Polycarbonate (PC) Injection Molding Service

Elimold specializes in PC injection molding services, offering custom prototyping and high-volume production parts with delivery as fast as 5 days. We also provide professional design support, highly competitive pricing, and a wide selection of materials and surface treatments.

Looking for a Reliable Supplier of High-performance Polycarbonate Injection Molding?

Our expertise lies in processing PC material into high-quality parts according to your drawings, specifications, or purchase order requirements. If you face challenges requiring customized PC molding solutions, we can provide the corresponding professional services.

Once you choose to partner with us, Elimold’s Custom Plastics team will work closely with you to deeply understand your needs and challenges, and develop prototypes for testing and validation. Once the solution is validated, full-scale production can begin. If you need custom injection-molded polycarbonate parts to your specifications, we can serve you. Regardless of order size or design complexity, we can deliver orders on time and within budget, meeting the expected size, shape, and function.

What is PC (Polycarbonate)?

Polycarbonate (PC) is an amorphous thermoplastic material, belonging to the category of polymers. Its molecular chain contains carbonate groups (-OC(=O)-O-). It is synthesized through the polymerization reaction of bisphenol A (BPA) and phosgene (COCl2). Furthermore, all general-purpose polycarbonates are based on BPA. The BPA component in the molecule imparts a high glass transition temperature (150℃/302℉). The rotational kinetics of the carbonyl groups within the molecule endow the material with high ductility and toughness. Therefore, this amorphous engineering material possesses excellent impact resistance, heat and cold resistance, creep resistance, electrical insulation, flame retardancy, and dimensional stability, and can resist ultraviolet radiation and aging. In addition, this material has a visible light transmittance exceeding 90%.

Performance Parameters of PC Material

- Density: Typically ranges from 1.20 to 1.22 g/cm³.

- Melting Point: Approximately 260°C to 270°C.

- Injection Molding Temperature: 270-320°C.

- Glass Transition Temperature (Tg): About 135-150°C.

- Cantilever Beam Notch Impact Strength: Around 60 KJ/m2.

- Tensile Strength: Approximately 60 to 70 MPa (Megapascals).

- Flexural Strength: Can reach about 90 to 120 MPa.

- Transparency: Up to 90% in the visible light range.

- Chemical Resistance: Good resistance to weak acids and bases, but sensitive to certain solvents and strong chemicals.

- Water Absorption: Good, with a low absorption rate of about 0.3%. Tends to hydrolyze at high temperatures.

We Offer Polycarbonate (PC) Material Grades

Elimold offers a wide range of polycarbonate (PC) materials, as well as modified PC materials. Modified PC refers to materials obtained by adding different reinforcing materials or additives to base PC resin to improve or enhance its original properties. The PC material grades we can provide include:

High and Low Molecular Weight PC

High molecular weight polycarbonates have longer chain lengths, generally resulting in higher strength, better heat resistance, and superior mechanical properties. They are suitable for high-performance applications such as bulletproof materials and high-end mechanical parts. Conversely, low molecular weight polycarbonates have shorter chain lengths, making them easier to process and mold, but typically meaning lower mechanical strength and heat resistance. This type of polycarbonate is more suitable for general consumer goods and non-heavy-duty applications.

Glass Fiber Reinforced PC

Reinforcing polycarbonate with glass fibers improves its mechanical strength and dimensional stability, making it more suitable for applications requiring high strength and rigidity.

Flame Retardant PC

Adding flame retardants can improve the flame retardant properties of polycarbonate. Unmodified polycarbonate has a flame retardant rating of V2, which is insufficient for many products. Adding flame retardants can achieve a V0 rating. Flame retardants can be halogenated or non-halogenated.

UV Resistant PC

By adding UV stabilizers, the weather resistance of PC for outdoor use is enhanced, reducing discoloration and performance degradation caused by prolonged UV exposure.

PC/ABS Alloy

By blending PC with ABS (acrylonitrile-butadiene-styrene copolymer), this alloy combines the high strength and heat resistance of PC with the processability and surface smoothness of ABS, and offers good resistance to stress cracking. This alloy is widely used in automotive parts, electronic device housings, and other fields.

Carbon Fiber Reinforced PC

The addition of carbon fiber improves the material’s strength and thermal stability, making it suitable for lightweight and high-performance applications in the aerospace and automotive industries.

