Metal Stamping Services

Elimold specializes in providing custom metal stamping services to meet the needs of a wide range of industries. We can provide you with full support from the design stage to material selection, tooling manufacturing, prototyping, mass production, and additional assembly and packaging services according to your needs. Our expertise covers all areas of stamping and forming, so we can provide the most suitable service support according to your project and budget. Contact us today to start your journey.

Precision Metal Stamping Manufacturers

If you have a complete design, our build-to-print services are ideal for you. As a leading precision metal stamping manufacturer, we specialize in producing stamped metal parts according to your drawings, specifications or purchase order requirements. If you have a project that needs to be manufactured, but have not yet determined a manufacturer, the Elimold team is dedicated to providing rapid prototyping and mass manufacturing services, and working with you to transform your product from concept to reality. Custom stamping solutions are customized to specifications, which requires identifying key requirements and what is required to meet them. Once the final design is approved, full production can be launched. However, we do more than just stamp metal. We provide a full range of value-added assembly solutions from a single source to help you streamline your supply chain.

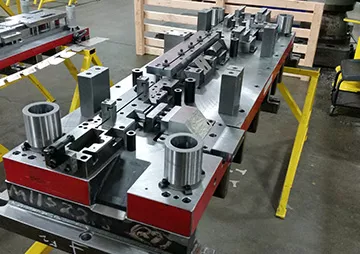

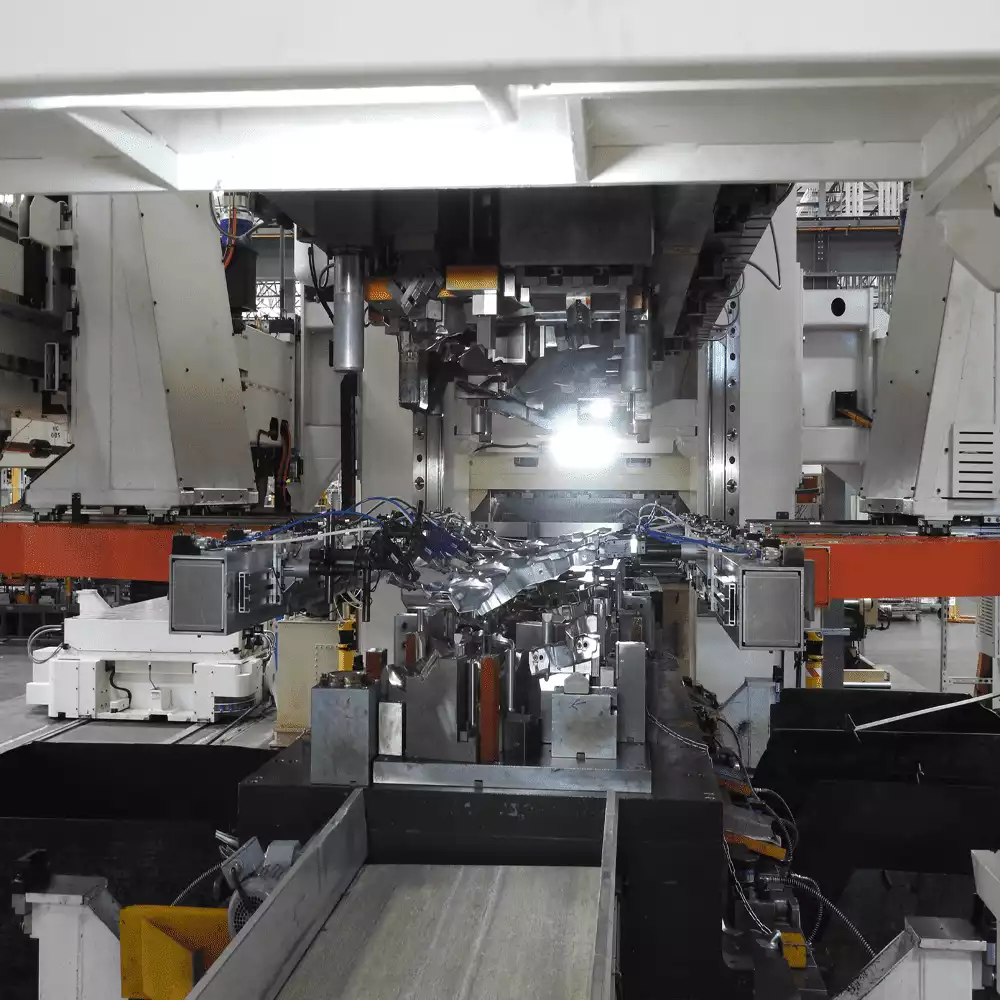

In-House Metal Stamping Manufacturing Facility

Our world-class manufacturing facility features 60,000 square feet of manufacturing space, 50,000 square feet of manufacturing space, tooling, stamping, welding, final assembly and warehousing services, and state-of-the-art equipment. Our experienced team of 150 employees is ready to meet your needs and