Multi-Spindle Screw Machining

Elimold has extensive screw machining experience working with a wide range of materials, finishes, tolerances and complex features, providing solutions and fast turnaround for even the toughest screw machining projects. If you need screw machining, Elimold is the source for quality, price and delivery you need.

Multi-axis Screw Machining Manufacturer

We are a full-service multi-axis screw machining company that is committed to helping our customers turn their metal part designs into reality and supporting them every step of the way. From prototypes to PPAP, small batches to large quantities, Elimold is here to support you. In addition to providing a full range of just-in-time production services, we can also meet your warehousing needs through inventory management and Kanban procedures, and ship products directly and carefully to your customers based on your needs and requirements. We value your delivery deadlines and guarantee that your orders will be shipped on time. Through our collaborative approach, our well-trained and experienced team can review your specifications to achieve the most efficient manufacturability while pursuing the lowest cost production processing. Choose Elimold for your multi-axis screw custom part machining needs and experience the ultimate in precision, quality and reliability. We are committed to innovation and excellent customer service to provide solutions that exceed expectations.

Full-service multi-axis CNC screw machining service provider

Elimold offers assembly services and in-depth quality control testing. Our capabilities range from small orders to industrial-scale orders. We are a factory that provides complete turnkey services. After the manufacturing and assembly services are completed, we can also meet your warehousing needs and ship directly to your customers when necessary. We value your delivery deadlines and ensure that your orders are shipped on time. Our in-house factory is equipped with state-of-the-art equipment. Our trained design team will review your design and assist with any specific changes required before the production process. We are committed to providing excellent customer service and providing the highest quality products at the most competitive prices.

