Metal Extrusion Services

Elimold provides cost-effective extrusion services. With our experienced professional engineering team and advanced equipment, we can not only manufacture high-quality molds, but also manufacture complex custom extruded parts in large quantities. In addition, we implement strict quality control throughout the production process, and can perform regular testing and verification at all stages of production to ensure that we can deliver excellent products every time. Contact us now for a free instant quote.

Professional Metal Extrusion Parts Manufacturer

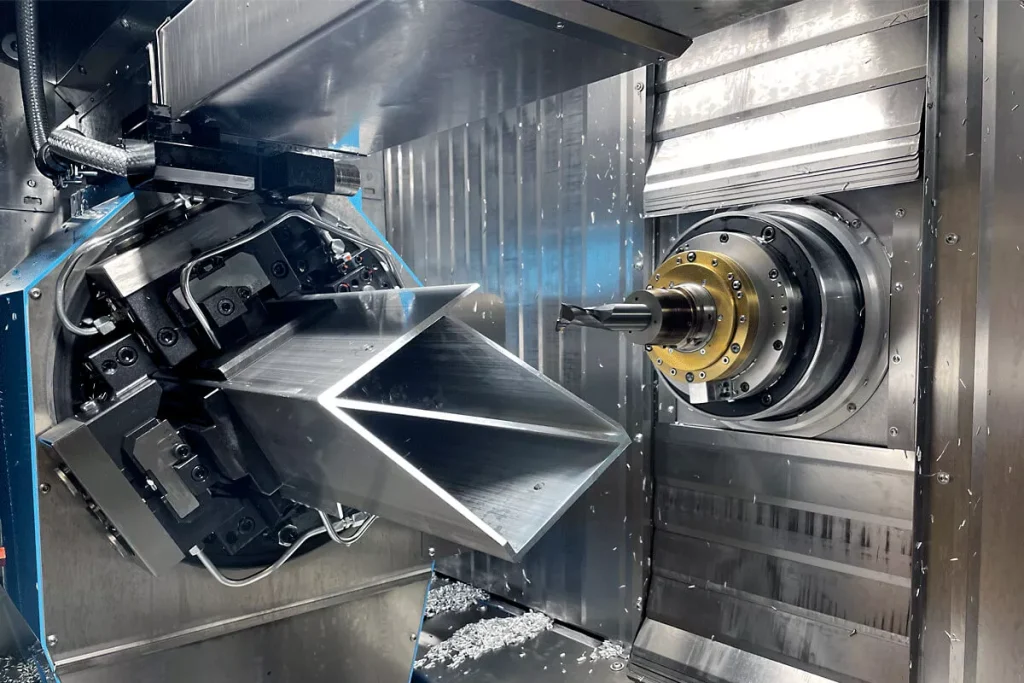

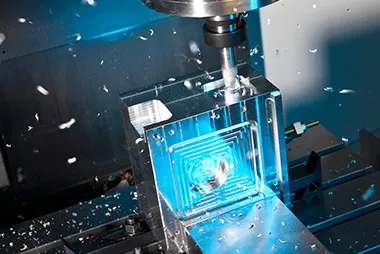

If you are looking for a custom metal extrusion parts manufacturer and the demand is high, then you should definitely contact an extrusion company directly. Many extrusion companies are only engaged in large-scale production, so these companies are reluctant to undertake small-volume metal extrusion projects unless you are their VIP customer. Therefore, it is difficult for you to get rapid prototype parts and small-volume custom extrusion parts for metal extrusion projects. But at Elimold, we have our own in-house extrusion factory, which can not only provide large-volume extrusion parts, but also small-volume and short-run custom metal extrusion parts services. And no matter the size of the project, we attach great importance to our customers’ projects, both in terms of quality and delivery cycle. We also regularly quality control the projects before they are shipped. In addition, compared with traditional extrusion companies, our in-house factory also has a professional CNC machine shop, so we can perform precision post-processing in-house.

Our Metal Extrusion Services Qualifications

Our experience in the field of metal extrusion services fully demonstrates our professional skills and dedication to providing excellent solutions. Our team’s illustrious history shows our extensive expertise in metallurgy, engineering and the intricate details of the extrusion process. Our state-of-the-art facilities and cutting-edge technology enable us to process a wide range of materials and manufacture complex profiles. Our professionals are certified to industry standards and carefully supervise every aspect of the extrusion process to ensure that the products are accurate and meet specifications. Our strict quality control procedures ensure that each extruded part meets strict standards for geometric dimensions, tolerances and material properties. Our team works closely with customers to provide tailor-made solutions with a deep understanding of design requirements. Renowned for our innovation and reliability, our metal extrusion services qualifications also reflect our determination to transform concepts into reality with precision and extreme professionalism.