deliver on time. Our offices and facilities are fully computerized, providing customers with instant tracking information. Our 24-hour production schedule ensures that we maintain one of the best on-time delivery records in the industry, ensuring that the task is completed perfectly every time. No matter the size or complexity of your order, whether it is a simple prototype design or a high-volume production of a multi-step manufactured part, you will be impressed by our dedication and fast delivery capabilities. If you would like to discuss how we can best serve you, or if you have any questions, please feel free to contact us.

Custom Metal Stamping Capabilities

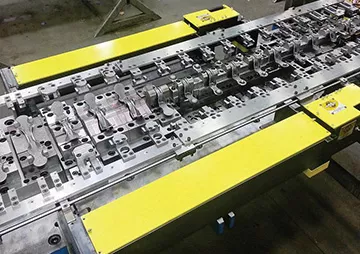

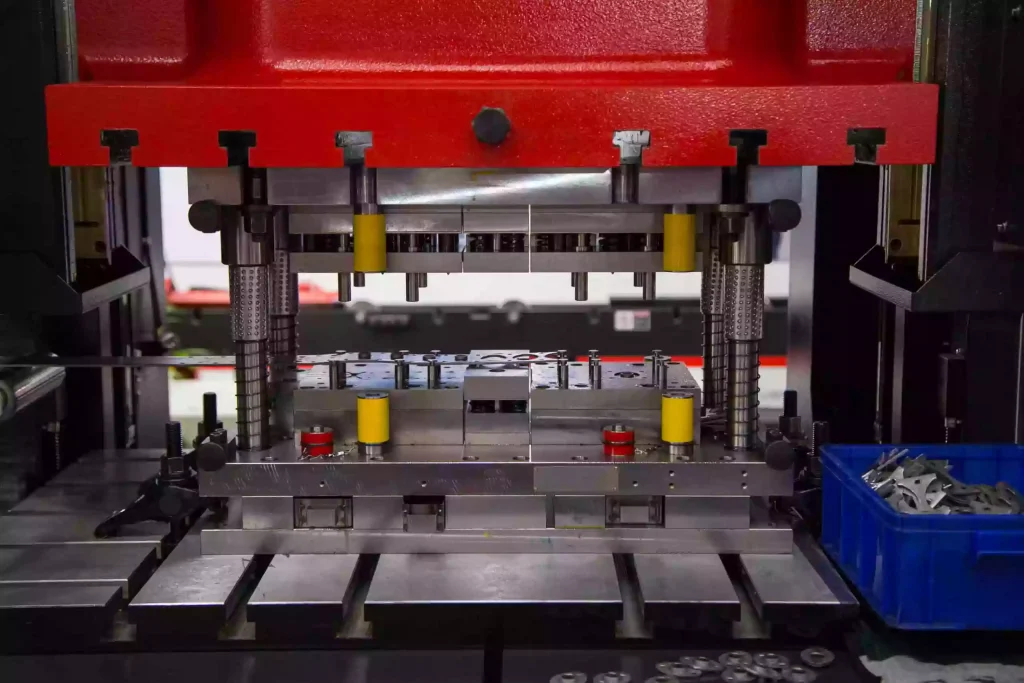

As a leader in metal stamping, our customers trust us for our expert design and development services. We manufacture metal parts of all sizes, from simple to complex. We support our customers from prototype development to high-volume production. We have the capacity to handle orders of up to 50 million parts. In Elimold’s in-house facility, we have 20 presses ranging from 55 tons to 1,800 tons. Our largest continuous press line is 800 tons, has a 144-inch press bed, and a coil capacity of 30,000 pounds. We also have five smaller continuous press lines ranging from 60 tons to 400 tons. The 1,100-ton hydraulic press has a bed size of 84 inches by 120 inches, a cushion stroke of approximately 12 inches for large draws, and a SSDC (solid state continuous press) capacity of up to 1,000 tons. We are able to punch workpieces up to 18 inches (about 45 cm) deep. The minimum material thickness for this process is 0.0120 inches (about 3.7 cm) and the maximum material thickness is 0.5 inches (about 12 cm). If you have any questions about precision metal stamping, your specific project, or what it’s like to work with us, please contact us.

