Metal Injection Molding (MIM) Service

Elimold’s Metal Injection Molding services can produce complex, precise parts at a fraction of the cost of other production methods. Metal Injection Molding can produce products with exceptional finish, durability and unique shapes. Our Metal Injection Molding facilities are fully equipped to handle orders of all sizes and in a wide variety of materials. Contact us today for a free, instant quote.

Professional Metal Injection Molding Manufacturer

Welcome to Elimold, a leader in Metal Injection Molding (MIM) manufacturing with over 25 years of experience. As a large, professional mold maker company, we focus on providing highly engineered solutions to meet your manufacturing needs. Our in-house facility has the expertise, advanced equipment, and proprietary processing technology to ensure that MIM and CIM products are of top quality that exceeds expectations. With seven major operating divisions, we provide you with the most efficient manufacturing solutions. Our commitment to quality, precision, and customer satisfaction has made us stand out among metal injection molding companies and become an industry leader. With our extensive expertise in metal injection molding and metal sintering, we are able to provide cutting-edge products that meet the needs of a wide range of industries. Explore the flexibility and innovation that Elimold offers. Contact our factory in Shenzhen, China today!

Elimold's in-house metal injection molding facility

Elimold’s in-house facility is a 221,000 square foot facility that includes production facilities and two large warehouses for raw materials, finished products, and space for customers to rent, with multiple loading docks for efficient pick-up and delivery. It is able to meet the manufacturing needs of small, medium and large batches of MIM parts, and integrates various process flows such as MIM design, mold design, tool manufacturing, debinding, sintering, surface treatment, etc. to the final MIM part inspection and assembly. The factory has more than 80 state-of-the-art 110-ton metal injection molding machines with injection volumes of 1.9 ounces, 2.7 ounces and 3.7 ounces, suitable for single-cavity and multi-cavity molds, supporting a wide range of industries. In addition, our factory has 24-hour operation capabilities and uses the most advanced integrated real-time manufacturing ERP software to improve the efficiency and turnover rate of production, data collection, troubleshooting, and overall organizational and customer communication. The precision MIM parts we produce are both cost-effective and of excellent quality. Our experienced technical team has broken through any limitations of the metal injection molding process, allowing us to manufacture MIM parts with excellent mechanical properties and various shapes to meet your needs.

