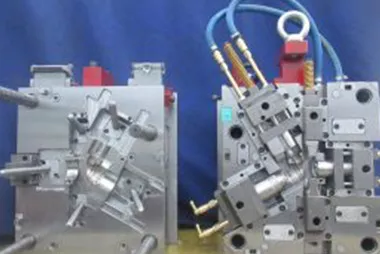

Mold Making Services

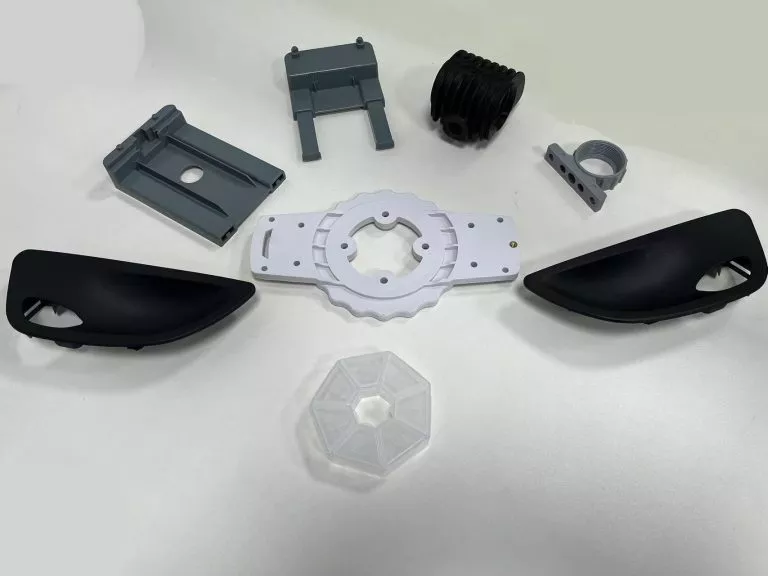

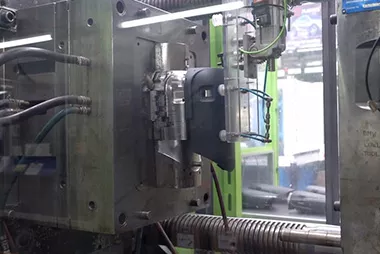

We do almost 100% of our mold making in-house, using steel, aluminum or composite materials. We can make plastic injection molds, die casting molds, centrifugal casting molds and more. Our fully equipped mold making department is located in our China facility. We have a design, engineering and manufacturing team that can provide turnkey solutions for your custom mold and molding needs. Contact us now for a free instant quote.

Experienced Mold Makers

Elimold has decades of experience in a wide variety of mold design and manufacturing and injection molding applications, providing custom molds that are built to last and perform. Because we design, build, validate, operate, maintain, and repair injection molds all within the same facility, the likelihood of unexpected delays, cost overruns, or quality issues on new mold projects is minimized. Our customers enjoy a single point of contact for their projects, avoiding the common “finger-pointing” conflicts between moldmakers and processors. Additionally, what sets us apart from other tool manufacturers is our ability to provide customized tool solutions based on our customers’ specific needs. As a diversified company serving a variety of industries around the world, Elimold is uniquely positioned to help our customers make the right decisions regarding the key considerations of tool design for their specific applications. If you have any questions or concerns about our products and services, please contact us today. You can also request a quote and we will provide some estimates based on your project. Contact us today and we will help you solve a variety of production problems.