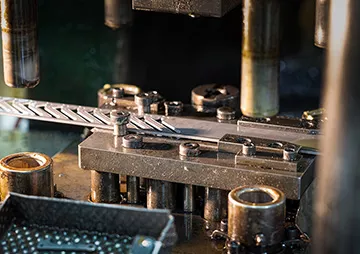

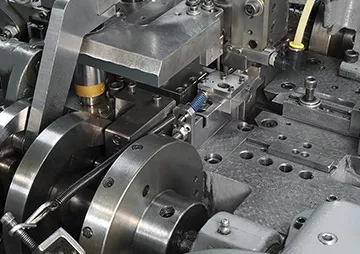

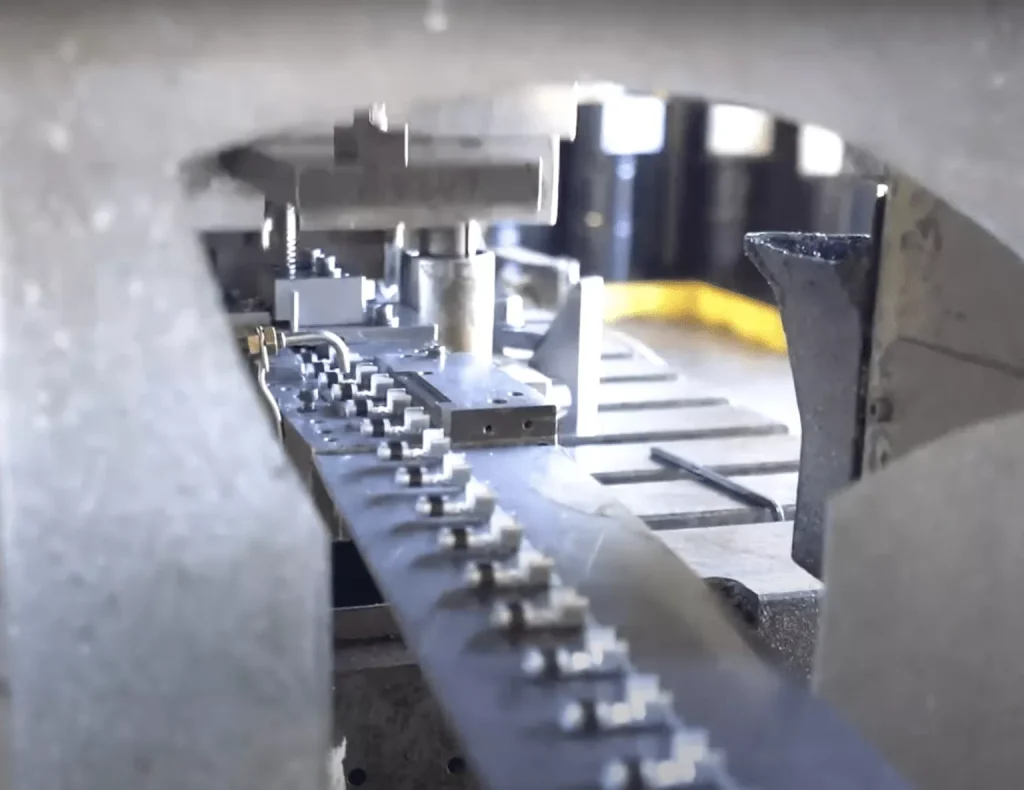

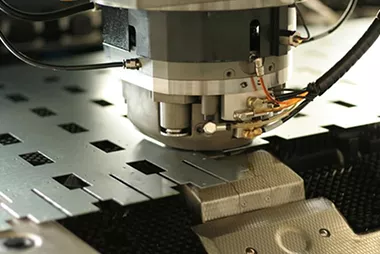

Leading-Edge Technology

Elimold invests in cutting-edge technology to improve process efficiency and produce high-quality and cost-effective products. We use progressive die metal stamping technology from Minster and Bruderer. Our in-house facility is upgraded with advanced manufacturing equipment to produce with greater precision and accuracy, and is able to achieve complex geometries and tighter tolerances. We also have a dedicated automation department responsible for developing in-mold sensor technology and camera vision systems to integrate quality assurance throughout all stages of stamping production. With a dedicated team, innovative equipment and excellent quality control, Elimold can provide progressive die high-speed stamping and heavy-duty stamping services to ensure reliable parts are delivered on time and on budget.