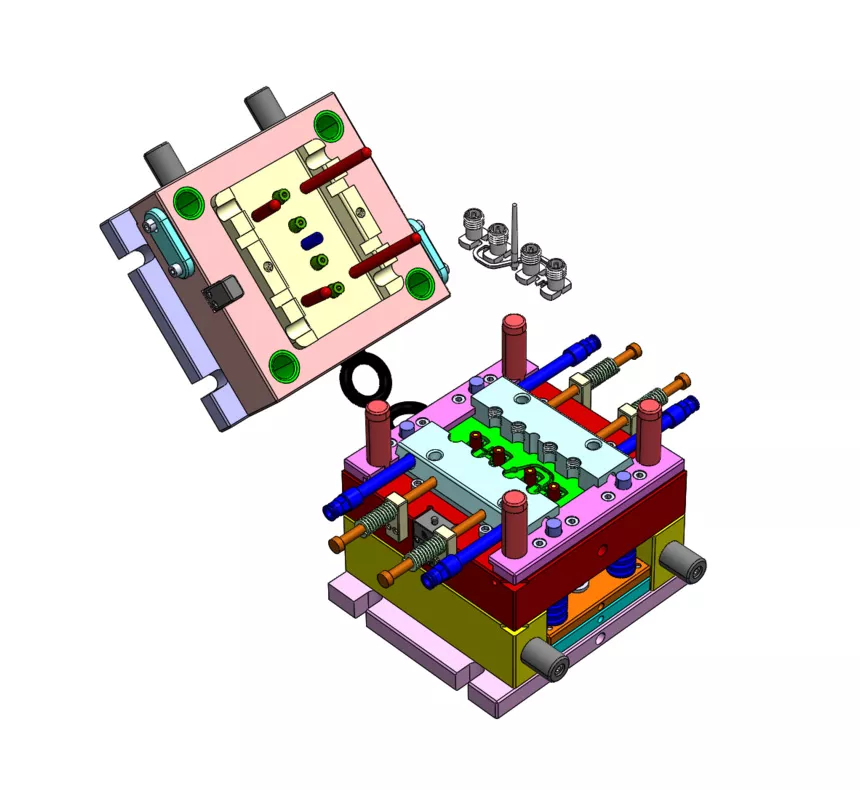

In-House Custom Mold Manufacturing Capabilities

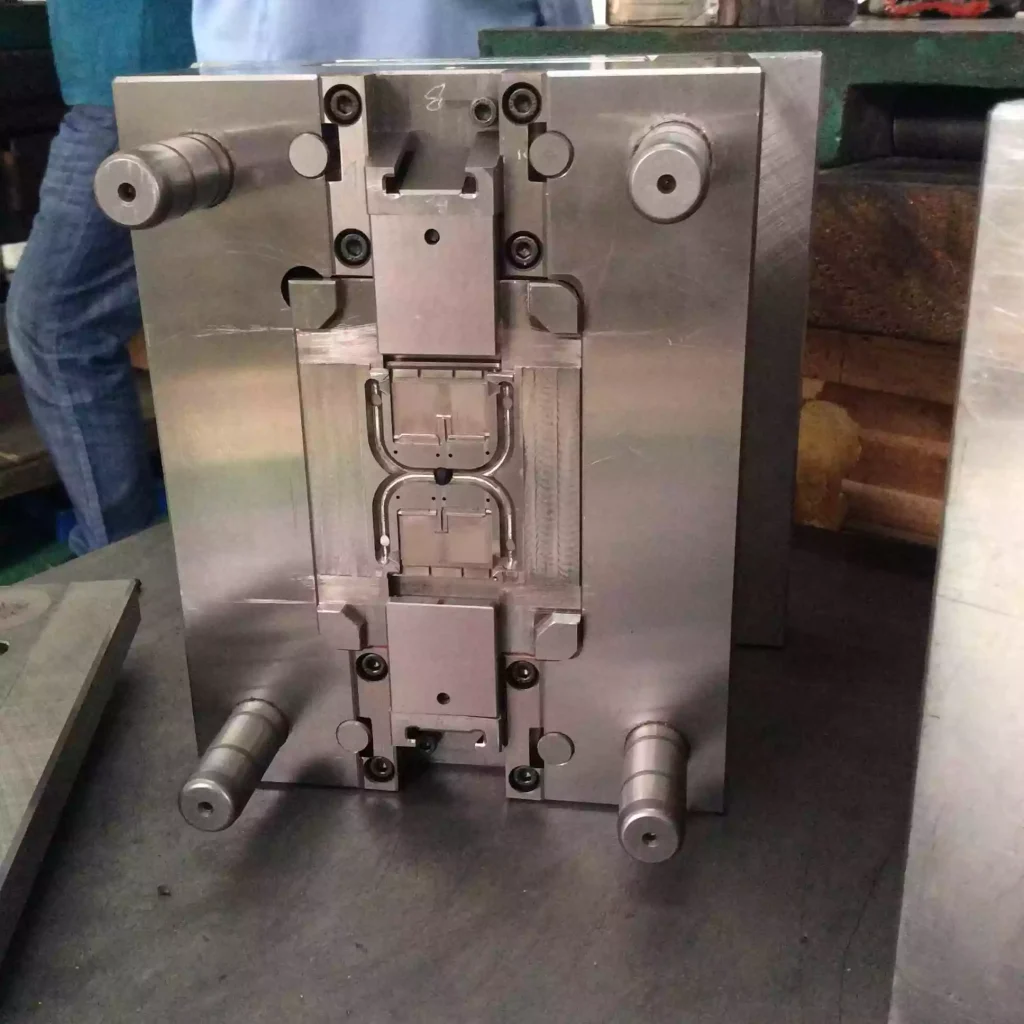

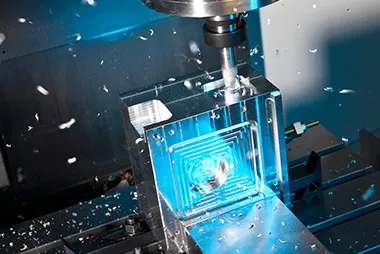

Elimold’s core competency is our ability to design and manufacture our own molds. We believe this is critical to delivering high-quality, high-precision MIM products efficiently and cost-effectively. Imagine seamless communication between the designers and moldmaking teams, which speeds up development and brings products to market faster. Direct quality control ensures that the molds meet your exact specifications and reduce defects. In-house mold manufacturing keeps everything streamlined, saving costs. This is a strategic advantage for any serious metal injection molding company. It also gives us a huge advantage, allowing us to quickly respond to the urgent needs of our customers and their markets. Our facilities and skilled craftsmen allow us to fully maintain molds and produce custom molds for up to 300 new products per month. In addition, we are constantly investing in the latest machines and technologies to increase production speed and precision.

ISO Class 7 Cleanroom Facility