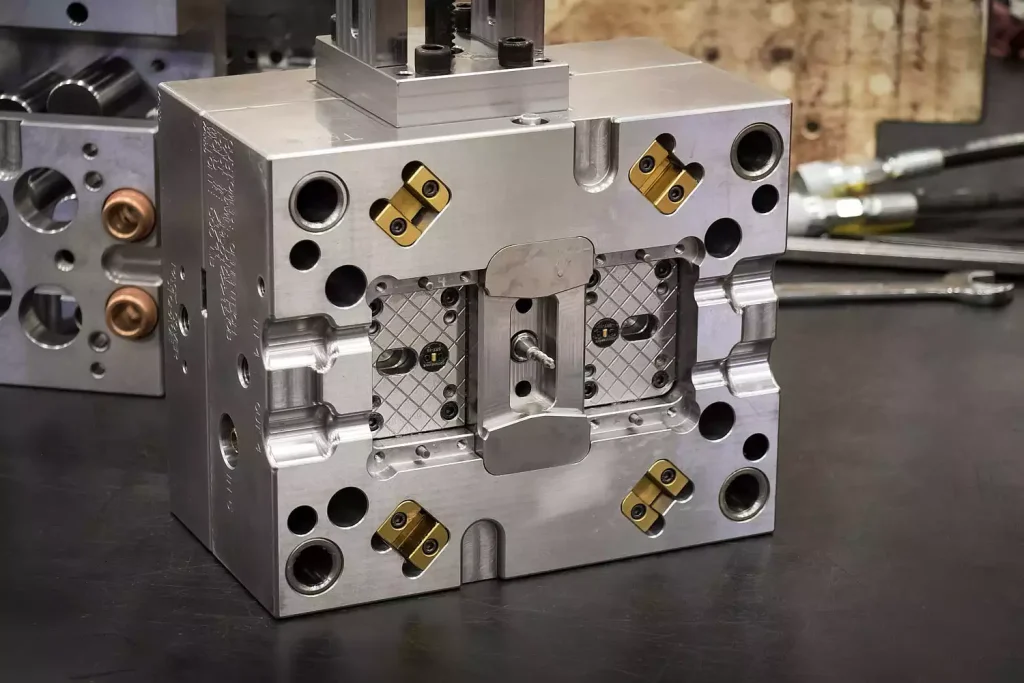

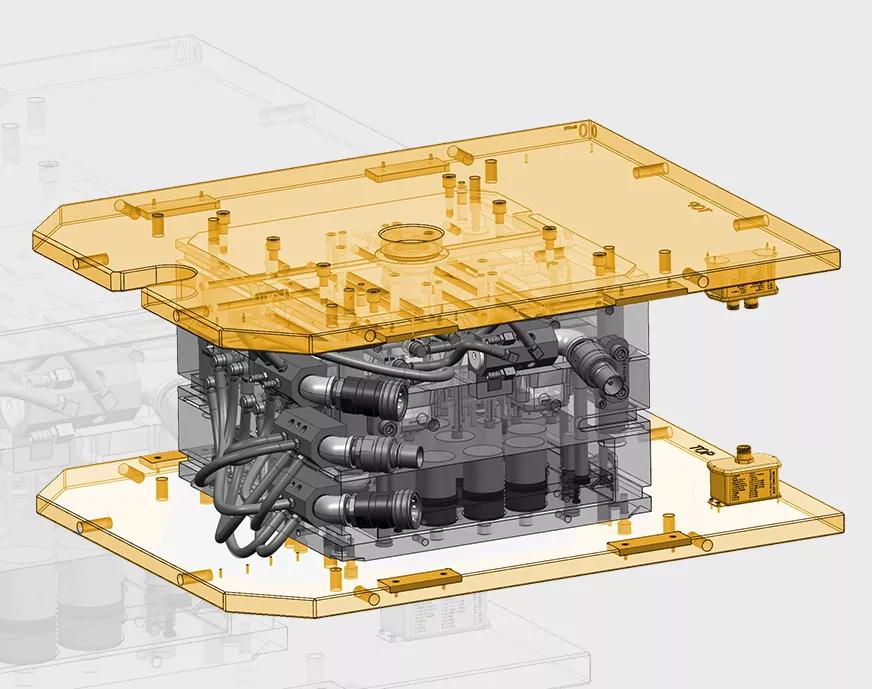

Full Service Mold Manufacturing Division

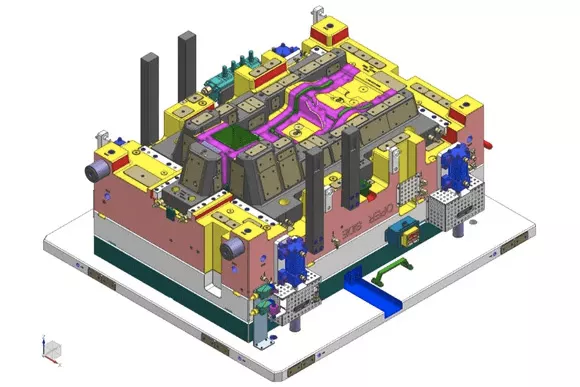

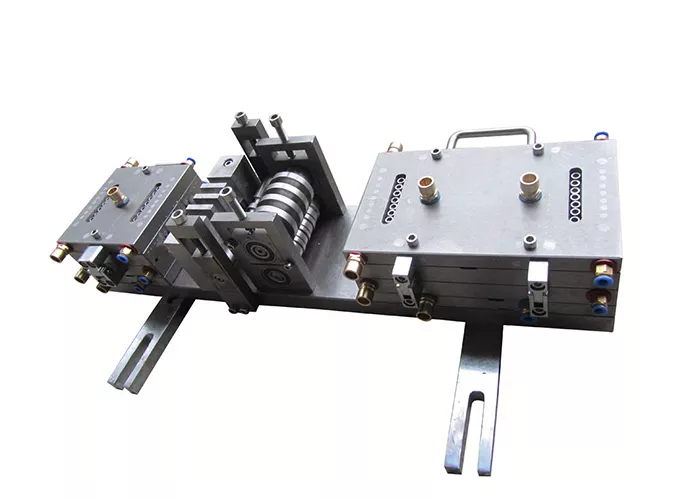

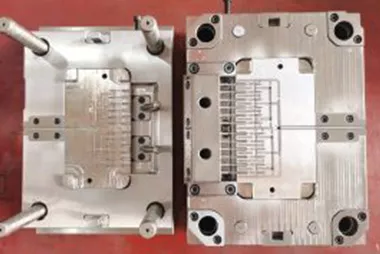

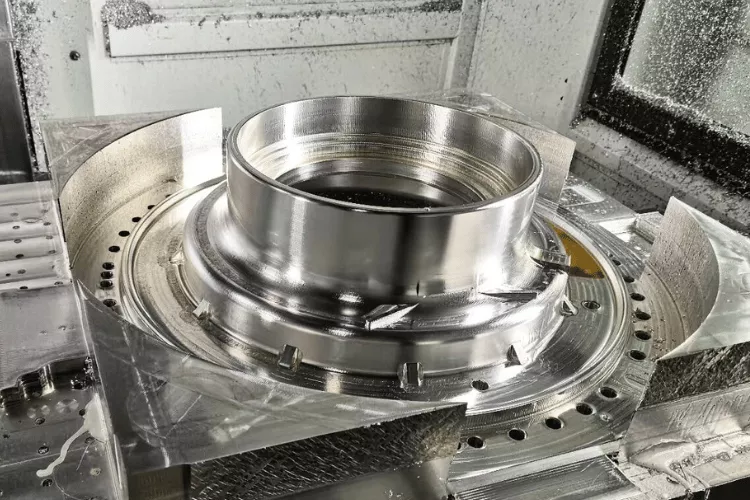

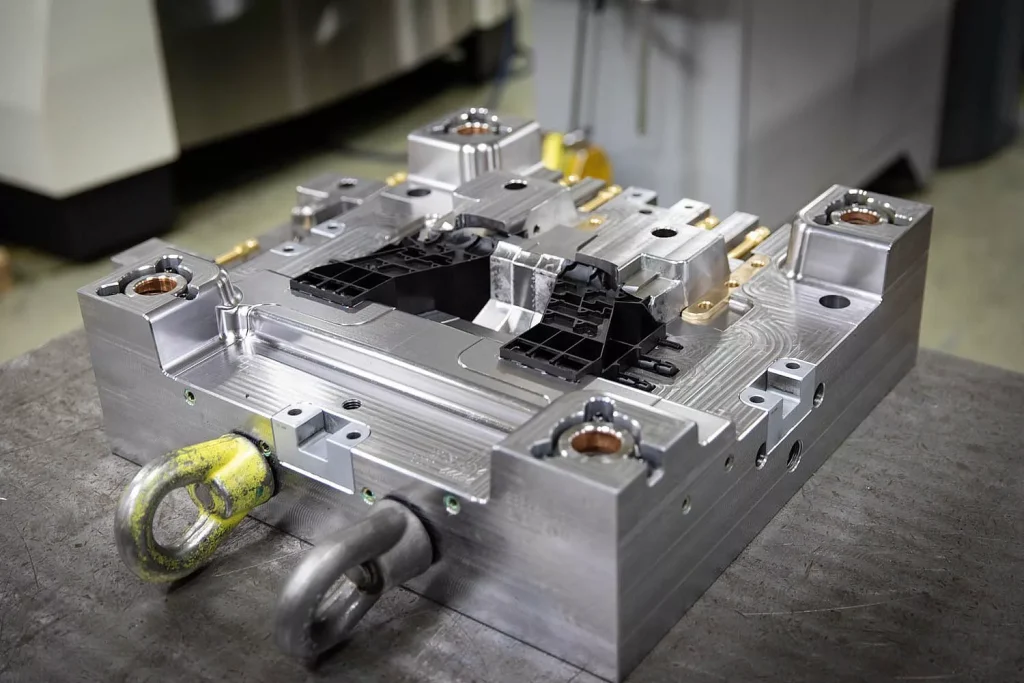

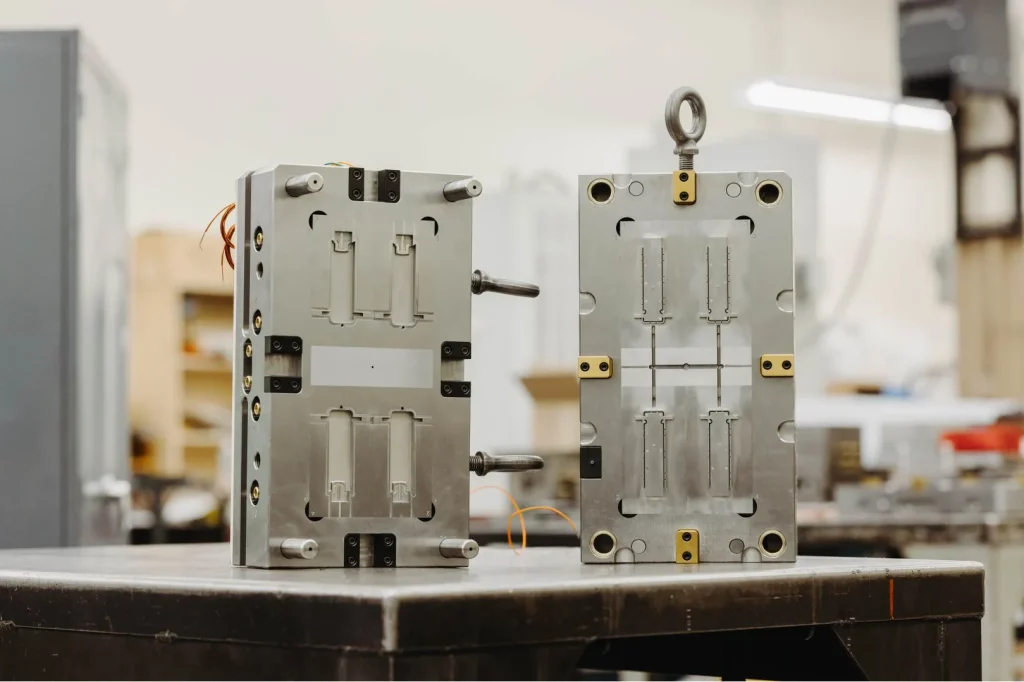

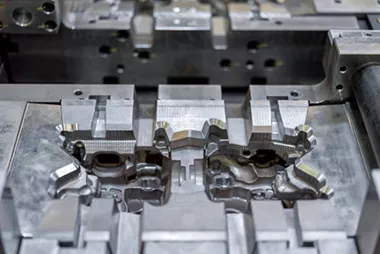

As a full service company, we offer in-house design, mold manufacturing and engineering support as part of our custom mold manufacturing capabilities. All mold design and manufacturing is performed by our team to provide complete custom applications. Our engineering staff and mechanical technicians are experienced in general purpose and engineered materials as well as specialty resins to help you develop molds that best fit the materials selected for your project. Our custom injection mold manufacturing capabilities begin with a comprehensive design review of the product and proposed mold layout to ensure product quality and mold functionality are met. We provide high precision conventional molds as well as modular molds (MUD cells) with CNC 3D machining, EDM, polishing and texturing.