Fast Turnaround Metal Stamping Services

We provide fast turnaround precision metal stamping services that produce high-quality precision metal stampings in a variety of shapes from virtually all heat-resistant alloys, ferrous metals, nonferrous metals, and exotic metals. We offer a full range of metal stamping and value-added assembly services, from simple blanking tools to complex custom stamping dies, to exceed your expectations. Our experienced and well-trained engineers, tool and die makers practice the principles of total quality management and utilize technologically advanced metal stamping systems and process controls to ensure that our customers’ delivery, inventory, and tracking requirements are consistently met.

Stamping Types

Metal stamping covers a range of processes, each tailored to specific manufacturing needs and design requirements. Elimold offers single and multi-stage stamping, progressive die, deep drawing, four-slide, and other stamping processes to ensure your product is manufactured in the most efficient manner. Major types include:

Progressive Stamping

Fine Blanking

Deep Draw Stamping

Compound Stamping

Long-run Stamping

Transfer Die Stamping

Four-slide Stamping

Slide Stamping

Short-run Stamping

Engineering and Design Support

Our engineers and designers work closely with you to optimize your design for cost-effective material selection, manufacturability, and end-use functionality. From concept to prototyping and finally production. We are here for you every step of the way, providing complex prototyping, design assistance, reverse engineering, and redesign of new or existing products quickly and accurately, leveraging modern software and cutting-edge testing tools. Our design engineering services cover all major areas of pre-production activities: from in-house tooling design, product and prototype development to material selection. Whether you are looking to prototype, produce in small quantities, or have a high-volume project, our team has the resources and expertise to get the job done perfectly.

Early Supplier Involvement (ESI)

We specialize in Design for Manufacturability (DFM) and Early Supplier Involvement (ESI) to help you optimize part designs, reduce costs, and streamline production processes. Early involvement in the design process means we can assist customers in optimizing their designs and tooling to meet specifications for efficient manufacturing and prototype parts. Our designers, engineers, machinists, and lab personnel are highly trained and have many years of experience. For every project, we speak with every potential customer immediately to ensure we fully understand the customer’s needs. It is not uncommon for us to recommend that you be involved in the design process. We want our service as a low-volume metal fabrication supplier to be as efficient and seamless as possible. This way, you can get the products you need up and running as quickly as possible.

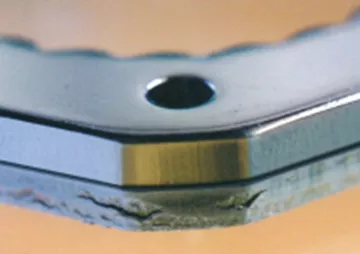

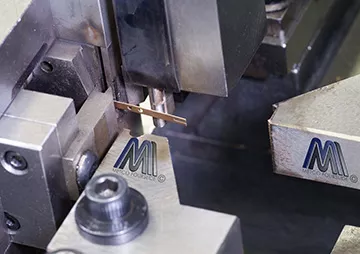

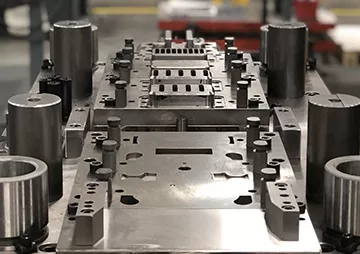

Stamping Die Service

In order to provide flexible metal stamping services, Elimold has established an internal stamping die workshop and warehouse. We design custom dies according to your drawings or samples, use suitable materials to make dies, whether it is progressive dies or fine stamping dies, we can meet your various needs. In addition to design and manufacturing, Elimold also provides modification and maintenance services. During the mass production of stamping parts, we will modify the existing stamping dies according to the customer’s temporary design requirements to make it more flexible to adapt to market changes. At the same time, we provide free maintenance for customers’ dies, such as adding lubricating oil, anti-rust liquid, etc., to ensure that each die can be put into production at any time.