PC/PBT or PC/PET Alloy

By blending with PBT (polybutylene terephthalate) or PET (polyethylene terephthalate), chemical resistance and impact resistance are enhanced, often used in products requiring chemical corrosion resistance and high impact strength.

Transparent PC

Although PC itself is transparent, specific modifications can further enhance its transparency and optical properties, making it suitable for optical products and decorative items requiring high transparency.

PC/ASA Alloy

Alloying with ASA (acrylate-styrene-acrylonitrile) improves weather resistance and UV resistance, making it suitable for applications requiring long-term outdoor exposure.

Complete Production Support Team

We have a dedicated manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

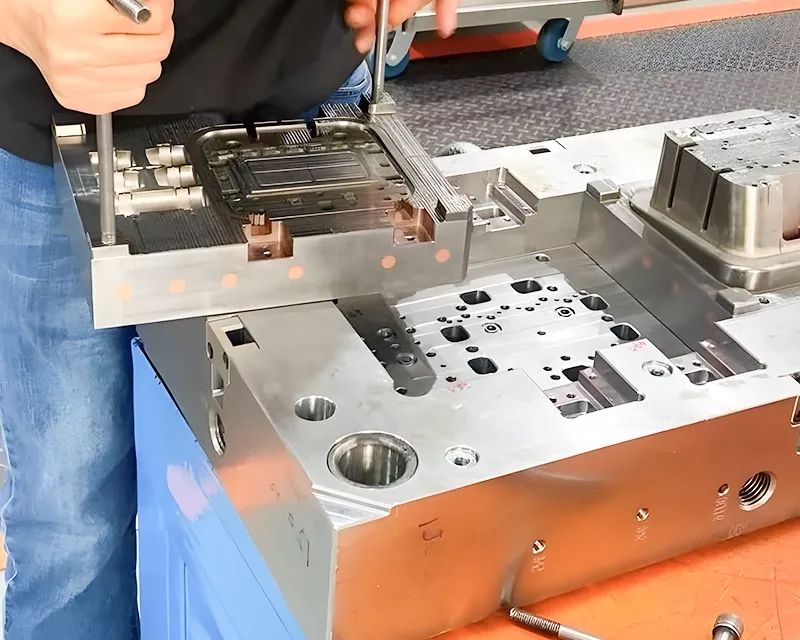

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

Contact us for Polycarbonate (PC) Injection Molding Cost

Contact us today to discuss your polycarbonate (PC) injection molding needs. We will provide a free quote and help you find the best solution for your project.

Outsourcing PC injection molding to Elimold

We are a leading manufacturer and supplier of polycarbonate injection molds in the industry. Elimold’s team of professional PC injection molding experts possesses extensive technical knowledge and is able to select the best materials to manufacture parts. Furthermore, we understand that the dimensions and designs of custom injection molded parts are not static. Our team will assist you throughout the entire process of design, manufacturing, and delivery, based on your specific requirements. Our goal is to provide our customers with high-quality products at affordable prices.

Advanced PC Injection Molding Plant and Latest Technology

Whether your project is large or small, Elimold can complete it cost-effectively. Our in-house polycarbonate injection molding production line in Shenzhen, China, is equipped with all-electric and hybrid injection molding machines (50-2200 tons), featuring barrel temperature control (accuracy ±1°C) and humidity control drying systems to effectively prevent material degradation. A real-time IoT monitoring system tracks key parameters (melt viscosity, buffer layer thickness, cooling rate). Furthermore, auxiliary equipment includes automated robotic parts handling systems, laser marking systems, and a 100% online optical inspection system to ensure defect-free products. For complex applications, we can utilize multi-color injection molding and overmolding technologies to combine polycarbonate with other engineering resins.

Strict Tolerance Control for PC Injection Molding Parts

Our advanced polycarbonate injection molding technology enables us to manufacture complex parts with extremely small tolerances (±0.01mm). Unlike traditional methods, our injection molding process for polycarbonate employs scientific molding techniques, conformal cooling channels, and high-precision molds to minimize warpage and internal stress. This allows us to produce highly consistent polycarbonate parts with excellent dimensional stability and surface finish.

Cost-Effective High-Volume Production Solutions

We have optimized injection molding processes for high-volume production of polycarbonate plastic parts, thus increasing production efficiency while maintaining quality. Furthermore, our automated production lines and recycled material programs reduce waste and lower unit costs, making us an ideal partner for large-volume orders. In addition, our in-house mold design team ensures faster production cycles and longer mold life, resulting in long-term cost savings. From prototyping to mass production, our services offer high-quality, cost-effective solutions, tailored to your project needs.