Elimold offers you unparalleled medical molding capabilities in a state-of-the-art ISO Class 7 cleanroom facility. This controlled environment minimizes airborne particles and contaminants, ensuring your components are manufactured to the most stringent standards. This meticulous process safeguards part integrity for patient safety and regulatory compliance. Trust us to deliver medical-grade MIM parts with unmatched quality and precision. At Elimold, we produce the highest quality, uniform MIM and sintered parts in the industry. With experienced experts across all departments and sophisticated quality control standards, we produce the high-quality, complex MIM parts you need.

Metal Injection Molding Capabilities

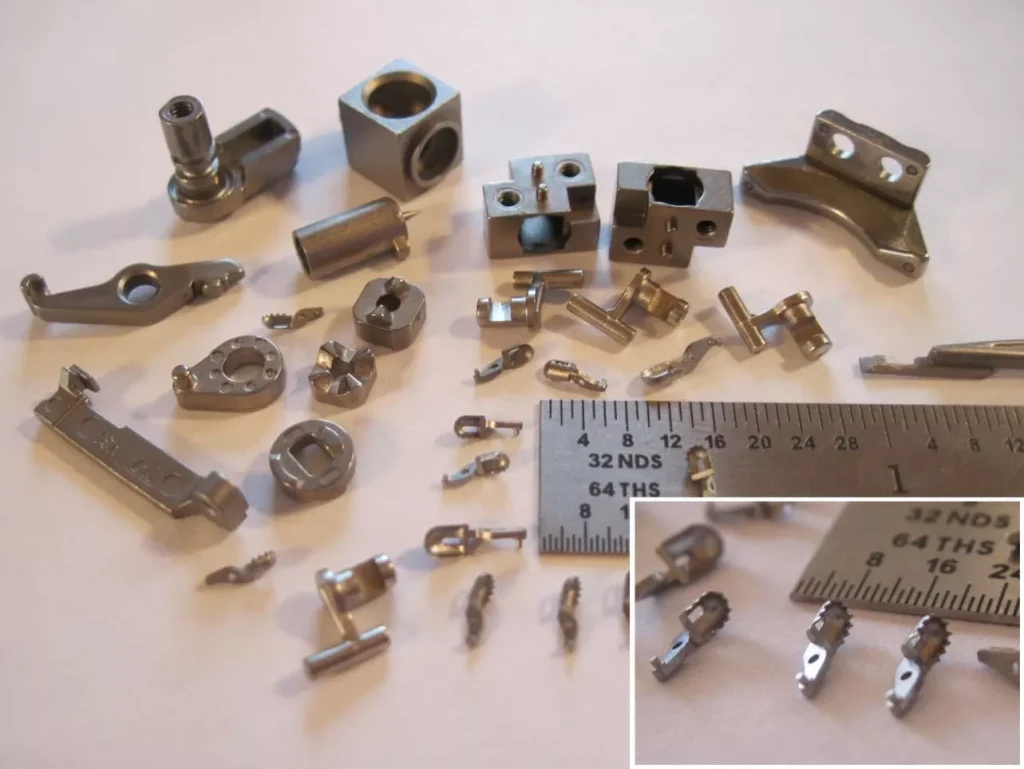

Metal injection molding is best suited for manufacturing small, complex parts. Accuracies of +/- 0.003 inches per inch are typically achieved without secondary operations. Manufacturing difficulties with other manufacturing methods can result in inefficiencies or even inability to manufacture. Because injection molding can achieve a variety of features (internal and external threads, miniaturization, branding), the added complexity of traditional manufacturing methods does not usually increase the cost of metal injection molding. The process is capable of producing parts weighing from 50 grams to 500 grams or more with tight tolerances. Typical error ranges are: ±0.5% of the dimension, up to ±0.3% of the target dimension. If you have any questions or would like to request a quote, please contact us today.