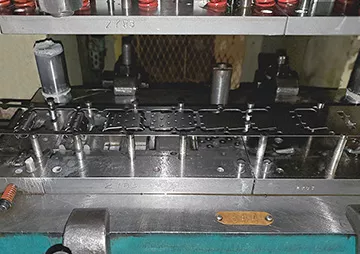

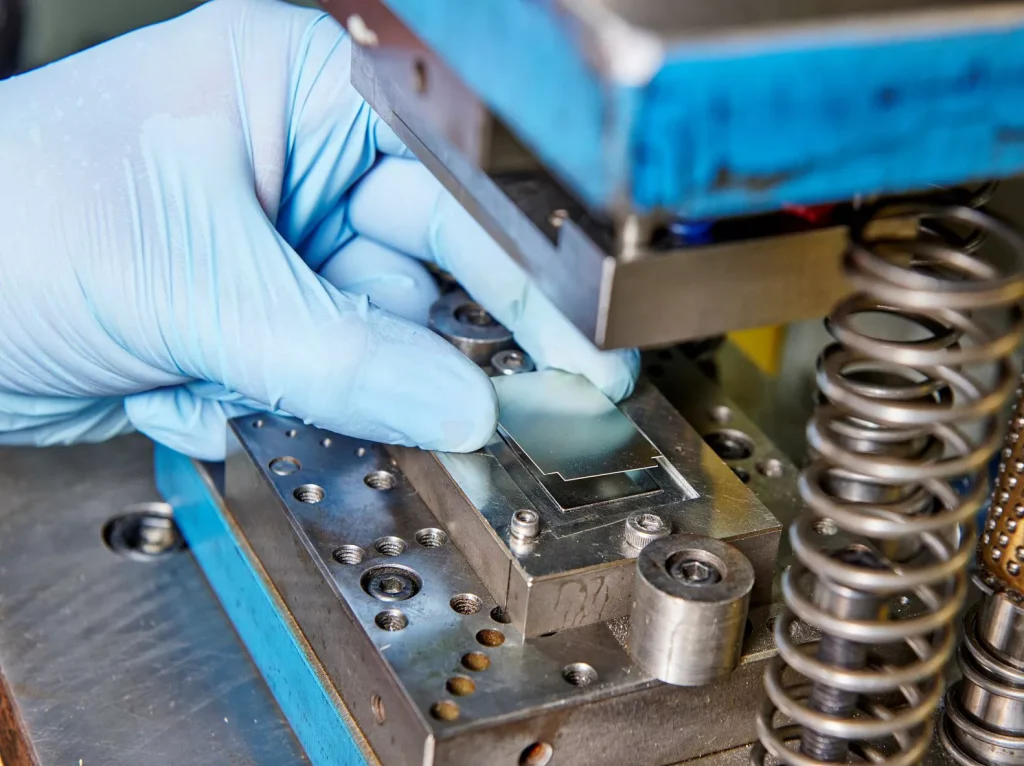

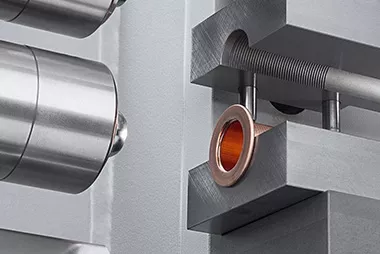

In-house Tool Design and Manufacturing

Elimold currently has 15 master toolmakers capable of building molds, stamping dies, cutting tools, machine tools, and a variety of other tools required for manufacturing. These experts all have many years of experience in toolmaking and can provide a full range of services from R&D consulting to design and prototyping. And we usually start with a design suitable for the specific task, and then create a tool with extremely close tolerances, appropriate clearances, adjustable shapes, suitable heat-treated alloys, wire-cut EDM precision geometry, and accurate assembly, assembly, and testing. Our in-mold sensors allow us to monitor tool performance in real time, thereby improving efficiency and reducing downtime caused by misfires, pulls, misalignment and other tool damage issues. Our ability to manufacture carbide precision stamping tools in-house allows for extremely high accuracy, regardless of complexity.

Types of Metal Stamping Die

We can custom various types of stamping dies to meet your specific needs. Our experienced engineers will work closely with you to develop a die that meets your design and production requirements.

Forming Tooling

Compound Tooling

Progressive Tooling

Are we the right supplier for you?

Every project has its own unique needs, and choosing the best supplier partner means finding one with the right combination of knowledge, expertise, and capabilities to meet or exceed your expectations. At Elimold, we are committed to making the impossible possible. When clients come to us with specific needs and creative challenges, our job is to provide customized product solutions that bring them excellent results. We perfect our service system to ensure that we are the ideal supplier partner for each of our clients. Please contact Elimold to tell us more about you, your needs, and determine if we are the right supplier for you.

Ready to start your metal stamping project?

