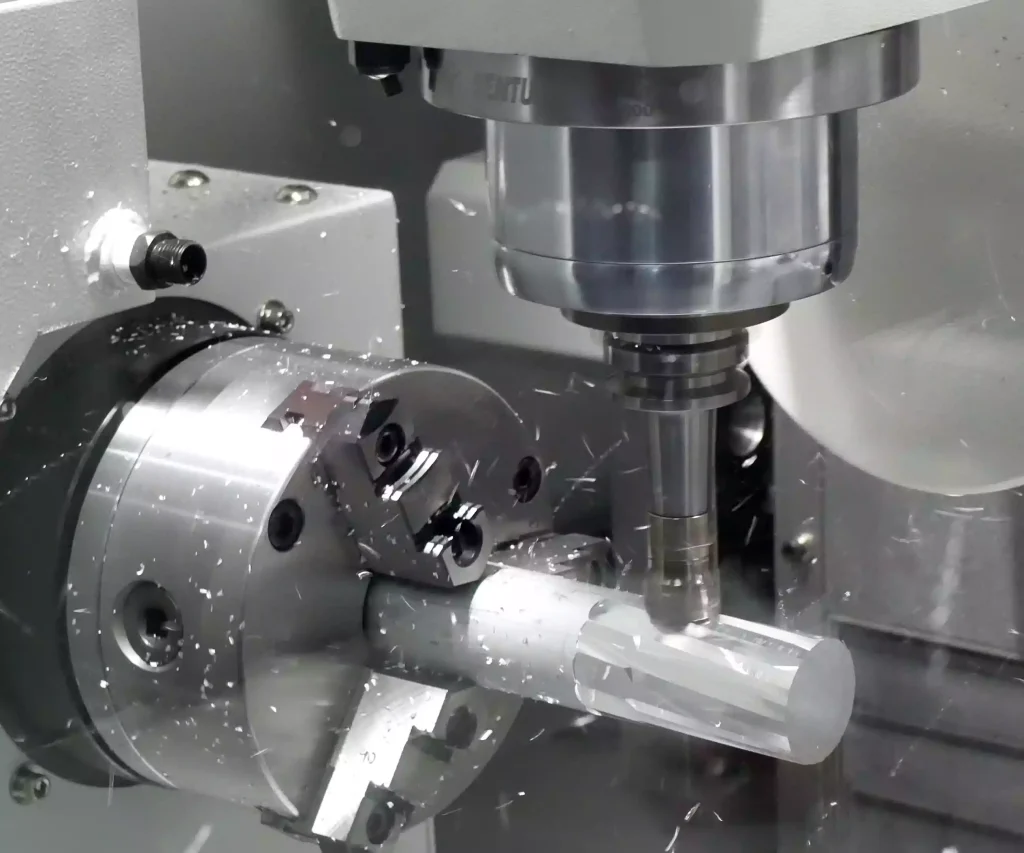

Multi-Axis CNC Turning Services

Elimold provides precision multi-axis CNC turning services to customers around the world. Our extensive machining capabilities and value-added services enable us to produce custom machined parts and assemblies to a wide range of specifications and standards. Our core strength is providing precision-crafted components at competitive prices. We deliver unmatched precision, ensuring consistent quality across all batches, regardless of production volume. Contact us now for a free instant quote.

Multi-Axis CNC Turning Manufacturer

Elimold is the industry’s leading manufacturer of multi-axis CNC turned parts. That’s why you can count on us to provide you with the most complex and difficult-to-produce components. Other companies may not be able to build the components you need for your various applications, but we have over 39 years of experience exceeding our customers’ expectations. That’s why our team has the expertise and technology to meet your on-time delivery and quality requirements.

