PET (Polyethylene Terephthalate) Injection Molding Service

Elimold provides professional Polyethylene Terephthalate (PET) injection molding services to various industries, offering fast delivery times, consistent quality, and cost-effective solutions for every project.

Comprehensive PET Injection Molding Service Capabilities

We provide end-to-end PET plastic parts manufacturing services, from concept to finished product, helping you turn your vision into reality. We also offer overmolding and insert molding (brass, steel, etc. inserts) services. We possess a full range of machinery capable of handling everything from single-cavity custom parts to multi-cavity molds. We have our own mold workshop, meaning your projects will not experience downtime; we can repair existing molds or perform engineering modifications at any time.

A Comprehensive PET Plastic Parts Production Support Team

We have a professional PET plastic parts manufacturing team working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

Professional-grade PET Products Require Professional Manufacturers

Don’t hesitate any longer, bring your PET products to market now. Our designers and engineers are ready to review your proposals and provide expert technical support. We will provide you with a quote as soon as possible and answer any questions you may have. Whether it’s medical-grade plastic parts or engineering plastic parts for aerospace, consumer goods, industrial, or electronics industries, Elimold is your ideal manufacturer.

What is PET (Polyethylene Terephthalate)?

PET (Polyethylene Terephthalate), also known as thermoplastic polyester, is a versatile thermoplastic polymer belonging to the polyester family. PET is primarily composed of two key monomers: ethylene glycol and terephthalic acid. This material possesses excellent physical properties, including high strength, abrasion resistance, low moisture absorption, good chemical resistance and transparency (optical properties), and stability over a wide temperature range. PET is typically found in small granular form. Elimold offers a variety of PET materials, including PET black, PET white, PET+GF30 black, and PET+GF30 white, to meet your specific injection molding needs.

Plastic PET Properties

- Density: 1.38-1.40 g/cm³

- Tensile Strength: 50-76 MPa

- Flexural Strength: 70-140 MPa

- Impact Strength: Moderate

- Thermal Conductivity: 0.15-0.24 W/(m·K)

- Melting Point: 250-260°C

- Coefficient of Thermal Expansion: 70 x 10^-6 /°C

Main Grades of PET Plastic

Depending on the different part structures and applications, Elimold typically uses various grades of injection-molded PET materials in its manufacturing processes, including…

Standard PET (Polyethylene Terephthalate)

Standard PET is the most common type of PET, widely used in numerous industries due to its excellent chemical, thermal, and mechanical properties. It is a semi-crystalline polymer, transparent, strong, and effectively blocks gases and moisture.

Amorphous PET (APET)

APET is a type of PET without a crystalline structure, making it very transparent and highly glossy. APET is mainly used in applications requiring transparency. It is not easily deformed at high temperatures, is easy to process and mold, and is very tough and resistant to chemical corrosion.

Crystalline PET (C-PET)

C-PET has a higher degree of crystallinity than standard PET, making it less transparent and having better heat resistance. Due to its ability to withstand high temperatures, C-PET is often used in heat-generating items. The higher crystallinity also makes it stronger and able to withstand greater pressure.

Biaxially Oriented PET (BOPET)

Biaxially oriented polyethylene terephthalate (BOPET) is a type of polyethylene terephthalate that has undergone biaxial stretching, resulting in higher strength, greater stability, and better light transmission. It possesses excellent tensile strength, good moisture resistance, and barrier properties.

Ethylene Glycol Modified PET (PETG)

Ethylene glycol modified polyethylene terephthalate (PETG) is a material modified by adding ethylene glycol during the polymerization process. This modification makes PETG more flexible than standard PET. It has better transparency and impact resistance than standard PET and is often used in applications requiring high durability and transparency.

Recycled PET (rPET)

rPET is made from recycled PET derived from consumer goods or industrial waste. Recycling PET reduces the environmental impact of plastic waste, conserves resources, and reduces greenhouse gas emissions. rPET retains many of the properties of virgin PET, but its performance may vary slightly due to differences in recycling processes.

Engineering Grade PET

Engineering grade PET is a high-performance PET designed for demanding industrial and engineering applications. This PET is modified to improve mechanical strength, heat resistance, and abrasion resistance. It is characterized by high strength, good dimensional stability, and resistance to abrasion and chemical corrosion.

Reinforced PET

Formulating PET with glass fiber or other reinforcing materials significantly improves its mechanical properties. These grades offer higher strength, stiffness, and dimensional stability, making them suitable for engineering applications.

UV-Stable PET

Enhanced resistance to degradation caused by UV radiation, maintaining excellent clarity and dimensional stability even after repeated exposure to sunlight.

Premium PET Material Sourcing Services

Our robust supply chain ensures we source the highest quality PET materials for your project. We work directly with manufacturers and their authorized agents to provide you with top-tier PET materials for injection molding, complete with detailed technical data sheets for each material. This approach helps avoid potential problems in material sourcing. For standard applications, we recommend using our stock materials, which are both economical and efficient. However, if your project requires special materials, we can provide customized materials based on your specific requirements.