MIM Tolerances

Metal Injection Molding tolerances are nominally ±0.3%-0.5%, although tighter tolerances can be achieved in some cases if deemed essential. MIM component production ranges over a large size range, making it difficult to address tolerances directly over such a wide range. In some instances, the choice has been to create a table of tolerance versus size, showing capabilities as follows: These MIM tolerances can be obtained within a single batch but wider variation is usually observed over time.

- ± 0.03 mm (0.0012 inch) for features below 3 mm (0.12 inch)

- ± 0.05 mm (0.002 inch) for features between 3 and 6 mm (0.12 to 0.25 inch)

- ± 0.08 mm (0.003 inch) for features between 6 and 15 mm (0.25 to 0.6 inch)

- ± 0.15 mm (0.006 inch) for features between 15 and 30 mm (0.6 to 1.2 inch)

- ± 0.25 mm (0.01 inch) for features between 30 and 60 mm (1.2 to 2.4 inch)

Metal Injection Molding Company

With many years of experience in metal processing services and custom molded product manufacturing, we provide professional metal injection molding services, covering consultation, design, prototyping to production, and become one of the top injection mold manufacturers and producers in various industries. Our capabilities range from top-quality and commercial-grade materials to end-use molded parts, custom prototypes, rapid mold manufacturing, and more, always providing cost-effective small or large-volume production for global customers. We have an experienced design and engineering team, advanced technology, and industry-leading equipment. At every step, we can provide you with meticulous consultation, attention to detail, and customized services to meet your needs and ultimately deliver high-quality results.

Metal Injection Molding Engineered Solutions

We specialize in providing custom manufacturing solutions using our expertise in Metal Injection Molding (MIM). Our experienced team works hand in hand with our customers to develop customized products to ensure optimal performance. We focus on a consultative approach, working closely with our customers from initial concept to production, paying attention to every detail. Our commitment to customization sets us apart in the industry and enables us to provide innovative solutions that enhance our customers’ competitive advantage. Our custom design services cover industries that require the utmost precision. We also offer rapid prototyping services to test and validate designs before full production. Using our MIM technology, we produce high-quality components at very competitive prices, reducing overall project costs.

Product Design Assistance and Design for Manufacturability (DFM) Feedback

To ensure your metal parts meet your needs and are cost-effective to manufacture, we provide product design assistance and Design for Manufacturability (DFM) feedback on processing, tooling, and visual and functional applications using the latest advanced 3D computer-aided design (CAD) and programming software. Design for Manufacturability (DFM) is your secret weapon for transforming innovative concepts into production-ready injection molded parts. By working early with our DFM experts, you can identify potential roadblocks, such as complex geometries or uneven wall thicknesses. We will recommend adjustments to optimize your design for efficient molding, minimizing waste and production costs. This ensures that your parts are not only fully functional, but also easy to manufacture, saving you time and money while turning your vision into reality.

Inspection and Testing

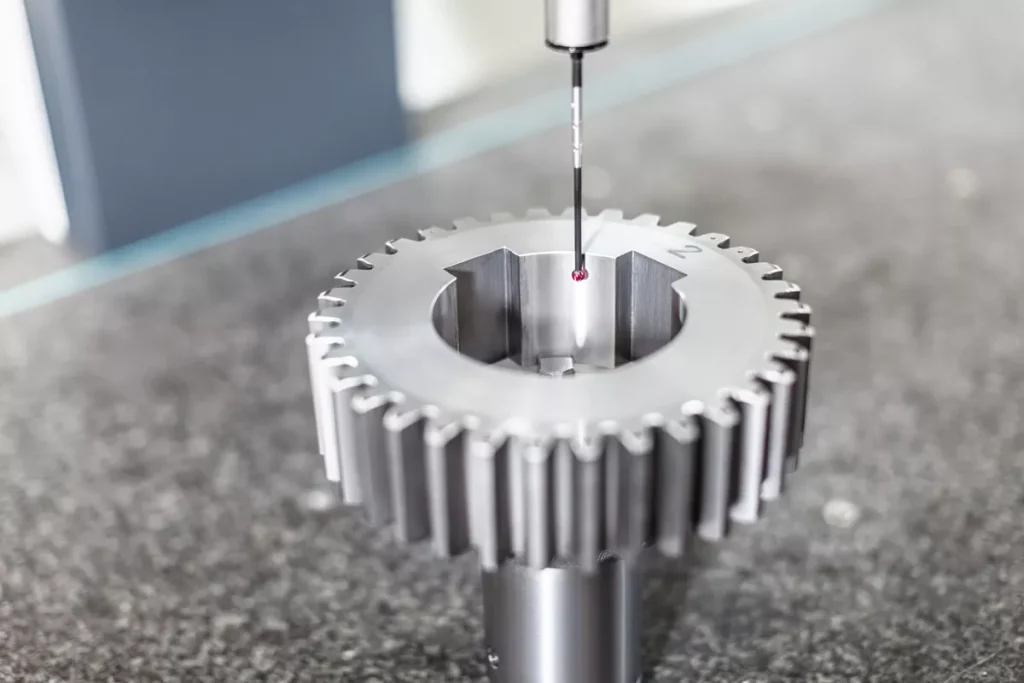

Our inspection and testing services are built to the highest standards of integrity and performance. We use advanced technologies such as X-ray inspection, ultrasonic testing and dimensional analysis to eliminate any defects. From start to finish, our rigorous testing ensures that mold quality exceeds expectations. Our unwavering commitment to quality provides unmatched reliability and long-term durability. In addition to the same dimensional inspections as other machining methods, MIM parts require sintered density and chemical composition analysis. In chemical analysis, it is particularly important to monitor carbon content. Some parts may also require X-ray inspection or other non-destructive testing to check for cracks or other internal damage.