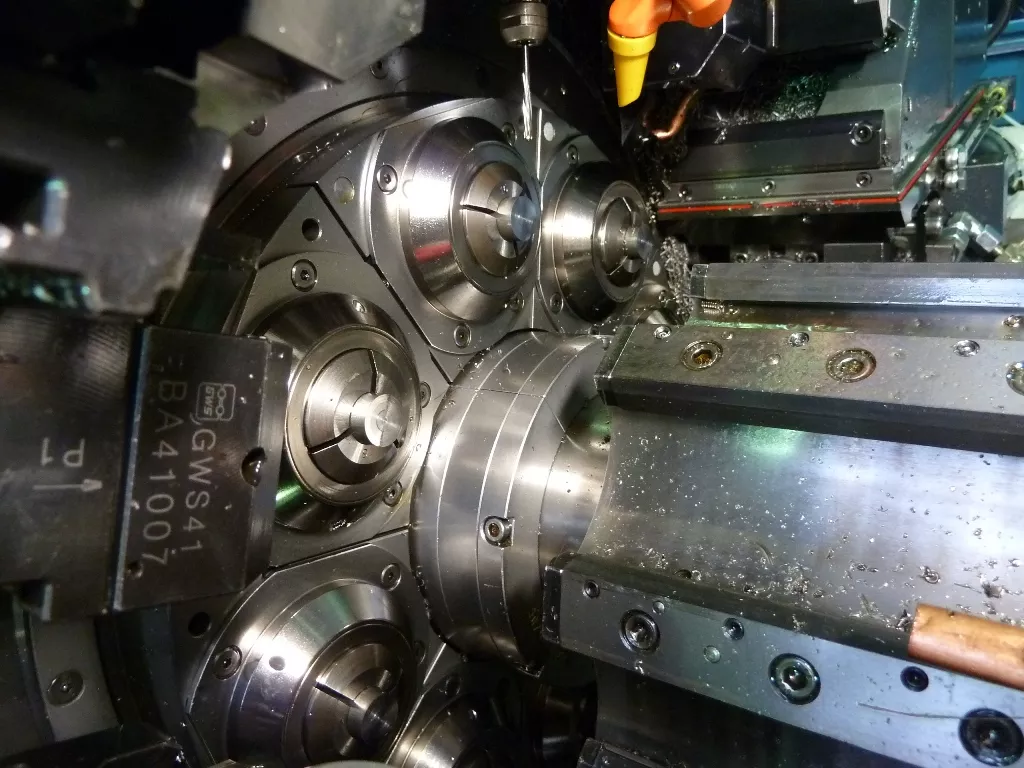

And we love taking on challenging projects. Plus, our in-house factory’s certified processes ensure quality every time. Every part we produce using our multi-axis turning manufacturing process meets industry standards. Elimold’s in-house factory provides 24-7 automated production. We produce more than 300 different parts per month in a variety of metals and plastics. Learn more about how our cutting-edge technology, commitment to quality, and meticulous attention to detail make us the partner of choice for your machining needs.

Multi-Axis CNC Turning Factory

Elimold is a trusted solutions provider for medium and high volume turned parts production machining and assembly services for a wide range of industries. From prototyping to mass production, our multi-axis CNC turning centers, skilled machinists and clearly defined processes enable us to produce extremely complex components with precision. Our advanced machining centers are able to regularly achieve tight tolerances and exacting surface finishes. All manufacturing processes are ISO 9001:2015 certified, ensuring process certification standards and consistency of critical dimensions.

Our 45,000 square foot manufacturing facility is equipped with a wide range of advanced machining equipment, providing us with the tools needed to manufacture virtually any machined part or assembly our customers require. This makes us a responsive partner that can meet our customers’ specific delivery needs, including Just-In-Time (JIT), Advanced Ship Notice (ASN), Electronic Data Interchange (EDI) and Kanban. This responsiveness is ideal for demanding customer projects in the OEM market, contract manufacturing, government contracting and other major industries.

One-Stop Multi-Axis Turning Contract Manufacturer

Elimold is a one-stop contract manufacturer that provides comprehensive multi-axis CNC turned parts production solutions for your project. We use quality-assured internal and external processes to ensure your product from concept to completion. And we provide the experience and supply chain capabilities to virtually eliminate redundant processing steps and the associated costs of your project.

And our capabilities go far beyond manufacturing. Our team provides 3D CAD-CAM services that can transform the simplest sketches into precision components. Whether it is reverse engineering or manufacturing to customer designs, Elimold has the experience and capabilities to take on your next project. And enjoy convenient international shipping services. The quality of Elimold’s parts speaks for itself, but our internal streamlined process from development to delivery is what sets Elimold apart from the competition. We are a truly unique machine shop, from the quality of our workmanship to the quality of our people.

Machining Processes

Our state-of-the-art machining technologies ensure unmatched precision, and from complex geometries to multi-axis machining, our capabilities are diverse to meet the unique needs of businesses around the world.

