PI (Polyimide) Injection Molding Service

Elimold specializes in providing reliable, cost-effective, and custom PI (Polyimide) injection molding services to meet the needs of high-volume production and complex part designs. We look forward to providing you with innovative product solutions. Contact us now for a project quote.

Looking for a PI (polyimide) Injection Molding Manufacturer?

Elimold’s professional polyimide injection molding services can meet all your needs! Whether you need to create polyimide molds for your latest invention or are looking for a reliable polyimide injection molding service provider, we can provide the solutions you require. Our professional engineers and production team can complete the work quickly and efficiently, so you can rest assured that no matter the size or complexity of your project, we will handle your project needs promptly and professionally. Let our reliable services make it easy for you to obtain the polyimide products you need and deliver them on time and in the way you expect.

A Comprehensive Production Support Team for PI Plastic Parts

We have a professional team dedicated to manufacturing polyimide plastic parts, working behind the scenes to meet your production order needs. We manage the entire process and keep you updated on the latest progress.

Engineering & DFM

Mold Making

Injection Molding

Surface Treatments

Quality and Compliance

Assembly and Shipping

What is Polyimide (PI)?

Polyimide (PI) – Polyimide (PI) exists as both thermoplastic and thermosetting resins and is a class of polymers known for their excellent heat resistance and flame retardancy. Thermoplastic polyimide is a special engineering plastic developed from PI, possessing excellent thermoplastic processing properties. It can be processed using all PI processing methods and is suitable for extrusion and injection molding.

The rigid structure of polyimide gives it a high glass transition temperature (Tg > 300°C), endowing it with good mechanical strength and high modulus. Therefore, even at temperatures above 260°C, this material maintains high levels of strength, dimensional stability, and creep resistance. Its low wear rate, ability to operate under unlubricated conditions, and high pV value make it ideal for applications involving harsh friction and wear, extending service life and reducing maintenance costs.

Polyimide Injection Molding Process

Polyimide injection molding involves injecting molten polyimide into a specific mold on an injection molding machine. The basic process includes injection, stamping, compaction, and cooling. This technology can produce complex and intricate shapes. However, polyimide processing requires high temperatures and releases corrosive gases. Therefore, special attention must be paid to mold design, molding equipment, and overall material handling. Thermoplastic polyimide injection molding is particularly suitable for one-time molding of complex polyimide molded parts, eliminating the need for secondary processing and solving the problems of high processing difficulty and limited product forms associated with traditional PI molding processes.

Expert Project Management

We don’t rush things, but we ensure accuracy. Our process combines human expertise with cutting-edge AI technology to provide you with a fast and accurate, tailored quote. While we don’t offer instant quotes, this approach ensures every project undergoes a comprehensive evaluation and is prepared for success. We take the time to understand your needs to provide an accurate quote. Choosing us means more than just a number; it means a partner to help you succeed.

Seamless Transition from Prototype to Full Production

Our prototype molds are designed with scalability in mind. Once your prototype is complete, the same modular steel inserts can be upgraded to accommodate higher production volumes without requiring a complete mold rebuild. With just a durability upgrade to the prototype molds, our process enables up to 250,000 cycles of mass production. This avoids the downtime and costs commonly associated with transitioning from prototyping to mass production. With our streamlined and efficient processes, you can transition from the concept phase to mass production faster and more efficiently, maintaining precision and quality throughout the process.

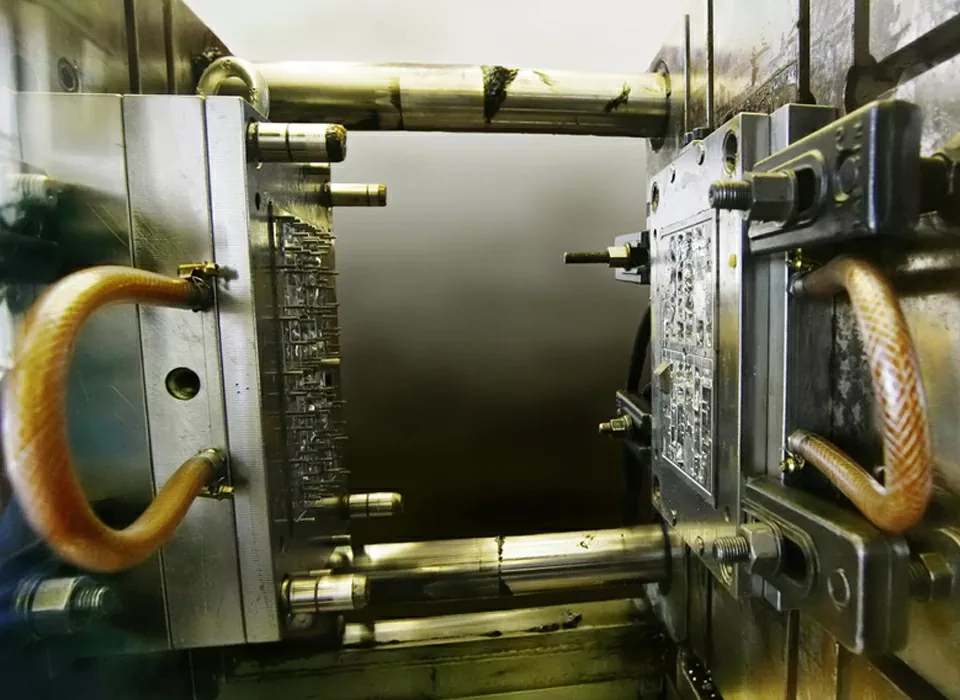

PI Injection Molding Factory

Our factory is fully equipped to meet your high-volume, high-speed production needs. We have over 130 presses, ranging in tonnage from 40 tons to 2200 tons, ensuring every project meets the required precision specifications. In addition, we have a well-equipped on-site tooling and CNC machine shop for press maintenance, mold repair, and value-added services such as machining and custom or other surface treatments to meet your needs. With our extensive expertise and state-of-the-art injection molding machines, we use a wide variety of high-performance PI plastics for vertical, horizontal, and 45-degree angle injection molding.

Other Value-Added Services

Our manufacturing capabilities extend beyond injection molding; we also offer cleanroom injection molding capabilities. Our factory is equipped with ISO Class 8 cleanrooms, enabling the production of injection-molded parts with extremely high cleanliness requirements, such as those for medical, food and beverage, electronics, and pharmaceutical applications. Combined with our extensive experience, we can produce multi-component Class A surface parts with complex geometries, undercuts, and thin walls. We can easily achieve tolerances of ±0.001 inches.

Industry Certifications and Quality Management Capabilities

At Elimold, ISO 9001:2015 certification is just the beginning of our exceptional service. We strive for excellence in every project, including providing First Article Inspection (FAIR) reports and material certifications to ensure end-to-end traceability and superior quality. Our testing center utilizes advanced coordinate measuring machine (CMM) technology to ensure every part is meticulously crafted and perfected. We not only meet your expectations but exceed them. Choosing us means choosing precision, reliability, and a team dedicated to delivering superior parts.

Get Your PI Injection Molded Parts Now!

Unlock precision and quality with our PI injection molding services! Request a custom quote now!