Metal Extrusion Manufacturing Facility

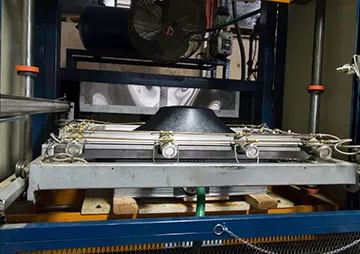

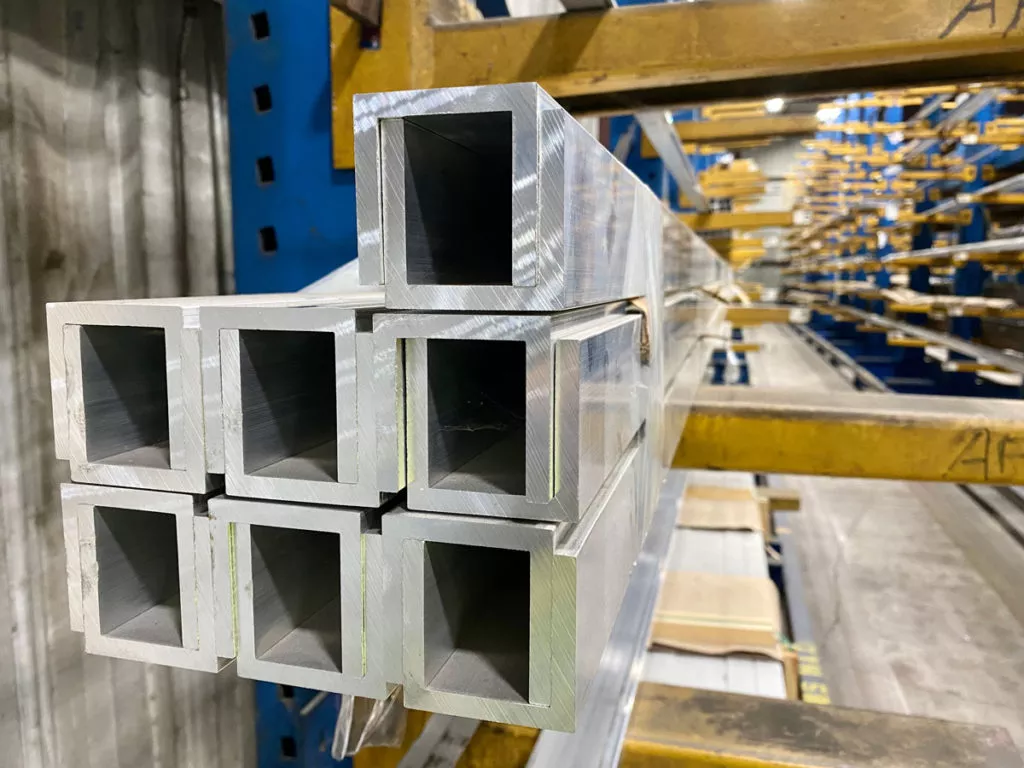

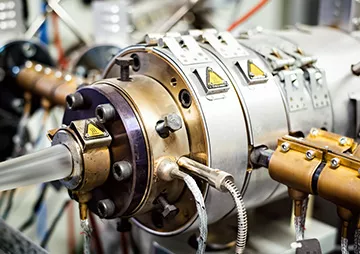

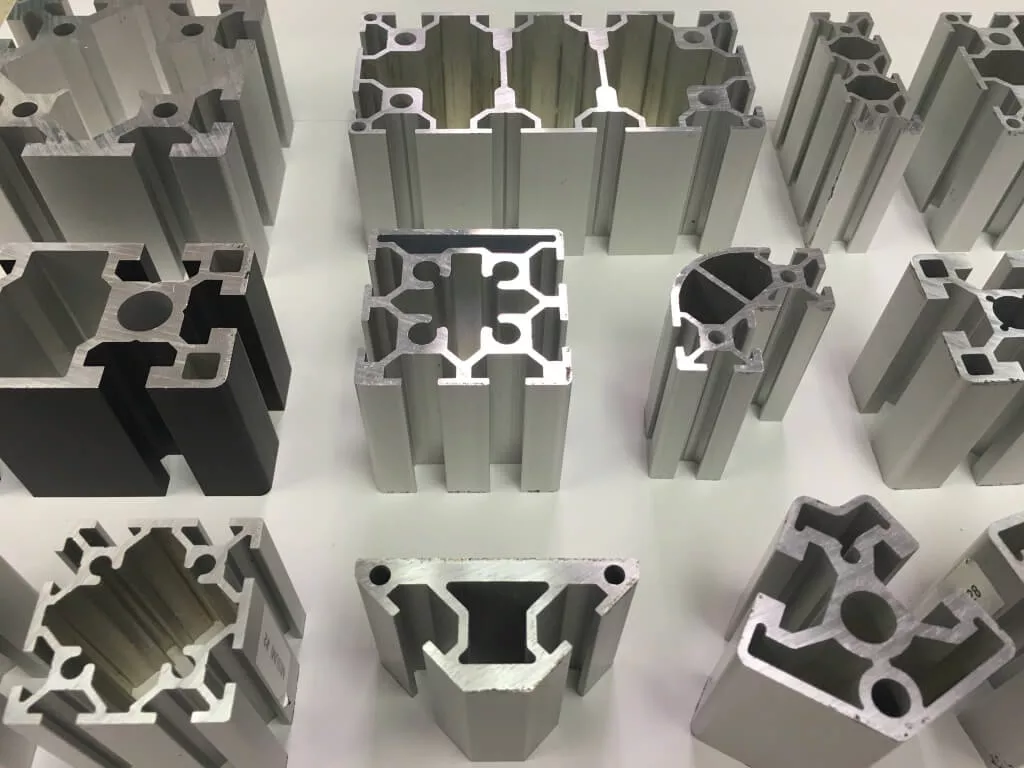

We have two manufacturing facilities with a total of 200,000 square feet of capacity. We have 58 state-of-the-art extruders capable of extrude everything from small components to large structural profiles, and can handle everything from prototypes to small batches to full production runs. Elimold is well-equipped to handle extrusions of all shapes and sizes. Our advanced computer-controlled extruders can produce extrusions up to 11 inches wide and 53 feet long. We carry an extensive inventory of standard shape dies to quickly produce your order, or we can design custom dies to your exact specifications. We provide expert customer support from your first contact through delivery of your finished product. We work with you to ensure your part tooling and engineering are accurate before production begins. In addition, with thousands of square feet of warehouse space, we can stock custom extrusions for immediate shipment.

Engineering Design Assistance

We can help you optimize the design of your extruded parts to help you achieve a more cost-effective product or a better overall extrusion solution for your application. So when you work with Elimold, the design support provided by our dedicated team of engineers can help you create the best solution for both cost-effectiveness and turnaround time. Our philosophy of continuous improvement runs through the project from the beginning, providing design and engineering services for custom extruded parts. In addition, even small changes in the design of metal extrusion parts at this stage can result in significant cost savings in downstream processes. That’s why our value stream engineers and designers will help you identify these improvement opportunities as early as possible, at no additional cost to you. When developing custom extruded parts with special geometries, it is also beneficial to work with an experienced extrusion parts manufacturer. Elimold has the experience to extrude effectively and reduce costs effectively.

CAD/CAM Support

To provide you with the best experience, we use industry-standard technology to provide you with the custom metal extrusion parts you need. Our engineers provide CAD/CAM engineering support to help you capture and develop the most stringent design specifications required to manufacture specialized extrusion products. Therefore, you can rely on our precise tolerances to meet the ever-changing industry needs. If you need a precision custom metal extrusion part with tight dimensional tolerances and excellent surface quality, please contact us. With many years of experience in this industry, we always understand and value the timeliness of the project and are committed to completing goals on time and efficiently.

Custom Metal Extrusion Parts Manufacturing and Engineering Solutions

Elimold can provide custom manufacturing and engineering solutions for the specific needs of various industries. And our project managers and experts personally review each metal extrusion project and manually quote to ensure that we meet your unique needs while providing a fast and convenient manufacturing experience. When you send your project drawings to Elimold, we will match experienced engineers to review your design and provide feedback to improve manufacturability, cost-effectiveness and efficiency. Whether you need a single prototype or full-scale production, Elimold’s engineers are ready to work with you. Our expertise covers a wide range of industries and applications, please contact us to discuss how to turn your idea into reality.

