PEEK CNC Machining

Elimold is a leading manufacturer of high-performance PEEK machining and products. With state-of-the-art production facilities and a highly skilled team of technicians, we can handle projects of all sizes and complexities. Whether you need prototyping or mass production, we are committed to delivering exceptional results on time and within budget.

Professional PEEK CNC Machining Parts Manufacturer

As experts in PEEK CNC machining, Elimold has handled thousands of custom parts orders, all characterized by extremely high geometric detail and demanding specifications. Our team is proficient in cnc peek machining processes and can provide three-axis, four-axis, and five-axis plastic machining services, including milling and turning. Whether you need prototype parts or high-volume production, we can deliver high-quality custom parts efficiently and cost-effectively. Furthermore, our team of manufacturing experts is ready to answer any questions you may have about your projects and offer free design and material processing advice based on our experience. Please feel free to contact us anytime for a free quote on your PEEK CNC projects.

Your Partner in PEEK Machining

We can produce PEEK prototypes using our advanced equipment, tailored to your specific requirements. Our goal is to comprehensively address all your needs, from design to final product. Therefore, Elimold invests heavily in R&D, dedicated to producing the most cost-effective parts for our clients. Consequently, we offer you the most competitive peek cnc machining service prices, and our delivered products require no rework, saving you significant costs. If you are developing peek machined parts, Elimold is ready to review your project and provide support. Regardless of your application area, our experienced engineers and operations experts are committed to helping you succeed.

Comprehensive Engineering Support for PEEK CNC Parts Projects

Elimold offers comprehensive support, from Design for Manufacturability (DFM) consultation to rigorous quality control. Therefore, each project is supported by a dedicated team of experts covering all aspects including engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistently high quality, reliable delivery, and superior service at every stage of the project. Furthermore, we develop sample designs for you before starting mass production of peek cnc milled parts.

In addition, our DPD and MBD (Digital Product Definition/Model-Based Definition) process allows us to directly use your digital CAD models. By leveraging your design files, we can eliminate machining errors and improve the precision and accuracy of the final parts. This ensures that we can provide higher quality parts at a lower price.

Comprehensive Production Support Team

We have a team of experienced manufacturing experts working behind the scenes to fulfill your production orders. We manage the entire process and provide you with ongoing updates.

Account Manager

Application Engineers

Logistics

Quality Control

What is PEEK?

Polyetheretherketone (PEEK) is a reinforced thermoplastic polymer with relatively high temperature resistance and good processability. Peek retains its function, albeit with reduced efficiency, at temperatures up to 500°F (260°C) and above. This is because Peek maintains its mechanical properties and chemical composition unchanged within its enclosed environment.

Furthermore, this material can be produced in various forms, including sheets, rods, tubes, granules, and filaments. In addition to unfilled peek, it can be reinforced by adding 30% glass fiber or 30% carbon fiber to create reinforced products. Glass fiber reinforced peek exhibits significant properties, including high durability, high stiffness, and high strength, and maintains dimensional stability even in harsh thermal and chemical environments due to the addition of glass fiber. Polyether ether ketone (PEEK) is a colorless, organic, crystalline thermoplastic polymer belonging to the polyarylether ether ketone (PAEK) family, and is widely used in engineering fields.

PEEK CNC Machining Materials

Whether manufacturing complex geometries or meeting stringent industry standards, Peek ensures reliable performance and durability in harsh environments. Below are some commonly used peek materials we offer.

General Purpose PEEK

USP VI Grade PEEK (TECAPEEK)

PEEK GF30

PEEK-CA30

PEEK-HPV

PEEK-1000

Our Unique PEEK CNC Machining Capabilities

Elimold not only processes peek finished parts from various materials such as sheet, bar, and tube, but also leverages our strong machining capabilities to fully utilize the synergistic effects of various manufacturing processes. Unlike traditional methods of producing complex geometries using semi-finished products, which result in significant material waste, combining injection molding and machining is a viable option. Therefore, we can perform final finishing on near-net-shape peek preforms from injection molding to achieve the final geometry required by our customers. Furthermore, we can also perform post-processing on custom peek profiles and tubes.

PEEK CNC Machining Tolerances

Our machining processes achieve tight tolerances (±0.01mm) and smooth surface finishes to meet functional and aesthetic requirements. For most plastics, our standard machining tolerance is ±0.03 mm (±0.0012 inches). For stable engineering plastics such as PEEK, POM, and G-10, we can achieve even tighter tolerances depending on the part geometry. Critical dimensions should be clearly indicated on your technical drawings. With advanced 5-axis and multi-axis machining technology, we are able to efficiently and reliably produce complex geometries of unfilled, glass fiber, and carbon fiber reinforced peek.