Designing and producing a custom metal stamping can be complex. New parts often require extensive investments in tools, while existing parts can be prone to quality issues with suppliers. If you have a question about your part, please reach out. We have both design and manufacturing experts (including design engineers) available to help.

Prototyping & Custom Stamped Parts

Elimold’s prototyping department has state-of-the-art equipment to create custom metal stamping dies, ensuring a precise production process. Our engineering team works closely with our customers to design innovative and efficient prototypes that meet unique industry needs. We are willing to work with you to produce small or large batches based on your specific needs. Our team is committed to providing you with custom metal stampings that are guaranteed to satisfy you and exceed your expectations. We are also able to process strip and wire, further enriching our product line of custom metal stampings.

From Prototypes to Low-Volume Production

We offer exceptional stamping and forming services for all of your metalworking needs. Our team is proud, experienced, and ready to take on any project you have in mind. Our stamping capabilities provide cost-effective solutions for one-off prototypes, full-scale mock-ups, and low-volume production runs. Our team of metal stamping experts and craftsmen have the expertise and dedication to take on every job. Some contract manufacturing companies are reluctant to offer low-volume metal fabrication and metal stamping services. This is because they specialize in high-volume production and are not qualified to take on low-volume business. Our sheet metal team can take on prototype work as low as 10 parts, and production work up to 5,000 parts.

In-house Production and Inventory Management

We apply our expertise to every project to ensure consistent quality and on-time delivery. Our team works with you to establish the most cost-effective processes to produce the highest quality metal stampings. We become an integral part of your supply chain by actively participating in your Material Resource Planning (MRP), Electronic Data Interchange (EDI), Vendor Managed Inventory (VMM) and Kanban systems.

In addition, we use a Just-in-Time (JIT) inventory model to produce exactly what is needed, minimizing waste and reducing costs. We deliver orders quickly and efficiently because we do everything in-house, from quoting and design to production and packaging. We understand that sometimes customers encounter unexpected situations, so we also reserve capacity to handle emergency orders. If you need a specific component urgently, please feel free to contact us.

Quality Systems

All of our facilities are ISO 9001 certified. In addition, Elimold has extensive experience with quality control systems and processes across many industries and specific applications.

- Production Part Approval Process

- Control Plans

- Failure Mode & Effects Analysis (FMEA)

- Measurement Systems Analysis (MSA)

- Initial Process Studies

- Statistical Process Control (SPC)

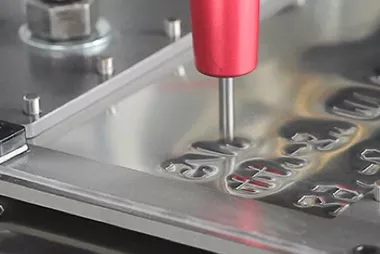

Quality Management

Elimold stamped parts are fully inspected using vision systems, optical comparators, coordinate measuring machines (CMM) and functional gages. And we are certified to ISO 9001:2015 and ITAR certified, with cybersecurity certified to NIST SP800-171, ensuring your export restrictions (ITAR) documents are always secure. And all stamping operations are routinely inspected after each consecutive run to ensure that output is within specifications. Quality and consistency are part of the Total Productive Maintenance (TPM) program to detect wear on stamping dies (usually made of D2 steel). For long-running stamping lines, measuring with a gage (or a gauge) is standard practice. Regular inspections ensure that output is within specifications, and quality and consistency are ensured through a Total Productive Maintenance (TPM) program. Stamping dies are inspected for wear and measuring with a gage or a gauge is standard for long-running stamping lines.

Value Added Services

We can maintain quality and cost targets for metal parts during assembly, inspection and packaging using both manual and automated processes. Computerized workstations provide detailed instructions for metal parts, proper equipment setup and expected production rates to ensure that customer delivery targets are met. Elimold Value Added Services has a variety of advanced equipment to perform operations such as welding, inserting, tapping, drilling and cleaning. In addition, we have four robotic welders to ensure increased production, quality and precision of welds.

Metal Stamping Supply Chain Management

Elimold provides services at every stage of metal stamping production, from the very bottom of the supply chain, we manage product materials, metal stamping production, pre- and post-stamping processes, as well as product handling, tactical scheduling, logistics and delivery. From early design concepts to tooling, to the production of finished metal stamping parts. This is a key business model we have developed to help customers reduce their supply base and centralize the entire manufacturing process for sourcing at one facility. We have a tight chain of suppliers that have gone through our rigorous approval process and qualification review, which focuses on quality, price and delivery. We also track the performance scores of all suppliers based on key quality indicators. When we undertake new and existing projects, the production process at all levels of our supply chain is fully managed and led by our team of expert project managers dedicated to these projects to ensure that schedules, delivery and other key factors are always met.