- Straight Turning

- Taper Turning

- End Facing

- Facing

- Shoulder Facing

- Contour Turning

- Form Turning

- Internal Broaching

- Parting

- External Broaching

- Boring

- Taper Boring

- Internal Forming

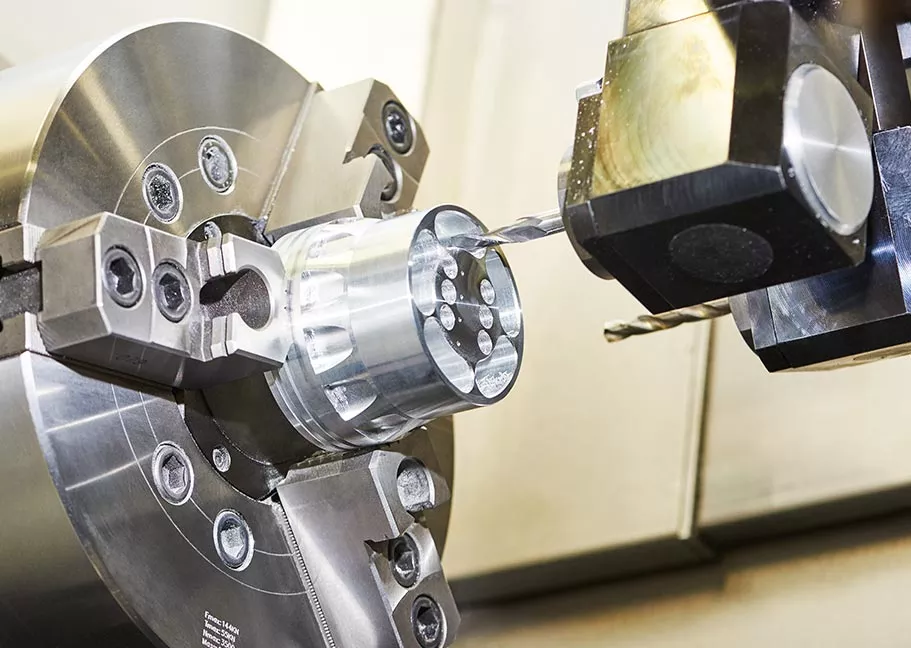

- Drilling

- External Threading

- Internal Threading

- Reaming

- Internal Cut Knurling

- External Cut Knurling

- Pressure Knurling

- T-Slotting

- Side Slotting

- Edge Rounding

- Side Plunging

- Profiling

- Plunging

- Thread Milling

- Thread Rolling

Multi-axis Turning Tolerance

Elimold uses the right multi-axis turning equipment to meet your exact tolerance requirements every time. Our in-house state-of-the-art machine shop Once parts are completed, our quality assurance department uses advanced computer-controlled measuring machines to inspect, test and confirm tolerances. The components we help produce require high precision. Our capabilities include:

- Complex turning: .060 inch to 84 inches in length

- Complex turning: .060 inch to 38 inches in diameter

- Thin-walled machining: .010 inch wall thickness on cylindrical housings, deep pocket turning and micro-tubing

- Dimensional tolerances to 0.0001 inch with +/- and measurement to 0.0000020 inch

Ready to start your next multi-axis CNC turning project?

Our multi-axis turning services produce complete components with the durability and precision you need. Are you looking for a partner for your next project? Contact us today to get a CNC multi-axis turning quote.

Full-Service Multi-Axis CNC Turning Shop

At Elimold, we take a multidisciplinary engineering approach, leveraging our extensive manufacturing expertise to provide tailored support and guidance throughout your project lifecycle. We work closely with our customers to ensure cost-effective, sustainable manufacturing solutions that meet and exceed customer expectations. Our comprehensive engineering support services include manufacturability assistance, rapid prototyping, and functional testing customized to your specific needs.