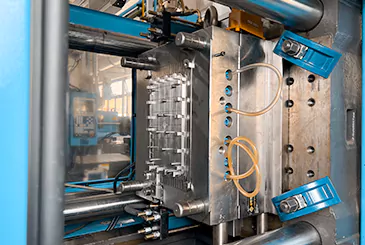

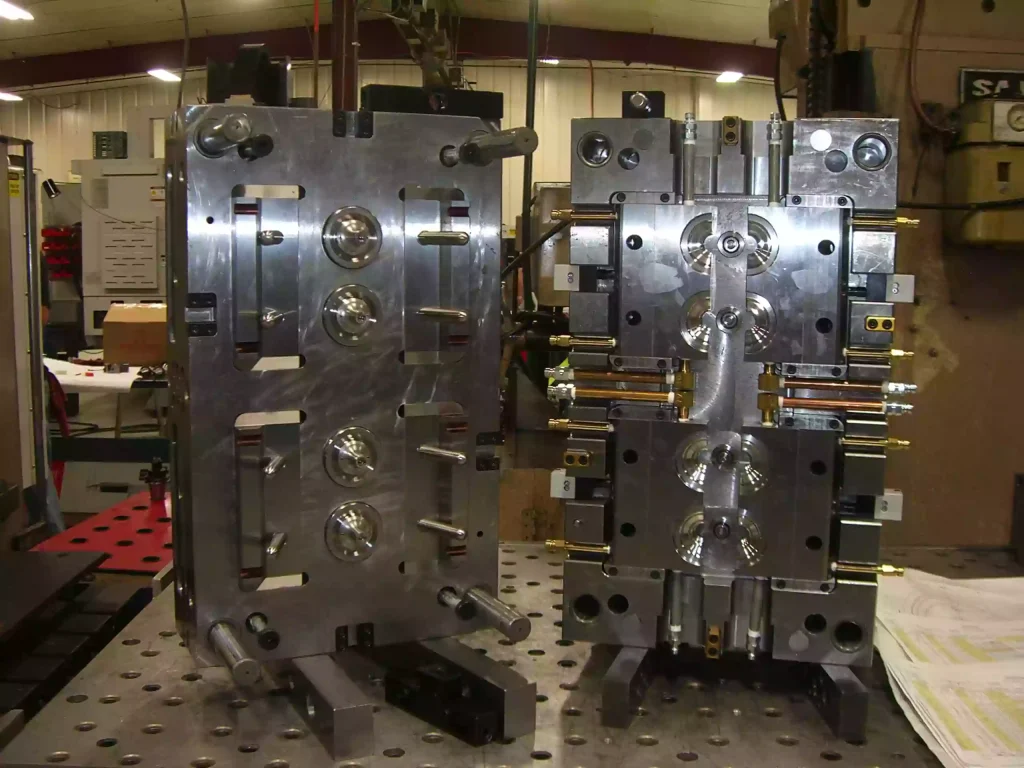

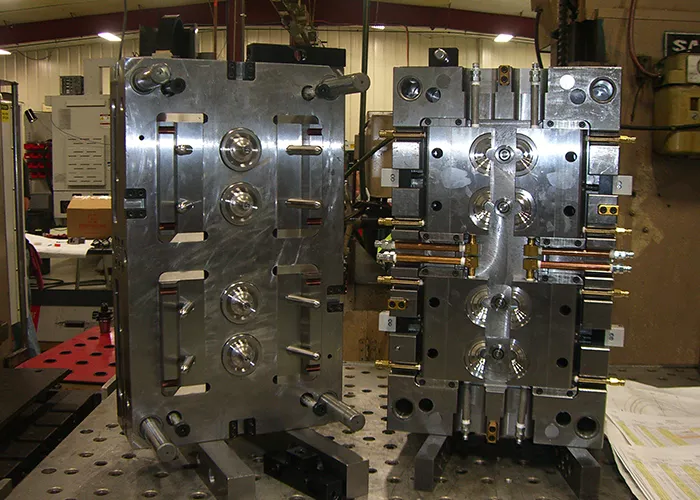

Elimold's In-House Mold Manufacturing Facility

We have complete in-house mold manufacturing and injection molding capabilities. All production processes are carried out in our own factory in China, ensuring that we have full control over quality and production schedule. With more than 80 mold making machines and 150 injection molding machines, the factory has the ability to undertake large-scale production orders with a monthly output of nearly 10 million pieces, ensuring on-time delivery and meeting long-term supply requirements. Our custom mold design and manufacturing services cover everything from conceptual injection mold design to complete in-house manufacturing of any mold. Our professional technical support team is always available to help you solve problems and answer any questions about our custom mold products.

