Low Volume Production

Looking for a low-volume production solution that fits your needs? Elimold offers a range of services to meet your needs, from low-volume parts to mid-volume production. Tell us your goals and we’ll guide you through the various processes and determine the best fit for you! From 3D Printing, Additive Manufacturing, Vacuum Casting, Injection Molding, CNC Machining, Metal Stamping to Rapid Prototyping, we’re sure to find a solution that fits your budget, timeline, and production requirements!

Low-volume production service provider

Are you looking for a manufacturer that can produce small batches (tens to thousands of parts)? If you are looking for low-volume production, Elimold is the place for you. Many third-party manufacturers tend to avoid low-volume production in favor of long-run production of relatively simple geometries, but Elimold’s overall focus is to support customers from early prototyping and transition production to low- to medium-volume production.

We specialize in the production of low-volume, high-mix custom parts, with a focus on helping our customers move their part designs from early prototype concepts and rapid prototyping to bridge and full production. During this process, our experienced engineers make recommendations on manufacturing methods, materials, and processes to ensure that your parts can be produced reliably and cost-effectively. They always keep the end goal in mind and make improvement recommendations that can be effectively implemented throughout the product life cycle.

One-Stop Shop for All Your Machining Project Need

When designers, engineers, and businesses think about product development, many consider prototyping and mass production as the primary goal. But sometimes, for those who need a small number of finished parts (from a few hundred to a few hundred thousand), low-volume production is the best option. By using a professional prototyping and manufacturing service like Elimold, our customers are able to get the exact number of parts they need, no matter what the final quantity may be.

At Elimold, we’ll help you every step of the way, from initial product design review and quote to quality inspection of newly manufactured parts. In addition to specializing in prototyping and high-volume production, we’re experts in low-volume production. Contact our team of experts today for a free project evaluation and initial quote. If you need a prototype to validate your design first, check out our rapid prototyping services.

Our Services

Elimold offers a comprehensive range of services to support low volume production and assembly of plastic molded parts, including:

- Design Assistance: Our experienced team of engineers and designers work closely with our customers to conceive and develop custom solutions that meet their specific needs and requirements. Whether you already have a detailed design or need assistance turning your idea into reality, we are here to help you every step of the way.

- Prototyping: We understand the importance of prototyping in the product development process. Our rapid prototyping services allow customers to quickly and cost-effectively test and iterate designs, ensuring the final product meets their expectations before going into full production.

- Low-volume production: From small batches to limited production runs, we can produce custom parts in small batches with precision and consistency. Our flexible production processes allow us to adapt to changing needs and deliver high-quality products on time and within budget.

- Assembly Services: In addition to our production services, we also offer comprehensive assembly services to streamline the manufacturing process and reduce lead times. Whether it is a simple sub-assembly or a complex integration of multiple components, our experienced assembly technicians ensure that each product is assembled to the highest standards of quality and workmanship.

- Quality Control: At Elimold, quality is our top priority. We use stringent quality control measures at every stage of the production process to ensure that every part meets our stringent standards. From incoming material inspection to final product verification, we strive for perfection.

On-demand low-volume production in as fast as 24 hours

Our specially designed low-volume production services provide customers with hundreds to thousands of multi-purpose parts. Elimold can simplify and accelerate your rapid prototyping product development cycle. With an average lead time of 24 hours, we can produce the specified number of parts you require for market access, consumer testing, and transition to mass production.

Our digital capabilities, cross-manufacturing technologies, instant quotation system, strong material selection and finishing services are all part of our competitive advantage. Partnering with Elimold, you will stay ahead of the competition, shorten production time, and be ready to market in days! Contact us today with your 3D CAD file to get a free quote here.

