Low Volume Plastic Injection Molding

Elimold provides efficient and economical solutions for low-volume injection molding and mold making, ensuring fast turnaround and high-quality results. Don’t let mass production hold you back, our small batch production services provide precise customization, paving the way for you to create your own unique product.

Partner for Custom Low-Volume Injection Molding Services

If you are looking for a trusted partner in the field of custom low-volume injection molding, Elimold is the ideal choice. As an ISO-certified injection molding company, we always adhere to the standards of excellence. We use certified materials and our products are widely trusted in various industries. All manufacturing, assembly and packaging processes are meticulously carried out in ISO Class 8 clean rooms equipped with state-of-the-art injection molding equipment.

Elimold is known for its unwavering commitment to quality. We ensure that each product not only meets but also exceeds relevant industry standards through strict quality control. Beyond simple injection molding, Elimold provides holistic solutions. Our areas of expertise include product design, development, material consulting, mold manufacturing, injection mold design, and a range of complementary services. As a leading low-volume injection molding company, we have a reputation for our ability to custom injection molded parts and strictly adhere to various industry regulations.

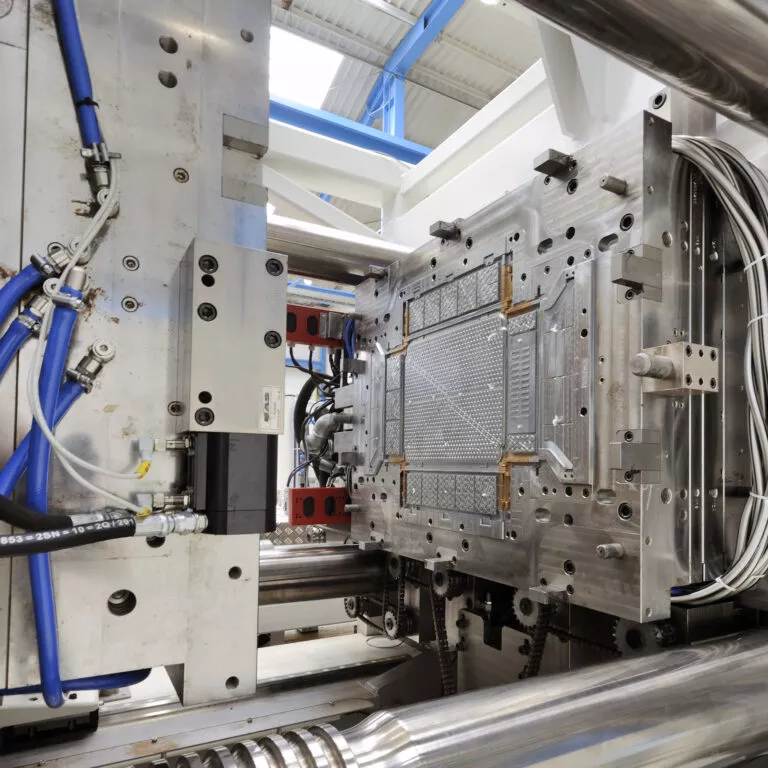

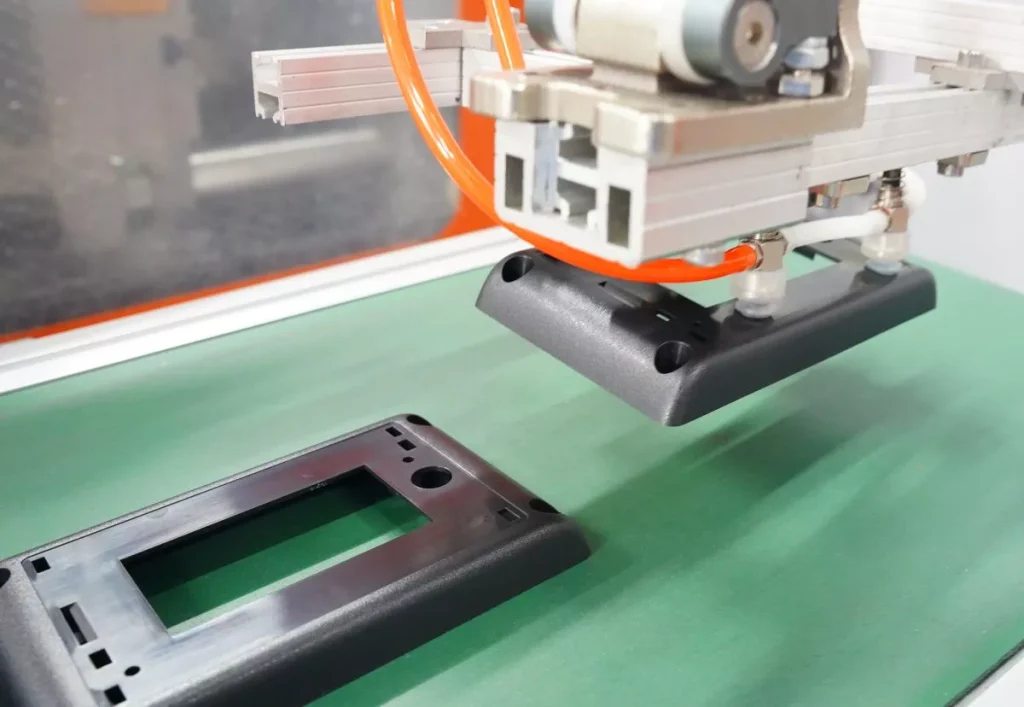

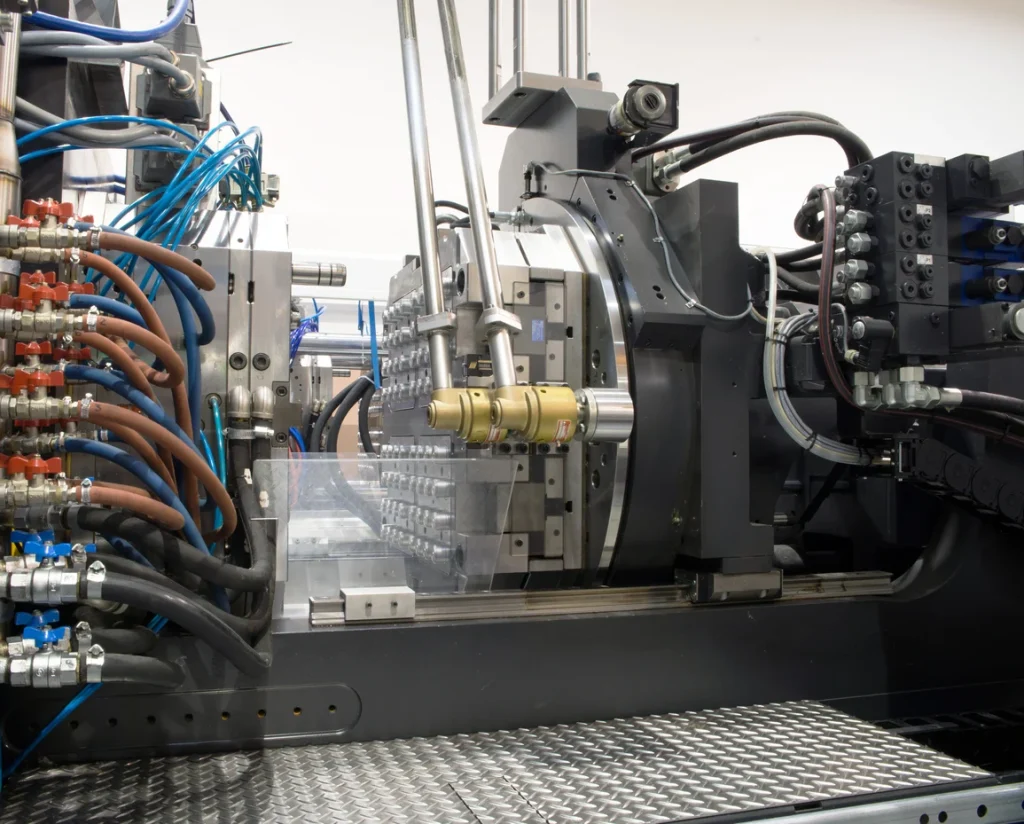

Elimold's In-House Injection Molding Facility Capabilities

Elimold is a full-service, low-volume plastic injection molding company that can help you take your project from the initial design stage through production. We have a dedicated, skilled, hardworking team that uses cutting-edge technology to create high-quality molds for the automotive and consumer product industries. We provide on-site design reviews and demonstrations, mold supply, and mold trial support for our customers. Our experienced engineers and machinists always adhere to the highest standards. The factory has a secure internet data sharing built in-house, and every effort is made to ensure that projects are completed on time.

