Magnesium CNC Machining

Elimold offers professional CNC machining services for magnesium alloys, suitable for prototyping and mass production. We provide expert service, fast delivery cycles, high-quality surface finishes, and precision custom parts.Get instant quotes, fast lead times, and competitive pricing.

Precision Machining Magnesium Alloy Component Supplier

Elimold is renowned for its successful machining of metals that other manufacturers are unwilling to handle. Customers can confidently design with new materials, knowing that Elimold can process even the most specialized materials, such as magnesium, to achieve high-quality and cost-effective solutions.

We enjoy a prestigious reputation in the industry as a world-class supplier of precision-machined magnesium alloy components. Few companies possess as much knowledge and industry experience in magnesium alloy machining as Elimold. Over the years, with this experience, Elimold has developed proprietary processes to ensure maximum operator safety when machining these highly flammable materials.

Customized Magnesium Alloy Parts Solutions

We excel at solving complex engineering challenges for OEM clients, leveraging our extensive OEM-level experience to provide innovative and cost-effective solutions. We focus on advanced thixotropic forming technology to produce high-quality magnesium alloy parts with near-net-shape accuracy, superior material properties, and lightweight advantages. Therefore, whatever the requirements of your specific project, our safety record is impeccable. This means that as our client, you can have complete peace of mind that your products will be launched on time, without delays caused by unforeseen circumstances. We are experts in this field and always prioritize safety.

Our Magnesium Machining Safety Measures

We strictly adhere to safety procedures when machining magnesium alloys. Our proven machining methods ensure the safety of all personnel. Our safety systems include:

- A Class D fire suppression system using Met-LX extinguishing agent to extinguish magnesium fires

- Explosion-proof vacuum cleaners for the safe collection of discontinuous chips

- A non-water-compatible coolant compatible with magnesium (water reacts with magnesium to produce hydrogen gas)

- Dry machining using compressed air cooling

- CNC programming for safer chip formation

- Thermal monitors to detect heat buildup

- Separate storage areas for materials

What is Magnesium?

Magnesium is a chemical element with the symbol “Mg,” atomic number 12 in the periodic table. It is a silvery-white alkaline earth metal, somewhat similar in appearance to aluminum, and is a solid with a relatively high density at room temperature. It is the eighth most abundant metal on Earth, covering approximately 2.4% of the Earth’s crust. With a density of only 1.74 g/cm³, magnesium is considered the lightest structural metal on Earth. Magnesium consists only of magnesium atoms, each with 12 protons in its nucleus, each surrounded by a corresponding number of electrons.

Furthermore, its melting point is 1202°C (2196°F), and its boiling point is 2477°C (4491°F). Like other metals with the same structure, magnesium exhibits poor ductility during low-temperature processing. Interestingly, pure magnesium lacks sufficient strength for most structural applications. Therefore, magnesium is often alloyed with other elements to improve its mechanical properties, making it an ideal choice for lightweight, highly durable materials. Magnesium alloys are primarily composed of magnesium, supplemented with other elements such as aluminum, zinc, manganese, cerium, and thorium. These alloys are favored by various industries due to their corrosion resistance, thermal conductivity, and ease of processing into complex shapes.

Magnesium Alloy Types Suitable for CNC Machining

When machining magnesium alloy parts, selecting the appropriate material is crucial for achieving optimal performance and machinability. Elimold commonly uses the following magnesium alloy grades:

Magnesium Alloy AZ61B

AZ61B is a wrought alloy offering higher strength than AZ31B, with good corrosion resistance and moderate ductility. Suitable for forging, extrusion, and machining, it delivers excellent mechanical performance for mid-load structural parts. AZ61B is commonly used in aerospace, sporting goods, and transportation applications requiring strength with reduced weight.

Magnesium Alloy AZ31B

AZ31B is a highly formable wrought magnesium alloy known for its excellent machinability, ductility, and weldability. Often used in sheet and plate form, it is ideal for applications requiring lightweight, thin-walled structures. AZ31B is widely used in aerospace, electronics, and prototyping thanks to its easy machining and well-balanced strength and formability.