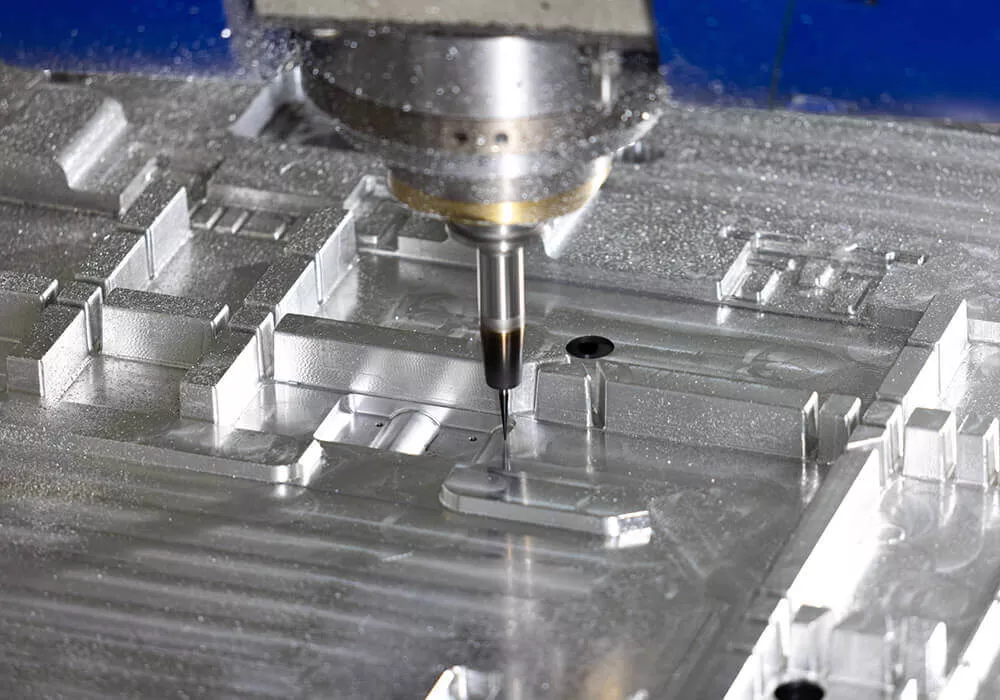

Professional Mold Manufacturing Workshop

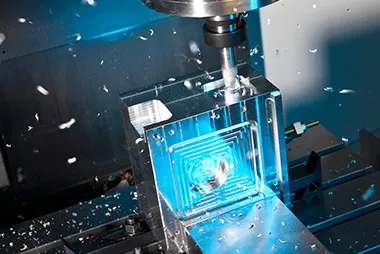

Our mold workshop is equipped with advanced equipment, such as high-speed CNC machines, wire cutting machines, mirror EDM machines, etc., which are imported from Taiwan, Switzerland and Japan. These equipment help us ensure that mold manufacturing reaches the highest precision and high quality. In addition, all processes are completed in-house, which enables us to shorten the delivery cycle. Our workshop has more than 30 skilled mold makers, most of whom have more than 10 years of mold manufacturing experience. They are familiar with all processing technologies and are able to eliminate cost issues at each step in the mold manufacturing process. Employees are crucial to the company, and their experience and hard work enable Elimold to guarantee high-quality molds at reasonable prices.

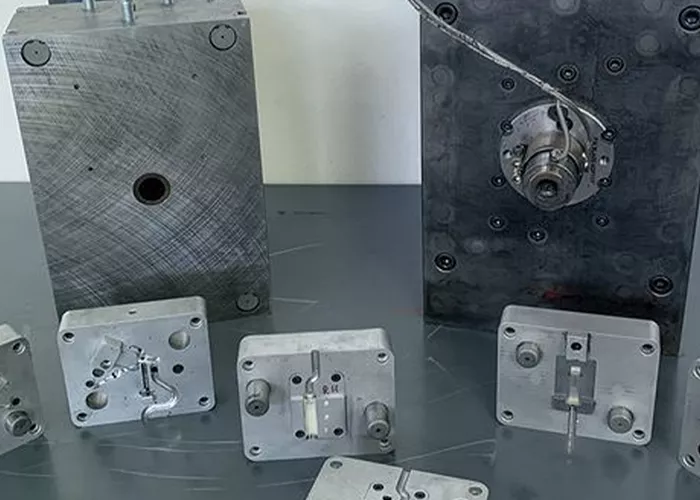

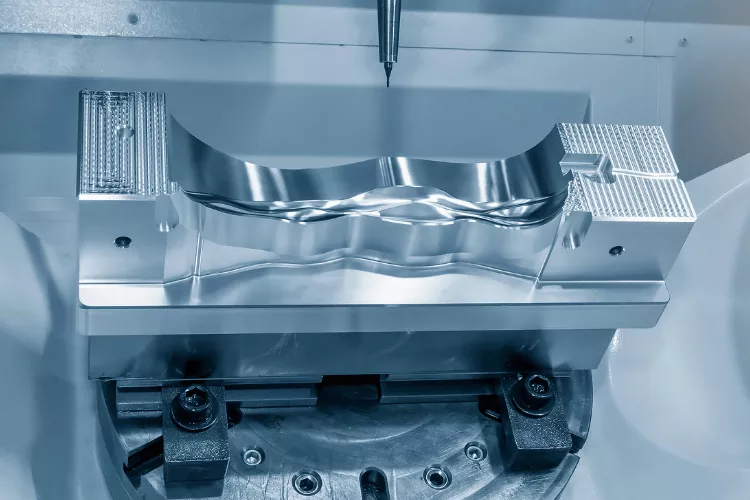

Precision Mold Parts Machining Equipment

Elimold has the knowledge, creativity, hardware and software to transform your product blueprints and prototypes into production parts. We have a full on-site prototyping department to test and fine-tune your newly built molds, and breathe new life into existing molds that need rework or modification. Our precision machining equipment includes a full range of CNC EDM, milling and lathes, precision grinding and polishing equipment. CAD design services and CNC programming connect the entire process from prototype to production parts. Elimold has 14 CNC machining centers with travels of 600-5800mm, 15 CNC drill presses, 18 EDM machines with travels of 300-980mm, and 13 wire-cut EDM machines, ensuring that we can meet all customer mold precision requirements.

Comprehensive Mold Manufacturing Technical Support

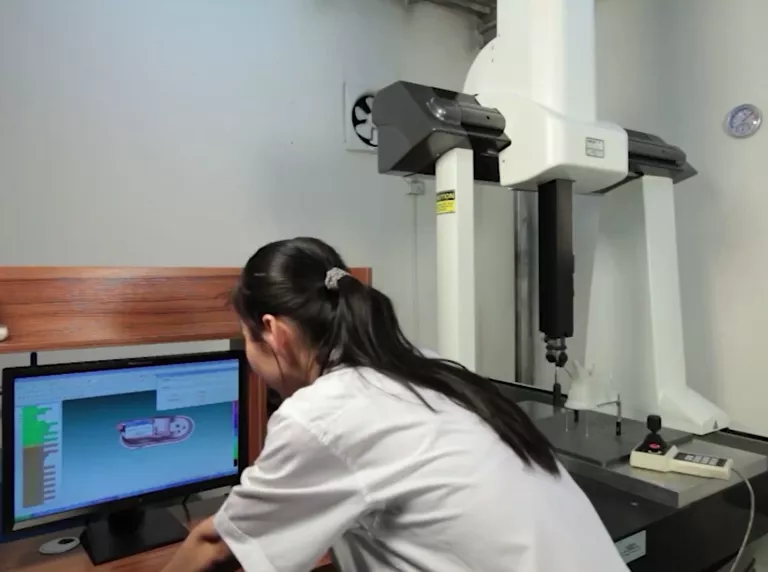

As a quality-conscious company, we perform dimensional inspections to ensure accuracy, and all molds undergo any other necessary testing. We offer comprehensive technical support, perform repairs and rebuilds as needed, and record all maintenance activities in our mold history. With our flexible production methods and emphasis on customer service, we can complete most molds in as little as one to two weeks, and we offer expedited service for time-sensitive projects. As a professional company, we have the time to listen carefully to our customers and provide solutions that will improve the quality of their products. To learn more about our mold manufacturing capabilities or to request a quote, please contact us directly.