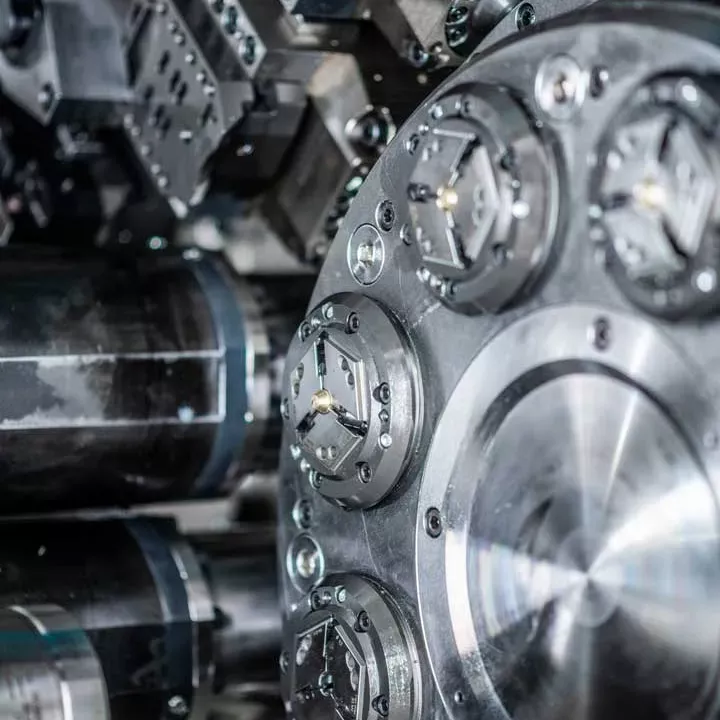

Our Core Precision CNC Screw Machining Capabilities

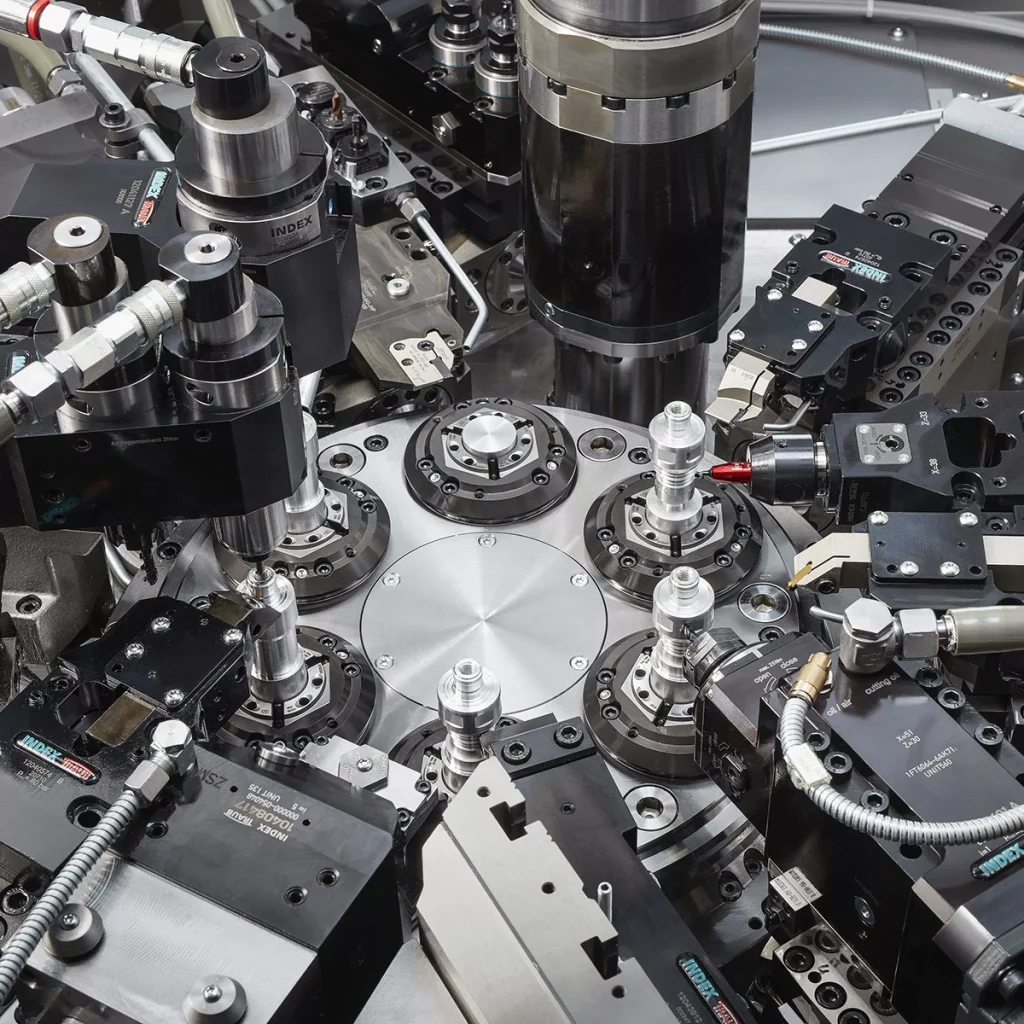

From micro precision machining to high accuracy multi-spindle production, Micro Precision Components can match the machine to your specific high precision component requirements to optimize cost effectiveness and maximize quality! We specialize in micro components, but we also produce large parts with high precision and tight tolerances. Our facility has 38 multi-spindle automatic screw machines that can process parts from 3/32″ (2.0mm) to 1″ (25.4mm) in diameter with tolerances of +/-.0005″. In addition, we have over 70 other CNC lathes/mills and CNC Swiss lathes.

Multi-Axis Screw Machining Facility

We provide multi-spindle screw machining services to a wide range of industries in a 46,000 square foot ISO registered facility. Our in-house facility is fully equipped with multi-axis screw machining equipment to provide our customers with exceptional precision machining services. In addition, our team of experts understands the importance of adhering to industry standards, which is why we hold multiple ISO certifications. As a result, our multi-axis screw machining services are ideal for straight symmetrical fittings, as well as other products. Whether you need 500 pieces for an unexpected customer request or 1,000,000 pieces for a project supply, our facility can deliver the right part on time and within your desired delivery schedule. Whatever your needs, we are committed to meeting them.

