Monel CNC Machining Services

Looking for a high-performance Monel alloy CNC machining manufacturer? Engineers and purchasing professionals choose us because we offer high-quality products ready for production, consistent delivery times, and rapid collaboration. Our team has extensive experience in Monel alloy machining, combined with a rigorous quality management system, enabling us to deliver complex, high-precision parts, ensuring that their assembly and performance meet design requirements.

Are You Looking for Reliable and Fast Monel CNC Machining Services?

With our extensive experience, broad expertise, and advanced CNC equipment, we are able to provide you with high-quality Monel parts through an optimized and streamlined machining process. Elimold can machine any custom Monel part to your needs, from prototyping to mass production. As a leading precision machining expert, we consistently adhere to strict tolerance control and superior quality. We are committed to providing you with satisfactory Monel machining solutions, implementing rigorous quality control and inspection from raw materials to finished product delivery. Therefore, we only offer high-quality Monel parts, satisfactory service, faster delivery, higher reliability, and lower component costs to our global customers. You can trust Elimold as a reliable partner for your custom Monel parts needs.

Professional Monel Alloy Parts Manufacturer

When your project demands exceptional performance from Monel alloys, don’t opt for ordinary machining services. The machining of Monel alloys is highly complex and requires a partner with extensive experience and deep material knowledge. Professional Monel alloy machining services can determine whether your project is successful and durable, or plagued by premature failure and high rework costs.

Elimold offers superior Monel alloy machining services to help you achieve your goals. We not only possess expertise in machining the hardest alloys but also provide optimal solution advice from the outset. If you encounter difficulties in material selection or need a reliable partner to assist you with your Monel alloy CNC machining projects, please contact us immediately. We will help you bring your designs to life with the precision and quality you expect.

Partner with Monel Machining Experts

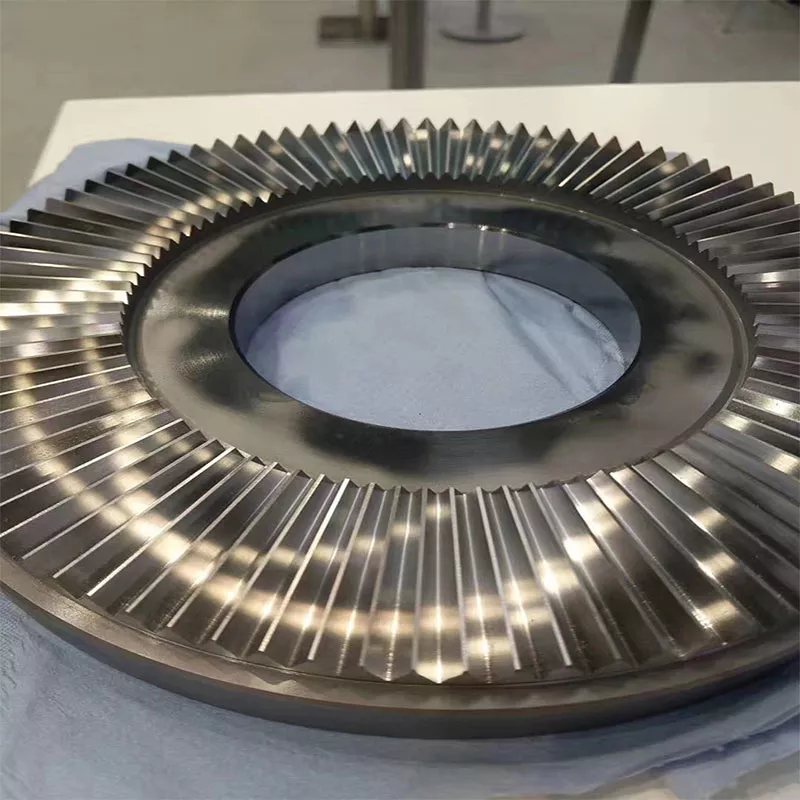

Our team of manufacturing experts is intimately familiar with the unique properties of Monel. They consider details such as adjusting feed rates and depths of cut to maximize efficiency while maintaining part dimensional stability. Our advanced technology and equipment overcome the inherent challenges of machining Monel. Our multi-axis CNC machine tools and custom-designed tooling solutions ensure exceptional precision and surface finishes, easily handling even the most complex geometries. We are proficient in turning, milling, and drilling this high-toughness alloy, consistently producing parts that meet stringent quality standards.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order, we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

What is Monel?