Low-volume production is typically carried out in our 45,000 square foot mold and molding facility in Shenzhen, China. The facility has 150 injection molding machines with pressures ranging from 40 tons to 3300 tons. We are able to provide both low-volume and high-volume injection molding, and have the skills, knowledge, and experience to deliver exactly what you need, whether it is 10 or 1,000,000 plastic parts, and can scale up production as needed. To learn more about our low-volume production capabilities and plastic injection molding services, contact us today!

Our Services

Elimold offers a comprehensive range of services to support low volume production and assembly of plastic molded parts, including:

- Design Assistance: Our team of experienced engineers and designers works closely with clients to conceptualize and develop custom solutions that meet their specific needs and requirements. Whether you have a detailed design in mind or need assistance bringing your ideas to life, we’re here to help every step of the way.

- Prototype Development: We understand the importance of prototyping in the product development process. Our rapid prototyping services allow clients to test and iterate their designs quickly and cost-effectively, ensuring that the final product meets their expectations before moving into full-scale production.

- Low Volume Production: From small batches to limited production runs, we have the capabilities to manufacture plastic blow molded parts in low volumes with precision and consistency. Our flexible production processes enable us to adapt to changing requirements and deliver high-quality products on time and within budget.

- Assembly Services: In addition to production, we offer comprehensive assembly services to streamline the manufacturing process and reduce lead times. Whether it’s simple sub-assembly or complex integration of multiple components, our skilled assembly technicians ensure that every product is assembled to the highest standards of quality and craftsmanship.

- Quality Control: Quality is our top priority at Elimold We employ rigorous quality control measures at every stage of the production process to ensure that every part meets our exacting standards. From incoming materials inspection to final product validation, we leave no stone unturned in our quest for perfection.

Types of our injection molding services