Testing Options For MIM Parts

- 3D laser or measuring probe

- Impact strength

- Yield point

- Chemical analysis

- X-Ray

- Fluxing

- Ultrasound

- Tensile strengths

- According to customer requirements

Talk to Elimold's Metal Injection Molding Experts

Navigating the intricate details of metal injection molding can be difficult if you’re facing performance or application challenges. Whether you’re considering MIM for a new project or looking to enhance an existing manufacturing process, Elimold’s experts are ready to help. We are committed to leveraging the full potential of MIM to meet your specific needs and ensure your project is a success from conception to production. Learn how Elimold can transform your ideas into metal parts with exceptional precision and quality. Contact us today to begin your journey to manufacturing excellence.

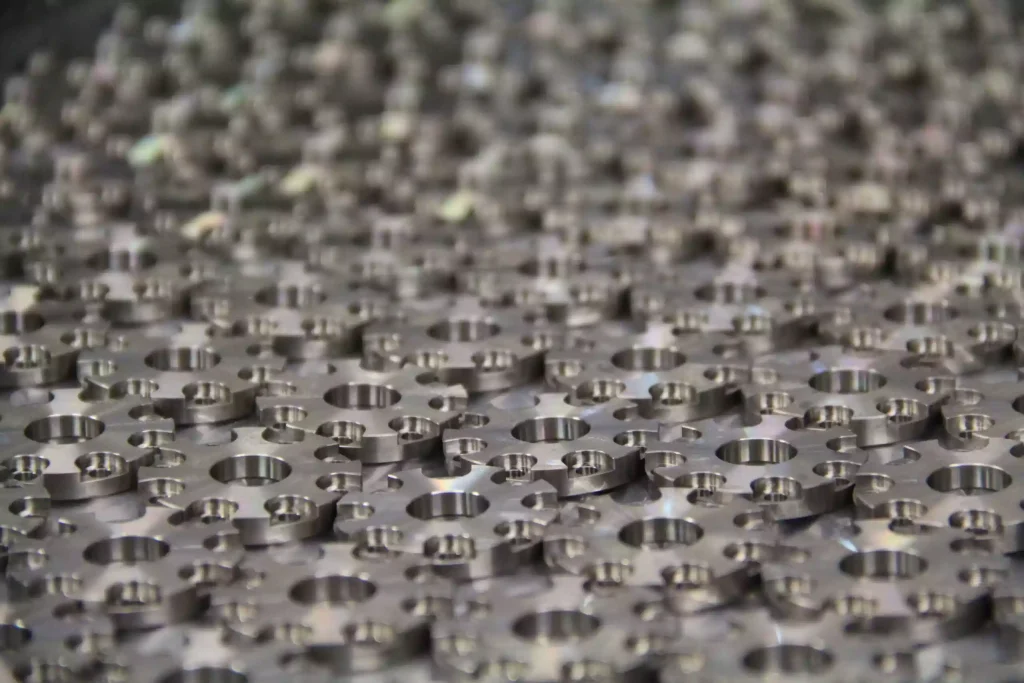

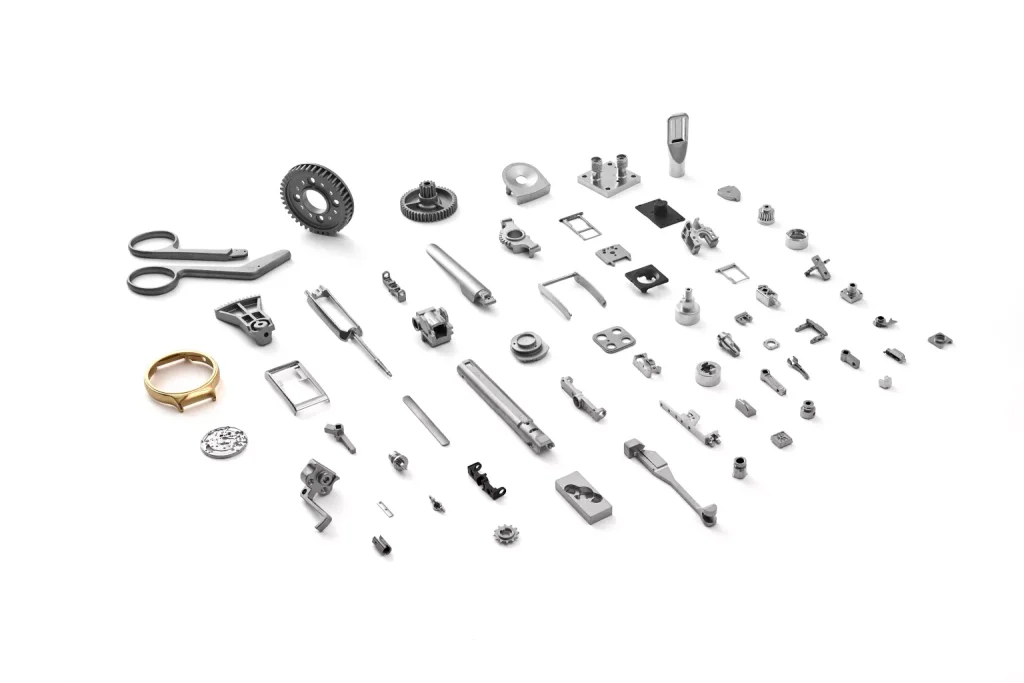

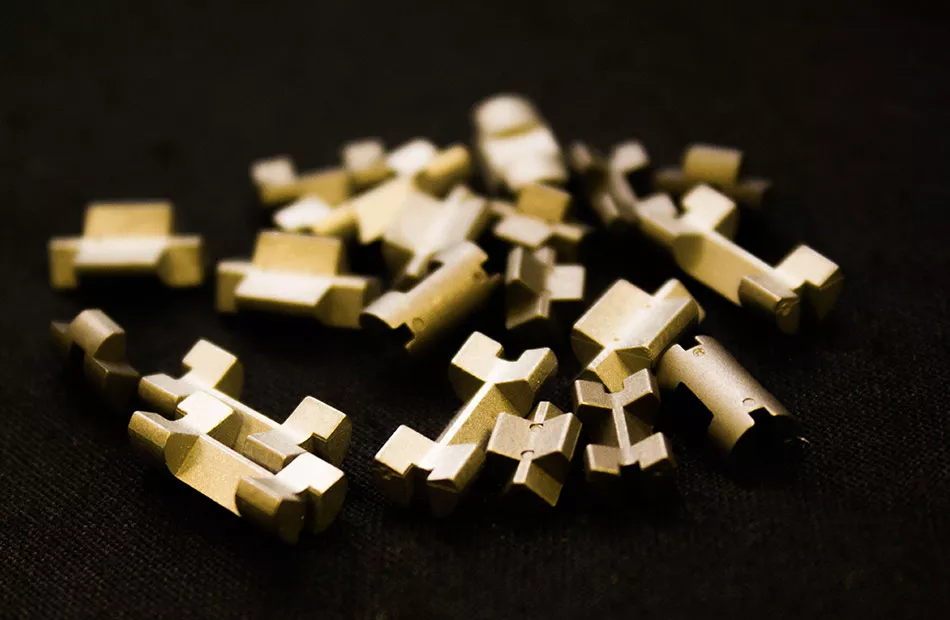

Small Parts Metal Injection Molding

Are your parts small and complex? Metal Injection Molding (MIM) may be the right choice for you. Metal Injection Molding (MIM) represents the pinnacle of manufacturing efficiency and versatility for engineers and designers who demand precision, complexity, and cost-effectiveness in metal part production. Elimold uses this advanced process to transform complex designs into high-performance components, making the transition from concept to reality seamless. Our proprietary MIM technology maximizes the performance of your designs. Our in-depth knowledge of the MIM process and alloys enables us to quickly design and produce high-quality MIM components.

Comprehensive Metal Injection Molding Services

Elimold offers integrated in-house capabilities, advanced facilities, and ongoing communication to optimize process efficiency, control costs, shorten production time, and reduce risks from start to finish. We help you manufacture custom metal parts with years of trusted expertise. When you choose Elimold, you work with a leader in the manufacturing industry with extensive experience in engineered materials. Our innovative and cost-effective engineering solutions are designed to meet the diverse needs of our customers while maximizing value. In addition, we provide comprehensive design and engineering support to ensure that every aspect of your project is handled professionally and meticulously. Quality is always our primary concern, and we adhere to strict standards and strive to deliver products that exceed expectations. We offer five full-density options to meet your specific needs, no matter how complex your project is. Contact us today to experience the Elimold difference! Let us turn your ideas into reality!

Rapid Prototyping Services

We provide low-volume R&D design and prototyping services at a low cost to get you to high-volume production. Our prototyping services ensure your design meets your form, fit and function requirements before the injection mold is manufactured. Our team will work closely with you from concept drawings or designs to finished metal injection molded parts to ensure they are manufactured in the most cost-effective manner to achieve your end-use goals. Alternatively, we can utilize 3D printing to manufacture your first prototypes. If you are producing less than 1,000 pieces but don’t want to pay for full production, we have a flat-rate low-volume program called SUPERMOLD. This has many benefits, including faster time to market and lower initial investment, while still allowing you to produce high-quality parts.

Design & Product Engineering

Our mold making capabilities are supported by a highly trained design and engineering team that can turn your ideas into reality. Our multidisciplinary engineering team is well versed in product, custom metal injection mold, fixture and gage design. We use several different 3D design environments, including ProEngineer and SolidWorks. We provide a full range of product design support services, including industrial design, finite element analysis (FEA) and 3D flow analysis. And, our engineering process begins at the proposal stage. This allows us to calculate costs with a high degree of accuracy and help products quickly transition through the development process. The engineering team conducts a comprehensive product design review and plans every aspect of the mold and manufacturing process. Once the project is launched, our APQP team meets with customer representatives to carefully plan every step of the project. Our multidisciplinary team of quality, product, tooling and manufacturing engineers work closely with our field sales engineers to communicate with customers at every stage of the project. Our efforts enable us to build strong customer relationships.