Monel is a registered trademark of Special Metals Corporation. It is a rust-resistant (stainless steel) metal alloy primarily composed of nickel (up to 67%) and copper, making it a nickel-based alloy with copper as the main alloying element. In addition to nickel and copper, Monel may also contain trace amounts of iron, manganese, carbon, silicon, sulfur, aluminum, and titanium. The specific composition of Monel depends on the required properties and application. Generally, Monel is known for its high strength and excellent corrosion resistance in both fresh and seawater, while also exhibiting excellent resistance to high and low temperatures.

Monel Grades For CNC Machining

Specific grades within each series may differ in alloying elements and properties. Please contact the Elimold Materials team for detailed specifications of each Monel grade for more accurate information.

Monel 400

It contains approximately 63% nickel and 28% to 34% copper, with trace amounts of iron. It possesses extremely high mechanical strength and excellent corrosion resistance. However, its toughness presents some challenges for machining. Monel 400 can be machined, but the process presents some challenges. This alloy undergoes work hardening under the influence of cutting tools, thus requiring close monitoring of feed rate, cutting speed, and tool wear.

Monel R405

It is similar to Monel 400, but with a higher sulfur content (0.06%). The additional sulfur makes R-405 alloy machinable better than the 400 alloy because the sulfur forms nickel-copper sulfide inclusions in the material, which act as chip breakers.

Monel K-500

The composite material of aluminum and titanium allows for tensile strengths up to 1100 MPa. Machining this ultra-hard material requires advanced tools and techniques. This alloy is a high-strength variant of Monel alloy, with small amounts of aluminum and titanium added to the basic formula. It possesses all the advantages of standard Monel 400, but with increased hardness and strength through precipitation hardening heat treatment.

Expert Monel Machining Starts Here

To explore how our services can elevate your production capabilities and meet your specific needs, we invite you to request a quote today.

A Trusted Custom Monel CNC Machining Brand

We don’t offer standardized services; instead, we provide bespoke solutions. Our team can produce a wide range of CNC-machined Monel alloy parts to meet your specific requirements. From large industrial parts for chemical reactors to precision Monel alloy screws for critical components, our capabilities are broad and in-depth. Elimold is a trusted brand for providing advanced Monel alloy machining services. With CNC technology and cutting-edge equipment, we are able to perform complex machining operations on a variety of CNC-machined materials, including Monel alloy.

Monel Machining Capabilities

Our advanced machining capabilities encompass four-axis and five-axis milling, Swiss-type lathe machining, and even micro-machining. This enables us to manufacture parts with the highest precision and smallest tolerances. We can achieve tolerances as small as 0.0005 inches. When turning Monel alloys, straightness tolerances are ±0.001 inches, concentricity tolerances are ±0.0003 inches, and inner and outer diameter tolerances are ±0.0005 inches. Our machining capabilities can process parts with diameters up to 72 inches, lengths up to 168 inches (4 meters), and widths and heights up to 72 inches. We undertake prototyping as well as small-batch to high-volume production.

CNC Manufacturing Process

Elimold excels in precision Monel machining, offering a variety of CNC machining technologies capable of producing complex geometries with an accuracy of ±0.005 mm, and providing comprehensive manufacturing solutions. Trusted by engineers worldwide, we are your reliable partner for high-performance alloy components.