Surface Treatment Capabilities for Polycarbonate Injection Molded Products

Our surface treatment capabilities for polycarbonate injection molded products include:

- Hot Stamping

- Edge Binding

- Pad Printing

- Screen Printing

- Defect Coating

- Conductive Coating

- Decorative Coating

- Metallization

- Electroplating

Secondary Machining of Polycarbonate Parts

Polycarbonate can be machined. Elimold offers a full range of machining services, including turning, drilling, tapping, and grinding, as well as ultrasonic mounting, ultrasonic welding, pad printing, and assembly. When designing parts requiring fastening, self-tapping screws are recommended over threaded screws. For parts requiring repeated assembly and disassembly, threaded metal inserts should be used. Ultrasonic-mounted inserts are superior to molded inserts because the knurling on molded inserts can create notch effects in the plastic, reducing its strength.

Polycarbonate Injection Molding Quality Control Procedures

Elimold has a unique product inspection and management system to ensure products meet final project requirements. Therefore, our quality management team inspects the first few or one-off products produced before each batch, and engineers conduct inspections every few hours to promptly identify and prevent production defects, thus avoiding large numbers of defective products and rework. Finally, after production is complete, the final product is inspected using sampling methods to check the dimensions, appearance, structure, and positional accuracy of the product to ensure it meets final requirements.

Are you looking for a reliable and affordable professional manufacturer of polycarbonate injection molding?

Do you need high-quality polycarbonate parts but don’t want the hassle and expense of traditional molding methods? Have you tried other methods, but none have achieved the desired results? Elimold’s polycarbonate injection molding services allow you to easily obtain the high-quality parts you need without any hassle or expense.

We are one of the few companies specializing in the design, manufacture, and delivery of polycarbonate (PC) injection molded parts. With extensive experience, we are able to turn concepts into reality. We strive to exceed our clients’ expectations and ensure that every project we undertake leaves them satisfied. The Elimold team can assist you with every step of this process, whether you already have molds or only a product idea; we are the ideal partner for your plastic product manufacturing.

FAQ

Compared to materials like PMMA (acrylic), ABS, and ASA, PC offers superior impact resistance and transparency, while also exhibiting better heat resistance than many other plastics.

Achieving optical transparency in polycarbonate injection molding requires precise process control and specialized molds. We utilize mirror-polished SPI A1-grade cavities, strictly control moisture content (below 0.02%), and optimize barrel temperatures between 280-320°C. Our transparent plastic injection molding process includes a nitrogen-assisted molding option to eliminate surface defects, ensuring crystal-clear polycarbonate injection molded products.

All PC injection molding processes at the Elimold plant adhere to ISO 9001:2015 certification standards. We employ scientific injection molding principles, combined with real-time cavity pressure monitoring, automated visual inspection (for detecting surface defects), and coordinate measuring machine (CMM) verification (for inspecting critical dimensions). Our polycarbonate injection molding quality system also includes complete material traceability and SPC documentation to meet automotive and medical-grade requirements.

Several key factors must be considered when designing polycarbonate (PC) injection molds to ensure successful production. First, the mold should have good venting capabilities to avoid air bubbles and ensure complete filling. The design and location of the gate are crucial to minimize flow marks and weld lines. The arrangement of cooling channels must be carefully designed to maintain uniform cooling and shorten cycle times. The mold surface should be smooth to enhance the appearance of the transparent PC parts. Furthermore, the mold dimensions must take into account the shrinkage rate of PC.

Yes, polycarbonate parts are suitable for a variety of post-processing techniques, including painting, metallization, and coating. These processes enhance aesthetics, increase durability, and impart specific functional properties to meet the diverse needs of various industries.

Polycarbonate exhibits good compatibility with overmolding processes, allowing it to be combined with other materials to create more robust hybrid parts. By overmolding with elastomers or rigid plastics, designers can achieve complex geometries, integrate soft-touch features, or enhance structural integrity when needed, thereby expanding its application prospects across industries.

Polycarbonate parts are available in a variety of colors, including transparent, translucent, and opaque. Common surface finishes for polycarbonate parts include glossy, matte, and textured surfaces to meet aesthetic preferences and functional requirements in various applications.

Ready to Work On your Next Project?

Let us help you provide high quality parts in short time. Get your project started now!