Full range of low volume solutions

Elimold is able to provide the right manufacturing process services for your project. Low-volume, high-mix is our main manufacturing focus, and through innovative engineering, we can provide the right solution for your project size. Our unique advantages allow us to enter the market at the lowest cost and flexibly expand your project when needed. And the right size allows us to bring products to market faster with lower capital expenditure. Our low-volume production services provide the most direct solution from start-up to part delivery. Our ISO 9001:2015 quality team is ready to provide PPAP and 100% inspection plans for all projects. Quality concepts are integrated throughout the engineering design stage of each component and verified during the production process. In addition, our flexible production space can accommodate lightweight assembly equipment and modular units. We provide full-set assembly assistance for your project, including welding, gluing, heat staking and custom packaging. Our contract manufacturing team has extensive experience in the entire product delivery process from the engineering stage to the sales cycle. Our experience will provide guidance and support to your team throughout the project life cycle.

Lead Time Capabilities for Low Volume Services

Lead times for our low volume services vary by project. In most cases, batches of 50-5,000 parts can be completed or started within our standard 4-6 week lead time. Depending on the complexity of the part and expedited options, we can shorten or lengthen a specific lead time beyond our standard lead time. Whatever the lead time is, we will let you know at the time of your quote so you know when the part will arrive at your dock.

One-stop Low-volume Manufacturing Solutions

As demand for low-volume production continues to grow, Elimold excels at producing everything from a single part to over 1,000 parts with unmatched precision. Whether you need a custom, high-quality one-off product like a trophy, or thousands of custom parts like widgets, we can provide you with a tailored solution to meet your unique needs. Our low-volume manufacturing services can help you streamline operations, increase efficiency, and support your business goals.

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Manufacturing Tolerance Levels

At Elimold, we understand that custom parts, whether prototypes or small series, must not exceed certain dimensions, so we ensure that a wide range of tolerances are applied, depending on the customer’s requirements. We understand that tight tolerances are not always a good thing, so we leave it up to the customer to decide how much tolerance to use, and we try to be as precise as possible.

Our minimum accuracy is 0.01 mm, and the maximum accuracy is up to the customer’s requirements. Factors such as thermal expansion and contraction, vibration and wear can affect the accuracy of a part, so the accuracy is entirely dependent on the customer’s needs, and we ensure that the accuracy is maintained at the level required by the customer.

Low Volume Production of Prototypes

Prototyping goes hand in hand with low volume production because they allow companies to try out small batches of products before placing large orders. This way, designs can be continually improved and modified, and products can be tested in small quantities before mass production.

Elimold understands the challenges at each stage of the product lifecycle and provides corresponding value-added services throughout the product development process. As a design company, Elimold is committed to deploying the right design capabilities from the beginning to facilitate a smooth transition from prototype development to production. As a production company, Elimold uses close links with the technical teams responsible for initial development work to ensure that any unexpected problems in the production process can be quickly and effectively resolved by the team responsible for developing parts and tools from the beginning.

If your goal is high-volume, low-cost production, we are ready to meet your initial production needs, and our engineering team will help you prepare for optimized part design and manufacturability analysis. All of our assembly and measurement equipment is calibrated to ISO/IEC 17025 or equivalent standards, and production work follows our ISO 9001 quality processes.

Product Improvements Under One Roof

In addition to providing high-quality production, Elimold is well-positioned to conduct product development in parallel with ongoing production. The involvement of the engineering team throughout the product development cycle provides an excellent opportunity to incorporate design improvements into existing lines, or to gain additional insights for future product development and upgrades. We will work with each customer to apply the valuable experience accumulated from one product in the same series to the next, adding additional value to each development effort.

Low Volume Services Provide Traceability of Project Processes

Elimold works with each customer to understand the traceability applicable to each product, thereby optimizing production costs based on the needs of each product. We have extensive experience in developing the necessary processes for critical certifications, such as FAA certification or certification of aerospace hardware. Our standard production process includes the use of work instructions and travel records to document the manufacturing process. Such documentation can be completed at the final unit level, or, if applicable, we can provide batch traceability of all sub-assemblies and even traceability to material certification of each component to enable any necessary root cause analysis of returned parts.

Quality Management and Inspection

Elimold always puts quality first. We adhere to strict quality control measures throughout the production process to ensure that each product meets the highest standards of excellence. From material selection to final inspection, we always follow strict quality assurance procedures to ensure that custom parts meet design standards.