As a premium low-volume injection molding company, we provide one-stop plastic molding services and produce a wide range of custom mold products. Our designers are highly skilled and have an ISO Class 8 cleanroom to reliably and cleanly produce custom plastic molded parts. We specialize in providing the highest quality custom plastic injection molding production as well as injection mold solutions for small and medium-sized companies in a variety of industries. Our products are manufactured by a scaled production facility and are offered with transparent and transparent pricing.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Ready to discuss your low-volume injection molding project?

Elimold can coordinate your entire mold manufacturing project from design to delivery. With its quality assurance system, our mission is to provide molded products that fully meet or exceed customer requirements and expectations. Company management is committed to continuous quality improvement. For superior quality and efficient low-volume molding services, contact Elimold’s professional team today for a free instant quote.

Cleanroom Custom Small Batch Injection Molding

Elimold can provide small batch cleanroom injection molding, and the in-house injection molding factory has a dedicated production workshop of more than 3,600 square meters, equipped with 30 advanced plastic injection molding machines. Our cleanroom is ISO 13485-2016 and CMA certified, and is praised by our demanding partners as “world-class” because the actual test results of our 100,000-class cleanroom exceed ISO Class 8, which is equivalent to ISO Class 7 cleanroom.

We regularly monitor temperature, humidity and air filtration to identify and eliminate sources of contamination, thereby ensuring part traceability and compliance. Strict control of equipment and procedure validation ensures that customer projects are executed with extremely high precision and repeatability. When manufacturing precision parts, injection molding companies must have a production environment that meets the relevant dust-free and sterile requirements. Therefore, as a precision custom component manufacturer, our investment in Class 7 and Class 8 cleanrooms has brought higher efficiency and a better environment, resulting in high-quality precision products at more competitive prices.