Ready to start your next project?

Whether you need rapid mold prototyping or finished product production, Elimold has the skills and experience to ensure you get excellent results. From concept to final completion, our custom mold services and prototype plastic mold solutions help customers turn their ideas into reality efficiently and accurately. To learn more about whether our capabilities are right for you, please contact our team or request a quote.

One-stop Mold Manufacturing Service

Our one-stop mold manufacturing service can provide product design analysis, rapid prototyping, mold flow analysis, precision machining, assembly and packaging services. The full range of services also includes support and acceptance of existing molds, mold repairs, and comprehensive mold management and parts custom molding solutions. No matter what type of new mold you need, Elimold’s team can provide you with high-quality mold and parts custom molding services with its expertise and craftsmanship.

Product Design Analysis

Rapid Prototyping

Mold Flow Analysis

CNC Machining

Raw Material Procurement

Custom Parts

Assembly and Packaging

Decoration Services

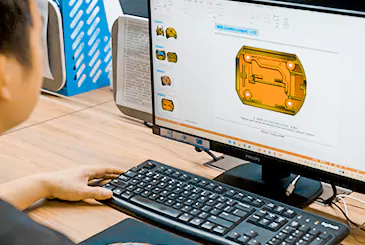

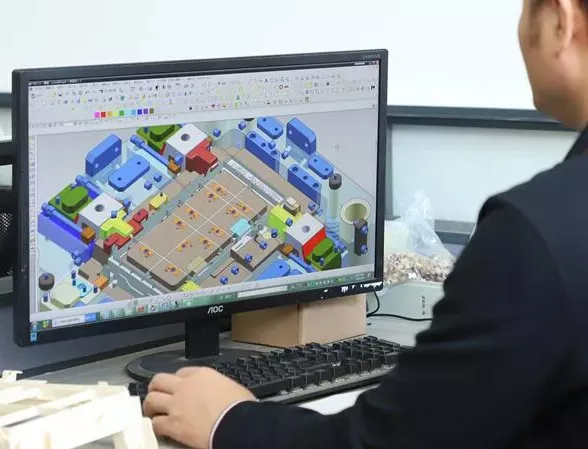

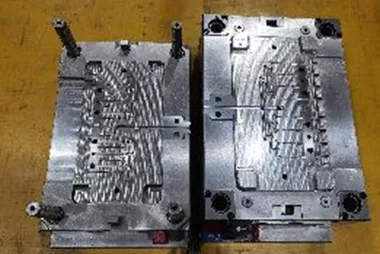

Professional Injection Mold Design Team

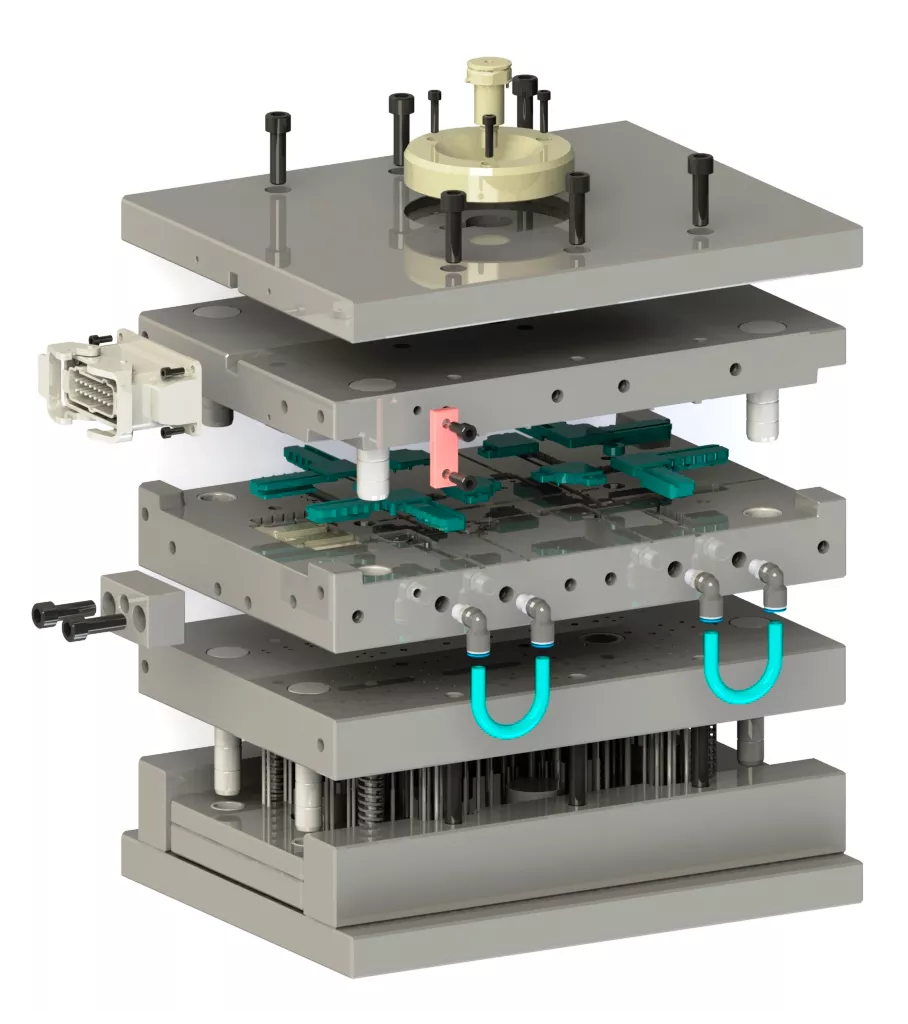

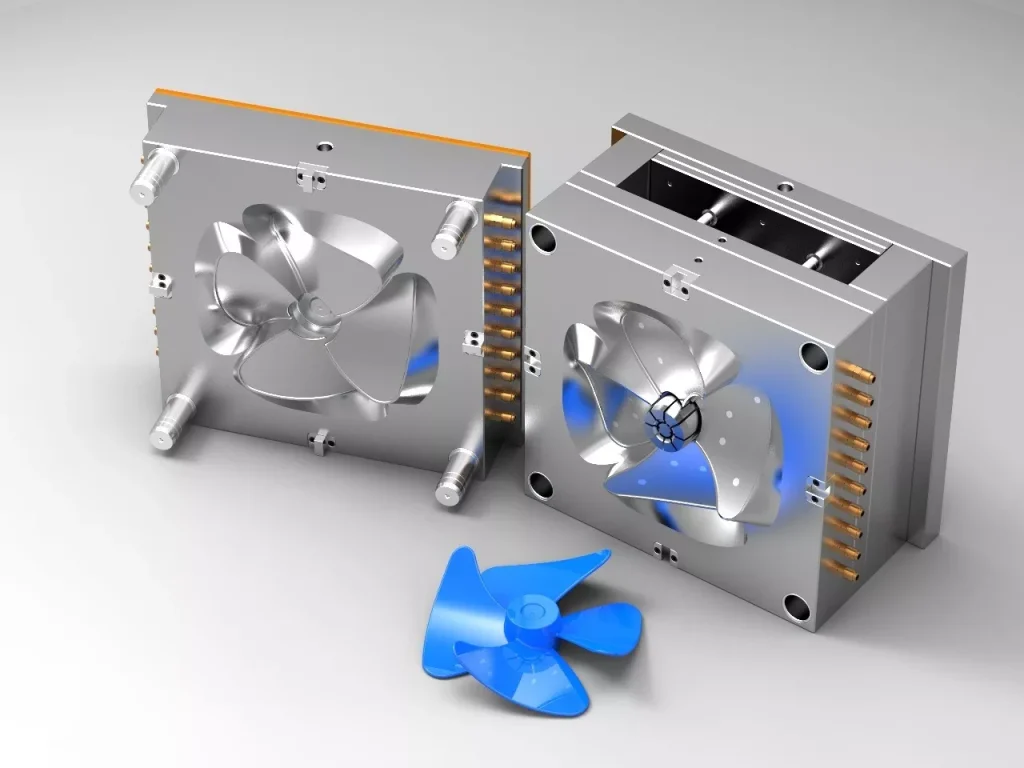

We have an experienced team dedicated to the design and manufacture of plastic injection molding molds. We have the necessary expertise to assist you in designing your mold. The mold is the most important and costly component of the entire process. From the initial design stage, there is very little room for error. There are several different parts that need to be considered during the design process, including parting lines, runners, and gates. In addition, shrinkage and many other specifications must be considered to avoid costly mistakes. Any design flaws may mean a costly redesign. But don’t worry, our company uses cutting-edge design methods to eliminate errors and ensure excellent results. We take a holistic approach to mold design, and during the design process, we perform multiple analyses and follow strict procedures to ensure that the mold is ready for production.

Mould Design Capability