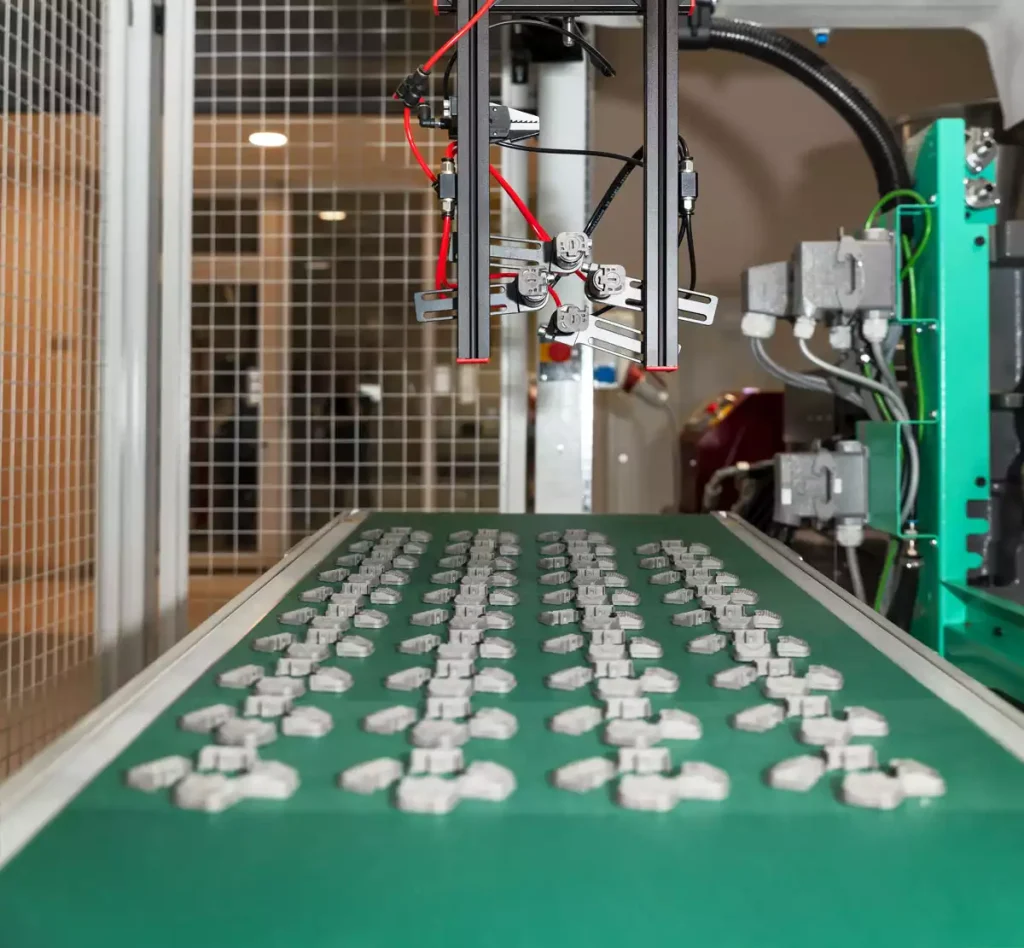

Large-scale MIM Production

Elimold is able to apply MIM technology to produce MIM parts in large quantities, multiple alloys, different sizes and complex structures. When you provide the relevant project design drawings or sample parts, and we have completed the relevant rapid prototyping, all parts are of good quality. We will plan further large-scale production and send the batch order to you. In addition, due to the high cost of molds, MIM is usually not suitable for small-volume production. Usually large-scale production is very effective. Generally speaking, for small parts, an annual output of 100,000 pieces or more is ideal. The minimum reasonable production volume should be between 5,000 and 20,000 pieces per year. Less than 5,000 pieces is feasible, but the overall economic advantage will be lost compared with other production methods.

Assembly Services

At Elimold, seamless integration is key to our turnkey solutions. Our assembly services bring components together into a single, high-quality product. From the fusion of molds and precision-machined parts to the assembly of complex components, we ensure flawless results. We are committed to excellence and provide fully assembled, ready-to-use solutions with precision and meticulousness. Our advanced MIM technology offers unparalleled precision and cost-effectiveness, capable of producing complex geometries that are not typically achievable with traditional methods. With our commitment to quality, state-of-the-art facilities and a dedicated team of experts, we ensure that your parts meet the highest standards. So everyone cares about your parts, and it shows in the quality of the final part.

Metal Injection Molding Service Provider

We provide professional metal injection molding services to meet your unique product development needs. Whether you need simple or complex three-dimensional structures, Elimold is your trusted MIM manufacturer, always committed to providing high-quality and high-tolerance products. Maybe you don’t know which process to use, so let us provide a free engineering consultation to help you. The sooner you get your supplier involved, the more likely you are to save a lot of costs, which may be time, money, functions, or even new ideas. We focus on “challenging” projects that require extra attention, experimentation, or the use of new materials. There is no better mold company than Elimold for this kind of task.

Elimold's MIM Technology for Complex 3D Parts

Metal Injection Molding (MIM) is an alternative to traditional sheet metal processing, milling, and casting. MIM can be used to manufacture complex three-dimensional shapes, is compatible with a wide range of materials, and is suitable for mass production. MIM can create three-dimensional shapes that cannot be achieved by machining or sheet metal processing. Therefore, in some cases, multiple parts that are traditionally manufactured by milling or other machining operations can be molded into a single part by metal injection molding, thereby reducing costs. 3D printing is a method that can create three-dimensional shapes using metal powders. However, the advantage of MIM over 3D printing is that it is more suitable for mass production, is more flexible in material selection, and requires less post-processing. We are able to produce high-quality MIM parts because we have expertise in the entire production process, from the production of our own powders to the molding process. Elimold is unique in its ability to sinter workpieces to 99.5% density, stably mass-produce tiny parts with complex shapes, and use MIM to process parts made of titanium and titanium alloys.

Need A Metal Injection Molding Manufacturer?

Need a custom, high-precision metal part using metal injection molding? Contact us today to discuss your project and discover how our metal injection molding services can bring your product to life!

What is Metal Injection Molding?

MIM is great for making strong, stiff, dense, and complex parts, while also offering a host of other excellent mechanical properties. It can be produced in large quantities in one go, and can actually handle heavy-duty parts more economically than investment casting, machining, or even stamping. MIM has far fewer design restrictions than some other processes, and no matter how complex the part, you don’t have to assemble multiple components together to make the final part, the process can be done in one go. In addition, MIM produces less material waste and scrap than other methods, which means you can get the most out of your money and materials—up to 98% of your material can be turned into usable parts. This injection molding process is almost always used for large-scale production of small, complex parts that are difficult to make with other methods (for example, if the part has very thin walls).