We provide one-stop low-volume injection mold manufacturing services

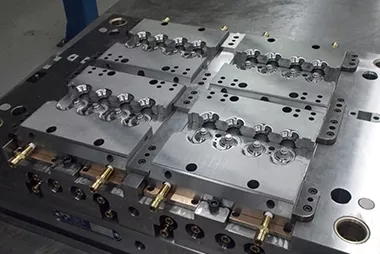

Elimold’s custom molds and low-volume molding cover all aspects from prototype to mass production. Our low-volume molds, whether short-run, small batch or multi-cavity molds, are monitored and controlled, so you can be confident in every aspect of mold design and manufacturing. Attention to production details ensures that goals, tasks and preset project results are completed as planned at every stage of the process. All low-volume molding, from design to manufacturing, is completed in-house and provides our customers with a competitive advantage in terms of cost, quality and delivery cycle.

Moreover, we can work with customers to design and manufacture products and develop the most efficient low-volume molds to achieve cost-effectiveness. We specialize in providing high-quality low-volume molds for the plastic injection molding industry and provide a wide range of services. From low-volume molding to insert molding and pad printing, Elimold is a brand you can trust for plastic injection molding services. We treat every cooperation as a partner, integrating years of plastic injection molding knowledge and technical expertise into our facilities designed to provide a comprehensive plastic injection molding experience.

Testing and Prototyping

Before moving to full production, it is important to conduct thorough testing and prototyping. This phase helps identify design flaws, evaluate functionality, and make necessary adjustments without incurring excessive costs. Rapid prototyping is essential in product development because it allows designs to be created and iterated quickly before mass production. This approach ensures that rapid prototypes are thoroughly tested and refined, resulting in a higher quality, better performing final product. In the world of low-volume injection molding, well-thought-out design is the cornerstone of successful and cost-effective production. By considering these design factors and working closely with your manufacturer, you can navigate the intricacies of part design and achieve the best results that align with your project goals.

DFM, Mold Feasibility Report

All injection molding projects are completed with a quick and detailed Design for Manufacturing (DFM) report highlighting all risks, areas for improvement, and recommendations. Once the report is approved, rapid mold production begins immediately with comprehensive in-process and 100% outgoing quality control (QC) checks. It is critical to follow Design for Manufacturability (DFM) principles. Work closely with the manufacturer to optimize the part design for the chosen molding technology. This requires considering factors such as draft angles, wall thickness, and undercuts to ensure smooth demolding and minimize defects. Well-designed parts not only increase production efficiency, but also improve the quality of the final product.

Quality Inspection and Management Process

When you use our low-volume injection molding manufacturing services, you will be able to indicate the dimensions in your part design that are most critical to the function of the part. By annotating these critical-to-quality (CTQ) features in your 3D CAD model, you can ensure that the parts you order are consistent with the model. In addition, it means that the next time you order these parts, we can follow these exact steps to manufacture consistent, repeatable parts that meet your CTQ specifications.

Inspection is a key part of this CTQ process. Therefore, our application engineering team will review your model and email you an Inspection Statement of Work (ISOW) to let you know if there are tolerance and moldability issues with the circled features. Once the ISOW is sent, we will produce and inspect your order as quickly as possible.

Once we have completed the molding process development, which ensures that we have a consistent and repeatable process to produce quality parts, we will inspect the first three shots of the tool using an automated coordinate measuring machine (CMM) and provide you with a three-part First Article Inspection (FAI) report and a 30-part process capability report.

Let's get started on your new project!

We provide you with custom small batch injection molding solutions, covering the entire process from design to mold, material selection and manufacturing. Contact our professional team now to solve your problems.

