Multi-Axis CNC Machining

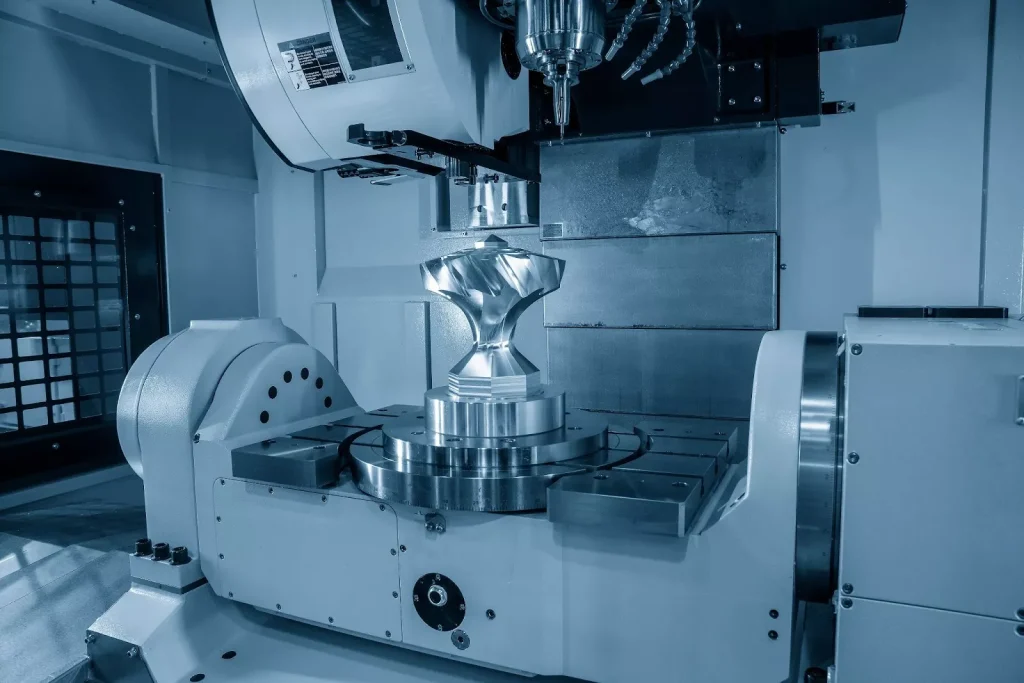

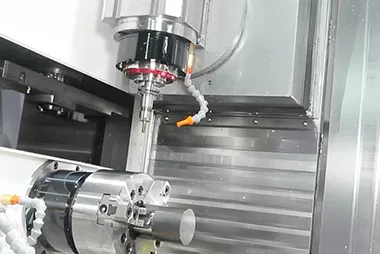

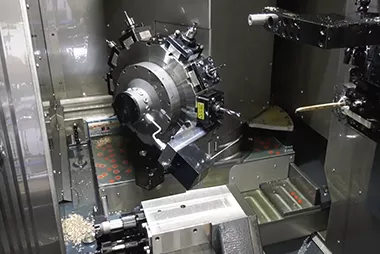

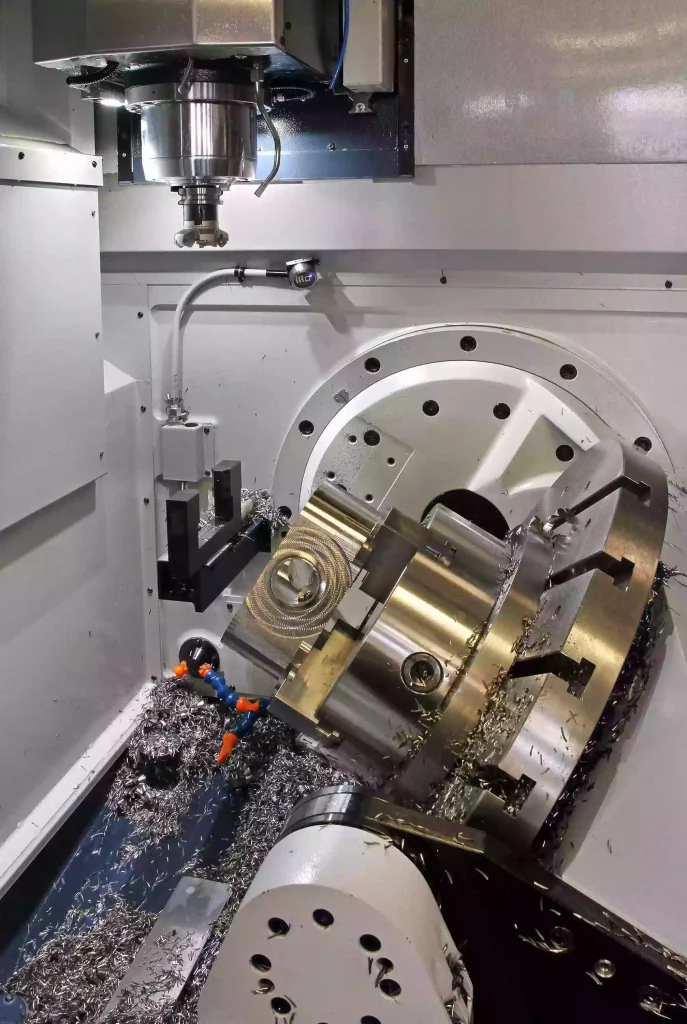

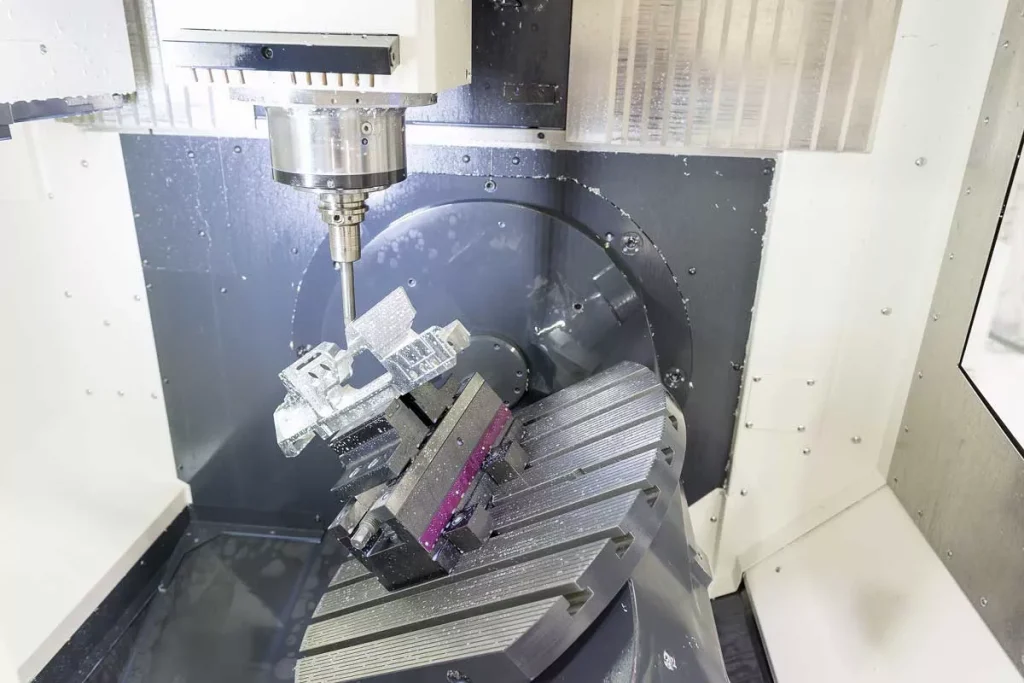

Elimold provides price-optimized multi-axis machining services, delivering high-precision custom parts to a variety of industries around the world. With our state-of-the-art equipment in our in-house facility, we can achieve tolerances of ±0.001 mm and faster production speeds, ensuring cost-effectiveness for both prototyping and mass production. We are ISO 13485 and IATF 16940 certified, with a delivery time of 1-5 days.

Multi-Axis Machining Manufacturer

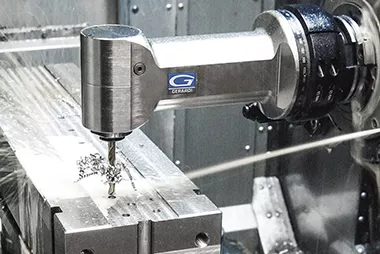

At our custom parts manufacturing facility serving the world, we specialize in precision processes, including CNC multi-axis machining, that provide exceptional accuracy and versatility. With cutting-edge technology, our team is able to expertly process a wide range of components from simple prototypes to complex parts using CNC multi-axis machining techniques. Our commitment to quality ensures that whether you require metal or plastic manufacturing, our CNC multi-axis machining capabilities can meet your precise specifications. In addition to rapid prototyping, we also excel in efficient production runs, emphasizing our fast turnaround times driven by CNC multi-axis machining processes. When you choose us, you benefit from our commitment to providing excellent results for your manufacturing needs, based on the latest innovations in CNC multi-axis machining.

Multi Axis Machining Services at Elimold Company

Are you looking for a more efficient and accurate solution to your manufacturing needs? Look no further than Multi-Axis Machining!

With Multi-Axis Machining, you can achieve unparalleled precision, and accuracy in your processes. Our state of the art technology allows for complex designs and shapes to be easily produced with little to no human intervention. Plus, our machines are designed to handle a wide range of materials, from plastics to metals, ensuring that your product is manufactured with the highest quality standards.

Our team of expert technicians are highly trained and experienced in operating our Multi-Axis Machining equipment, ensuring that your project is completed on time and to your exact specifications. And with our competitive pricing, you can rest assured that you’re getting the best value for your money.

Whether you’re in aerospace, automotive, medical or any other industry that requires precision manufacturing, Multi-Axis Machining has the solution for you. So why wait? Contact us today to learn more about how we can help you take your manufacturing to the next level!