Multi-axis Screw Machining Process

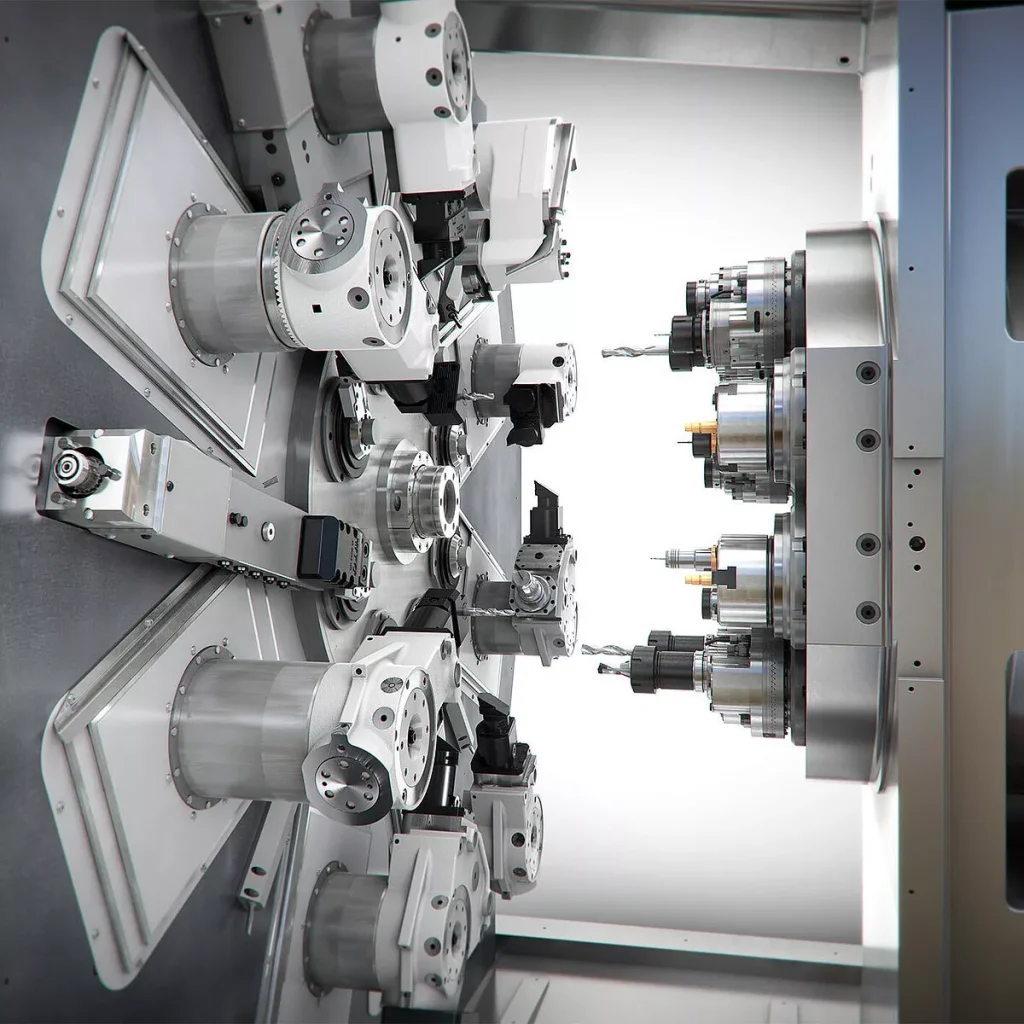

Elimold’s manufacturing approach incorporates a range of multi-axis screw machining processes, and our multi-axis screw machining equipment is able to perform multiple machining processes simultaneously, including but not limited to the following:

- Turning

- Forming

- Drilling

- Reaming

- Roll Threading

- Tre-Panning

- Broaching

- Shaving

- Grooving

- Cut Threading

- Roll Stamping

- Recessing

- Cross Drilling

- Live Milling

Rapid Prototyping and Engineering Services

Elimold has many years of experience in high-quality precision multi-axis screw machining. Our factory has the most efficient equipment in the industry, capable of providing flexible, versatile and accurate screw machining services. We assist our customers from concept design, rapid prototyping to full-scale production. From simple to the most complex tasks, our screw machining services combine the highest precision, competitive pricing and lead time, without sacrificing quality. For customers who need engineering and design assistance, we provide highly qualified personnel as well as advanced software and equipment. We provide comprehensive CAD design and CAM programming services, and can provide reverse engineering capabilities as needed. Our screw machining services cover 5,000 to 5,000,000 parts, and delivery time will be provided according to the specific project. We also provide expedited and emergency services when necessary.