Low-volume injection molding service provider

Elimold is different from other prototype and low-volume injection molding production companies. We have the experience and equipment to provide unparalleled speed, flexibility and support. We apply our superior molding expertise to provide comprehensive technical guidance and mold selection for your project. We not only provide estimates for new projects, but also provide detailed quotes after understanding your needs. We pride ourselves on working closely with you from the beginning to ensure that the work specifications match your project goals. We also pride ourselves on speed, providing fast-delivery low-volume injection molding services without sacrificing quality and precision. We are constantly improving our production processes, adopting new methods, reducing inefficiencies, and shortening our customers’ lead times. Whether you need short-term production, rapid mold manufacturing or prototyping services, we can help you find the best solution and deliver it quickly and efficiently.

Low Volume Injection Molding Manufacturer

Whether you need a quick bridge tool to provide production parts during high-volume mold building or want us to provide production parts throughout the planning process, we have you covered. Our team is able to meet all necessary production requirements, such as CPK studies or PPAP certification. We perform process checks during production part runs to ensure consistency and reliability of identical parts. In addition to molding services, we also provide ready-to-use molds at our customers’ factories, which are manufactured to the customer’s mold standards. With Elimold’s in-house mold department, we are able to provide precision-made plastic injection molds in China that are highly reliable and have a long service life. We pride ourselves on speed and provide fast injection molding services without sacrificing quality and precision. We are constantly improving our production processes and adopting new methods to reduce inefficiencies and shorten our customers’ lead times.

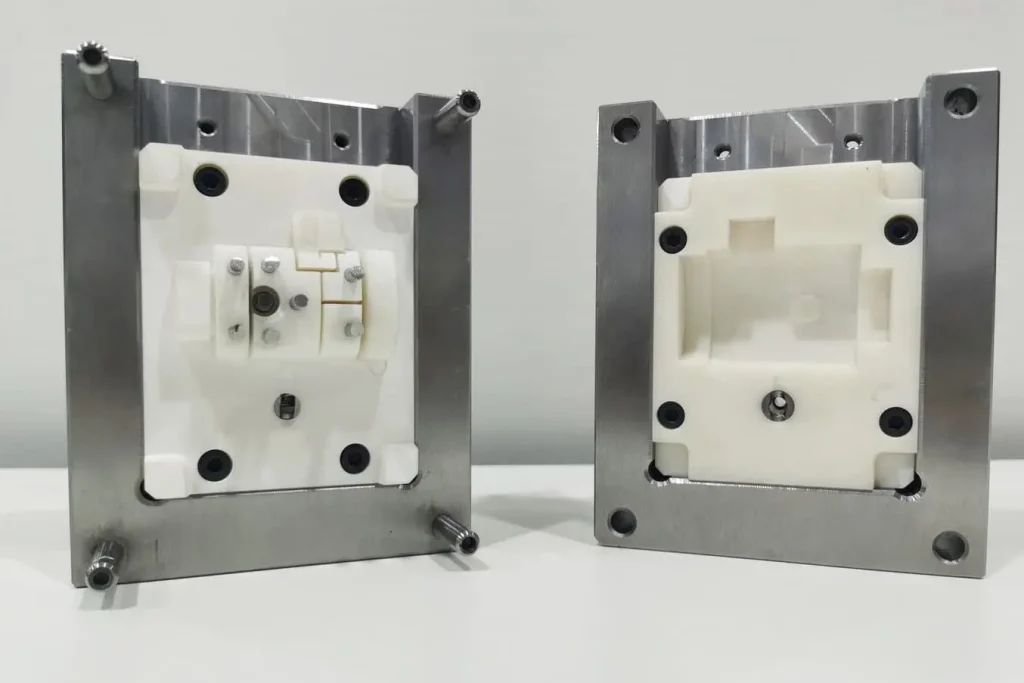

3D Printing Prototype Injection Mold

If you want physical samples of your plastic parts as quickly as possible, consider choosing Elimold as your rapid prototyping and prototype injection mold partner. We have the 3D printing capabilities to create and ship your products quickly and easily.

- Orders per part run of 50-10,000 shots; up to 100,000 annually. (Negotiable)

- Tolerances of +/- .005” standard; tighter tolerances per review of math data.

- Turnaround time of one day to four weeks per review of data, based on part size, geometry, and volumes.

- Geometric specifications of NC cut focus +/- .0005” with EDM and grinding to achieve tight tolerances. Undercuts, holes, clip details, etc. that are not in line of straight pull from mold may require action.