High quality mold manufacturing is the core business of Elimold. We have 10 professional mold designers who have rich experience in material properties and mold structure, and have provided high-end customized mold manufacturing services for more than 10 years. They will take every case seriously. Before the design starts, our designers will run mold flow analysis and participate in technical meetings for each mold with the tool shop and various departments to avoid potential manufacturing problems and troubleshoot. All of these are a strong guarantee for our high quality and short delivery time.

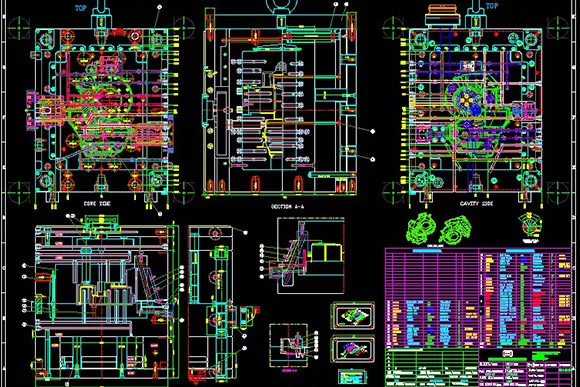

Our design team will provide:

- Industrial Design

- Appearance Design

- Structure Design

- Mold Design (2D & 3D)

- DFM (Design for Manufacturability)

- Mold Flow Analysis

Our Custom Mold Design Capabilities

With over 20 years of mold design expertise from Elimold’s dedicated team, your ideas will become manufacturable, scalable, and competitive.

DFM Report

Moldflow Analysis

2D & 3D Mold design

Complex Geometric Design

The software we use

Our engineer mainly used the following software:

- Pro/ENGINEER

- SolidWorks

- AutoCAD

- Moldflow

- MasterCAM

- Unigraphics

- Animatronic

- Surfcam

- CATIA

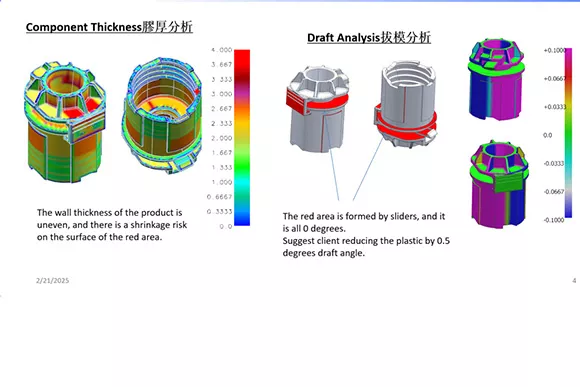

DFM for Optimizing Injection Molded Part Design

DFM refers to optimizing product design by comprehensively considering factors such as manufacturing process requirements, material selection, and processing technology during the product design stage. In injection molding, the core goal of DFM is to ensure that the part design meets the requirements of the injection molding process. DFM principles can help designers and manufacturers foresee potential manufacturing problems from the beginning, ensuring that parts not only meet functional requirements, but can also be produced in the most cost-effective and efficient way. At Elimold, we provide professional DFM services to help customers optimize injection molded part designs. Our team will review your design and provide optimization suggestions as well as perform mold flow analysis to predict potential problems. Finally, ensure that your design meets the requirements of the injection molding process while reducing costs and improving quality.

Injection Molding Mold Flow Analysis Service

Mold Flow Analysis for Mold Design To ensure the best results, we run Moldflow analysis simulations to evaluate the mold design and further improve it. We want to ensure that the mold can be successfully manufactured. Simulations allow us to improve injection parameters, determine and optimize cycle times, determine optimal gate locations, analyze cooling systems, improve weld lines, and more. This is a vital step in our design process and provides us with excellent insights that allow us to create the best mold the first time.