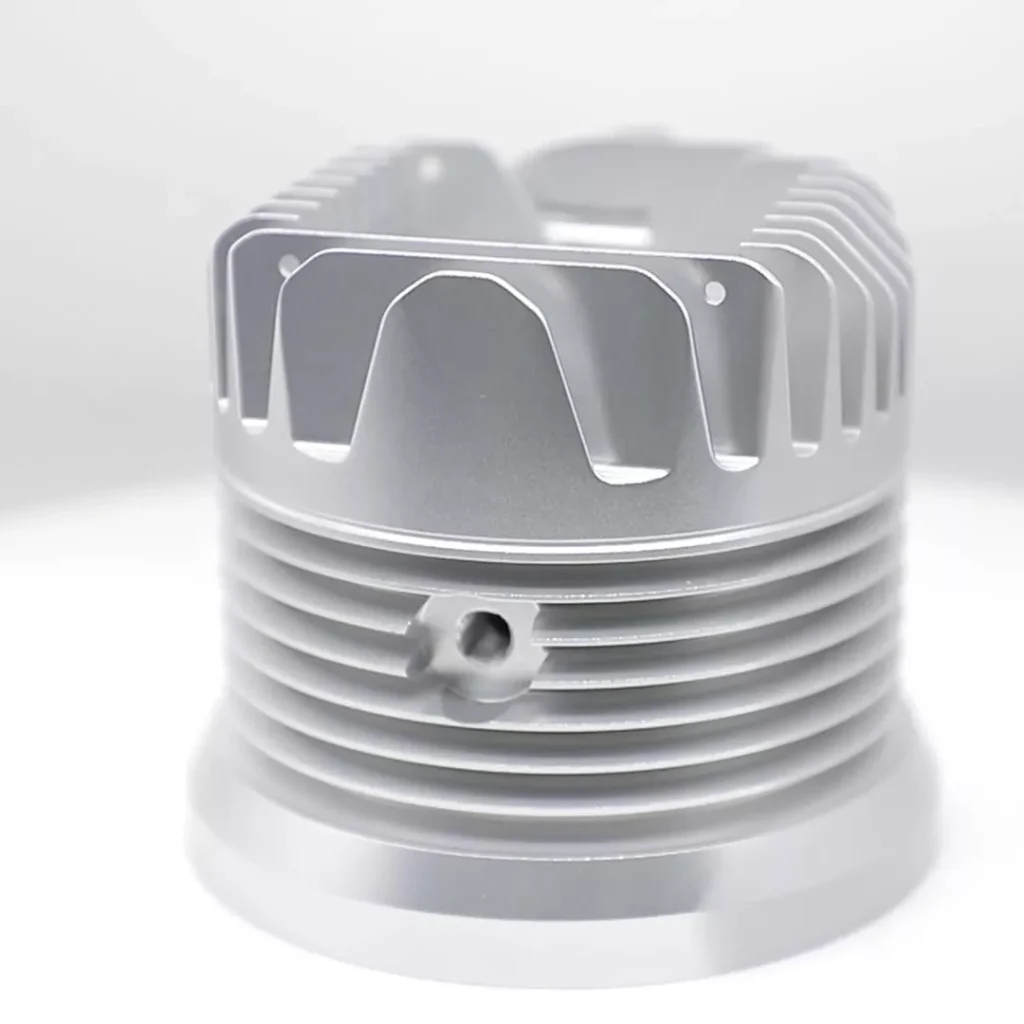

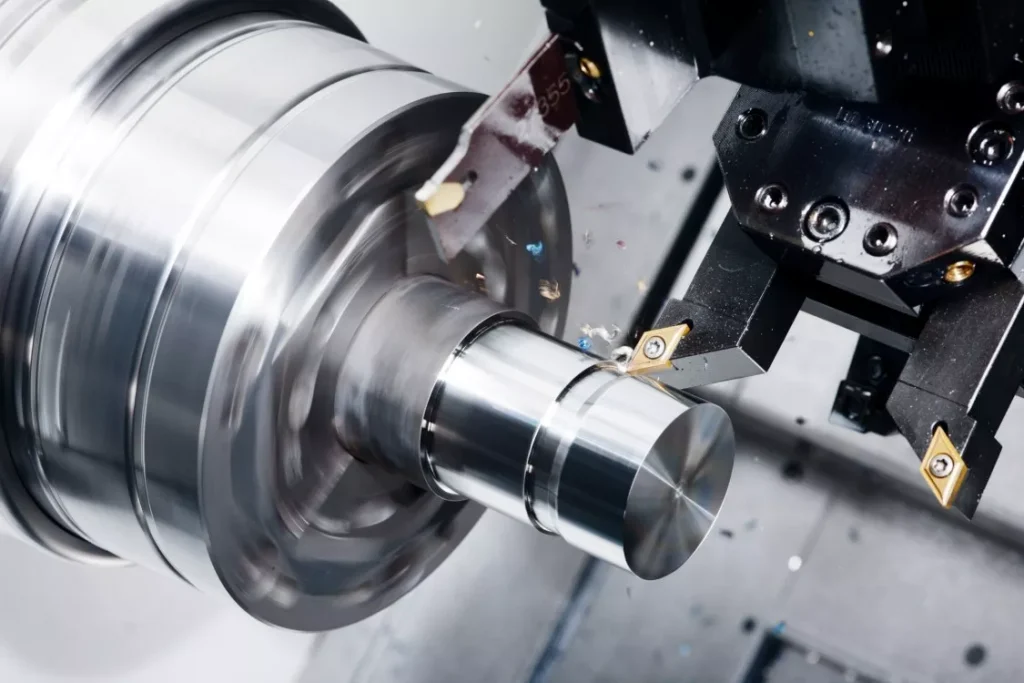

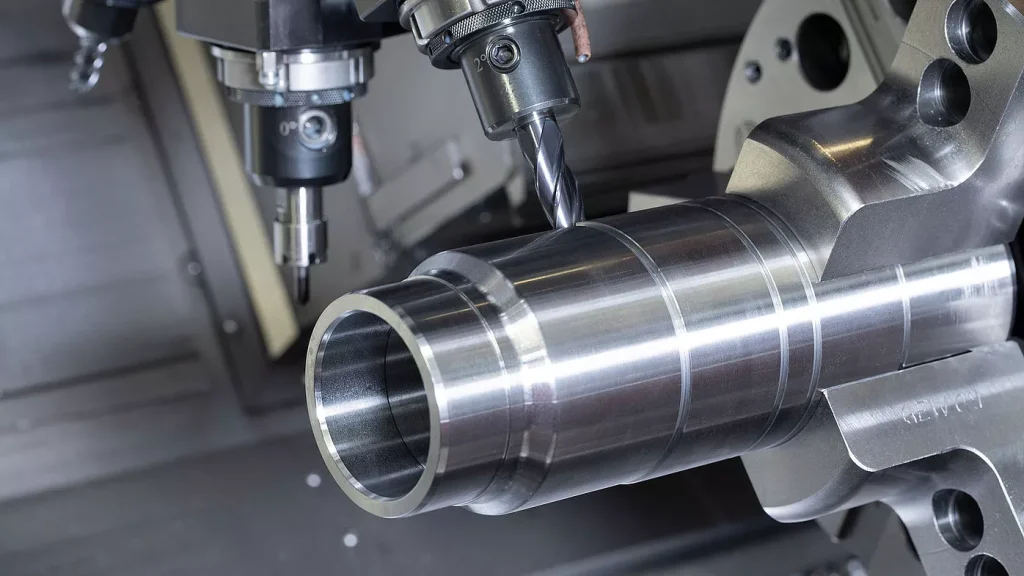

Our advanced machining capabilities will help you realize your engineering vision. Our shop is known for handling complex, large machining projects with unparalleled precision and efficiency. These parts are produced using the latest and most advanced Swiss lathes. Our advanced CNC machining centers are capable of completing high-precision, close-tolerance turning operations with unmatched efficiency and repeatability. Utilizing a multi-axis Swiss lathe with multi-axis machining capabilities can help reduce machining cycle times and lower your overall production costs. For complex components and assemblies that require precision-engineered and tight-tolerance geometries, our multi-axis CNC turning solutions can achieve the high-precision machining results your products require.

Custom Multi-Axis CNC Turning Parts

By seamlessly integrating advanced Multi-Axis CNC Turning technology, Elimold has positioned itself at the forefront of precision engineering of custom machine parts. Their dedication to innovation is reflected in state-of-the-art manufacturing processes that produce complex, custom-machined parts with exceptional precision and efficiency. The company’s responsive service is the cornerstone of its operations, ensuring that its customers’ unique specifications and requirements are not only met but exceeded. A commitment to custom solutions cements lasting relationships with customers, making Elimold a trusted partner in achieving product excellence. Additionally, their competitive cost structure highlights their commitment to delivering value, making them an industry leader in custom machined parts.

Rapid Prototyping Services for Multi-Axis Turned Parts

At Elimold, we not only provide precision manufacturing to our customers, we also provide solutions. We provide a prototyping service to assist customers with design and manufacturing process development. As part of this service, we are happy to provide design for manufacturability as feedback to help customers reduce costs and improve the manufacturability of components. We can also work with customers to help them build new product promotion projects. We have a number of trusted agencies to which we can subcontract their finishing processes. This allows us to provide a complete end-to-end solution to all of our customers. This ensures that they can get the quality standards they expect from Elimold, as well as shortened lead times, reduced costs, and less organizational headaches.

Team of Product Development Engineers

While Elimold’s engineers use the same CAD programs as the rest of the industry, we leverage our team’s deep, broad manufacturing experience to provide you with superior product development and design. Our team of engineers is comprised of engineers with years of experience in machining. This means we understand the limits of manufacturing and push those limits to successfully overcome any design challenge. And our experience working with multi-axis turning means we understand the challenges and possibilities of this process better than anyone. Most importantly, our product development engineers will work with you to improve existing designs and explore cost savings in the process. You know your job best, but we can help you with product development and research. When you work with Elimold, we’ll be there for you every step of the way.