Quality Management Standards

Every component we manufacture undergoes a rigorous quality control process. We understand that our CNC-machined Monel alloy parts are used in critical applications where any failure is unacceptable. Our commitment to quality assurance means you can rely on the durability and performance of our finished products. We strictly adhere to ISO 9001 standards and achieve complete production traceability, ensuring the highest quality. All Monel-machined parts come with certification, giving customers confidence in the integrity of the materials. A culture of regular audits and continuous improvement ensures that components are always manufactured to the highest standards.

Low-Cost Monel Parts Manufacturing Services

We are renowned globally for our on-time delivery, budget control, and tolerance control. We understand that every project is unique, therefore our custom Monel machining services are designed to meet the specific needs of our clients. With years of experience providing high-quality custom Monel parts manufacturing and machining services, we can reduce lead times and costs. Furthermore, the Elimold team’s rigorous quality assurance and inspection processes ensure that every precision Monel CNC machining service we provide meets the highest standards. Contact us now, and we will work with you to provide you with the best quality, most cost-effective Monel machining services on the market.

From Prototype to High-Volume Production

Our highly skilled team utilizes advanced technology to deliver precision-machined parts to your specifications. We prioritize fast delivery while ensuring product quality, guaranteeing on-time project completion. Whether you need prototyping or mass production, Elimold’s expertise and efficiency can handle your Monel CNC machining projects. If you have drawings and need a quote, please use our convenient online inquiry form. If you are unsure what you need, you can also ask us questions through our online consultation form. Either way, our pre-sales engineers will contact you promptly.

Monel CNC Parts Surface Finishing Service

Our Monel alloy parts post-processing service uses advanced technology to ensure optimal performance and service life of the parts.

As Machined

Anodizing

Brushed Finish

Sand Blasting

Heat Treatment

Teflon Coating

Black Oxidize

Electroless Plating

Electroplating

Painting

Powder Coating

Electrophoresis

Tumbling

Alodine

Electropolish

Passivation

SPI Finish

Turnkey Monel CNC Machining Solutions

Our factory is ISO 9001:2008 and AS9100 certified and complies with ISO 13485 standards. We have a Class 100 cleanroom and offer turnkey solutions to streamline your supply chain, shorten delivery times, and reduce overall costs. We not only provide intelligent Monel alloy machining but also one-stop services such as ultra-high purity welding, CNC pipe bending, and Class 100 cleanroom assembly and packaging. Elimold undertakes projects that other companies are unwilling to take on.

Non-Destructive Testing (NDT) Services

To ensure products do not fail due to undetected substrate defects, Elimold offers NDT services for Monel alloys. We are a leading Nadcap-certified provider of surface defect inspection and assessment services, focusing on verifying that critical functional components meet their intended use. We offer the following Monel alloy NDT services:

- Visual Inspection

- Liquid Penetrant Testing

- Magnetic Particle Testing

Providing Monel Alloy Machining Services for Your Industry

Monel alloy parts are widely used in various industries due to their excellent corrosion resistance and high strength.

FAQ

Delivery time depends on the geometry and quantity of the parts. Please submit your drawings with our inquiry so we can arrange delivery as soon as possible.

Yes. We offer machining, inspection, finishing coordination, and complete turnkey assembly services to ensure parts meet shippable standards.

No, Monel alloys are generally nonmagnetic, but can exhibit useful magnetism under certain conditions. Monel 400 and R-405 have Curie temperatures close to room temperature, so they are not magnetic at higher temperatures. Furthermore, even within material specification tolerances, variations in composition can cause some batches to be magnetic while others are not.

Monel alloy K-500 is special because of its extremely low Curie temperature, far below ambient temperature, so it can be reliably considered a nonmagnetic material using conventional material manufacturing methods. However, by selectively removing aluminum and copper from the surface of Monel K-500 through oxidation, a surface layer rich in magnetic nickel can be formed. Wires and strips manufactured using this special process are widely used in electronic components.

