilled machinists, welders, assemblers and painters will work with you to ensure that your manufacturing and short-term production projects are completed smoothly and on time. At the same time, Elimold is also a convenient plastic and metal manufacturer, providing one-stop services from project review, manufacturing, inspection to shipment for small batch production. With a variety of services and one-stop services, we are able to manage your projects in a timely and cost-effective manner and meet your expectations and requirements.

Strong inspection capabilities and effective inspection processes

Our company has an excellent inspection team with well-trained and experienced inspectors focusing on batch product inspection. Coordinate measuring machines (CMM), 2D optical machines, digital calipers, height gauges, etc.

We are doing the first batch of products to ensure that the production is going smoothly and correctly. If there are any problems, the production will be stopped immediately. Our comprehensive inspection capabilities and production capacity help us provide customers with stable quality and competitively priced batch products CNC machining parts with fast delivery.

What is Low-Volume CNC Machining?

Low-volume CNC machining utilizes computer-controlled turning, milling, drilling, and other machining techniques to produce small batches of custom parts. Low-volume or low-quantity CNC machining is a manufacturing service focused on the rapid full production of finished products in small to medium quantities, typically between one and a few thousand pieces. It is an increasingly popular option for many product categories, allowing for faster time to market with less investment in tooling and materials, quick response to short product life cycles, and acting as a bridge between initial prototypes and high-volume production. It is an ideal solution for businesses that need to produce small batches before launching a new product, need to test market demand, or experience fluctuations in production demand. As the market demand for more custom products with shorter lead times grows, manufacturers must respond quickly to meet this demand and remain competitive.

Advantages Of Low-Volume CNC Machining

How can low-volume cnc machining help you and your business? Here are just some of the ways:

- Create a bridge between a few prototypes and full-scale production

- Reduce cost with no minimum order values

- Provide rapid access to emerging markets

- Respond quickly to shorter product life cycles

- Allow for faster design changes

- Lower financial exposure

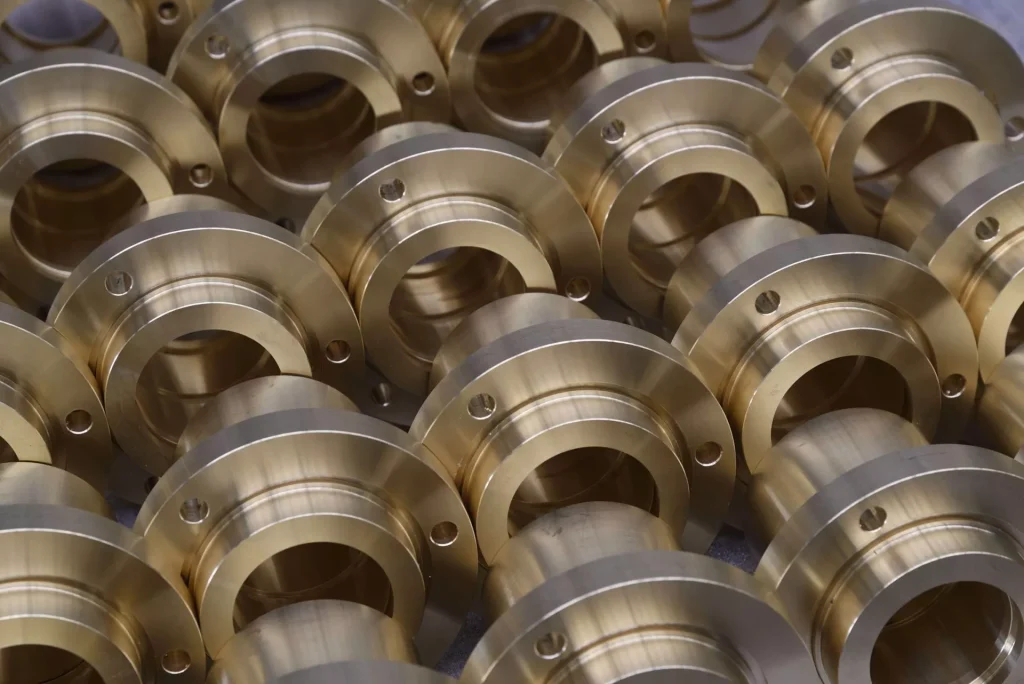

Small Batch CNC Machining Materials

Many different types of materials are compatible with small batch CNC machining. We offer over 70 materials, all scaled to ensure cost-effectiveness.