Design for Manufacturing (DFM)

Our most comprehensive service, Design for Manufacturing, focuses on building prototypes, product development, and high-volume production of precision turned parts. We pride ourselves on our manufacturing capabilities, and our engineers can apply their experience to a wide range of needs. To date, we have provided manufacturing solutions for thousands of customer designs. This experience means not only that we have the technical ability to do the job well, but also that we understand which process steps affect cost. Our experience enables us to balance the complexity of a design and its impact on manufacturing costs.

Quality Inspection and Certification Standards

Elimold is AS9100D and ISO9001:2015 certified and is committed to continuous improvement in all areas of quality including manufacturing, inspection, document control and training. Our processes include document and data control, management review, process control, measurement equipment calibration, first article inspection of all parts, in-process inspection and final inspection, all to the highest standards. All material and processing certificates are maintained through our cloud-based ERP system and are instantly accessible, ensuring timely and accurate reference when necessary. All Elimold inspection equipment is calibrated and traceable to the requirements of ISO 10012, ISO 17025 and ANSI/NCSL Z540.1.

Need help with your multi-axis CNC turning project?

Elimold’s team of engineers has over two decades of industry experience, providing a dynamic range of manufacturing and machining services, including multi-axis CNC turning. Our experienced professionals serve a wide range of industries, providing them with high-quality precision parts that meet exacting standards.

Perfect for Complex Prototypes and Production Runs

Our multi-axis turning capabilities make Elimold an ideal partner for both prototype development and mass production. Being able to machine complex parts with tight tolerances more easily with minimal setups reduces turnaround time and reduces costs. This is especially important during the transition from prototype to mass production, ensuring consistency and precision at every stage. Additionally, during production, turned parts are inspected in our quality lab to ensure they meet the drawing requirements. Afterwards, the manufactured products are tested in our fully-featured metrology lab. This ensures that every component you need for your application will meet the design requirements, and also provides services to test whether the parts will work properly under any extreme conditions. Choosing Elimold gives you peace of mind that every component used in your project is safe.