Our inspection and testing are also very strict, and the inspection equipment includes coordinate measuring machines (CMM), 3D scanners, calipers, inclinometers, micrometers, pin gauges, hardness testers, etc. We also perform assembly tests according to customer requirements to meet customer needs. Elimold is committed to providing you with the best customer experience and qualified products that meet ISO 90001 and ISO 13485 standards.

Send us your 3D file. Tell us what you need. We'll deliver your parts on time

Ready to work with Elimold for your low-volume production and assembly needs? Contact us today to learn more about our services and how we can help you realize your vision. With our commitment to excellence, advanced technology, and personalized service, we know we can exceed your expectations and help your business grow.

What is low-volume manufacturing?

Low-volume manufacturing is a professional service that provides production-quality parts, but in batches ranging from a single unit to thousands. It is ideal for advancing ideas from the concept stage to the prototyping stage, and as a bridge to mass production at this stage.

Low-volume manufacturing is considered a professional service because most manufacturers prefer not to do it. Their assembly lines and supply chains are optimized for high-volume production to take advantage of economies of scale. There is nothing wrong with this approach per se, as it is the best way to ensure the lowest per-unit cost. However, it often requires large minimum order quantities and expensive tooling. But if a product developer wants to start with low-end product quantities, from 1 part to 1,000 parts, how can they do that? This is exactly where Elimold can help.

How to do low volume production

What is the secret to successful small batch production? Does the raw material type, processing method or finished product quality make a difference? Our customers care that small batch production does not mean a compromise in quality or precision compared to large batch production. Rest assured that we use the same materials, the same equipment and apply the same strict quality control measures when processing small batch orders.

How do we do it? We are experts in high-mix, small batch production because our systems are optimized and highly scalable, from a single part to millions of parts. This means that we have a strong supply chain for raw materials, so you don’t have to bear the burden of minimum order quantity restrictions. In addition, we have a digital manufacturing platform that integrates all the equipment in our internal factories into a single network. This allows us to quickly and efficiently allocate resources between various work centers, so that even complex orders can be processed quickly.

Advantages Of Low-Volume Manufacturing

Are you wondering how low-volume manufacturing can help your product go from concept to completion? How can low-volume manufacturing help you and your business?

- By producing a small-run of parts or products, you will gain rapid access to emerging markets before the competition.

- Compared to full-scale production, low-volume manufacturing will reduce the cost of tooling without requiring any minimum orders.

- Low-volume manufacturing enables you to shorten overall production lead times, saving you time and energy when it comes to product development.

- If there’s an encounter with shorter product life styles, low-volume manufacturing allows you to respond quickly and iterate parts in a more optimal way.

- Lower exposure to unnecessary financial expenditure, keeping you from breaking the bank on high-volume production.

- Lastly, the quick turnaround that comes with low-volume manufacturing also allows for faster design changes, reducing costs and overall production time.

Material Options

Elimold has a reliable source of raw materials and is committed to providing products that meet your designs and specifications. We continuously improve production management, process optimization, supply chain cooperation and cost control, and strive to improve customer satisfaction with fast, efficient and competitive prices.

Metals

- Aluminimu

- Stanless Steel

- Copper

- Zinc

- Magnesium

- Alloy Steel

- Soft Steel

- Brass

- Titanium

- Inconel

- Steel

- Bronze

- Brass

- Titanium

- lron

- Magnesium

Rigid Plastics

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate (PC)

- Polymethyl methacrylate (acrylic) (PMMA)

- Polypropylene (PP)

- Glass-filled, polyamide (PA-GF)

- Acetal polyoxymethylene (POM)

- Low-density polyethylene (LDPE)

- Polyolefin Elastomer (POE)

- Customer-supplied materials

- Glass-filled polycarbonate (PC-GF)

- Thermoplastic elastomer (TPE)

- Custom-sourced Resins

- Polystyrene + polyphenyl ethers (PS-PPE)

- Polybutylene terephthalate (PBT)

- Thermoplastic vulcanizates (TPV)

- Polyphenylene sulfide (PPS)

- High-density polyethylene (HDPE)

- Thermoplastic polyurethane (TPU)

- Nylon 66 (PA66)