- Same day cost and part feasibility in most cases.

What Is Low Volume Injection Molding?

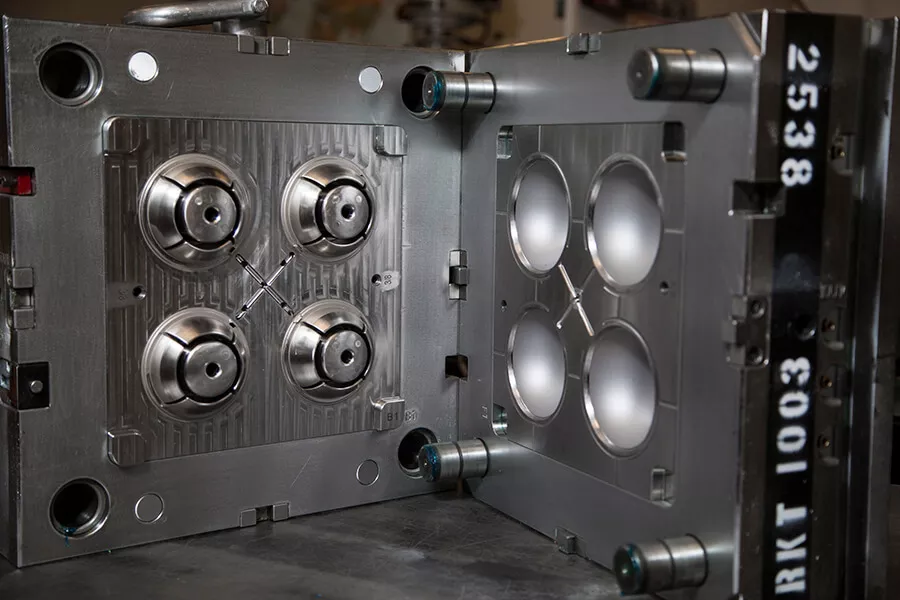

Traditionally, because of high tooling costs, injection molding is usually regarded as a manufacturing process for high-volume and mass-scale production. Injection molding is a popular method for manufacturing parts, but it’s not always economical or feasible for small-batch injection molding. That’s where low-volume injection molding comes into play.Low volume injection molding is a production process that is particularly suitable for short runs, typically in the range of hundreds to thousands of parts. It’s a cost-effective solution for projects that don’t require the high quantities often associated with traditional injection molding, which is typically optimized for runs of tens of thousands to millions of units.Low volume injection molding utilizes the same basic process as traditional injection molding: melting plastic or another suitable material, injecting it into a mold, cooling it, and then ejecting the finished part. However, it often uses different equipment or techniques to make it more suitable and cost-effective for small-run injection molding and small batch plastic manufacturing.

How to do low volume plastic injection molding?

Like the hardened steel mold production, low volume plastic injection molding requires a mold first, start with CAD design, and then CNC Machining, EDM, wire cut, polish etc. all processing ways used by building a hardened steel mold are adopted to make a mold for low volume production. Low volume plastic injection mold sometimes refer to rapid tooling or prototype tooling. To achieve cost effective, the mold use lower grates steel or aluminum, which don’t have to be withstand hundreds of thousands times of injection press as production mold. Molds made by pre-hardened steel or aluminum are capable of 10,000 to 100,000 molding cycles, this is enough for the needs of most of the low volume plastic injection molding. The manufacture process is shortened massively as the steel don’t have to be hardened, the workability of soft steel is also better than hardened steel, which make the processing is easier and faster.

Who Needs Low Volume Injection Molding?

Low volume injection molding is suitable for companies or individuals who need to produce small quantities of plastic parts. This could include:

- Startups: Startups typically have limited budgets and need to produce a small number of parts to test the market or validate their product design before investing in mass production.

- Small businesses: Small businesses may need to produce a limited number of parts for custom applications, and prototypes, or to fulfill small orders.

- Product designers: Product designers may need to produce a small number of parts to test their designs and ensure that they function as intended.