Building Partnerships

Elimold works with customers to solve design and manufacturing challenges. We work hand-in-hand with customer engineering and procurement teams to regularly co-develop solutions and deliver cost savings for complex projects. Our goal is to optimize efficiency on every project by seamlessly bridging the workflow between our customers and Elimold. Decades of experience have proven that the most cost-effective manufacturing strategies synergize the best engineering practices of our customers and Elimold. We remain committed to being a best-in-class service provider and a valuable resource for every customer by helping to improve efficiency in every aspect of the project.

Ready to Get Your Project Started?

For reliable delivery of stamped metal components, contact the experts at Elimold. With unmatched capabilities and a quality-first mindset, we deliver compliant components on time, every time. Contact us to learn more about our precision metal stamping services. We’d be happy to discuss your project in more detail.

Professional Metal Stamping Service Provider

We have powerful equipment to meet any challenge and even support our customers from the design stage to prototyping to finished products. No matter the size or complexity of the part, we can provide professional machinery and expertise to meet the needs of metal stamping projects in any industry. Our strict tolerance control ensures that the products you receive always meet the dimensions we specify. Our automated processes also ensure that each part is produced under exactly the same and repeatable conditions. This allows us to better monitor the progress of each part from start to finish. These automated equipment complement our reliable and skilled team of machinists. The combination of first-class stamping machines, quality control equipment and our team of skilled craftsmen ensures a high level of manufacturing quality.

What is metal stamping?

Metal stamping is the process of forming sheet metal into specific shapes using dies. This includes stamping individual sections of sheet metal as well as pressing it into specific shapes. The process may involve a single operation or may include multiple dies combined to produce the final part in succession. First, the sheet metal is placed in the stamping press with the dies and tools ready to perform their functions. When the press is started, it applies a high force that causes the dies to cut, bend, punch or emboss the metal into the desired shape. The process can be done in one go or in multiple stages, depending on the complexity of the part being produced.

Each set of dies is carefully designed to ensure that the metal is formed precisely to the specified dimensions and tolerances. The ability to perform operations such as blanking, piercing, forming and stretching in rapid succession makes metal stamping very efficient in mass production. In addition, technological advances have improved precision, making it possible to manufacture components with complex features and tight tolerances. Post-stamping operations may include deburring, cleaning and finishing, which further enhance the quality and functionality of the stamped part.

Material Selection

If you are unsure which material is best, we can help. Our experienced engineering team has extensive metallurgical knowledge and would be happy to help you select the best metal alloy for your application. Please contact Elimold to discuss your project requirements.

- Aluminum

- Rubber

- Brass

- Copper

- Carbon Steel

- High Strength Steel

- Galvanized Steel

- Ferrous and Non-Ferrous Metals

- Stainless Steel

- Nickel and Nickel Alloys

- Plastic

Additional Services Provided

In order to meet more product specifications and applications, Elimold provides comprehensive secondary finishing services

- Heat Treating

- Plating

- Finishing

- Powder Coating

- Assembly

- Kitting

- Painting

- Tooling

- Anodizing

- Annealing

- Number Stamping

- E-Coat

- Stress Relieving

- Vibratory Bowl Deburring

- Tumbling

- Assembly

- Packaging

- Rivet

- Inserting

- Welding

Benefits of Precision Metal Stamping

- Cost Efficiency: Metal stamping produces precision metal parts quickly, making it perfect for high volume production. As the production levels increase, labor costs decrease, making it cost-effective.

- Less Scrap Material: In addition to its efficiency, precision metal stamping also produces less scrap material than other metal forming processes, making it more cost-effective.

- High Quality and Accuracy: As the name suggests, precision metal stamping produces highly detailed, complex products at the precise tolerances that your application requires. Despite multiple pieces being cut together, each product is of high quality and accurate every time.

- Highly Automated Process: Metal stamping can be easily automated and can incorporate value-added secondary services into the die or press. These services can include in-die tapping, in-die welding, or automatic nut insertion, which increases the overall value of the part.