Meeting Industry Specifications Within Exacting Tolerance Thresholds

Our capabilities in producing machined components include a wide range of tolerances.

- 5-Axis Machining: .060” to 60” in rotation

- Complex Milling: .060” to 84” in length

- Complex Turning: .060” to 38” in diameter

- Thin-Walled Machining: .101” wall thickness on cylindrical housings, deep pocket milling and micro-tubing

- Dimensional tolerances are held to 0.0001” +/-

- Measurement tolerances are held to 0.0000020”

Engineering Team and Capabilities

Elimold has a team of highly qualified and experienced engineers. We often hold meetings with customers to explore ways to improve the manufacturing of custom parts. We have unique expertise in various technology systems, including American technology system, German technology system, Japanese technology system and Italian technology system. Our company integrates the advantages of all the above technology systems. Therefore, our concepts, theories, methods, methodologies and solutions are based on multicultural wisdom and universal creativity.

If your project requires outsourcing custom manufacturing services, Elimold is your ideal partner for reliable multi-axis machining services. Our in-house factory has advanced multi-axis machining equipment that can meet all your project needs. What’s more, our experienced in-house engineering team is ready to guide you through all the steps. This helps avoid complications or errors that may occur during the rapid prototyping and mass production stages. With professional multi-axis CNC machining services, we can also meet supply chain needs. Contact us today to discuss your next project with us.

Types of Multi-Axis CNC Machining

Elimold’s extensive knowledge of CNC machines ensures that we can provide tighter tolerances, higher reliability and higher production than all other manufacturing shops. We also regularly train operators to ensure that they have the skills they need to make the most of our equipment. As a result, Elimold offers a wide range of machining options, delivering high-quality results every time, and stands out with highly competitive prices. Our reliable service reduces costs and increases delivery speed, helping you complete your project on time and within budget.

3-Axis CNC Machining

4-Axis CNC Machining

5-Axis CNC Machining

3+2-Axis CNC Machining

6-Axis CNC Machining

7-Axis CNC Machining

9-axis CNC machining

12-axis machining

Rotary table machining

Tilt rotary table machining

Multi-angle head

Hexapod robot

Ready to start your next multi-axis CNC machining project?

Elimold is ready to take on your toughest precision machined part challenges. Whether you need complex parts, intricate geometries, or work with hard-to-machine materials, our multi-axis CNC capabilities deliver precision, efficiency, and exceptional quality. Contact us today to learn more about how our multi-axis machining services can help you achieve your goals.

Complete Multi-Axis Machining Manufacturing Solutions

Whether your needs are simple or complex, Elimold has a solution for you. Our engineers are experienced and well-versed in a wide range of materials. Our typical quantity range is 25 to 250,000, and we can provide Kanban service when needed to reduce the pressure of large-volume inventory requirements, whether it is a single component, kit or complete assembly. Our goal is always to provide customers with custom solutions to meet their precision multi-axis machining needs. With excellent flexibility and responsive service, advanced equipment and skilled staff, we can complete nearly all precision multi-axis CNC machining projects on time and on budget.