Ready to start your next multi-axis screw machining project?

Contact us today to learn more about our multi-axis screw machining capabilities and how we can help take your business to the next level. Let Elimold be your trusted precision machining partner.

Compliance and Quality Standards

At Elimold, we are committed to providing our customers with the highest quality parts. We have implemented a rigorous quality control process to ensure that every part we produce meets our strict standards of accuracy and precision. Elimold operates a quality management system certified to ISO 9001:2015. We offer a range of quality inspection services, including Failure Mode and Effects Analysis (FMEA) engineering, to ensure that your products meet our high standards. Our experienced team of machinists and engineers closely monitor every stage of the manufacturing process, from initial design to final inspection, ensuring that all parts meet the required specifications. We use the latest technology and equipment to perform a range of quality control tests, including dimensional measurement, surface finish analysis and material testing. We also keep detailed records of all production processes so that any problems that may arise can be quickly identified and resolved.

Inspection Department

Fully equipped Quality Control Department on-site to include:

- Coordinate measuring machine

- Precision Gage Block Sets

- Profilometer

- Large selection of thread gages

- Quality Control Manual available upon request

- Measuring microscope

Quality Control & Continuous Improvement

At Elimold, we believe in continuous improvement and are always looking for ways to enhance our processes and capabilities. Our team regularly evaluates new technologies and processes in machining to stay ahead of the curve. This commitment to innovation allows us to provide our customers with the latest and most advanced solutions for their precision machining needs.

In addition, we have a dedicated team of quality assurance experts who ensure that our quality control processes are in compliance with industry standards and regulations. We regularly invest in employee training and development to ensure that our team is up to date with the latest technologies and best practices in precision machining. Our emphasis on quality control and continuous improvement is what makes us stand out from other precision machining companies. Our commitment to providing high-quality parts, combined with our expertise and cutting-edge technology, ensures that we are the ideal choice for all your machining needs.

What is multi-axis CNC screw machining?