- Replacement part manufacturers: Companies that manufacture replacement parts may only need to produce a small number of parts to meet the demand for a specific product.

- Medical device manufacturers: Medical device manufacturers may require low volume injection molding to produce small quantities of custom parts or prototypes for testing and validation.

- Aerospace and defense companies: Aerospace and defense companies may need to produce small quantities of specialized parts for military or space applications.

Why you need low volume plastic injection molding?

In a fast-paced market, it is critical for a company to get new custom products into the market quickly, in most of the cases, it could be just a market-testing product with 10,000 units’ volume or even less. But the plastic parts still need to be customized by injection molding to achieve the specified tolerance, finish, function. Traditionally, a hardened steel injection mold would requires a very high investment before you get a piece of sample, and it usually take 8-12 weeks to complete, which are unacceptable for a new product developing at the earliest phrase.

We need a solution to reduce the cost of injection molding and shorten the lead-time of for companies to launch new custom plastic products. Low volume plastic injection molding is what you are looking for, which means low cost, quick turn around and on budget.

Material Options

Elimold can manufacture small quantities of parts using a wide range of materials. The choice of material depends on the end use, production method, desired surface finish, and the number of parts to be manufactured. Each material offers specific properties such as mechanical strength, corrosion resistance, and a high strength-to-weight ratio.

- Acetal polyoxymethylene (POM)

- Nylon 66 (PA66)

- High-density polyethylene (HDPE)

- Polybutylene terephthalate (PBT)

- Glass-filled polycarbonate (PC-GF)

- Polyethylene terephthalate (PET)

- Polyphenylene sulfide (PPS)

- Polystyrene (PS)

- Thermoplastic elastomer (TPE)

- Acrylonitrile butadiene styrene (ABS)

- Glass-filled, polyamide (PA-GF)

- Low-density polyethylene (LDPE)

- Polycarbonate (PC)

- ABS polycarbonate (PC-ABS)

- Polymethyl methacrylate (acrylic) (PMMA)

- Polypropylene (PP)

- Polystyrene + polyphenyl ethers (PS-PPE)

- Thermoplastic vulcanizates (TPV)

Finishing Options

For low-volume injection molding production, a variety of finishes can be applied to enhance the aesthetic, durability, and performance of your parts, ensuring they meet your exact specifications.

- Polished Finish

- Matte Finish

- Textured Finish

- Glossy Finish

- Bead Blasting

- Anodizing

- Powder Coating

- Electroplating

- Chroming

- Painting

- Silk Screening

- Laser Engraving

- Vibratory Finishing

- Heat Treatment

- UV Coating

- Sanding/Grinding

Industries We Work With

- Aerospace

- Automotive

- Defense

- Industrial equipment

- Marine and offshore

- Oil and gas

- Architecture & Construction

- Industrial design & Manufacturing

- Medical & Life Sciences

- High Tech & Consumer

- Industrial Products, Mold Toot & Die

Low-volume Injection Molding Applications

Elimold is your concept-to-production partner for all your high-mix, low-volume injection molding needs. Advanced technology, proprietary processes, and our highly qualified and talented team help us deliver products of exceptional quality.

- Enclosures for electronic devices

- Medical device housings

- Automotive interior components

- Aerospace brackets and clips

- Consumer product casings

- Custom connectors

- Wearable device parts

- Small appliance components

- Lighting fixtures and bezels

- Industrial equipment covers

- Display bezels

- Protective covers

- Custom seals and plugs

- Custom packaging inserts

- Laboratory testing components

- UAV/drone housings

- Tool handles and grips

- Cosmetic packaging

- Sports and fitness equipment parts

- Camera housings and accessories

- Hearing aid components

- Specialty plumbing parts

- Control knobs

- Charging docks

- Toy components

- Remote control shells

- Key fobs

- Sensor housings

- Switch casings

- Battery holders

- Mounting brackets

- Cable management clips

- Grommets and bushings

- Small gears and sprockets

- Fluid reservoir caps

- Ventilation louvers

- RFID tag enclosures

- Prosthetic components

- Diagnostic device shells

Request Your Free Low Volume Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Low Volume injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.