Machining Processes

- Milling

- Drilling

- Boring

- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

- External Threading

- Internal Threading

- Tapping

- Thread Milling

- Internal Forming

- Knurling

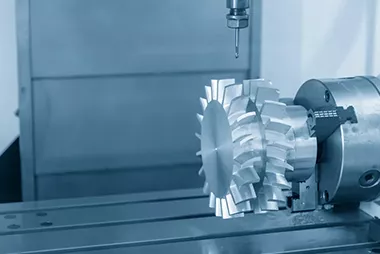

- Gear Hobbing

- Broaching

- Counterboring

- Countersinking

- Pocketing

- Profiling

- Reaming

- Parting/Cutting

- Facing

- Spline Cutting

Prototyping and Rapid Manufacturing

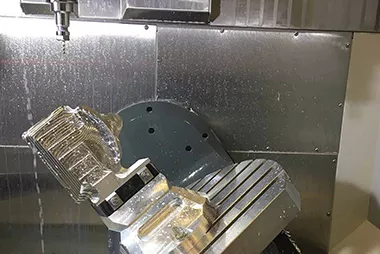

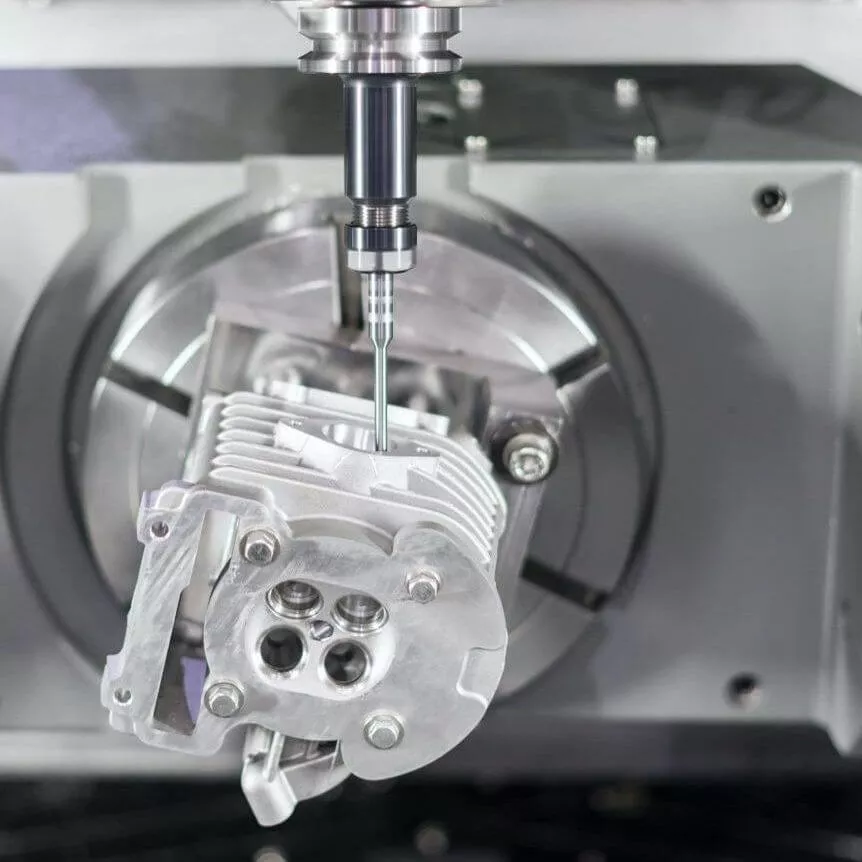

Multi-axis CNC machining enables fast turnarounds, low-volume production, and the creation of functional prototypes. Multi-axis CNC machining can quickly produce complex shapes, fine details, and diverse geometries, making it ideal for iterative design processes and accelerated product development cycles.

Rapid prototyping is a critical stage in product development, and at Elimold, we understand the importance of bringing your ideas to life quickly and accurately. Our prototype machining services are designed to help you test and refine your designs quickly and cost-effectively. We work closely with customers across a range of industries to produce prototype parts to their specifications, ensuring a seamless transition from concept to final production.

Quality Assurance Inspection

Elimold’s in-house factory processes parts to exacting tolerances every time. Once completed, parts are sent to our Quality Assurance department, which is equipped with several advanced computer-controlled measuring machines. We have a full-time inspection team. All tools, equipment and parts are calibrated, documented and archived in accordance with ISO 9001:2015 standards.

- CMM

- Gauges

- Inline

- Laser

- Magnetic

- Magnetic Particle

- On‐Stream

- Parts Sorting

- Penetrant

- Robotic

- Ultrasonic

- Video

- Visual

- Third Party

Secondary Services Offered

- Assembly

- Deep Hole Drilling

- Threading

- Pressing

- Welding

- Plating

- Passivating

- Etch and Chromating

- Heat Treating

- Centerless Grinding

- Anodizing

- Laser Marking

- Metal Finishing

Full range of multi-axis CNC machining services

Our manufacturing services embody the art and science of modern production. We focus on quality and versatility, providing seamless services from first draft to final product. We understand the multifaceted needs of our customers and provide a full range of services to meet the needs of any project, whether it involves cutting-edge technology or traditional manufacturing processes. Our commitment to excellence ensures that your expectations are not only met, but exceeded in all types of manufacturing.

And in a world where time is of the essence, our fast delivery services put you back in control. We focus on providing fast and effective solutions, prioritizing your project time without sacrificing quality. Whether you are in a hurry to get to market or under a tight deadline, our professional team is ready to streamline processes and speed up delivery. Your success is our business; with us, speed does not mean sacrificing exquisite craftsmanship. Trust us to complete your project on time with unparalleled efficiency.

Elevate Your Designs with Multi-Axis Machining

At Elimold, we’re dedicated to pushing the boundaries of what’s possible. Our multi-axis machining capabilities offer a world of design possibilities, from intricate curves to complex contours. Contact us today to discuss your project, request a quote, and experience the transformative power of multi-axis machining in your industry.