CNC Machining Service for Custom PEEK Parts

With years of experience in machining, we have accumulated extensive expertise in processing peek materials. Whatever your needs, we can meet your expectations for parts delivery.

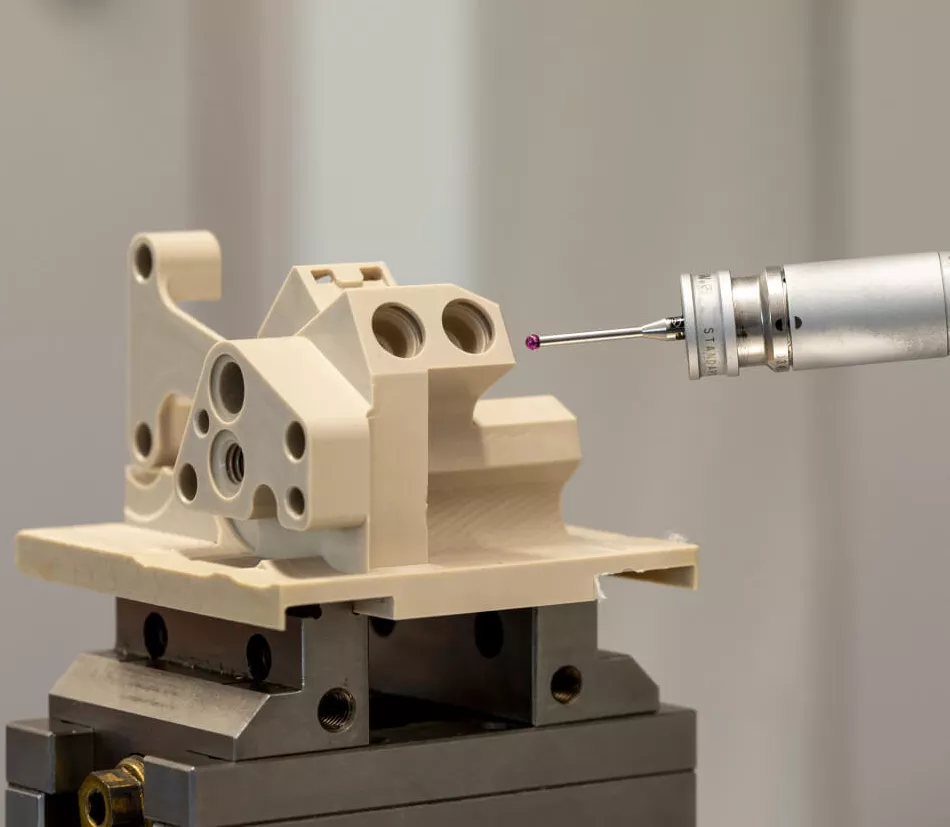

Comprehensive Quality Management

We integrate quality into every component, adhering to rigorous inspection and record-keeping processes to ensure that customized parts fully meet specifications. We are ISO 9001 and IATF 16949 certified, following stringent quality protocols designed specifically for high-performance peek components. Our in-house workshop is equipped with advanced inspection tools such as CMM and Zeiss, verifying every dimension and providing detailed inspection and first-article inspection reports to ensure every part meets your precise specifications. We can provide standard reports, Zeiss coordinate measuring machine reports, or complete inspection data based on your company’s templates, giving you complete transparency and quality assurance for every component. Furthermore, all materials are traceable to their source, with complete documentation proving their compliance and performance guarantees.

Precision PEEK Parts Rapid Prototyping and Low-Volume Production

We support rapid prototyping and flexible low-volume production to help you iterate and bring your products to market faster. Your concepts can be transformed into physical prototypes with unprecedented speed and precision. Our rapid CNC prototyping service accelerates product development cycles, allowing you to quickly validate designs, test features, and iterate using production-grade materials. If you wish to develop PEEK (polyetheretherketone) product prototypes, we are happy to discuss all the details with you. We will maintain close communication throughout the production cycle of machined parts.

Surface Finishing Options for PEEK CNC Parts

As Machined

PEEK can be left as-machined, providing a natural surface finish with minimal processing.

Sand Blasting

This can be used to create a matte texture on PEEK surfaces for enhanced appearance or grip.

Tumbling

Useful for smoothing edges and creating a more uniform finish on PEEK parts.

Teflon Coating

Applying a Teflon coating to PEEK can improve its wear resistance and reduce friction.

Painting

PEEK can be painted for aesthetic purposes or to provide an additional layer of protection.

Powder Coating

While less common, powder coating can be applied to PEEK for added durability and a variety of colors.