Magnesium Alloy AZ91D

AZ91D is a widely used die-cast magnesium alloy, primarily composed of aluminum and zinc. It offers an excellent strength-to-weight ratio and is highly castable. It provides good corrosion resistance and a smooth surface finish, making it ideal for high-volume manufacturing. It’s commonly used in automotive housings, power tools, and consumer electronics that demand lightweight and precise performance.

Magnesium ZK60A Alloy

Magnesium ZK60A is machinable but flammable. Lubricants and fire kits are essential during machining. It’s popular in aircraft parts such as brake housings, landing gear, and instrument bodies.

High-Quality Magnesium Alloy Machining Services

Our in-house factory is equipped with advanced CNC lathes and milling machines (5-axis CNC machining centers), employing cutting-edge machining technologies to perform a variety of machining operations including turning, milling, drilling, and boring, ensuring high-precision machining. We can meet the manufacturing needs of a wide range of projects, from simple batch production to high-precision machining of complex parts. Leveraging Elimold’s expertise in magnesium alloy machining, our experienced team will provide tailored support and clear communication to meet your specific needs and achieve outstanding results.

Various CNC Machining Methods for Magnesium Alloys

CNC machining methods can effectively cut magnesium alloys and manufacture a variety of parts suitable for different applications. Below are various CNC machining processes provided by Elimold.

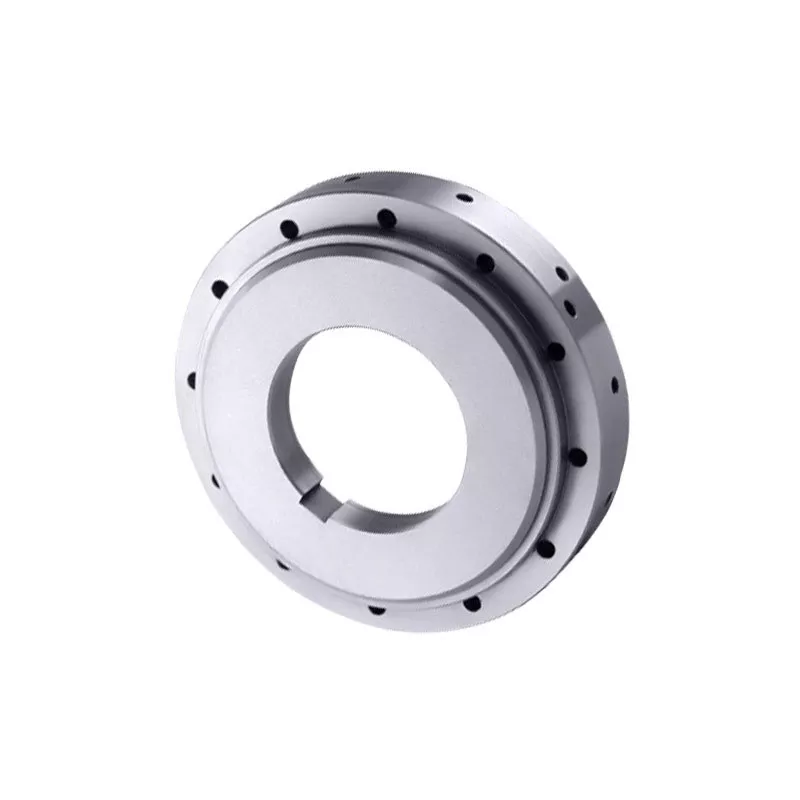

Magnesium CNC Parts

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Rapid Prototyping of Magnesium CNC Parts

Using professional CAD/CAM software and machine tools, we can produce highly complex non-standard parts in a very short time (rapid prototyping) based on the technical data provided by our clients. Because Elimold has extensive experience in magnesium machining, we can produce rapid prototypes of magnesium parts weighing up to 100 kg, and deliver products quickly after you place your order, while ensuring product quality and competitive pricing. We accept orders in vector file (2D, 3D) and technical drawing formats.

Our Magnesium Alloy CNC Machining Capabilities

With years of experience in magnesium alloy machining, Elimold possesses extensive expertise in this field. We can machine parts up to 1000 mm (39.4 inches), 500 mm (19.7 inches), and 400 mm (15.7 inches) in size, with a machining accuracy of +/-0.01 mm (0.0004 inches). For more information about our machining capabilities, or to request customized magnesium alloy turning and milling services for your project and a quote, please contact us today. Most quotes will be responded to within 4 hours.