Ultra-precision machining capabilities and cost savings

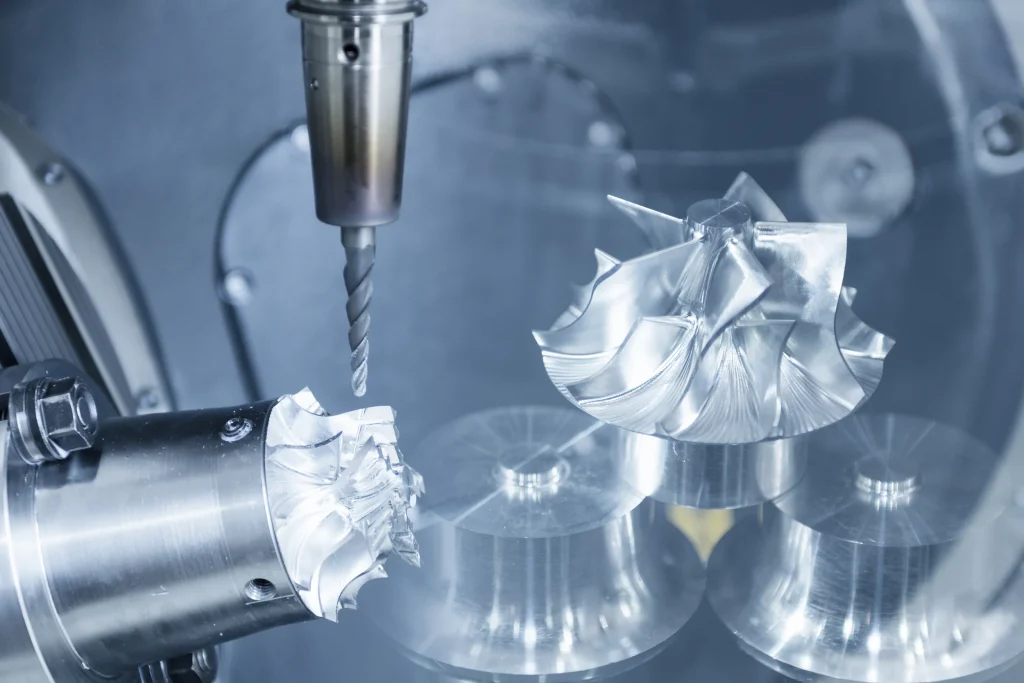

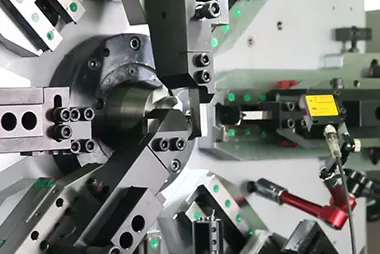

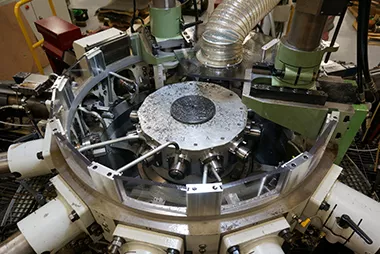

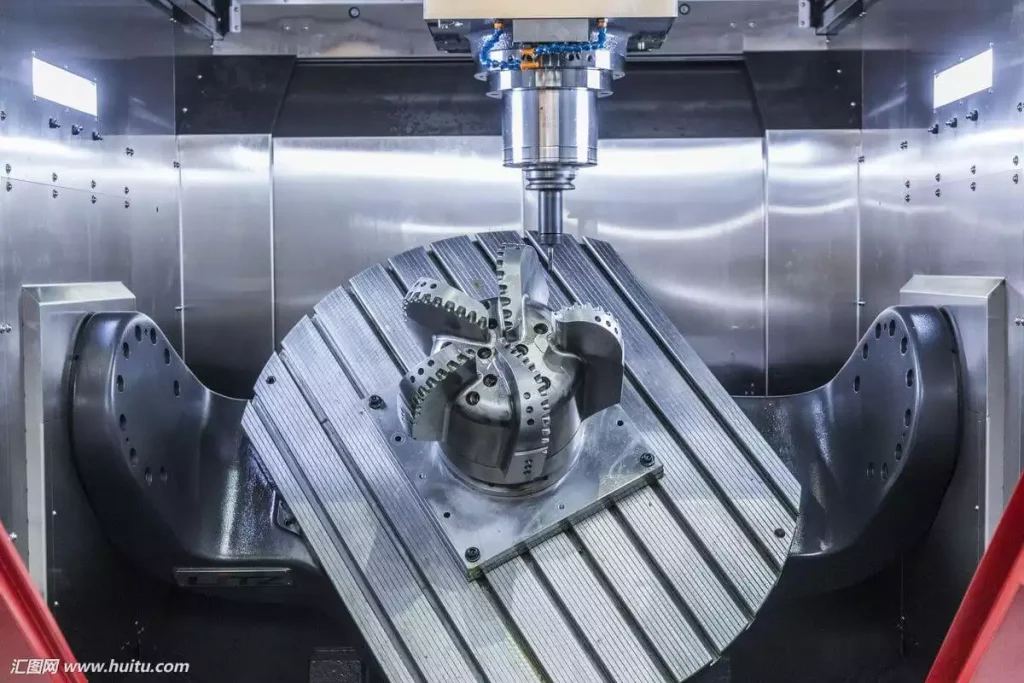

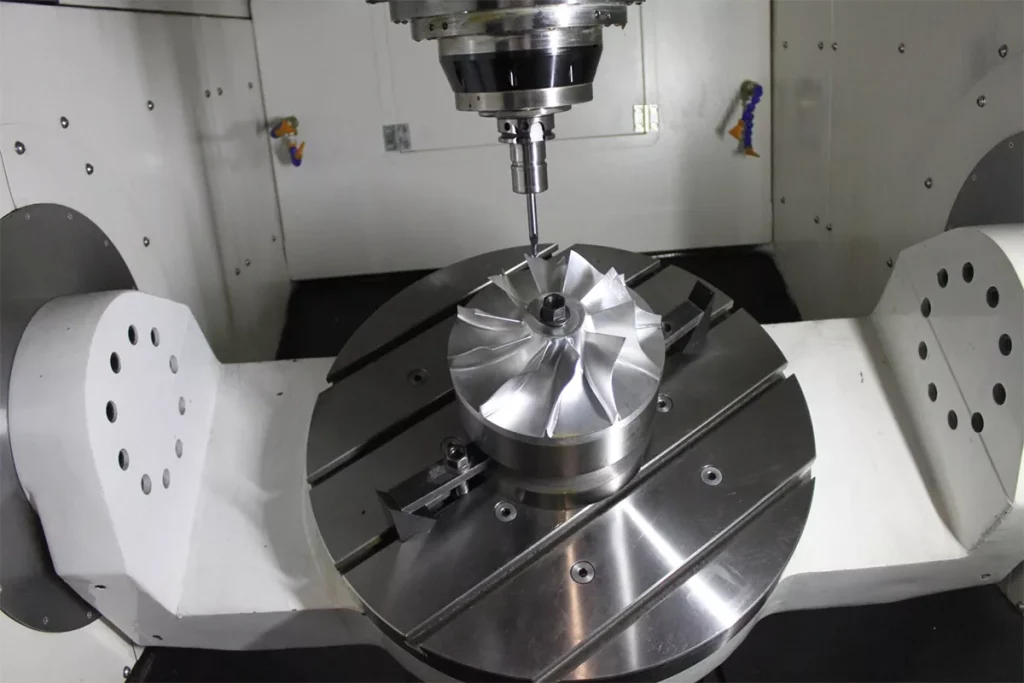

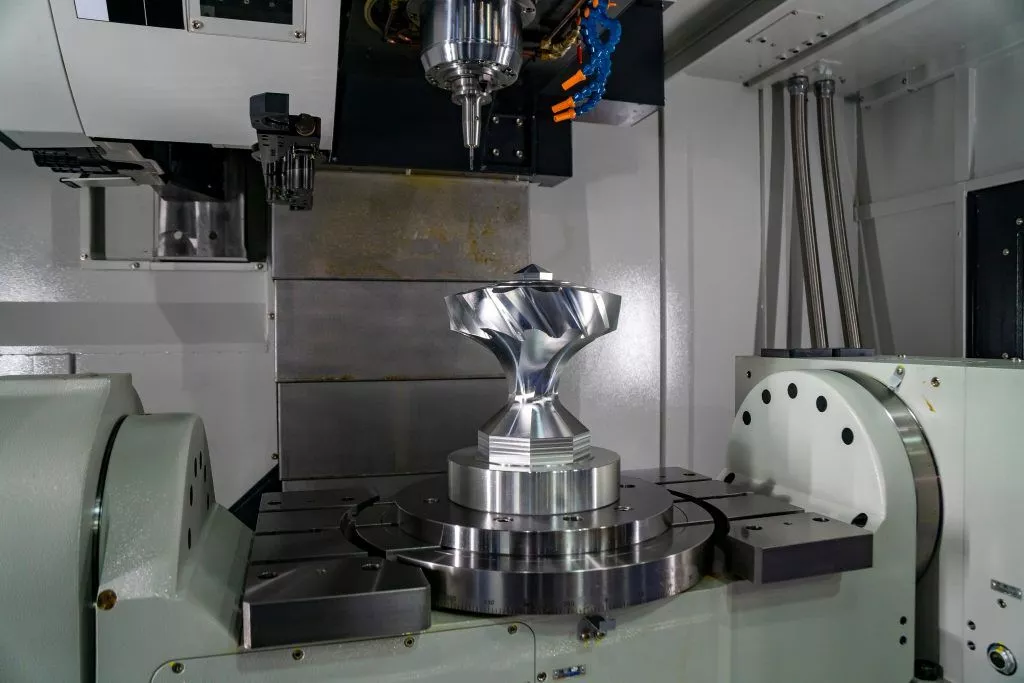

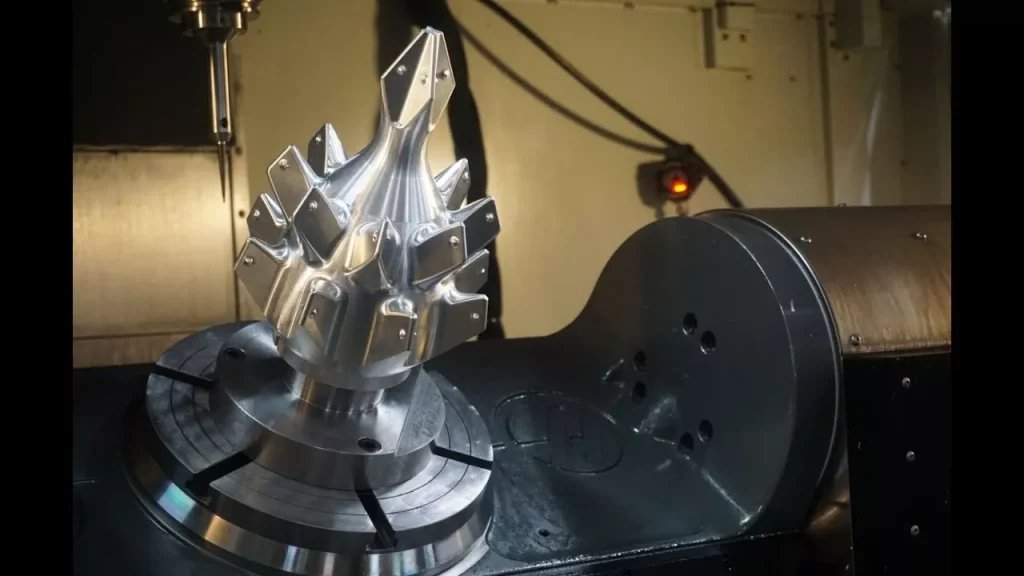

Backed by extensive experience and unparalleled creativity, the Elimold team conquers complex part manufacturing with state-of-the-art multi-axis CNC machining. Multi-axis platforms can cut part geometries and complex shapes not possible with other machining methods due to excellent mobility of the workpiece to the tool’s axis of rotation. This enhanced 6-sided machining capability improves accuracy by combining multiple independent operations, significantly reducing part handling and multiple clamping stages during machining. The spindle head operates closer to the workpiece, allowing the use of shorter cutting tools, less vibration and deflection, higher cutting speeds, tighter tool movements, and increased surface finishing capabilities.

Cost savings are another huge benefit of multi-axis technology. Consolidating 3-axis machining and other linear axis operations into a single unit increases throughput while reducing cycle times, expensive work fixtures and overall waste. It provides a more efficient and cost-effective solution with faster delivery times and production turnaround and superior quality.

What is Multi-Axis Precision Machining?