Metals

- Aluminum (1050, 5083, 6063, 6082)

- Stainless Steel (17-4 PH, 410, 420)

- Steel (A36, 4140, 1018, D2, O1, H13)

- Brass (C360, C260)

- Copper (C101, C110)

- Titanium (Grade 1, Grade 9)

- Magnesium (AZ31B)

- Inconel (625, 718)

- Bronze (Aluminum Bronze, Phosphor Bronze)

- Zinc Alloys (Zamak 3, Zamak 5)

- Nickel Alloys (Monel, Hastelloy)

Plastics

- ABS (Natural, Black, Flame-retardant grades)

- Nylon (PA6, PA66, Glass-Filled Nylon)

- Polycarbonate (Clear, Black, Flame-retardant)

- PEEK (Glass-filled, Carbon-filled)

- PTFE (Virgin, Glass-filled)

- Delrin (Acetal Homopolymer and Copolymer)

- HDPE (Black, Natural)

- PVC (Rigid, CPVC)

- UHMW-PE (Ultra-High Molecular Weight Polyethylene)

- PMMA (Acrylic, Impact-modified)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET, PETG)

- Polyetherimide (PEI / Ultem)

- Polysulfone (PSU)

Other Materials

- Carbon fiber reinforced polymers (CFRP)

- Glass fiber reinforced plastics (GFRP)

- G10, G11

- FR4 (Epoxy laminate)

- Micarta

- MACOR (Machinable Glass Ceramic)

- Alumina (Machinable grades)

- Steatite (Machinable ceramics)

- Bakelite

- MDF (Medium-density fiberboard)

- Plywood (for prototyping)

- Tooling board (Renshape, Ureol)

Types of low-volume CNC machining surface finishes

There are a variety of machining surface finishes available for low-volume CNC machined parts. Finishing is a critical process in low-volume CNC machining that can improve the aesthetics, functionality, and corrosion resistance of the product. The ideal surface finish for a particular part depends largely on its functional requirements. We can provide different types of machining surface finishes.

- Mechanical Finishing

- Sandblasting

- Polishing

- Brushing/Linishing

- Tumbling (Barrel Finishing)

- Chemical/Electrochemical

- Anodizing

- Electroplating

- Electroless Nickel Plating

- Passivation

- Phosphating

- Chemical Etching

- Black Oxide Coating

- Coatings

- Powder Coating

- PVD (Physical Vapor Deposition)

- CvD (Chemical Vapor Deposition)

- E-Coating (Electrophoretic)

- Spray Painting

- UV Coating

- Ceramic Coating

- Plastic-Specific

- IMD (In-Mold Decoration)

- Laser Marking/Engraving

- Vacuum Metallization

- Texture Molding (e.g. EDM)

- Other Treatments

- Laser Cleaning

- Heat Treatment (e.g. Tempering)

- Galvanizing

- Hydro Dipping

- Plasma Treatment

Alternatives to Low-Volume CNC Machining

Low-volume CNC machining may not be appropriate for certain applications due to the complexity of the part or the specialized tooling required to produce the part. In such cases, there are several alternatives to low-volume CNC machining, depending on the number of parts and the lead time required. These alternatives are listed and described below:

3D Printing

Small-Batch Injection Molding

Industries and Applications

- Automotive: Produces automotive parts such as engine parts, transmission parts, and chassis parts.

- Electronics: Produces a variety of electronic components such as housings, connectors, and heat sinks.

- Medical Devices: Produces a variety of medical devices such as implants, surgical instruments, and prostheses.

- Consumer Goods: Produces a variety of consumer goods such as electronics, toys, and home appliances.

- Defense and Military: Produces a variety of defense and military parts such as missile components, weapon systems, and armored vehicles.

- Jewelry: Produces high-end jewelry, creating intricate and delicate designs.

- Tooling: Produces tooling components such as molds, dies, and fixtures.

Request Your Free Low-Volume CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.