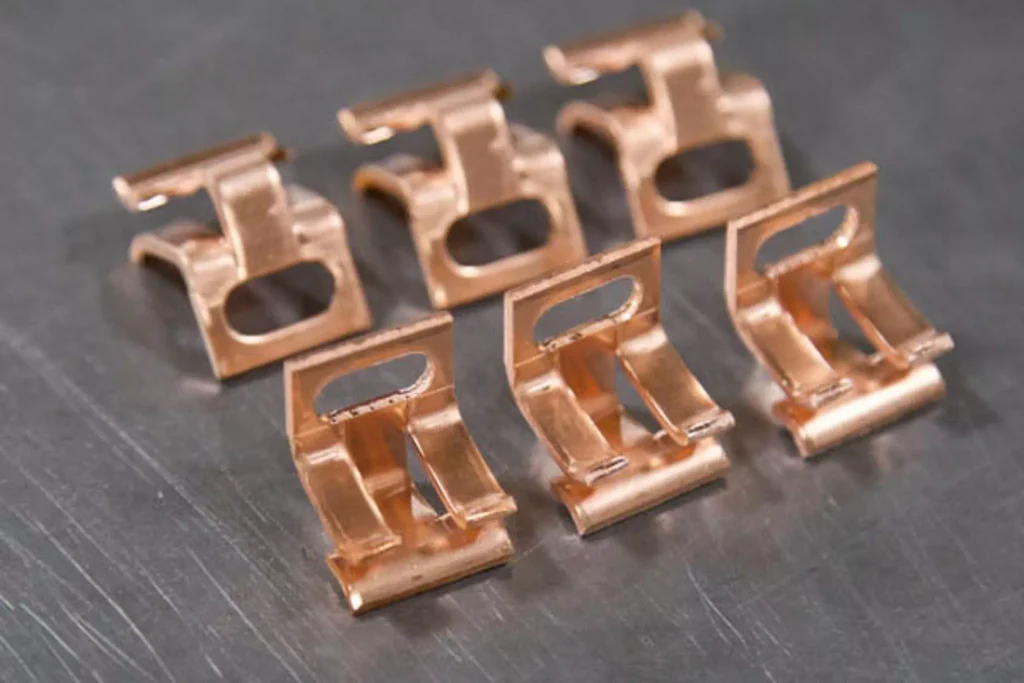

Common Applications and Parts

At Elimold, we can produce anywhere from a hundred to a million parts per year. We can also produce small batches of parts without any tooling options. When you are ready, we will help you determine the best option for your cost reduction requirements and total investment. Below are some common stamping parts we manufacture.

- Brackets

- Washers

- Clips

- Terminals

- Shields

- Connectors

- Gaskets

- Heat sinks

- Electrical contacts

- Spring clips

- Mounting plates

- Covers

- Busbars

- Reinforcement plates

- Retainers

- Spacers

- Hinges

- Filter screens

- Battery contacts

- Motor laminations

- Nameplates

- Locking tabs

- Clamps

- Decorative trims

- Fasteners

- Stiffeners

- Ventilation grilles

- Reinforced flanges

- Electronic enclosures

- Terminal lugs

- Medical instrument

- Appliance panels

- Sensor housings

- Sealing rings

- Light reflectors

- Fuse clips

- Switch contacts

- Louver panels

- Speaker grilles

- Automotive emblems

Full Service Stamping & Forming Contract Manufacturing

Elimold encourages you to work with us during the product design process to maximize manufacturability and minimize costs. Our team will work hand in hand with your team from engineering to prototyping to hard tooling and production. You can trust Elimold to manufacture your parts, assemblies, or complete products. We will provide you with a professional partner from start to finish. No matter the size or complexity of your order, whether it is a simple prototype design or a high-volume production of multi-step manufacturing parts, you will be impressed by our dedication and fast delivery capabilities. If you would like to discuss how we can best serve you or if you have any questions, please feel free to contact us. Whether you are in the design stage, prototyping stage, or looking for an industrial parts manufacturer, Elimold is the ideal choice for you.

Other Sheet Metal Fabrication Services

Our services are not limited to custom metal stamping. We also offer additional sheet metal fabrication services to provide our customers with an end-to-end solution, and we are committed to your success 24/7. Our team provides project support and is always available to address your needs or concerns. Every project we undertake is designed to be successful and reflects our commitment to the highest quality standards. These include:

Laser Cutting

Plasma Cutting

Punching

Die Cutting

Bending

Welding

Extrusion

Embossing

Forming

Riveting

Waterjet Cutting

Request Your Free Metal Stamping Quote Today

After receiving your drawings, our engineers will analyze your custom Metal Stamping parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.