A multiaxis machining center has a variable speed tool spindle head with a multidirectional rotary axes orientation. Raw material clamps into an indexing chuck or to a table. The spindle head assembly moves along the travel columns in unison with the chuck or index table to precisely maneuver the workpiece and cutting tool to achieve the proper cutting path required for removing material. Multi-axis machines lend themselves to a single setup, infinite geometry cutting, excellent chip management, longer tool life, repeatable manufacturing, and the speed of simultaneous 5-axis high precision machining. Like a standard milling machine, this is a subtractive manufacturing process.

Material Options

Elimold has equipment to process a wide range of standard and exotic materials. Our multi-axis CNC machines are capable of processing materials ranging from aluminum and stainless steel to more complex materials such as titanium, Hastelloy and other alloys and engineered plastics. This flexibility allows us to support industries that require parts with special material properties to ensure durability and performance in demanding environments.

Metals

- Aluminum

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Iron

- Lead

- Magnesium

- Nickel

- Stainless Steel

- Stellite (Hardfacing)

- Tin

- Titanium

- Zinc

- Alloy Steel

Exotic Metals and Other Materials

- Inconel®

- Invar®

- Iridium

- Kovar®

- Molybdenum

- Monel®

- Niobium

- Palladium

- Platinum

- Silver

- Superalloys

- Tantalum

- Ceramic

- Fiberglass

- Glass

- Polyester

Plastic Polymers