Our Extrusion Manufacturing Capabilities

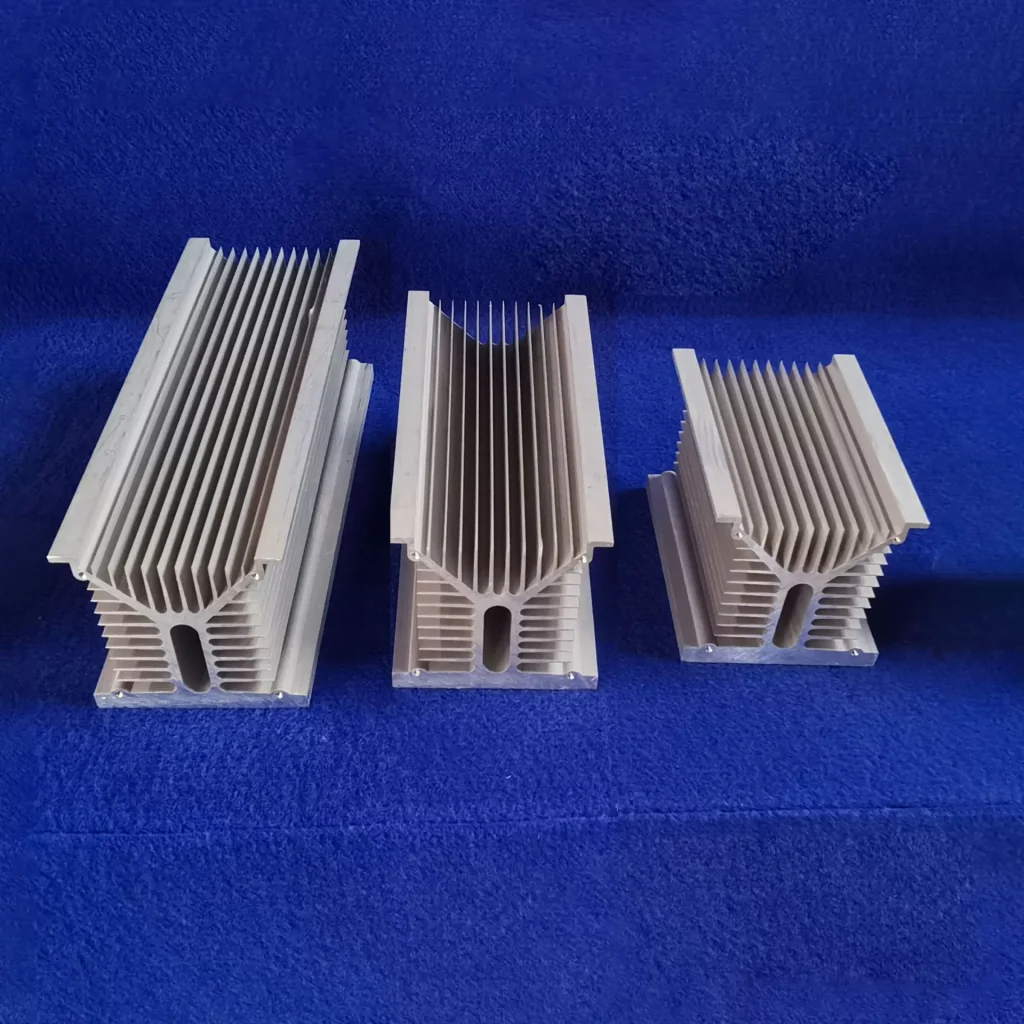

Elimold offers a fully vertically integrated extrusion supply with a state-of-the-art extrusion press line ranging from 1,250 to 5,500 tons. This enables us to deliver quickly and provide cost-effective solutions for your aluminum extrusion needs. We are able to produce rods, tubes and complex sections ranging from 152 to 432 mm (6 to 17 inches) in diameter, and parts ranging from 0.0005 inches to over 4 inches in thickness. Billets can be preheated to 1925°C (3500°F) using a gas or inert gas induction furnace. Extrusion ram speeds can be controlled from 1.27 to 203 mm/s (0.05 to 8.0 in/s). Our full range of extrusion processes enhances product quality. Depending on the design specifications and performance requirements, we can manufacture your components using processes such as dual durometer or triple extrusion, crosshead, cladding, embossing or beveling.