Material Options

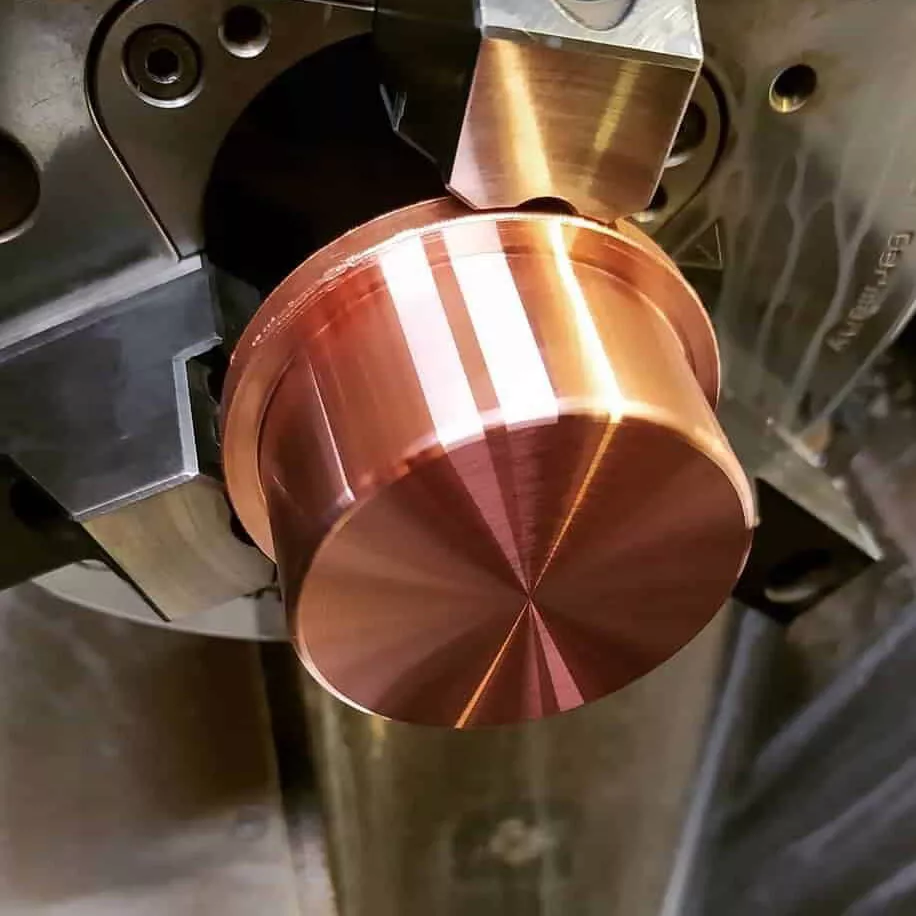

Elimold has many years of experience in machining, turning and grinding, processing almost all types of materials.

Metals

- Aluminum

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Iron

- Lead

- Magnesium

- Nickel

- Stainless Steel

- Stellite (Hardfacing)

- Tin

- Titanium

- Zinc

- Alloy Steel

- Inconel

- Invar

- Iridium

- Kovar

- Molybdenum

- Monel

- Niobium

- Palladium

- Platinum

- Silver

- Tantalum

Plastics

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal

- Acrylic

- Fiberglass Reinforced Plastics

- Nylon

- Phenolic

- Polyamide‐Imide

- Polycarbonate

- Polyetheretherketone (PEEK)

- Polyetherimide

- Polyethylene

- Polyphenylene Sulfide

- Polypropylene

- Polystyrene

- Polysulphone

- Polytetrafluoroethylene (PTFE)

- Polyvinyl Chloride (PVC)

- Polyvinylidene Fluoride (PVDF)