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal

- Acrylic

- Fiberglass Reinforced Plastics

- Nylon

- Phenolic

- Polyamide‐Imide

- Polycarbonate

- Polyetheretherketone (PEEK)

- Polyetherimide

- Polyethylene

- Polyphenylene Sulfide

- Polypropylene

- Polystyrene

- Polysulphone

- Polytetrafluoroethylene (PTFE)

- Polyvinyl Chloride (PVC)

- Polyvinylidene Fluoride (PVDF)

Surface Finishing Options

- Anodizing

- Bead Blasting

- Powder Coating

- Electropolishing

- Passivation

- Chrome Plating

- Zinc Plating

- Nickel Plating

- Black Oxide

- Brushing

- Polishing

- Sandblasting

- Painting

- Heat Treatment

- Laser Engraving

- Chemical Etching

- Vapor Polishing

- UV Coating (for plastics)

- E-coating

- Hardcoat Anodizing

- PVD Coating

- CVD Coating

- Teflon Coating

- Ceramic Coating

- Tumbling (Vibratory Finishing)

- Shot Peening

- Silkscreen Printing

- Pad Printing

- Sublimation Printing

- Electroplating

- Gold Plating

- Silver Plating

- Electroless Nickel Plating

- Deburring

- Texturing (via EDM or laser)

- Ultrasonic Polishing

- Clear Coating

- Enamel Coating

- Hydrographics

- Thermal Spraying

- Plasma Spraying

Advantages of multi-axis machining

- Improved Precision: Multi-axis machining enables the production of precision parts with complex features, such as curved surfaces and undercuts, that would be difficult and time-consuming to produce using traditional methods. Our ability to move the cutting tool along multiple axes provides our customers with greater precision and dimensional consistency.