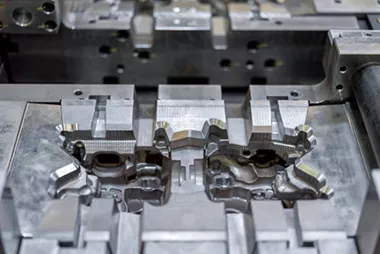

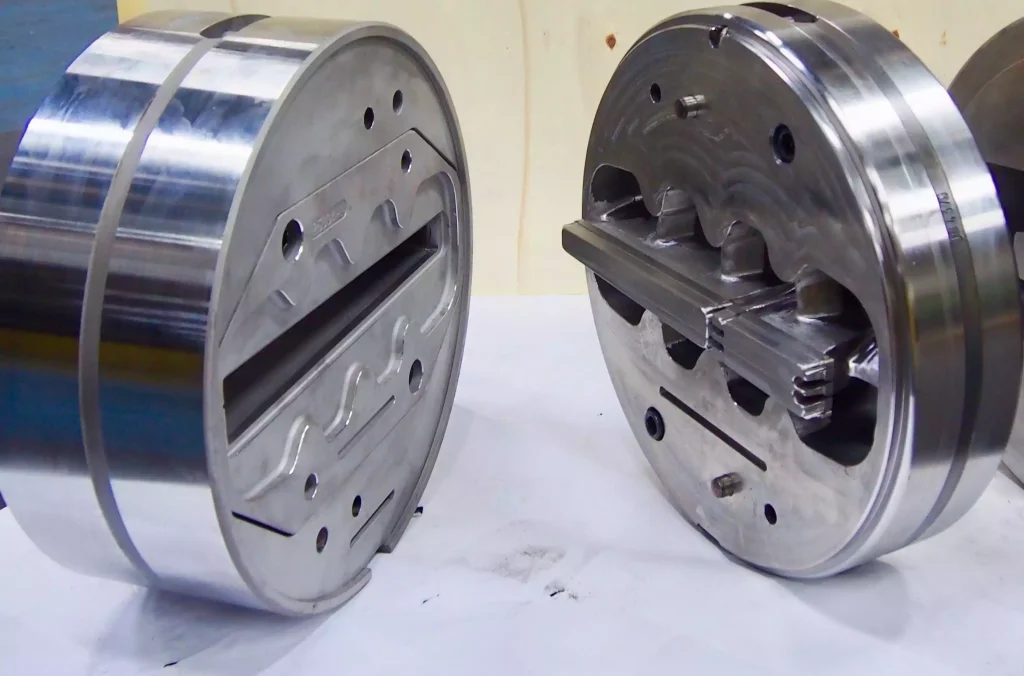

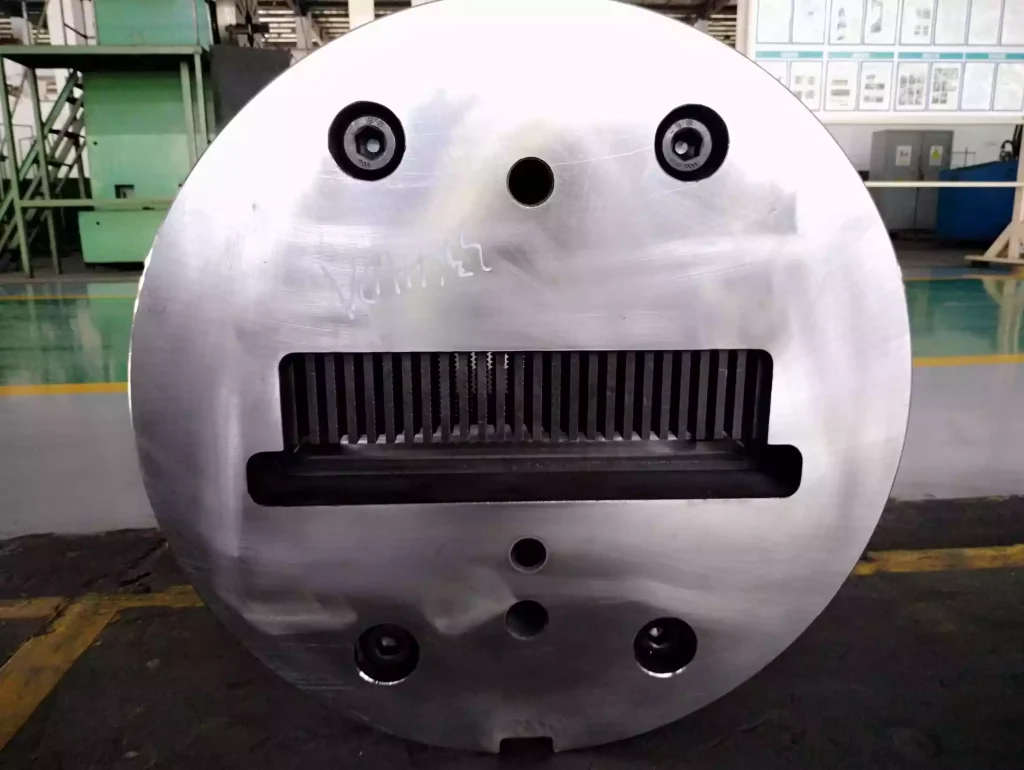

Custom Extrusion Die Fabrication

We can custom build dies to a cross-sectional profile to precisely produce your custom design. We create truly one-of-a-kind dies designed to bring our customers’ visions to life, often in the form of custom extrusions. We begin by listening carefully to our customers’ specific needs and custom build a cross-sectional profile to precisely match their requirements. Additionally, we can maintain our own dies as needed to facilitate custom extrusions that are uncommon and complex. To best meet our customers’ needs. All of our dies are built from our in-house die making shop. We welcome customers to choose any of our standard dies to avoid tooling and die costs.

Need a custom extruded part?

If you would like to discuss your project or need help selecting materials, please contact our experts.

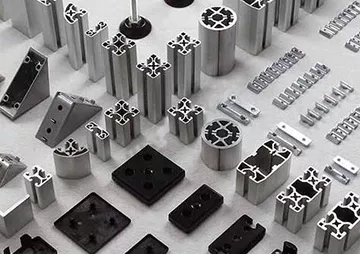

Custom Metal Extrusion Products

If you have custom manufacturing needs using the extrusion process, our team can complete them with shorter lead times. The Elimold team maintains high quality standards throughout the entire workflow. We adhere to industry standards and precise tolerances, and perform hardness and tensile testing throughout the manufacturing process. In addition to extrusion manufacturing, our company also provides design, engineering, assembly, packaging, labeling, and shipping services for all high-quality products. We have high-volume production capabilities. If you need a custom metal extrusion, our engineers will use their expertise in manufacturing and materials to recommend the ideal material from a performance and cost perspective. We provide precise tolerances, consistent products, reliable service, and a reputation for problem solving, all backed by extensive research and experience.

Types of Extrusion Processes

There are many types of extrusion to choose from. While the core principles remain the same, we apply them in different ways to achieve a wide range of different products. We can classify all metal extrusion processes into one of the following types, and we also offer plastic extrusion.

Metal Extrusion

Plastic Extrusion

Hot Extrusion

Cold Extrusion

Warm extrusion

Friction extrusion

Micro extrusion

Direct extrusion

Indirect extrusion

Hydrostatic extrusion

Impact extrusion

Lateral extrusion

Elimold's Service Process

After we receive your order, we will:

Step 1: Supply a complete cross-sectional drawing for you after review and discuss about your CAD files.

Step 2: Fabricate dies and extrude a sample to get your approval.

Step 3: Make the modification on the die if needed.

Step 4: Exercise process control when extruding your parts.

Step 5: Select from a variety of finishes processing to achieve the effect you want.

Step 6: Inspect finished extruded parts to avoid any dimension deviation.

End-to-end extrusion services

At Elimold, we understand all the factors that go into producing high-quality parts. This is why we ensure stringent quality control systems to choose the best profiles for your end-use and use other fabrication and post-production methods to improve your part’s characteristics and functionality. After receiving your order, we shall proceed to:

- Perform a free Design for manufacturing (DFM) review.

- Discuss the best aluminum profiles and design improvement options Fabricate your high-quality extrusion parts.

- Use our in-house process control systems to monitor and optimize your production.

- Perform heat treatment to improve the mechanical attributes of your part

- Engage the part in any post-processing (fabrication and finishing) to capture all desired details

- Perform final evaluation and quality control to ensure finished extrusions meet the specified dimensions, geometries, and surface finishes/details.

On-Time Delivery with Tested Performance

We are committed to completing projects on time and within budget, with 95% of our inquiry response times being between 2 and 48 hours and an on-time delivery commitment rate (OTD) of over 90%. We also have a comprehensive quality control and quality assurance process to ensure that our finished products perform as expected. At Elimold, we use a “make-to-stock” custom production method to meet your needs quickly and efficiently. This not only reduces costs, but also allows us to provide quality products at very competitive prices. Because we have in-house design, manufacturing and delivery processes, we are able to deliver custom plastic extrusions or metal extrusions in days, not weeks. We work closely with our customers to ensure that each product is designed, produced and delivered quickly.

Quality Management

Every order from Elimold goes through a rigorous quality control process. Your extruded product will be tested to the highest standards through a series of meticulous inspections. This is done throughout the entire production chain, including the individual packaging and shipping of your order. We manufacture products that meet strict and comprehensive quality standards and are trusted by renowned customers in various industries in Japan, Germany, the United States and elsewhere. We are ISO 9001: 2015 certified and our manufacturing partners are ISO 13485: 2016, ISO 14001: 2015 and IATF 16949: 2016 certified. It is no accident that we have been serving so many loyal customers for decades. We are always eager to provide new customers with the same excellent brand service.