Surface finishing and value-added services

- Anodizing

- Brazing

- Plating

- Burnishing

- Passivation

- Grinding

- Knurling

- Heat Treatment

- Stampings

- Bending

- Fabrication

- Mechanical Assembly

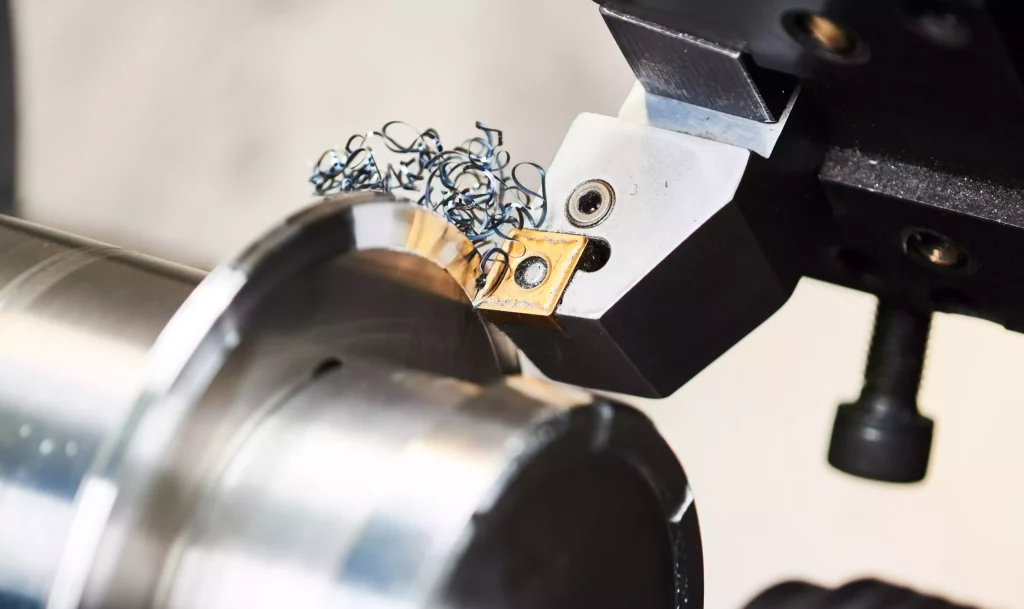

How Does CNC Multi-Axis Turning Work?

The CNC multi-axis turning technique requires maneuvering tools in four or more directions to shape objects and produce the necessary structure. This is accomplished by employing cutting-edge processes, such as laser or waterjet cutting, enabling accurate removal of excess material until the required shape is reached.

A CNC multi-axis turning milling center can operate on multiple axes, typically four to 12. This allows for the efficient and precise production of complex parts. In addition, it can create intricate designs and patterns in various materials, including steel, aluminum, plastics, and ceramics.

Advantages of Multi-Axis CNC Turning

Compared to other manufacturing methods, CNC turning offers several advantages, such as:

- Comprehensive CNC Large Machining: Our core business lies in sophisticated CNC machining technology, including advanced turning, milling and multi-axis machining capabilities. Our technology-driven approach ensures that we can complete the most complex projects with precision.

- Large Component Expertise: Our shop specializes in the production of large and heavy components, equipped with cranes that can handle over 50 tons, allowing us to complete the most challenging tasks effortlessly.

- Unparalleled Accuracy and Precision: Our skilled machinists, laser tracker technicians, and advanced laser equipment for verifying mechanical geometry ensure that we achieve excellent accuracy in long-distance measurement. We manufacture components to the size of bridges and adhere to strict tabulation tolerances.

- Expert CNC Programmers: Our CNC programmers are at the forefront of technology and excel in producing the precise geometric features required for today’s innovative projects.

- Comprehensive Inspection and Verification: Our inspection team utilizes the latest data reports, including structured data, graphical and table formats, to ensure that each machined profile meets strict quality standards.

Industries Served

We are uniquely positioned to produce precision components to exact specifications through our own manufacturing processes, enabling us to produce highly complex components to help companies across a wide range of industries.

- Advertising

- Aerospace

- Agriculture and farming

- Construction

- Automotive

- Automation

- Medical

- Construction

- Consumer goods

- Telecommunications

- Dental

- Defense Industry

- Energy

- Heavy Equipment

- Marine

- Oil and Gas

- Optics

- Packaging

- Robotics

- Semiconductors

Applications

Manufacturers who produce complex, critical and precision products rely on multi-axis CNC turning capabilities to deliver the parts they need at the highest quality, fastest speed and best comparable price. Partnering with an experienced and certified multi-axis CNC turning shop can provide a wide range of manufacturers in a variety of industries with the high-quality components they need.

- Adapters

- Axles

- Blocks

- Bolts

- Bosses

- Bushings

- Cages

- Clamps

- Collars

- Couplings

- Dowels

- Electronic Connectors

- Fasteners

- Fittings

- Gears

- Hardware

- Housings

- Hubs

- Inserts

- Knobs

- Manifolds

- Mounting Plates

- Nozzles

- Nuts

- Pistons

- Plugs

- Plungers

- Pulleys

- Retainers

- Rifle Firing Pins

- Cam Pins

- Rings

- Rods

- Screws

- Shafts

- Sleeves

- Spacers

- Spools

- Standoffs

- Studs

Other Machining Service Types

Looking for a partner for your next multi-axis CNC turning project? Then turn to the precision machining experts at Elimold! We have been providing precision CNC machining and manufacturing services for over 30 years. This experience has given us the knowledge and skills necessary to produce difficult machined components. As a result, we can offer many types of CNC machining services.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