Need To Discuss PET Injection Molding Project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Custom PET Injection Molding Solutions

Do you need custom PET plastic parts? Elimold specializes in providing best-in-class custom injection molding solutions to meet your diverse needs. Whether you require high-volume production with fast delivery or special custom orders, we have extensive experience and strong capacity. As a full-service injection molding company, we produce high-quality PET plastic parts using custom-designed molds and advanced manufacturing processes.

Mold Magicians: Reverse Engineering Services

Elimold boasts a team of mold magicians (mold experts) with extensive experience in mold design. Whether it’s a sample, an idea, or a picture, through our experienced mold experts, we can transform your ideas into injection molds and the final manufactured product, making your product the focus of attention in the market, whether it’s for medical, automotive, or industrial equipment parts.

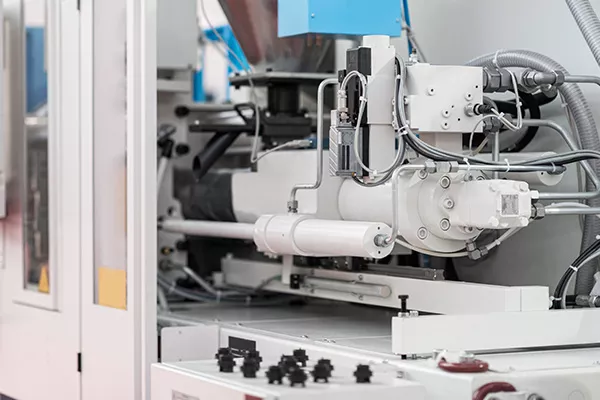

PET Plastic Injection Molding Equipment and Plant

Our in-house plant boasts over 120 advanced injection molding machines of various types, ranging in tonnage from 75 tons to 2200 tons. This allows us to complete a wide range of projects with precision and efficiency. Our machines are equipped with advanced technology, enabling the easy production of complex parts. This flexibility allows us to meet the needs of high-volume production and custom injection molding projects requiring special processes and attention. Therefore, we can produce parts from 50 to 1 million pieces or even more. Furthermore, Elimold is capable of operating 24/7, and can fulfill your delivery needs in as little as two weeks. If you require even faster parts delivery, we also offer convenient inventory solutions.

ISO Class 7 and Class 8 Cleanrooms in Our In-House Injection Molding Plant

Elimold manufactures and assembles a wide range of medical devices and components, a process that typically requires molding and assembly in cleanrooms. These operations are conducted in custom-built ISO Class 7 (10,000 sq ft) and ISO Class 8 (100,000 sq ft) cleanrooms exceeding 20,000 sq ft, including spaces for plastic and silicone molding as well as assembly work areas. Our services are suitable for highly regulated safety, security, and protective products. We are ISO 13485:2016 certified for contract manufacturing and assembly of medical products.

We Don’t Just Talk About Quality, We’re Certified For It

Quality has been the cornerstone of Elimold since its inception and remains the foundation for our steady growth over the decades. But don’t just believe our claims; our quality certifications speak for themselves:

ISO 9001 Certification

Our established quality management system and our unwavering commitment to continuous improvement meet the requirements of the ISO 9001 standard.

ISO 13485 Certification

We have achieved and maintained ISO 13485 certification by implementing quality system standards and requirements for medical devices sold in the United States.

IATF 16949 Certification

We have achieved ISO/TS/IATF 16949 certification due to our automotive-related quality management system, which continuously improves defect prevention, reduces variation, and minimizes waste.

SQF Certification

We have achieved SQF certification for food industry packaging materials and plastic molded food caps by adopting Good Manufacturing Practices (GMP).

Why Choose Elimold's PET Injection Molding Services?

When you need to design complex, precision PET parts, the Elimold team can help you achieve that. We offer a variety of molds and injection molding processes, providing diverse component configurations to meet your specific needs. Furthermore, compared to many other materials, the materials we use are lightweight, durable, strong, and affordable. In addition, in line with our sustainability and waste reduction initiatives, the plastic is easily recyclable, using only the amount needed to produce each part, ultimately reducing waste and benefiting our environment.

Tool Transfer Program

Don’t let your tooling investments go to waste. Our tool transfer program can give your existing tools a new lease on life. With nearly 20 years of mold-making experience, robust manufacturing processes, and a commitment to quality, Elimold will guide you through a successful mold transfer program, ensuring a rapid return to production. After assessing your current tools, process information, and project objectives, we will provide a comprehensive report and timeline, along with a quotation, to prepare you for your tool transfer.

Try Our Problem-solving PET Injection Molding Services Now

Elimold serves you with PET injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.