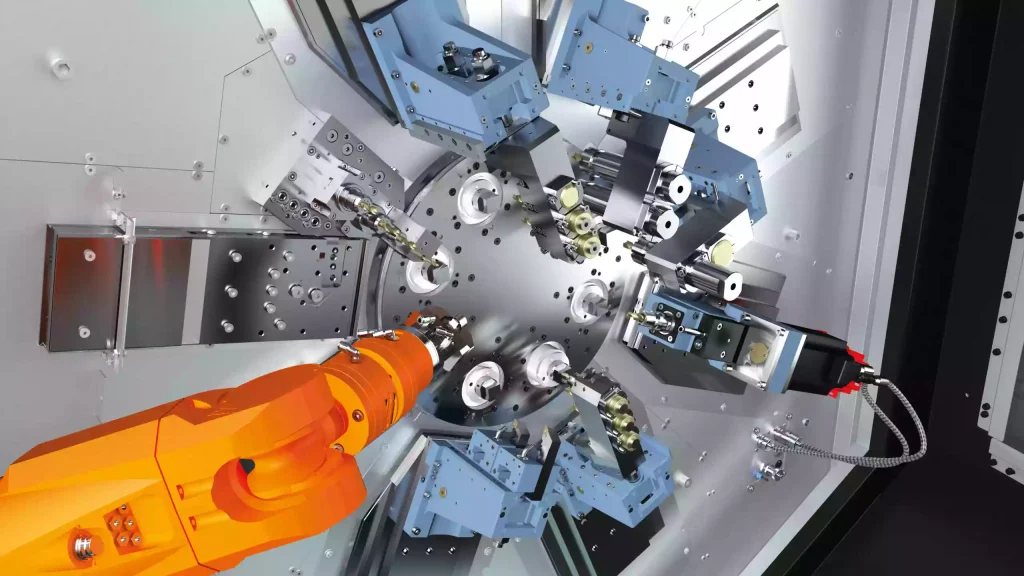

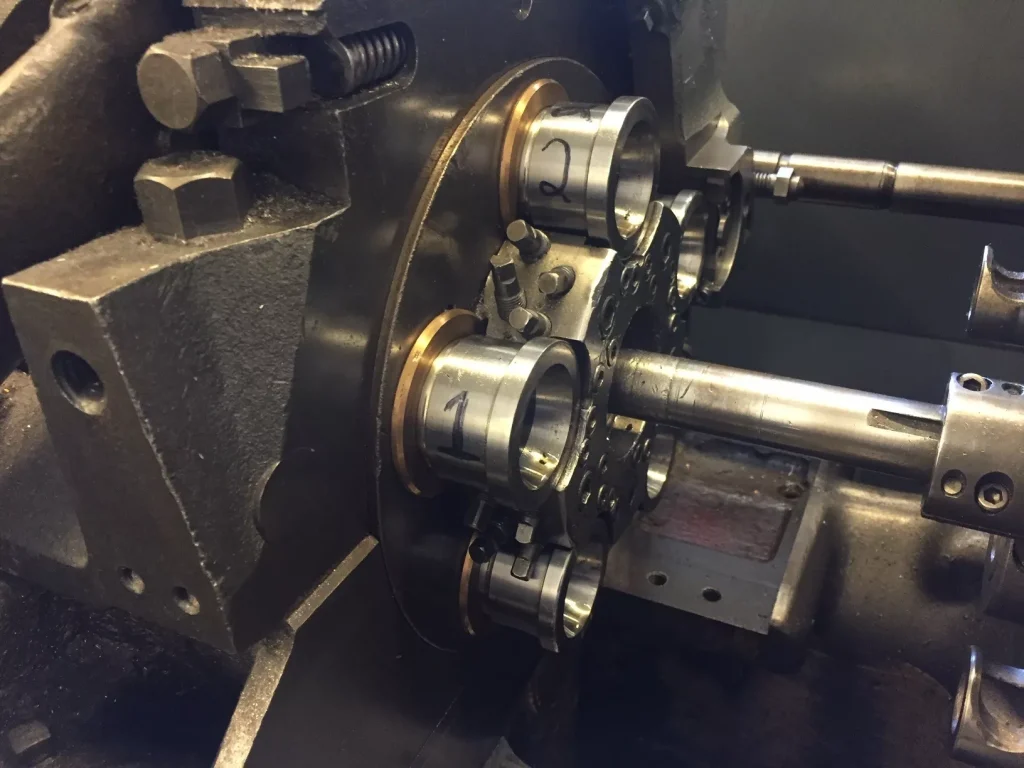

Screw machines were originally developed to automate and quickly produce large quantities of identical parts – including screws. While screw machines may not be much different than their original counterparts, modern technologies, and automation have made them highly efficient and cost-effective.

Elimold screw machines are perfect for your single-spindle and multi-spindle quick-turn part needs. Our screw machines can fit a series of different tools to allow for complex automatic screw machine work including tapping, forming, threading, and broaching.

A machine is only as good as the person operating it. Our skilled team includes some of the best screw experts in the business. Trust that Elimold can find the right solution for all your screw machining needs.

What is Custom Multi-Axis Screw Machining?

A multi-axis screw machine is an automated lathe that processes a wide variety of metals and materials into thousands of important machine parts. Screw machines form parts by clamping the workpiece from both ends and the middle while the tool carves the part, assembly or workpiece from multiple sides.

Screw machines are designed to cut metal quickly and can complete multiple machining options and processes simultaneously. Screw machines use mechanical levers, hand-cut steel cams and replaceable gears to determine the spindle speed of the process and produce unique nuts, bolts, parts and assemblies to customer specifications.