Quality Testing Equipment And Capabilities

Our manufacturing facility is ISO 9001:2008/TS 16949 certified and adheres to multiple industry standards, including those set by the American Society of Mechanical Engineers (ASME), the American Welding Society (AWS), and the U.S. Food and Drug Administration (FDA). Our tolerances easily meet (and often exceed) stringent industry standards. With an in-house, state-of-the-art facility, customers can be assured that they will receive timely delivery of every project, every time.

Unparalleled product quality is the foundation of our business, and our in-house facility can complete projects from start to finish, from raw material verification to final pre-shipment inspection of finished products. Our quality department inspects products using nine different inspection processes and tools, including: coordinate measuring machines (CMM), inspection gages, in-line inspection (ILI), on-line inspection (OSI), part sorting, penetrant inspection, video inspection, visual inspection, and third-party inspection. We also invest heavily in comprehensive training programs and state-of-the-art equipment to ensure excellence in everything we do.

Advanced Carl Zeiss Measuring Equipment

Whether you need standard or custom metal extrusion parts, Elimold is your best choice. Our new Ascona Vision System technology features one of the largest telecentric camera lenses ever made. This machine, built by Carl Zeiss, allows us to measure extrusion dimensions more accurately and quickly. We can measure dimensions that were previously impossible to measure with calipers. These lenses have reduced our manufacturing costs, and we look forward to passing the savings on to our customers. We are also able to utilize the latest extrusion technology to achieve more accurate weight per foot. This technology makes it easy to create measurement and manufacturing reports for customers and tooling suppliers, ensuring that we are only manufacturing the most accurate custom metal parts.

Ready To Get A Quote For Your Extrusion Projects?

Do you have a extrusion part you would like to be made?Send us your drawing and we’ll send you a quote as soon as possible. We are here to help turn the order around quickly and make your project more cost effective.

Custom Extrusion Parts Supplier

We are a leading supplier of custom extrusion parts. We perform basic design and produce extrusion dies. We understand conventional and exotic materials and can provide solutions to help you improve your overall tooling economics. Our custom extrusion manufacturing solutions for customers in various industries around the world go beyond tooling, material selection and mass production of extruded parts to include project production management, design for manufacturability (DFM), logistics and design optimization, and cost optimization. With Elimold’s services, you will enjoy a more optimized production process and higher quality extruded parts. Whether you are considering short-term, medium-term or very long-term production, we can help you minimize project time and optimize costs. Nothing reflects Elimold’s service quality more than your project’s fast time to market and continued high-speed development, which we know is the key to profitability.

Extrusion Parts Tailored To Your Needs

Our experienced team works closely with you to gain a deep understanding of your project requirements and design goals. Whether you require custom extruded parts with complex shapes, precise dimensions, excellent mechanical properties, or custom extrusions with unique profiles and lengths, we have the ability to turn your ideas into reality. We are committed to providing custom solutions that meet your needs and exceed your expectations. Our experienced team and trusted supplier network ensure that every custom product we help deliver meets the highest standards of dimensional accuracy, mechanical properties, and surface finish. We are committed to excellence, so you can trust us to provide custom extrusions with superior quality and performance.

Fast Turnaround Custom Extrusion Manufacturing Services

From engineering to testing, manufacturing to delivery, our team is committed to delivering exceptional quality to our customers. We adhere to strict quality and safety standards, and you can trust our components to perform to the most stringent specifications. No matter how complex or challenging the project, our team is passionate about finding the best solution for our customers. We work closely with each customer to ensure that every detail is taken care of and that the finished product achieves the performance, reliability, and longevity you expect. We know that time is money, so we move fast to expedite the design, production, and delivery of each component.

High-Volume Extrusion Part Manufacturing Services

For custom high-volume extrusion part needs, Elimold offers high-quality custom extrusion services to meet demanding specifications. Whether it’s a unique shape, special size, or custom finish, our high-volume custom extrusion services offer the best versatility and precision in the industry. And our advanced extrusion processes ensure consistent quality and tight tolerances, providing parts that meet your design requirements with extremely high precision. From concept to final completion, we work closely with you to ensure that every detail of your custom extrusion part meets your needs. We offer custom parts in a variety of lengths, cross-sectional areas, and surface treatments, providing the flexibility and performance you need, whether it’s a small project or a large industrial application. Choose Elimold to develop custom extrusion parts for a reliable, high-performance solution that makes your innovative designs a reality.

Low-Cost Extrusion Services

At Elimold, we have over 20 years of expertise in metal fabrication, providing high-quality custom metal parts that support critical systems around the world. We are dedicated to providing premium custom extruded parts in a wide variety of alloys to visionary customers who realize the potential of these materials. Our in-house facility features state-of-the-art equipment capable of providing some of the most complex custom extruded parts in the industry, from the smallest to the largest. Our experienced engineers will apply their expertise in manufacturing and materials to recommend the ideal material from a performance and cost perspective. We are committed to excellence and adhere to the highest industry benchmarks. We also offer precise tolerances, consistent products, reliable service, and a reputation for problem solving, all backed by extensive research and experience. To save 10-20% over your current supplier, please send us a sample or drawing of your extrusion.

Value-added Service: Inventory Plan

Elimold can serve as your logistics center to meet your various custom extrusion parts needs. When you work with us on a custom extrusion project, you can choose to store the parts in our warehouse and deliver them on time according to the required quantity. And our factory uses a digital and visual inventory management system, so you can always understand and pick up the goods according to the project needs. Our global logistics system ensures that metal extrusion parts can be delivered to you in time when you need them most. If you have the time, budget and need custom metal extrusions, please contact our quotation team now.

Ready to get started on your extrusion quote?

To learn more about our custom metal extrusions, please email [email protected] or request a quote online now. We can provide design, metallurgy and technical support. We welcome your orders and are committed to providing excellent service and quality.

What is Extrusion?

Extrusion is a manufacturing process widely used in various industries to create objects with a consistent cross-sectional profile. It involves pushing or forcing a material, typically a malleable plastic or metal, through a die to form a continuous shape. The initial step entails introducing the raw material, typically in the form of pellets, into a hopper. Subsequently, the material is conveyed into a heated barrel. Within the barrel, the material is melted and pressurized, and it is then forced through the die, which determines the final shape and size of the extruded product. Cooling mechanisms are employed to solidify the material as it emerges from the die. Extrusion offers several advantages, such as high production rates, versatility in creating complex shapes, and cost-effectiveness. It is commonly used to manufacture products like pipes, tubes, rods, and various profiles used in the construction, automotive, and packaging industries.

Advantages of Metal Extrusion

- Dimensional Accuracy and Stability: Modern extruders and processes are capable of producing close tolerance, durable, and dimensionally stable extruded profiles. The process is also suitable for both brittle and ductile materials.

- Low Part Cost: With careful design, extruded frames and housings can eliminate multi-part assembly. It is also easy to achieve high production volumes and is economical.