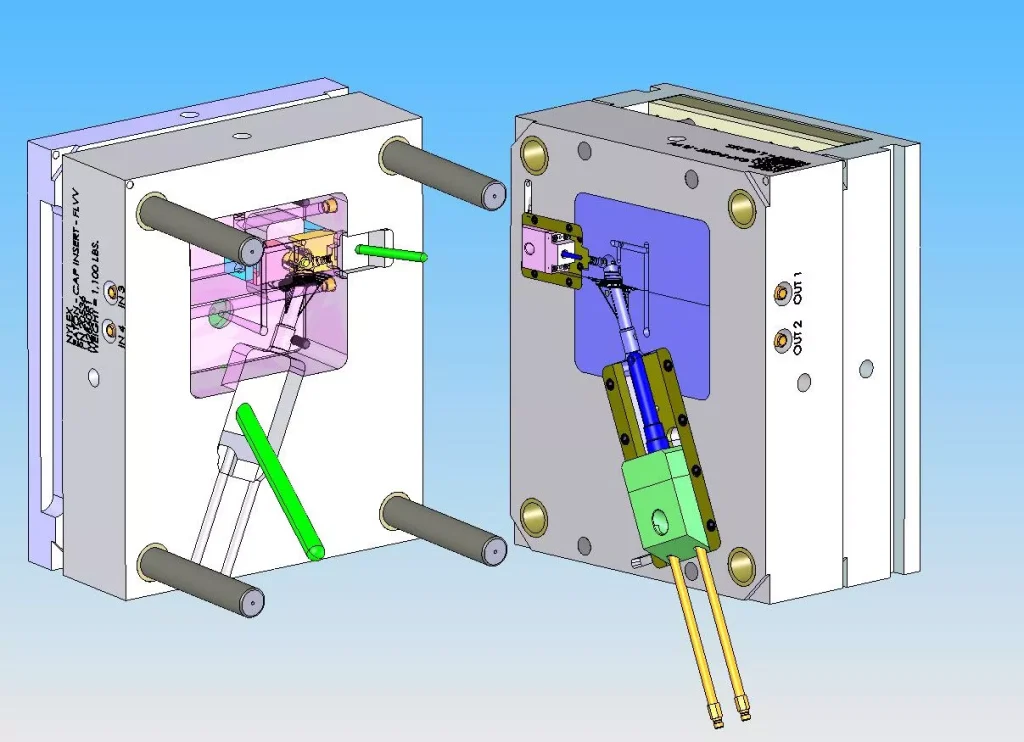

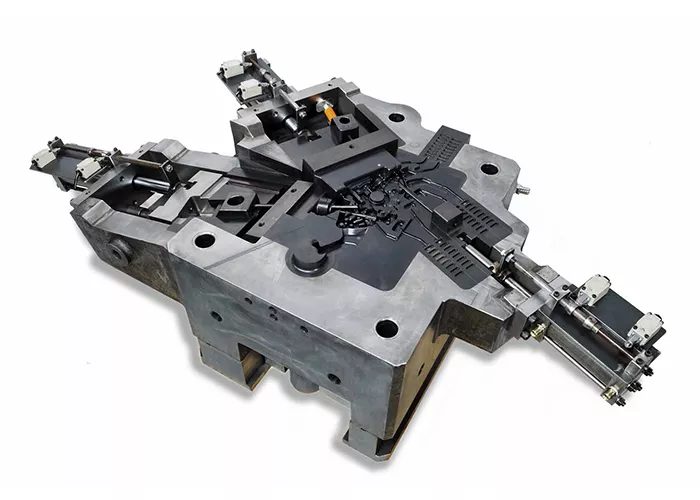

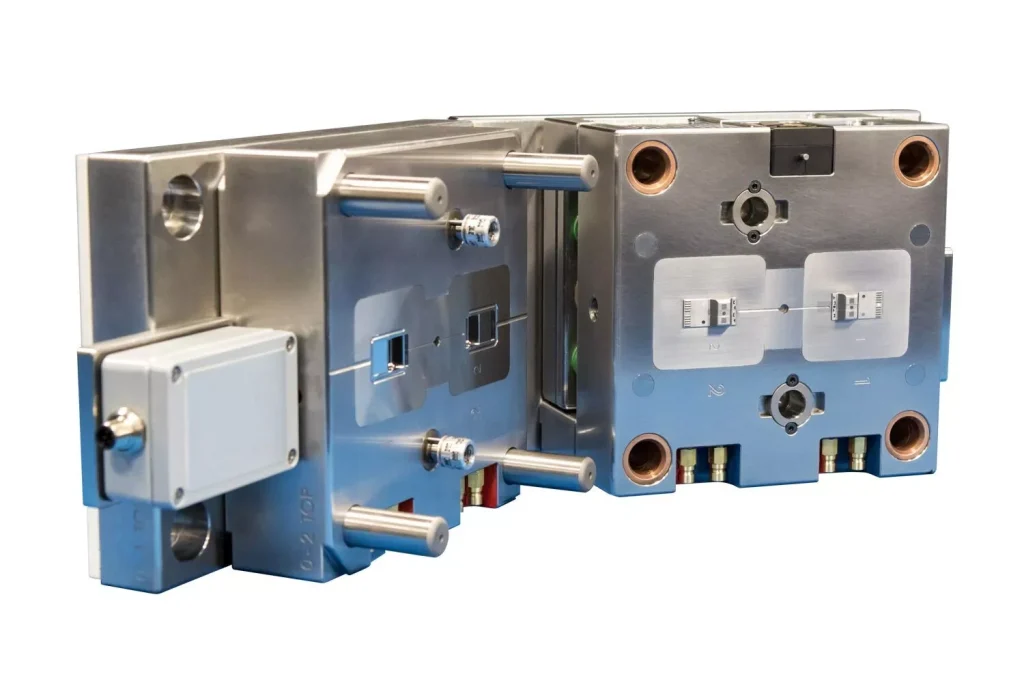

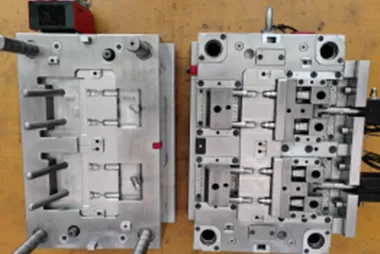

Turnkey Custom Mold Solutions

Could a subtle change in the way your mold is made improve your part production efficiency? Could a minor modification or adjustment to an existing mold save you time and money? At Elimold, we leverage our years of production experience to proactively optimize your molds, making the production process faster and more efficient, resulting in better quality parts at a lower cost. Our turnkey solutions include the design, prototyping, manufacturing and qualification testing of high-precision injection molds for applications including unscrewing, in-mold closure, packaging, technical and medical applications that require full interchangeability. Managing the entire project is an important way for Elimold to achieve the highest quality. From the first design meeting to the final production test, every aspect of your project will be completed in-house at Ivanhoe. We know your mold inside and out. If the mold quality is not up to standard, we will not ship it out. For our customers, this means a worry-free process and a finished mold they can rely on year after year.

Types of Molds We are Offering

Plastic Injection Mold

Metal Injection Mold

Die Casting Mold

Investment Casting Mold

Extrusion Mold

Sheet Metal Mold

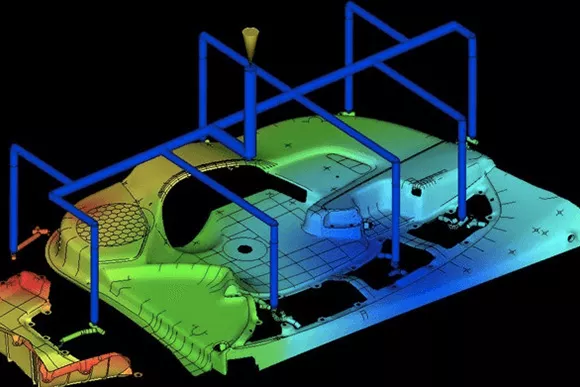

Reverse Engineering

Our mold designers convert simple sketches or 2D drawings into 3D models of molds to ensure accurate manufacturing. We can also reverse engineer the part to be manufactured to obtain an accurate model. In addition to single- and multi-cavity molds for structural foam molding, resin transfer injection molding and other process types, we are also able to manufacture multi-part molds to accommodate large objects. With a wide selection of materials and resins, we are able to create molds for prototype projects and custom production molds for different life cycle needs.