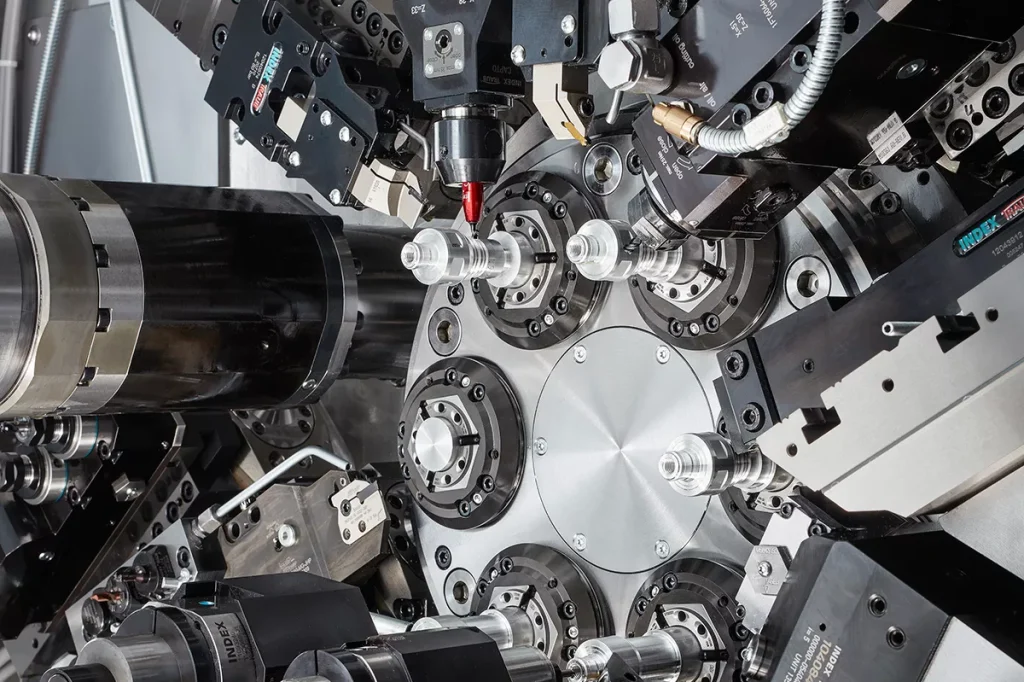

How Does Multi-axis Screw Machining Work?

At Elimold, we are proud to be one of the few contract manufacturers with both single- and multi-axis CAM-operated screw machines. Our single-axis machines can process barstock up to 1-5/8” in diameter, while our multi-axis machines can process barstock up to 2-1/4” in diameter.

Our screw machining process is a testament to efficiency. Here is a quick rundown of how we turn barstock into precision parts with multi-axis screw machining:

- Material Loading. Barstock is carefully loaded into the material magazine and then fed into the work chuck, ready for machining.

- Six stations with up to 18 different tools in the cut. Six stations, one for each spindle, can handle up to three machining operations per station.

- Rotate and Repeat. After each cycle of operation, the material rotates the workpiece to the next station, and the process repeats. When the workpiece rotates through all six positions, the finished part drops.

- Optimizing Cycle Times. We optimize cycle times to ensure that the station that requires the longest run time sets the pace for the entire process.

Multi-Spindle CNC Screw Machining Advantages

Multi-axis screw machining offers many advantages over other machining and manufacturing processes, such as:

Higher design versatility

Multi-axis screw machines can make parts that are too expensive or impossible to make with traditional machining and manufacturing techniques, such as very small or complex screws with multiple surface features.

Wider material applicability

Multi-axis screw machining processes are applicable to a wide range of metal and non-metal materials. In addition, the same machine can be configured and reconfigured to process different materials based on part and production specifications.

Lower deflection

In multi-axis screw machining operations, the distance between the workpiece support and the cutting face is extremely small, which reduces workpiece bending and cutting face deflection. This process feature enables manufacturers to achieve tighter tolerances on machined parts.