K-500 Monel alloy contains up to 3.15% aluminum and 0.85% titanium as alloying elements to improve hardness and strength after precipitation hardening heat treatment.

Monel alloy, due to its high nickel content, is more suitable for applications requiring extremely high corrosion resistance, especially in marine or chemical environments. Stainless steel, on the other hand, is more affordable and ideal for applications requiring structural strength and aesthetics. The choice between the two depends on specific manufacturing process requirements and the intended use of the metal component.

The price of Monel alloy varies between $15 and $30 per pound, depending on market demand and the materials being processed. Due to its nickel and copper composition, Monel alloy is generally more expensive than stainless steel. Its price reflects its durability and special properties, making it an ideal material for CNC-machined parts used in harsh environments. Custom CNC machining services include Monel alloy machining; pricing depends on the amount of material used and the complexity of the machining.

Yes, we offer rapid CNC machining services for Monel alloy. We utilize advanced four-axis and five-axis milling technology to meet tight delivery deadlines. Our team employs a variety of techniques, including milling, turning, and EDM, to achieve optimal machining results.

Monel QQ N 286 is the specification for Monel alloy, ensuring that the material meets stringent mechanical and chemical standards, making it suitable for demanding applications such as marine and chemical processing equipment.

Monel alloy is itself an expensive raw material. Machining it requires highly specialized and expensive tools, and they wear out faster. The machining process demands slower material removal rates, longer machining times, and high-pressure cooling systems. Due to its high toughness and unique machining characteristics, significant energy and resources are required to overcome these drawbacks, resulting in higher overall operating costs (electricity, consumables).

Using extremely sharp tools (never readjusted), maintaining the depth of cut with high feed rates, precisely controlling the cutting interface with high-pressure coolant, maintaining a stable chip load (avoiding live cuts), and utilizing optimal five-axis toolpaths to promote continuous and stable quantization of the optimal five-axis toolpath, thereby promoting continuous positioning, which in turn promotes stable positioning, ultimately producing the desired volume.

Elemold consistently achieves tight tolerance control, typically ±0.0005 inches (±0.012 mm) on critical dimensions of Monel parts. Surface roughness RA is 8-16 minutes (0.2-0.4 micrometers). We can even employ controlled micro-effect techniques such as precision grinding or electropolishing to achieve a finer surface finish.

Yes, our one-stop service includes seamless coordination of necessary post-processing steps. This includes solution annealing of Monel 400, age hardening of Monel K-500, machining strictly according to AMS/NADCAP specifications, CNC rotary machining, qualified welding using compatible nickel-based alloys (Enicu-7), professional grinding, and surface treatments such as electropolishing to maximize corrosion resistance and cleanliness.

Five-axis machining is suitable for manufacturing Monel alloy parts because it can complete the machining of complex parts in one pass, avoiding error-prone repositioning and handling difficult-to-machine materials. Additionally, it facilitates continuous cutting paths, resulting in smoother surfaces, less heat, and faster cycle times. It can machine undercut and depth features that are impossible or inefficient with three-axis machining, which is crucial for many Monel alloy parts.

Absolutely. We strongly encourage your early involvement in the DFM review. Our engineers can provide valuable feedback on your Monel alloy part design, such as recommended radii, tolerance allowances, functional integration, or machining method specifications, significantly optimizing the manufacturing process and cost-effectiveness while fully meeting the part's functional requirements. This proactive collaboration yields tangible cost and time benefits.

While every nickel-based alloy presents machining challenges, Monel alloys are generally considered easier to machine than other high-strength, high-temperature alloys such as Incor Nickel 718 or Hastelloy C-276. However, the unique machining challenges of Monel alloys (such as active work hardening and cumulative hardening) still far exceed those of stainless steel or titanium alloys. Our expertise covers all these high-performance materials.

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 4 hours.