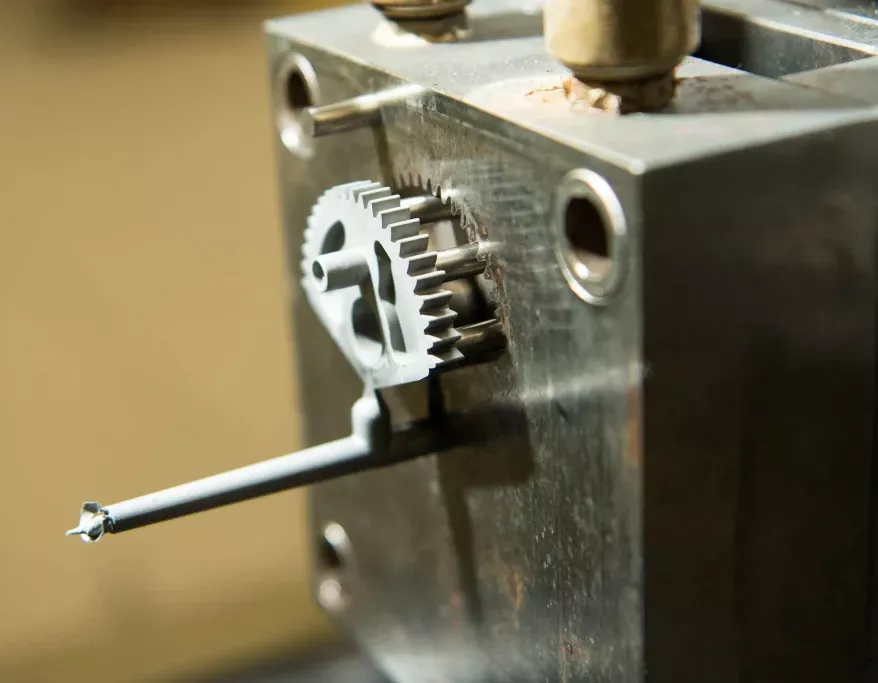

How Metal Injection Molding Works

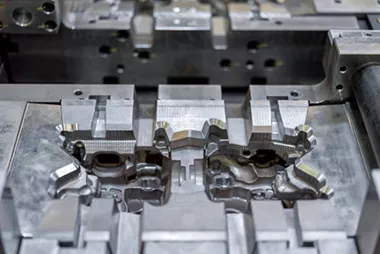

The simplest MIM shapes are produced in a two-part mold with flat surfaces that fit together to seal the cavity. One part consists of a core that mates with a cavity in the other part with a uniform gap between them, producing a shape with uniform wall thickness. The core forms the internal features, while the cavity forms the external features. All features are designed to allow the cavity to release the solidified profile and push it off the core by an ejector rod or ejector pin. The complexity of MIM components can be increased by adding slides, cores, and other tools commonly used in plastic injection molding. While the added features and their increased complexity can bring economic benefits by reducing secondary machining or assembly operations, this often increases the costs associated with tooling and start-up engineering. These benefits and costs must be carefully weighed at every stage of the design. There are many key aspects that must be considered when designing MIM components in order to fully utilize all the advantages of the process.

Metal Injection Molding Process

Feedstock Compounding

The MIM process starts with mixing APP’s proprietary MIM Feedstock, a combination of metal powder and binder.

Injection Molding

The MIM feedstock is injected into a mold with multiple mold cavities using automated injection molding machines to produce a “green part” that is 20% larger than the finished component.

Debinding

The parts then move through the first stage debinding. This removes most, but not all, of binders, and the part is prepared for sintering. This part is considered a “brown part”.

Sintering

During the high temperature sintering process, the part is heated near its melting point, all binder removal is completed, the part densifies, and the final part geometry is formed.

Secondary Operations

After sintering, parts can then be sent to secondary operations to improve dimension control, mechanical properties, and visual appearance, such as sizing, heat treating and coating.

Advantages of MIM

- Great geometric design freedom

- Production of complex parts

- Internal & external threads can already be formed during casting

- High dimensional accuracy

- Unique level of detail

- First-class surface quality

- Good dimensional tolerances of +/- 0.5%

- Better adhesion of anti-corrosion treatments

- Relative density of 95-98%

- Less complex processing

- Low manufacturing costs

- Economical even with medium quantities

Material Options

- Haynes 188

- Inconel 738

- MIM Ti-15Mo-5Zr-3Al(Grade 21)

- MIM Ti-6A1-4V (Grade 5)

- MIM W-Ni-Co

- MIM-2700

- MIM-420

- MIM-440C

- MIM-A2

- MIM-D2

- MIM-H13

- MIM-MP35N

- MIM-T15

- Inconel 600

- MIM 17-4 PH

- MIM Ti-15V-3Cr-3A1-3Sn

- MIM Ti-6A1-7Nb (Grade 26)

- MIM W-Ni-Cu

- MIM-304

- MIM-430

- MIM-52100

- MIM-CoCrMO (ASTM F75)

- MIM-Fe-3Si

- MIM-Haynes 25

- MIM-Ni18Co9Mo5

- Inconel 625

- MIM 316L

- MIM Ti-3A1-2.5V (Grade 9)

- MIM W-Cu

- MIM W-Ni-Fe

- MIM-4065

- MIM-430L

- MIM-8620

- MIM-CoCrW

- MIM-Fe-50Co

- MIM-M2

- MIM-S7

- Inconel 713LC

- MIM Ti-10V-2Fe-3Al (Grade 20)

- MIM Ti-5A1-2.5Fe (Grade 38)

- MIM W-Fe

- MIM-2200

- MIM-4140

- MIM-4340

- MIM-9310

- MIM-CoNiCrM

- MIM-Fe-5ONi

- MIM-M4

- MIM-Stellite 6

Surface Treatments Of MIM Products

- Radiation

- Electropolishing

- Galvanizing (chrome-6 free)

- Passivation

- Paint

- Powder coating

- Anodizing

- Prime

- Vibratory finishing

- CED coating

- Sand or glass bead blasting

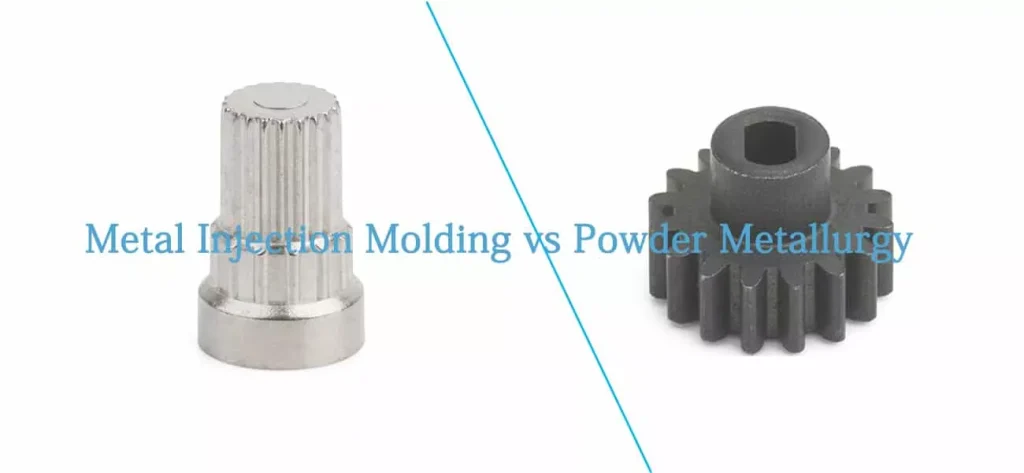

Comparison of MIM And Other Processes

MIM vs. Conventional PM

- MIM can produce geometries that eliminate secondary operations.