- Reduced Tooling Costs: The extrusion process is simple and can reduce tooling costs by 80-90% compared to other processes such as injection molding or die casting.

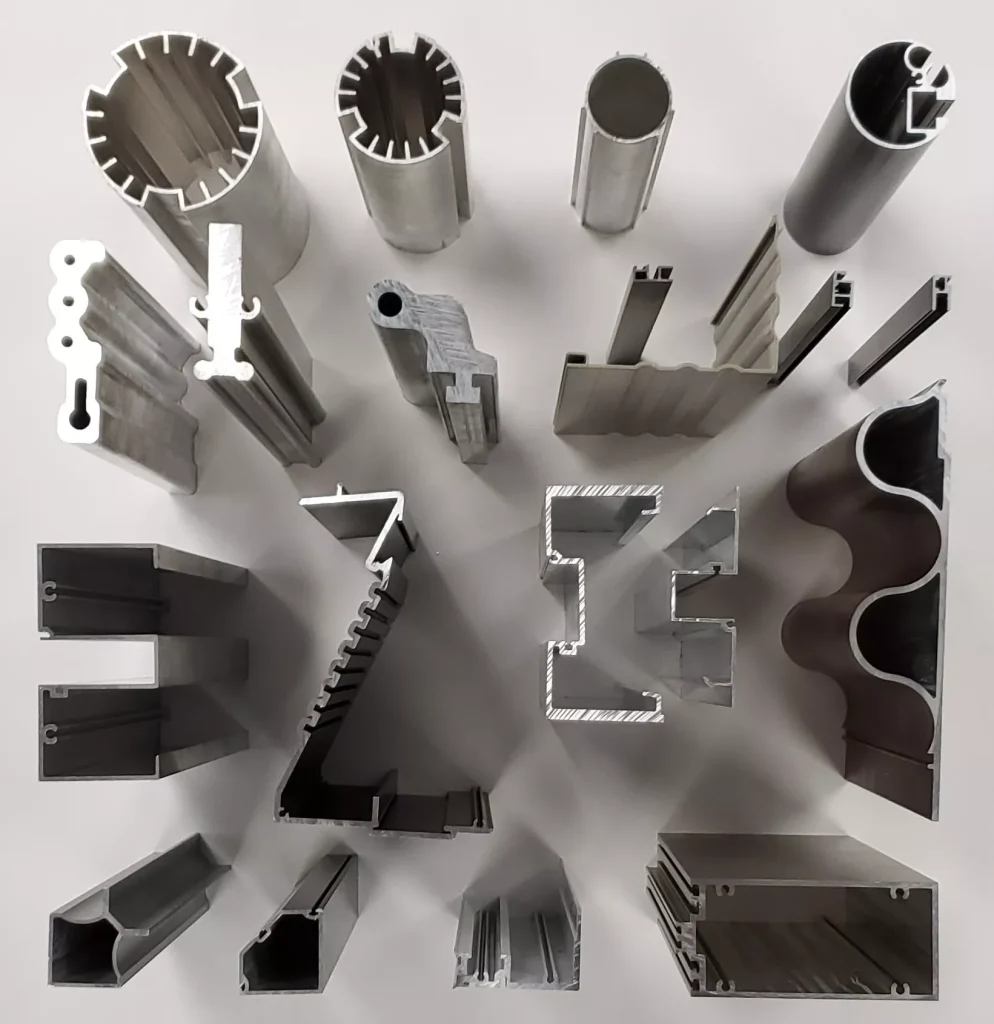

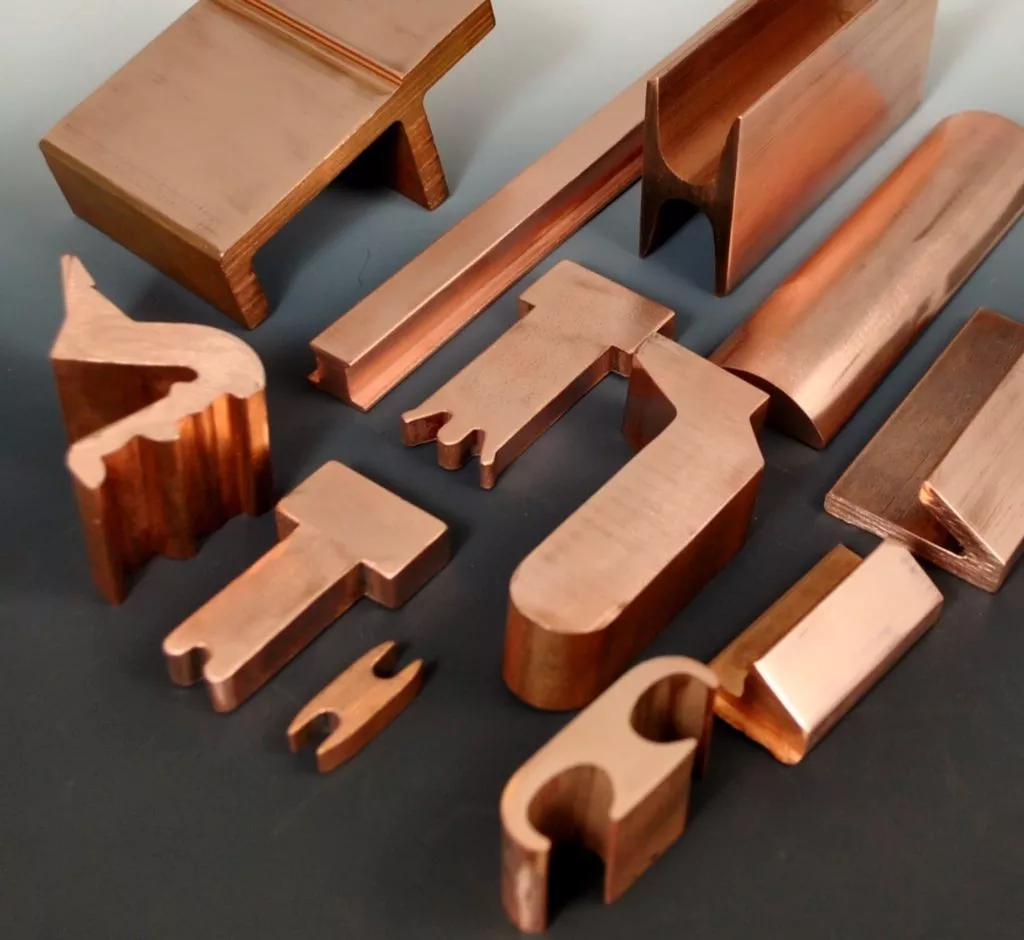

- Part Complexity: Extrusion is well suited to creating parts with complex cross-sectional shapes, including features such as undercuts, T-slots, and grooves.