Mass Production of Lightweight Magnesium Alloy Parts

For high-volume CNC machining of magnesium alloy parts requiring numerous machining operations, we design and manufacture customized processes for our clients’ projects, significantly reducing cycle time and optimizing costs. Our machining equipment is specifically designed for magnesium alloy machining processes and adheres strictly to necessary safety measures to provide a safe and reliable machining process.

Moreover, no one manufactures lightweight parts like us. At Elimold, we are experts in CNC machining of magnesium alloys, producing parts that are 33% lighter than aluminum alloys and have an excellent strength-to-weight ratio. Our workshops are equipped with professional safety systems and combined with precision multi-axis CNC machining technology to ensure that we provide you with everything you need.

Elimold has earned the trust of numerous clients with extremely high requirements for component quality and compliance with stringent standards through its outstanding reputation in magnesium alloy product manufacturing. Safety is our uncompromising principle, permeating every aspect of our work.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order, we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

Magnesium Alloy CNC Machining Experts

We have a professional team of engineers who can provide you with a one-stop service for metal processing, answering all your questions about processing and production. We can guide you throughout the entire process, from selecting suitable materials to design improvements, machining, surface treatment, and inspection. Once you send us your CAD files, we immediately begin collaboration until every part perfectly meets your specifications. No matter what kind of personalized design you require, Shenzhen Ronghua Machinery is dedicated to providing you with customized metal processing services.

Quality Management

Quality and reliability are core principles of our processes. All components undergo dimensional and visual inspections, and additional hardness or metallographic testing can be provided upon request. We have an ISO-certified quality management system and provide first-article inspection reports and certificates for all supplied materials. If the results do not meet your requirements, we will continuously improve until they fully comply. In addition to strict production process control, all components must undergo thorough final inspection. We possess coordinate measuring machines, salt spray test chambers, profile projectors, and other precision instruments. All tests are conducted in a temperature-controlled testing chamber at 20 degrees Celsius, and the coordinate measuring machine is calibrated. Compliance with GB/T 16857.2-2006 (ISO10360-2:2001) standards. All parts and subassemblies are 100% inspected. Labels can be affixed upon request, and final inspection reports related to all critical dimensions can be generated.

Surface Finishes For CNC Machined Magnesium Parts

Elimold offers a variety of surface treatment options for your CNC-machined magnesium alloy parts, each with its own unique advantages. Please choose the option that best suits your needs!

As Machined

Anodizing

Brushed Finish

Sand Blasting

Heat Treatment

Teflon Coating

Black Oxidize

Electroless Plating

Electroplating

Painting

Powder Coating

Electrophoresis

Tumbling

Alodine

Electropolish

Passivation

SPI Finish

Challenges of Machining Magnesium Alloy Parts

Due to the high risks associated with machining magnesium parts, only a few suppliers offer magnesium machining services. This is primarily because magnesium shavings are easily ignited by sparks during machining and burn at high temperatures. Therefore, machining lightweight materials like magnesium requires specialized techniques and suitable equipment. We are able to achieve machining precision up to IT 6 while strictly adhering to safety standards. Furthermore, we are equipped with fire suppression systems featuring emergency circuits to handle emergencies.

Significant Advantages of CNC Machining of Magnesium Alloys

Despite the numerous risks involved in manufacturing magnesium alloy parts, CNC machining of magnesium alloys offers several advantages. Magnesium is easy to machine, allowing for high-volume production. The tools required for machining are less prone to damage, reducing costs. Due to its good thermal conductivity, magnesium is suitable for applications requiring heat dissipation, such as housings for electronic devices. Furthermore, magnesium possesses inherent electromagnetic interference (EMI) sealing properties, shielding sensitive electronic components from interference. From an environmental perspective, magnesium is abundant. It is recyclable, and emissions generated during processing are negligible. Moreover, magnesium consumes less energy compared to other metals. This sustainability, coupled with the flexibility of its surface treatments (such as painting or anodizing), makes magnesium a preferred material for manufacturers seeking high performance while minimizing the environmental impact of CNC machining.

Common Application Industries of Magnesium Alloy Components

Magnesium alloys are widely used in various industries due to their unique advantages, including lightweight yet high strength, excellent machinability, and good thermal properties. Major applications include:

Why Partner with Elimold?