- MIM offers superior density, corrosion performance, strength, ductility.

- MIM can combine two or more PM components into one, reducing part count.

- MIM parts offer superior magnetic performance.

MIM vs. CNC Machining

- MIM designs save material and weight.

- Molding from a single tool eliminates multiple set-up operations.

- Difficult-to-machine materials can be molded into a net shape.

- MIM provides cost savings through better material utilization.

- Sprues and runners can be reground and reused as feedstock with no compromise to final properties.

MIM vs. Investment Casting

- MIM can produce thinner wall sections, sharper cutting points.

- MIM produces better surface finish.

- MIM is better for small-diameter blind and through holes.

- MIM greatly reduces requirements for finish machining.

- MIM produces high volumes of small components at a lower cost, with faster lead times.

Differences between MIM and PCM

Metal injection molding (MIM) and powder compression molding (PCM) are two very different manufacturing processes. MIM uses fine metal powder to create high-precision, complex parts, while PCM compresses powder into simple-shaped, less-precise parts. MIM is more expensive and suitable for medium and large-volume production, while PCM is more economical and suitable for small-volume production.

Difference between MIM and Die Casting

The difference between MIM and die casting is similar to plastic injection molding, with MIM requiring more post-processing. Die casting does not require as many steps and is generally faster. It is also well suited for making larger metal parts. Unlike metal injection molding, the die casting process uses a mold to form the metal part. Two pieces of metal are joined together to form a cavity in the mold. Molten metal is poured into the cavity. After the metal cools, it is ejected from the mold using a machine called a shot blaster. The process requires the use of molds made of steel or aluminum. Die casting is one of the most commonly used processes for small to large castings. The process is well suited for low to medium volume production.

Parts and Applications

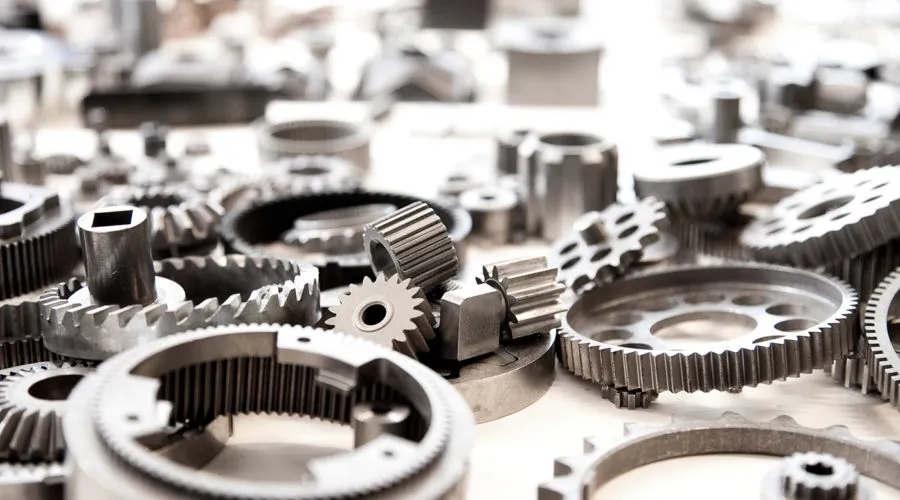

- Watch gears

- Medical surgical scissors

- Dental brackets

- Orthodontic braces components

- Smartphone vibration motors

- Laptop hinge components

- Firearm trigger components

- Gun slides

- Fuel injector nozzles

- Turbocharger vanes

- Electronic connector pins

- Heat sink parts

- Microphone housings

- Hearing aid components

- Laptop locking mechanisms

- Camera lens mounts

- Automotive sensor housings

- ABS sensor components

- Turbocharger rotor parts

- Gear shift components

- Aerospace fasteners

- Electric shaver heads

- Lock cylinder components

- Mechanical watch cases

- Medical endoscopic instruments

- Implantable orthopedic screws

- Insulin pump components

- Microsurgical tool parts

- Fuel cell bipolar plates

- Drone motor housings

- Compact valve bodies

- Pressure sensor diaphragms

- Fluid control valve components

- Small pump impellers

- Hand tool gear parts

- Precision hinge pins

- Automotive mirror adjustment gears

- Printer cartridge components

- Sensor probe housings

- Micro motor shafts

Explore MIM manufacturing solutions with Elimold

Metal injection molding (MIM) provides a powerful solution for producing high-precision complex metal parts, making it an essential process for a variety of industry applications. MIM combines design flexibility, material strength and cost-effectiveness, making it the first choice for manufacturers committed to innovation and optimizing production lines. Elimold has strong manufacturing capabilities and can provide advanced MIM solutions to help you improve your production level. We can serve various countries and regions around the world. No matter where you are, please contact us now to find out how we can help you!

Other Manufacturing Services

Elimold is a provider of contract offshore manufacturing services in the metal and plastics processing sectors. We can help you find the right solution for contract metal fabrication, metal casting, plastics manufacturing parts, assemblies and even complete machine manufacturing.

CNC Machining

Die Casting

Metal Fabrication

Precision Metal Stamping

Powder Metal

Plastic Manufacturing

Request Your Free Metal Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Metal Injection Molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.