- Extended Equipment Life: By tilting the tool/table to maintain optimal cutting position and a steady chip load, we can extend equipment life and reduce cycle time.

- Reduced Equipment Costs: Precision parts can often be manufactured in a single setup using multi-axis machining, resulting in fewer tool changes, increased uptime, reduced human error, and, in turn, lower costs for our customers.

- Expanded Design Possibilities: The versatility of multi-axis machining opens up new possibilities. We can develop highly complex components with smoother transitions and complex contours and shapes, facilitating the manufacture of innovative and customized parts.

- Achieve Superior Surface Finish: With rotating fourth and fifth axes, your product can be oriented to get closer to the cutting tool. When the part is closer to the cutting tool, the tool can be shorter, reducing sensitivity to vibration at high speeds, which reduces the impact on surface finish.

Multi-axis CNC Machining Service Provider

Are you looking for a more efficient and precise solution to meet your manufacturing needs? Multi-axis machining is the answer! With multi-axis machining, you can achieve unparalleled machining precision and accuracy. Our advanced technology can easily produce complex designs and shapes with little to no human intervention. In addition, our machines are able to handle a wide range of materials from plastics to metals, ensuring that your products meet the highest quality standards. Our team of professional technicians are well-trained and experienced in operating multi-axis machining equipment to ensure that your projects are completed on time and to your exact specifications. Our highly competitive prices provide you with peace of mind and great value for money.

Other CNC Machining Services

If you need to produce parts in a cost-effective manner, our multi-axis CNC machining services may be the right choice for you. In addition, we offer a comprehensive range of CNC machining service options to create high-quality solutions for a variety of applications. If you want to work with a professional team with quality as the core, we can help you too.

CNC Milling

CNC Turning

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Cost Control for Machining Projects

Cost control is one of Elimold’s driving forces in producing precision parts. To ensure our customers get added value from their CNC parts program, we focus on making our machining services as efficient as possible.

We use Lean Manufacturing practices, including 5-S Workplace Organization, Cellular Manufacturing, Quick Changeover, and more, to help us identify and eliminate waste. This helps keep our costs competitive and helps us constantly improve our existing processes, while also building optimal flow into our processes from the beginning.

Why choose Elimold?

Our exceptional knowledge of CNC machines ensures that we deliver tight tolerances, greater reliability, and a higher throughput than all other manufacturing shops. We also regularly train our operators to ensure they have the skills necessary to make full use of our equipment.

As a result, Elimold offers a wide range of machining options possible, and delivers top-quality results every single time, with competitive pricing to top it off. The reliability of our service reduces maintenance costs and unplanned downtime, which will help you stay on schedule and on budget.

Industries We Serve

Our multi-axis CNC machining services lead the way in technological advancements, providing unmatched precision and efficiency. Multi-axis machining capabilities allow us to machine parts with complex geometries, ensuring the highest precision and quality. Whether your project involves complex aerospace components, industrial machinery parts, or automotive components, our multi-axis CNC machining capabilities are designed to exceed your expectations.

- Advertising

- Aerospace

- Agricultural and Farming

- Architecture

- Auto/Truck/Transportation

- Automation

- Automotive

- Biomedical

- Biopharmaceutical

- Biotechnology

- Building and Construction

- Chemical

- Commercial

- Communications

- Computer and Electronics

- Construction

- Consumer Goods

- Cosmetics

- Cryogenic

- Dairy

- Dental

- Defense Industry

- Department of Energy (DOE)

- Department of Defense (DOD)

- Electrical

- Electronics

- Government

- Heavy Equipment

- Telecommunications

- Hydraulics

- Ice Making

- Industrial

- Laboratory

- Natural Gas (NG)

- Machine Tools

- Machinery

- Manufacturing

- Marine

- Material Handling and Processing

- Medical

- Medical Devices

- Military

- Municipal

- Nano Technology Manufacturing

- Oil and Gas Pipeline

- Optical

- Packaging

- Plumbing

- Pneumatics

- Printing and Publishing

- Process Gases

- Pulp and Paper

- Pulp Manufacturing

- Pumps

- Railroad

- Robotics

- Semiconductor

Your Trusted Multi-Axis CNC Machining Partner

If you are responsible for sourcing or need custom machined parts, Elimold is your premium partner for custom manufacturing that can make your work faster, easier, and more efficient. Our custom multi-axis CNC machining services offer a range of CNC machining capabilities, utilizing many types of CNC machine tools to produce simple and extremely complex geometries

Your preferred provider of cutting-edge multi-axis CNC machining and prototyping services. We are committed to precision and innovation, providing customized solutions for a wide range of industries around the world. At Elimold, we pride ourselves on our state-of-the-art facilities, experienced team, and ability to provide top-notch multi-axis machining solutions that meet each customer’s unique needs.

Request Your Free Multi-Axis CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Multi-Axis CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.