Higher productivity

Once configured and loaded, the multi-axis screw machine can operate autonomously, minimizing operator involvement. Because the machine can accommodate multiple spindles and tools, a single operation is often sufficient to produce near-net-size parts.

Higher cost-effectiveness

Multi-axis screw machining processes enable high-volume production of precision parts, often with little or no secondary finishing. Swiss screw machines can incorporate a variety of cutting tools to perform different machining operations and achieve different elements on the workpiece.

Higher Levels of Control

While the multi-axis screw machining process itself allows for the manufacture of precision parts and products, integrating CNC technology into the equipment allows manufacturers to achieve tighter tolerances and reduce the potential for production errors.

Material Options

Elimold is able to process a wide variety of materials to meet your specific application needs. Whether you need to process metal or a specific plastic material, we are ready to meet your needs in a quick and economical manner. We process a wide variety of materials, if the material you need to process is not listed here, please feel free to contact us.

Metals

Steel

Stainless Steel

Aluminum

Brass

Bronze

Copper

Zinc

Nickel

Cast Iron

Carbon Steel

Plastics

Acetal

Delrin

Nylon

Polycarbonate

Lexan

Acrylic

PVC

Teflon

UHMW

Garolite

Surface Finishing Options

At Elimold, we offer optional secondary processing and additional services when customers order primary processing services from our factory. Our secondary processing services include in-house assembly as well as outsourced heat treatment, grinding and plating services. These services can enhance the durability, appearance and performance of the machined parts.

- As machined (Ra 3.2μm / Ra 126μin)

- Smooth machining (Ra 1.6μm / Ra 63μin)

- Polishing (Ra 0.8μm / Ra 32μin or better)

- Bead Blasted

- Tumbled

- Powder Coated

- Black Oxide

- Anodized (Type II Or Type III)

- Chem Film (Chromate Conversion Coating)

- Plating

- Custom

Industries Served

Elimold’s screw machining services serve applications across diverse industries. We specialize in crafting precision components for:

- Aerospace & Defense

- Agricultural Machinery

- Automotive & Transport

- Communications

- Construction, Mining & Heavy Equipment

- Consumer Products

- Energy & Utilities

- Engine Manufacturers

- Fluid Control Equipment, Pump, Seal & Valve

- Fuel Systems

- Hydraulics

- Industrial Machinery & Equipment

- Medical

- Power Generation

- Recreational Equipment

Applications

We have experience using multi-axis screw machines to produce parts for a variety of industries, providing complex, high-precision parts for applications where precision and finesse are important. Our expertise in precision machining enables us to produce high-quality parts quickly and efficiently, making us an ideal choice for your machining needs.

- adapters

- fittings

- valve components

- bushings

- spacers

- bosses

- loading hooks

- testing caps

- stent components

- contacts

- antenna components

- connectors

- brass fittings

- torque wrench components

- screws

- nuts

- handles

- sockets

- pump components

- bosses

- retainers

- reducers

- glands

- studs

- cabin knobs

- antenna mounts

- connectors

- display components

- castor mounts

- adjustment screws

- nuts

- bolts

- shock components

- adapters

- thread mounts

- couplers

Other CNC Machining Services

At Elimold, we offer the most precise, highest quality turnkey CNC machining capabilities and services in the industry, with our in-house state-of-the-art CNC machining equipment. Because we have so many fully functional machines, we are able to offer a wider range of customization options and faster delivery times than many of our competitors. With 130 different machines, as well as turning and milling centers, we offer a wide range of manufacturing processes to produce high-precision parts to your exact specifications and requirements.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

We Partner with Innovative, Growth-Minded Manufacturing Companies

We have built successful partnerships with top companies around the world through superior quality, superior performance, and a commitment to growth and innovation. We are honored to work with a wide range of businesses across dozens of industries. These partnerships are built on trust and shared goals, are mutually beneficial, and create lifelong bonds.

Request Your Free Multi-Spindle Screw Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Multi-Spindle Screw Machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.