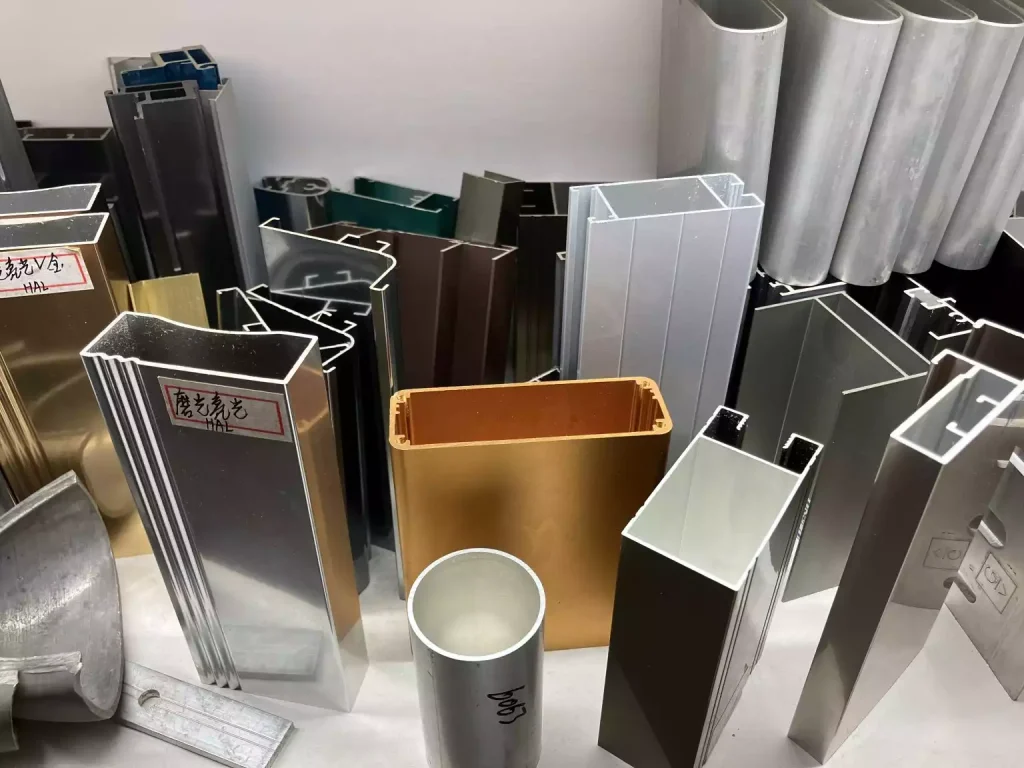

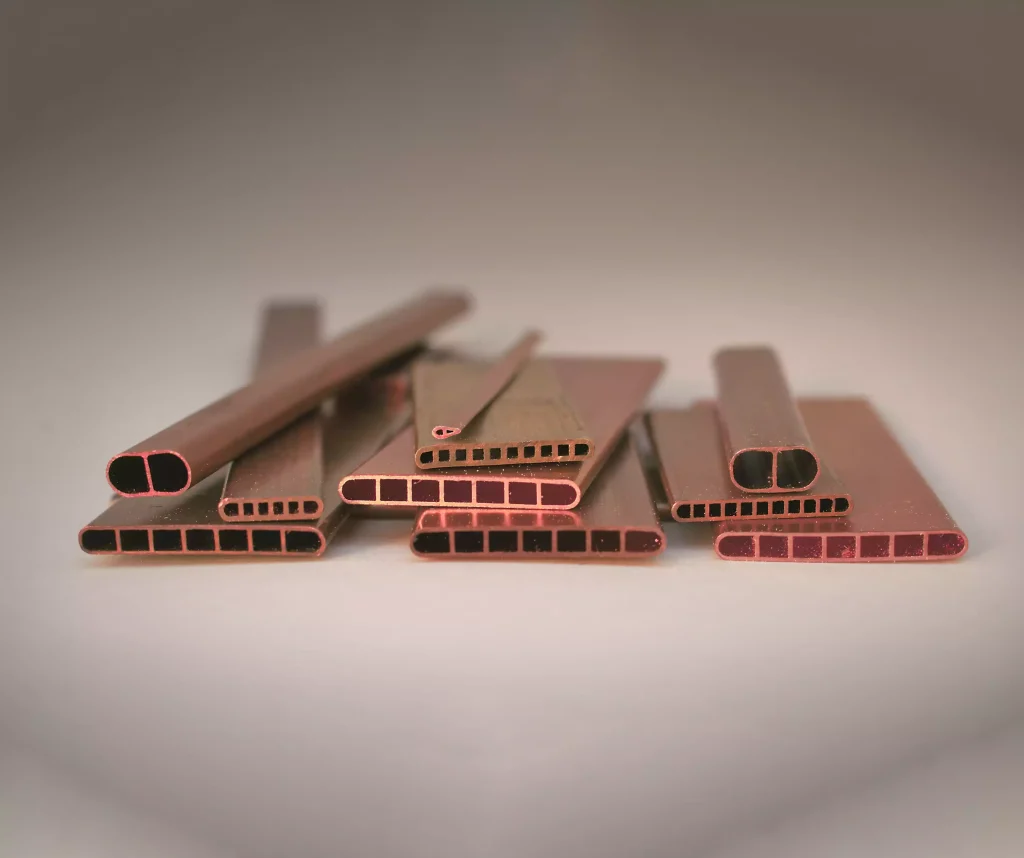

Materials & Specifications

Materials used in our extrusion process include, Metals: Aluminum (2xxx series and 7xxx series), Brass, Bronze, Copper, Carbide Aluminum, Stainless Steel, and Steel. Commonly used plastics include Acrylic, Butyl, Foam, Polyethylene, High Density Polyethylene, Polypropylene, High Density Polypropylene, Neoprene, Polyvinyl Chloride (PVC), Rubber, Polyurethane, and Vinyl.

Additionally, extrusion generally minimizes the need for secondary operations, but does not provide the same dimensional accuracy or surface finish as machined parts. The surface finish for steel is 3 microns (125 uin) and for aluminum and magnesium is 0.8 microns (30 uin). However, the process can produce a wide variety of cross-sections that would be difficult to produce cost-effectively using other methods. The minimum thickness for steel is approximately 3 mm (0.120 in), while the minimum thickness for aluminum and magnesium is approximately 1 mm (0.040 in). The minimum cross-sectional area for steel is 250 mm2 (0.4 in2), while for aluminum and magnesium it is less than 250 mm2. Minimum corner and fillet radius of 0.4 mm (0.015 in) for aluminum and magnesium, 0.8 mm (0.030 in) for steel and 4 mm (0.120 in) for corners

Post Machining of Extruded Parts

Once extrusion is complete, your parts are ready for processing. Subsequent services such as drilling, cutting or punching can all be done in-house. This saves you the time and costs of performing these operations in your own factory.