We are your trusted partner for magnesium alloy CNC parts projects. We maintain successful partnerships with numerous companies worldwide, continuously improving our capabilities and capacity to stay abreast of the latest industry trends and demands. Leveraging our expertise in magnesium alloys, we can assist with design for manufacturability, machining strategies, and post-processing to ensure optimal performance and cost-effectiveness. Each part undergoes rigorous process quality checks and traceability agreements to ensure consistency and reliability at every stage.

FAQ

Making magnesium is generally more cost-effective than machining materials like titanium and stainless steel due to its soft texture and ease of machining. However, the price of magnesium fluctuates depending on the mining process and market demand. While the raw material price of magnesium may be higher than aluminum, its faster machining speed can offset the overall production cost, making it competitive in certain applications.

Magnesium is one of the lightweight metals commonly used in CNC machining, possessing excellent machinability and a superior strength-to-weight ratio. Unlike other materials, magnesium is highly flammable and reactive, thus requiring strict safety procedures, specialized equipment, and skilled operators to ensure safe and precise machining.

Due to the extremely high fire risk of magnesium, only a limited number of suppliers offer magnesium machining services. The machining process generates fine dust and debris, which are highly flammable and can potentially cause explosions if not handled properly. Strict operating procedures are crucial for safety—dust and debris should be quickly removed using vacuum or high-pressure systems to prevent accumulation. In addition, it is crucial to have Class D fire extinguishers available, as they are specifically designed for extinguishing fires involving metals such as magnesium.

Yes, magnesium is well-suited for CNC machining, often used in applications where weight reduction is a priority. It responds well to precision machining and is an ideal material for manufacturing intricate parts with complex geometries. Magnesium's excellent machinability supports fast and efficient machining, but its flammability means that appropriate safety measures must be taken throughout the machining process, such as controlling chip removal and having Class D fire extinguishers available.

Magnesium alloy parts should be stored in a dry, well-ventilated environment, away from moisture and corrosive substances. Furthermore, magnesium alloy parts should be stored separately from materials that may cause galvanic corrosion (such as steel or other dissimilar metals). Using suitable packaging materials, such as VCI (volatile corrosion inhibitor) paper, also helps protect against environmental factors.

Yes, water-based coolants can cause corrosion and salt deposits, reducing machining performance and tool life.

Magnesium alloys WE43 and QE22A are excellent choices for high-temperature applications, exhibiting superior mechanical properties, creep resistance, and fatigue resistance at high temperatures.

Magnesium alloys can undergo various surface treatments, such as anodizing, powder coating, and chromate conversion, to improve their corrosion resistance, durability, and aesthetics.

While magnesium alloys offer excellent performance, machining them requires specialized techniques. However, their lightweight nature and superior performance often more than compensate for this investment in high-performance applications.

This metal's excellent strength-to-weight ratio, lightweight properties, and ease of machining make it suitable for fields such as aircraft manufacturing, where lightweight yet high-strength materials are required. It also offers many other advantages, including high strength and good corrosion resistance, allowing for the design of objects where weight reduction is necessary without compromising performance.

Industries that benefit most from CNC-machined magnesium-based components include aerospace, automotive, defense, and electronics. For these industries, weight reduction is crucial, as it increases strength and reduces density, thus improving the performance of all products; therefore, they prefer magnesium-based metals.

Our magnesium alloy CNC machining service stands out because of our advanced machining equipment, experienced team, and unwavering commitment to quality. We focus on high-volume production, precision magnesium alloy machining, and urgent and expedited services to ensure that we meet our customers' unique needs and tight delivery deadlines.

You can easily weld magnesium alloys using arc welding, resistance welding, and oxy-acetylene welding techniques.

Most metal alloys can typically be machined down to a wall thickness of 0.020 inches (0.5 mm) unless otherwise specified. Even thinner features can be achieved with careful coding.

We can perform post-processing and aging treatments on various alloys, depending on your preference.

Partner with Elimold for a Seamless and Enjoyable Collaboration

Experience a smooth and efficient partnership with Elimold, where we provide precise manufacturing solutions tailored to your needs. Join our satisfied clients and let’s create success together.