Flexible Plastics

- Flexible Plastics

- PC-ABS

- Flexible polyurethane (FPU)

- Polyethylene (PE)

- Polyethylene terephthalate (PET)

- ABS polycarbonate (PC-ABS)

- Low-density polyethylene (LDPE)

- Polystyrene (PS)

Other Materials

Sunthetic Rubbers

- Thermoplastic elastomer (TPE)

- Thermoplastic vulcanizates (TPV)

Silicone Rubbers

- Liquid Silicone Rubber

Bio-Chemicals

- Zinc

- Silicone

Rubber-Like Plastics

- Silicone

- Elastomeric polyurethane (EPU)

Surface Finishing Options

At Elimold, we offer a number of post-processing solutions like surface treatment and finishing to help perfect the look, feel and performance of your parts. No matter the minimum order, we strive to deliver perfection. This includes ensuring the highly precise finishing of all final products.

- Standard

- Brushing

- Polishing

- High Gross Polishing

- Bead Blasting

- Painting

- Tinting

- Anodizing

- Soft-touch Painting

- Crome coating

- Logo & Symbols

- Powder Coating

Industries We Serve

Elimold has been committed to helping companies around the world meet their low-volume production needs. We have completed thousands of projects and are proficient in matching the best technology and materials for each project. We have provided low-volume production services for the following industries:

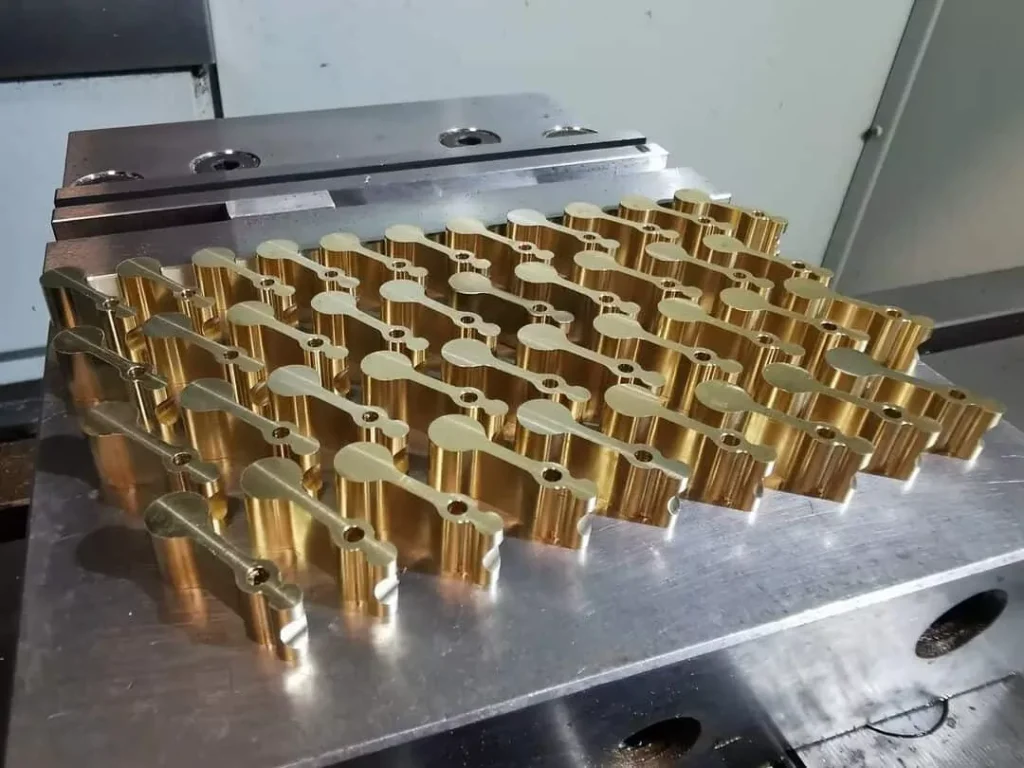

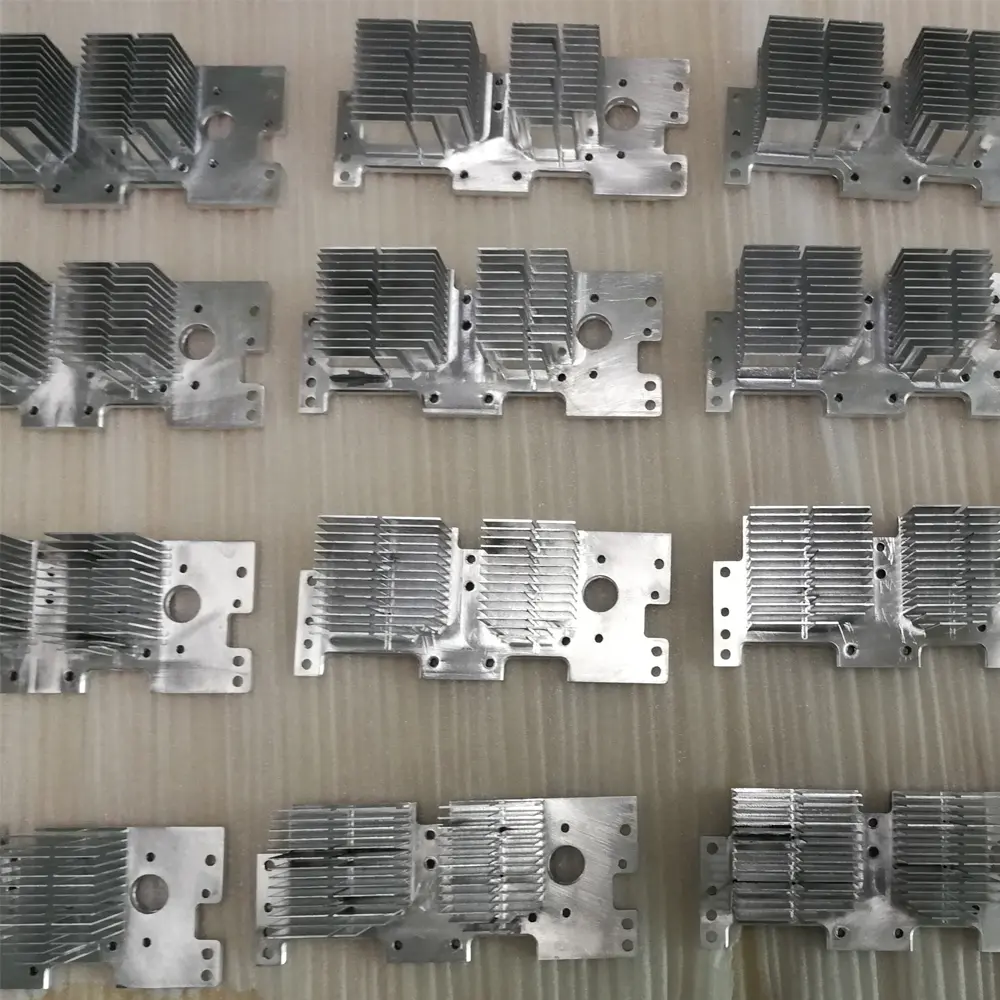

Unlimited Capacity and In-House Production

As a specialist low-volume manufacturer, we support your upcoming pre-production schedule by manufacturing high-quality, precision-machined custom parts. Whether you require production-grade plastics, various metals or custom aluminum machined parts, we can manage any machining project for you, from prototypes to low volumes.

- Brackets

- Housings

- Panels

- Gears

- Enclosures

- Mounting plates

- Frames

- Bushings

- Flanges

- Manifolds

- Connectors

- Covers

- Casings

- Clips

- Clamps

- Handles

- Shafts

- Couplings

- Seals

- Spacers

- Caps

- Valves

- Base plates

- Heat sinks

- Guides

- Hinges

- Locks

- Sleeves

- Plates

- Rods

- Nuts

- Bolts

- Studs

- Washers

- Dowels

- Rings

- Wheels

- Pulleys

- Nozzles

- Tubes

Request Your Free Low-Volume Production Quote Today

After receiving your drawings, our engineers will analyze your custom parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.