- Cutting

- Drilling

- Grinding

- Boring

- Tapping

- Deburring

Finishing Options for Metal Extrusions

Aluminum extrusions are used in the mass production of many non-appearance parts where finishing may not be particularly important. However, custom metal extrusions are also used to produce high-value products that may benefit from the addition of color, text, logos, and other finishing processes. Applicable surface treatments for metal extrusion parts include:

- Basic mechanical finishing

- Anodization

- Painting

- Powder coating

- Silk-screen printing

- Laser engraving

Secondary Machining Services

We can combine extrusion with other manufacturing methods such as CNC milling, turning and bending to create final parts. Our team offers a full range of services, from secondary machining, surface treatments to special requirements.

CNC Machining

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

High-Quality Custom Metal Extrusion Solutions

We are committed to providing high-quality solutions that meet our customers’ needs and focus on customer service. Our experienced team will work with you to ensure that the solution that meets your needs is provided in the most economical way. We are committed to producing high-quality extruded parts that meet your expectations, delivering on time and on budget, and providing excellent customer service. We understand that the custom extruded parts we deliver are critical to the performance of your finished product, and the quality of our products affects the quality of your products and even your reputation. Therefore, our quality inspection team will physically test parts during and after production to ensure consistent product quality and meet product specifications. In addition, we use sustainable and environmentally friendly production practices to minimize material waste and maximize production efficiency. It is this commitment that makes our customers choose Elimold for long-term cooperation.

Full Range Extrusion Services

Utilizing our world-class production facilities, we offer custom design, tooling, surface treatment, and value-added assembly services. As an engineering company that supports businesses at every stage of growth, we combine extensive industry expertise with cutting-edge technology to deliver unmatched metal extrusion services. Our experienced team of professionals works closely with our clients to develop custom solutions that meet their project needs and exceed their expectations. When you choose Elimold for your custom extrusion service needs, you get a partner who will work with you from start to finish to ensure your project is completed to your specifications. What’s more, our innovative team can help you redefine what’s possible. With our custom extrusion services, we can mold up to six colors on a single part. Our innovation and execution are unmatched in the industry.

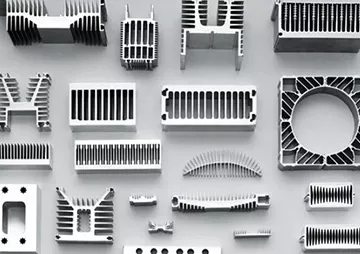

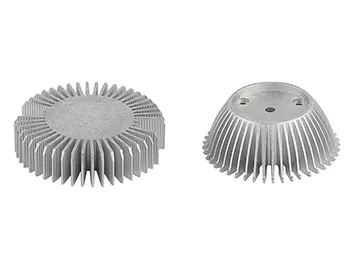

Parts and Applications

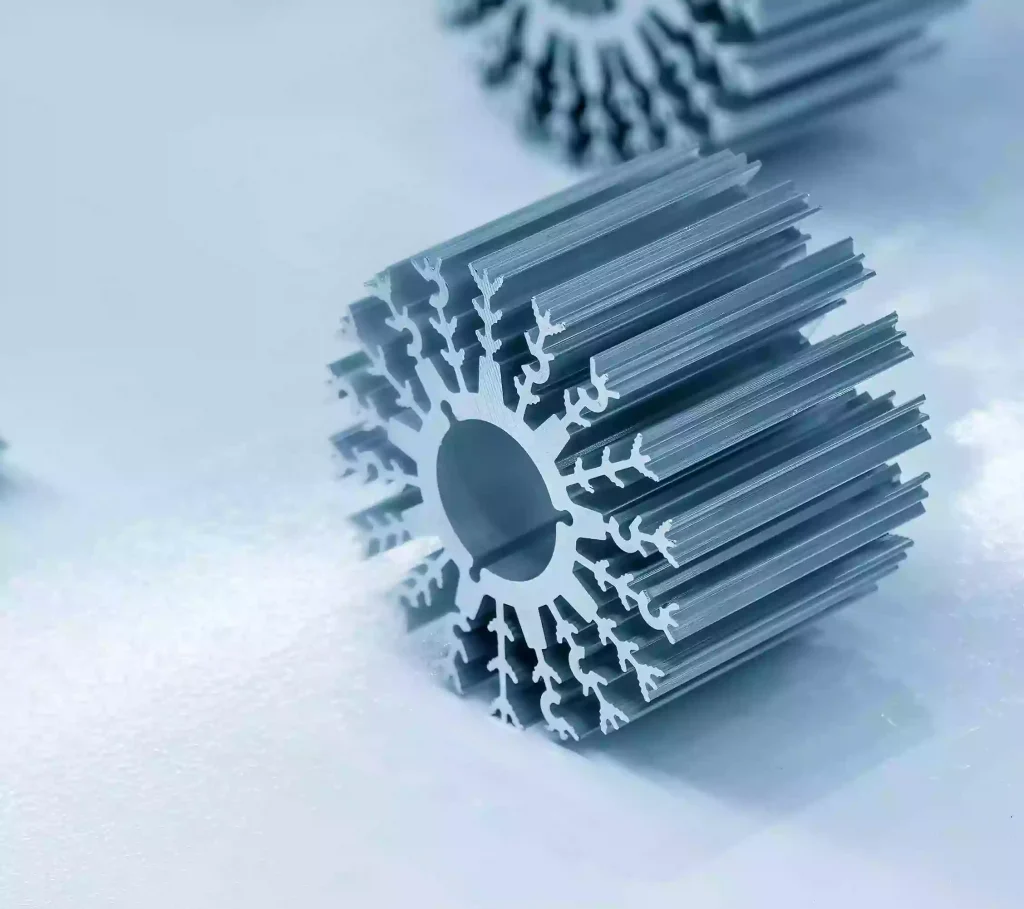

- Aluminum window frames

- Heat sinks

- Curtain wall components

- Door tracks

- LED housings

- Structural tubing

- Automotive trim

- Bicycle frames

- Tent poles

- Display racks

- Conveyor rails

- Electrical enclosures

- Solar panel frames

- Signage frames

- Lighting fixtures

- Furniture profiles

- Handrails

- Stair nosing

- Cable management channels

- Greenhouse frames

- Air conditioning ducts

- Fence posts

- Truck trailer rails

- Boat hull components

- Architectural moldings

- Retail shelving brackets

- Bus window frames

- T-slot framing systems

- Bumper reinforcements

- Radiator frames

- Window blinds tracks

- Motor housing shells

- Pipe clamps

- Luggage racks

- Partition wall structures

- Escalator panels

- Tent structure connectors

- Wall panel trims

- Garage door rails

- Ladder rungs

Request Your Free Metal Extrusion Quote Today

After receiving your drawings, our engineers will analyze your custom Metal Extrusion parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.