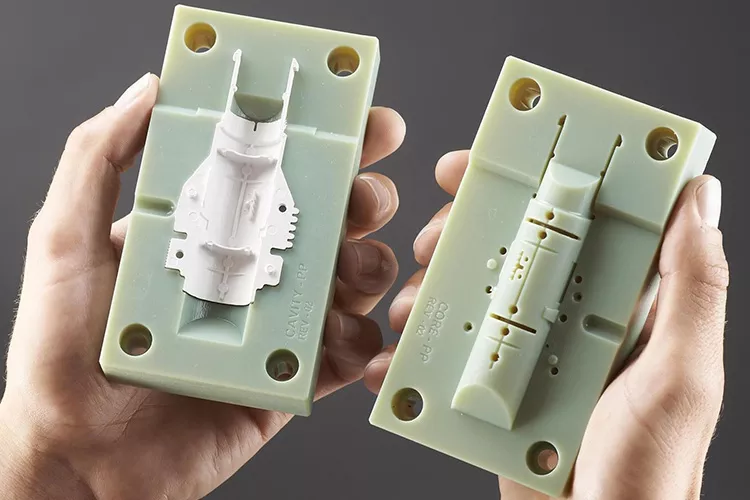

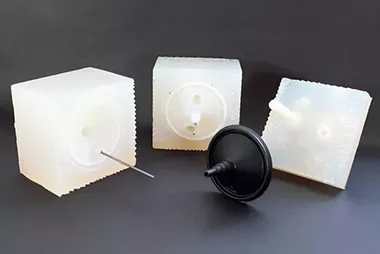

Test Molding

A trial mold is highly recommended when transitioning from prototyping to mass production. A trial mold is different from a manufacturing mold in that it is made of hard plastic or 3D printing material (or other materials, as the case may be) and is used to cast prototypes or small quantities of parts. Unlike metal molds, trial molds cannot be reused and are therefore discarded after a few production cycles. Trial molds cost only a fraction of metal manufacturing molds, but can save a significant amount of project costs if further design improvements are needed after the prototyping and testing phase. Therefore, trial molds are only suitable for further prototyping and testing and small production runs.

3D Printed Mold Prototype

Once the design is fully optimized, we 3D print a mold prototype. This will allow us to analyze the mold at actual size to ensure the finished product is of high quality, accurate, and ready to use. Our company has advanced rapid prototyping technology that can print a working prototype in a few hours to a few days. In addition to design verification, 3D printed molds are a fast and cost-effective way to discover hidden problems before starting final mold production. This step is designed to avoid expensive redesigns.

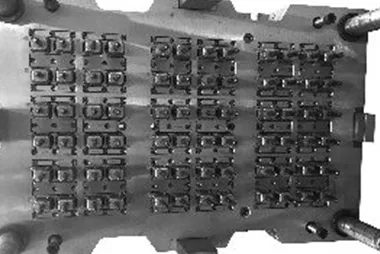

Type of Injection Mold

Choosing the right injection mold for your project is crucial, as different mold types will directly impact production efficiency, product quality, and cost. Based on your needs and production scale, there are various types of injection molds available.

Single-Cavity Mold

Multi-Cavity Mold

Two-Shot Mold

Insert Mold

Hot Runner Mold

Cold Runner Mold

Experienced Mold Making Team

Elimold’s custom mold making team can work with your engineers to develop the ideal solution for your custom application. From a CAD file, blueprint, or specification, we will create a complete mold design to meet any of your standard requirements. Our facility can produce molds from Class 101 to Class 105 for up to one million uses. We can also produce finished molds much larger than our competitors, with press sizes ranging from 50 tons to 6,600 tons. All mold making shops pride themselves on precision, but few have a history of reliable production. Our facility is capable of producing finished products with tolerances as tight as 60,000ths (140-inch span) and 140,000ths (23-foot span).

Mold Manufacturing for Contract Molding

We also provide custom plastic injection molding services, so about 50% of the injection molds we make will remain in-house for contract molding. With our comprehensive experience and knowledge in injection molds and injection molding, we are able to provide you with the most suitable and economical molding solutions. We can provide a one-stop service for mold manufacturing and injection molding and other services. In terms of injection molding, we have advanced equipment with high production precision and high efficiency to ensure product quality and on-time delivery. In addition, we focus on innovation and continuous improvement, constantly exploring new materials and technologies to provide customers with more choices and the best solutions.

Interested in our mold making services?

Our commitment to quality, precision, and customer satisfaction sets us apart in the mold making industry. Partner with us today to help you realize your next project with the reliability and efficiency that only a trusted, professional manufacturer can provide.

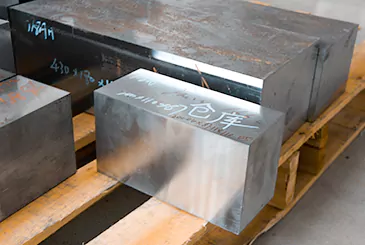

Custom Mold and Tooling Materials

Material selection for precision molds is critical to their quality and longevity. Choosing the right mold material can also reduce the cost of custom molded parts. What material should your mold be made of? Elimold has a wide selection of custom mold materials, and our experienced team will provide professional advice based on your project and product development stage. Below are the common types of materials we offer.

Aluminum Alloy

Plastic

Tool Steel

Stainless Steel

Materials that match your tooling

Depending on the material specifications and current sources, we can often continue to source from the same source as your current supplier and use the same material. If this is not possible, we have hundreds of polymer formulations and can provide a standard compound that matches your drawing or requirements. If your current supplier/vendor controls the required raw materials, Elimold and its raw material partners can quickly develop materials that meet the required specifications. If a part does not have a documented specification, we can help you develop an ASTM specification to meet the specific environment and application of your product.

Why Do We Recommend Test Molding?

It’s just a little bit more costly but will lead to great improvements in your project. Test molds are mostly used in the phase when you need to test product functionality and material durability. Tooling and molding for manufacturing can be a big expense, but the cost will be even bigger if you have to remold due to design flaws and other problems. The test molding is exactly the process to help detect those flaws and make improvements to your product. Test molds are often used only a couple of times and cost less than 20% of a real mold for production. It’s a worthwhile investment.

Moving Existing Tooling

If you have existing tooling that produces your product, but are unhappy with your current vendor or supplier, Elimold can help. We have helped several customers quickly transfer existing tooling to us, minimizing the impact on the customer’s part supply and subsequent production cycle. We have an in-house manufacturing facility in Shenzhen, China, so we can produce your products cost-effectively and efficiently, saving costs. And, we inspect incoming tooling before production setup to detect any issues that may affect quality or operator safety. At Elimold, your tools are treated with the utmost care, both during production and in storage. This attention to detail ensures that your tools will produce high-quality, within-to-tolerance parts for a longer period of time, without the need for rework.

Mold Maintenance and After-Sales Service

All injection molds manufactured and stored at Elimold are properly stored after molding production is completed, the core and cavity are covered with anti-rust spray, the mold plate is clean and tidy, and is labeled and marked for easy access for the next production. We ensure that when you need more plastic parts, they are available immediately. Any changes to parts and molds will be recorded and traceable. In addition, all injection molds exported to any country in the world are accompanied by 2D/3D design drawings, CNC programming data, injection parameters, measurement reports, etc. We also provide EDM copper parts, interchangeable blades, and easily worn parts to facilitate your easy maintenance or mold replacement.

Our Custom Manufacturing Services

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Overmolding

LSR Injection Molding

Request Your Free Mold Making Quote Today

After receiving your drawings, our engineers will analyze your custom Mold Making and parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.