How do we guarantee the quality of our PEEK materials and achieve full traceability?

We partner only with certified, high-performance PEEK resin suppliers and provide complete traceability, including resin batch certificates and composition analysis reports, so you know that every component meets your performance and compliance requirements. From medical-grade peek to aerospace-grade material certifications, we ensure you have the right materials for your application, helping you avoid mistakes and achieve reliable, high-quality results without compromise. We also offer transparent cost breakdowns so you understand the true cost structure of custom cnc parts.

Your Designs Are Absolutely Safe With us

Clients come first. Therefore, we always safeguard your designs and never share them with any other client. We also work closely with our clients to ensure they can clearly articulate their needs. Once your designs are submitted to our design team, all requirements and specifications will be strictly confidential. As an Elimold client, you will have a dedicated contact person who will keep you informed of project progress and maintain close contact at every step. Send us your project requirements now.

Industries and Applications

Elimold focuses on providing cnc machining solutions for peek components to industries with extremely high requirements for performance, precision, and reliability. Our extensive experience in engineering plastics enables us to support a wide range of critical applications.

Other PEEK Plastic Parts Manufacturing Services

PEEK materials can be processed not only through cnc machining but also through additive manufacturing or injection molding. The specific process chosen depends on the requirements of the final product and time and budget constraints. For 3D printing, peek materials are available in FFF filaments and SLS powder.

However, the application of peek materials in cnc machining and injection molding still far exceeds that in additive manufacturing. Because 3D printing can easily achieve complex (partially hollow) geometries, it is becoming increasingly popular in the field of printing biocompatible medical implants.

FAQ

Because PEEK is a high-performance material, some difficulties may arise during machining. Metals dissipate heat better than plastics; therefore, excessive heat buildup in the workpiece can not only alter certain properties of PEEK but may even cause deviations in dimensional or shape requirements. To machine this material while maintaining high tolerances and achieving a fine surface finish, specialized carbide cutting tools, along with the correct coolant and other appropriate machining parameters, are required.

For CNC-machined PEEK parts, annealing is a necessary step to eliminate internal stress and improve the material's dimensional stability. The annealing temperature for these parts depends on their melting point, so they need to be gradually heated to a specific temperature, held for a period of time, and then slowly cooled. This method ensures that all dimensions meet requirements, prevents part deformation, and avoids exceeding the tolerances allowed by the drawings.

Besides part geometry, tolerances, and intended application conditions, factors affecting the final machined part, such as temperature and chemicals, must be considered when designing PEEK machined parts.

In my experience, Delrin is easier to machine due to its lower hardness and better chip removal. However, PEEK's superior heat resistance (up to 260°C) and chemical resistance make it more suitable for high-performance or harsh environmental applications.

Compared to polyoxymethylene (POM), polyetheretherketone (PEEK) offers higher temperature resistance, superior chemical resistance, and greater mechanical strength. POM is cheaper but lacks the high-performance characteristics of PEEK. POM is suitable for general applications, while PEEK is better suited for harsh environments with extremely high durability and reliability requirements.

PEEK CNC parts can have wall thicknesses as thin as 0.0008 inches with tolerances of 0.0002 inches. PEEK-machined parts retain their functionality, but strength will be reduced due to softening within this range.

Yes, PEEK is resistant to almost all chemicals except concentrated sulfuric acid. However, incompletely crystallized PEEK may experience stress cracking in solvents such as acetone.

PEEK, like other high-performance engineering thermoplastics such as PEI, PPS, PAI, and PSU, offers high temperature resistance, chemical resistance, and excellent mechanical and electrical properties. These materials are widely used in high-strength applications in the aerospace, automotive, and electrical industries. Due to their similar properties, other alternative materials may be considered depending on the specific application.

PEEK and PTFE are not the same. PEEK is a thermoplastic polymer with excellent chemical resistance, high strength, and low weight. Polytetrafluoroethylene (PTFE) is a fluoropolymer with properties such as chemical resistance, extreme temperature resistance, and abrasion resistance. Both materials have their advantages and disadvantages in CNC machining services.

PEEK plastic machining services offer numerous advantages, including high precision, high accuracy, excellent mechanical properties, and resistance to extreme temperatures and chemicals. PEEK materials are renowned for their strength and durability, making them ideal for industries such as aerospace, medical devices, and automotive engineering. CNC machining can easily create complex shapes and designs, ensuring the final product meets the required precise specifications.

Need CNC Machined Parts in PEEK?

Experience unprecedented precision with our Peek CNC machining services. Contact us today to learn how we can help you take your projects to the next level and take full advantage of our state-of-the-art technology and team of experts.