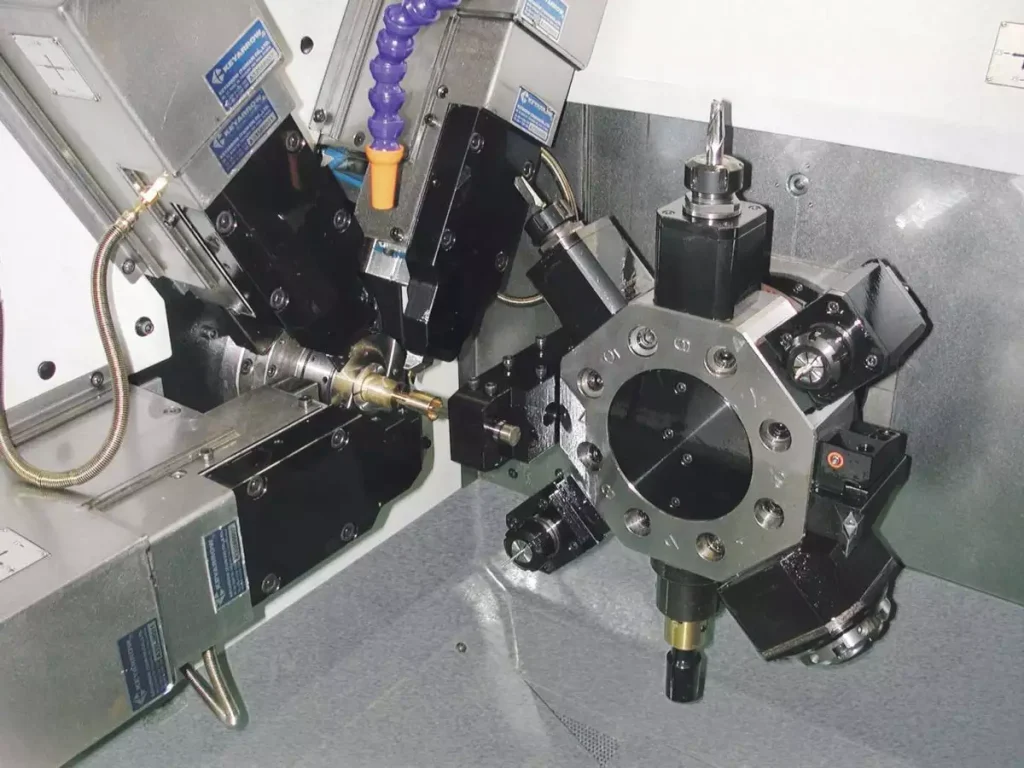

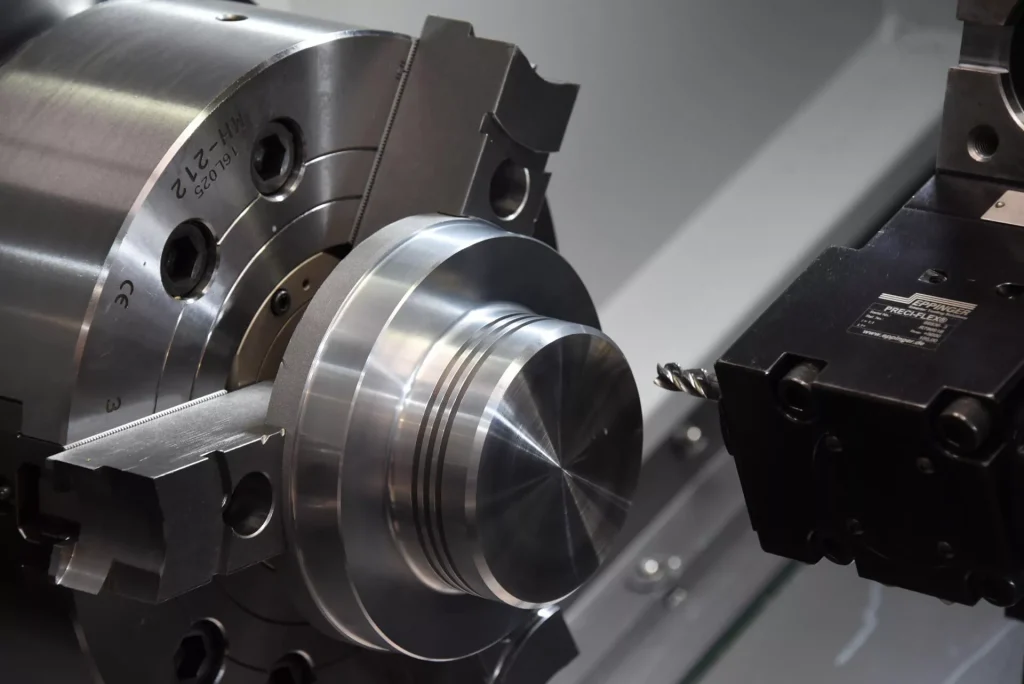

Multi-axis CNC turning equipment

Equipped with state-of-the-art CNC turning centers, our team can handle our customers’ most challenging machining projects. These versatile work centers feature live tooling, double spindles, and multi-axis (up to five axes) capabilities, which enable us to turn and mill components in the same operation. They are also arranged in cells to maximize efficiency for parts requiring multiple sequences. Other equipment capabilities include large swing lathes, automatic bar feeders, tool life management, and machine vision cameras.

Request Your Free Multi-Axis CNC Turning Quote Today

After receiving your drawings, our engineers will analyze your custom Multi-Axis CNC Turning parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.